ASTM E2861-16(2020)

(Test Method)Standard Test Method for Measurement of Beam Divergence and Alignment in Neutron Radiologic Beams

Standard Test Method for Measurement of Beam Divergence and Alignment in Neutron Radiologic Beams

SIGNIFICANCE AND USE

5.1 As discussed in Practice E748, traditional neutron radiography typically employs a high flux reactor source with a well defined collimation system to produce an image on film. The alignment of the imaging plane and the divergence angle are generally well defined and a small degree of misalignment or uncertainty in divergence angle makes little difference in the final image. These systems are well characterized by their physical dimension, the L/D ratio, and image quality indicators (Beam Purity Indicator and Sensitivity Indicator) described in Test Method E545. Neutron computed tomography is an example where it is important to know with some precision both the beam’s centerline and the degree of beam divergence, especially if the beam does not closely approximate a parallel beam. Portable or movable neutron imaging systems often utilize shorter collimation systems, a less precise alignment and poor symmetry in divergence angles, which may affect image analysis. In these example cases, direct measurement of the alignment and the divergence angles is desirable as calculation from system geometry would be less straightforward and accurate. Fabrication of the device is an extension of the Test Method E803 L/D device, providing different information through a similar approach.

SCOPE

1.1 This test method covers the design, materials, manufacture, and use of a divergence and alignment indicator (DAI) for measuring the effective divergence of a thermal neutron beam used for neutron imaging as well as determining the alignment of the imaging plane relative (usually normal) to the centerline of the beam. This test method is applicable to thermal neutron imaging.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2861 − 16 (Reapproved 2020)

Standard Test Method for

Measurement of Beam Divergence and Alignment in

Neutron Radiologic Beams

This standard is issued under the fixed designation E2861; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.2 Other Documents:

ANSI Y14.5M Dimensioning and Tolerances

1.1 This test method covers the design, materials,

manufacture, and use of a divergence and alignment indicator

3. Terminology

(DAI) for measuring the effective divergence of a thermal

3.1 Definitions—For definitions of terms used in this guide

neutron beam used for neutron imaging as well as determining

other than those defined in this section, refer to Terminology

the alignment of the imaging plane relative (usually normal) to

E1316.

the centerline of the beam. This test method is applicable to

thermal neutron imaging.

3.2 Definitions:

3.2.1 neutron image—record in two dimensions of the

1.2 The values stated in SI units are to be regarded as the

intensity of neutron radiation. Examples include radiographs,

standard.

radioscopic images, computed radiography (CR) images, and

1.3 This standard does not purport to address all of the

track etch images produced from a neutron source.

safety concerns, if any, associated with its use. It is the

3.2.2 neutron imaging—process of making a neutron image.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

4. Summary of Test Method

mine the applicability of regulatory limitations prior to use.

4.1 The DAI allows the user to determine the alignment of

1.4 This international standard was developed in accor-

the imaging plane with the beam centerline and the beam

dance with internationally recognized principles on standard-

divergenceforathermalneutronbeam.Theusercandetermine

ization established in the Decision on Principles for the

if the imaging system is aligned, aligned only in one direction

Development of International Standards, Guides and Recom-

or completely misaligned and the angle of misalignment, as

mendations issued by the World Trade Organization Technical

well as the divergence angle for the imaging system. The DAI

Barriers to Trade (TBT) Committee.

is made using aluminum plate and rods, and incorporates

2. Referenced Documents cadmium wires for contrast. Circular symmetry is utilized to

simplify manufacture. An important feature of the DAI is

2.1 ASTM Standards:

flexibility to adapt the “as-built” dimensions into the analysis.

E543 Specification forAgencies Performing Nondestructive

The DAI is placed with the five stand off posts against the film

Testing

cassette or radioscopic imaging device in the physical center of

E545 Test Method for Determining Image Quality in Direct

thebeam.TheDAIisperpendiculartotheselectedbeamradius

Thermal Neutron Radiographic Examination

when the center S1 and center S4 cadmium wire images

E748 Guide for Thermal Neutron Radiography of Materials

overlap (see Figs. 1 and 2).The degree of misalignment can be

E803 TestMethodforDeterminingthe L/D RatioofNeutron

measured by the cadmium wire image positions.After the DAI

Radiography Beams

is aligned, analysis of the cadmium wire “+” image spacing

E1316 Terminology for Nondestructive Examinations

yields the beam divergence.

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee E07 on

Nondestructive Testing and is the direct responsibility of Subcommittee E07.05 on

5.1 As discussed in Practice E748, traditional neutron radi-

Radiology (Neutron) Method.

ography typically employs a high flux reactor source with a

Current edition approved Dec. 1, 2020. Published December 2020. Originally

well defined collimation system to produce an image on film.

approved in 2011. Last previous edition approved in 2016 as E2861 – 16.

DOI:10.1520/E2861-16R20. The alignment of the imaging plane and the divergence angle

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2861 − 16 (2020)

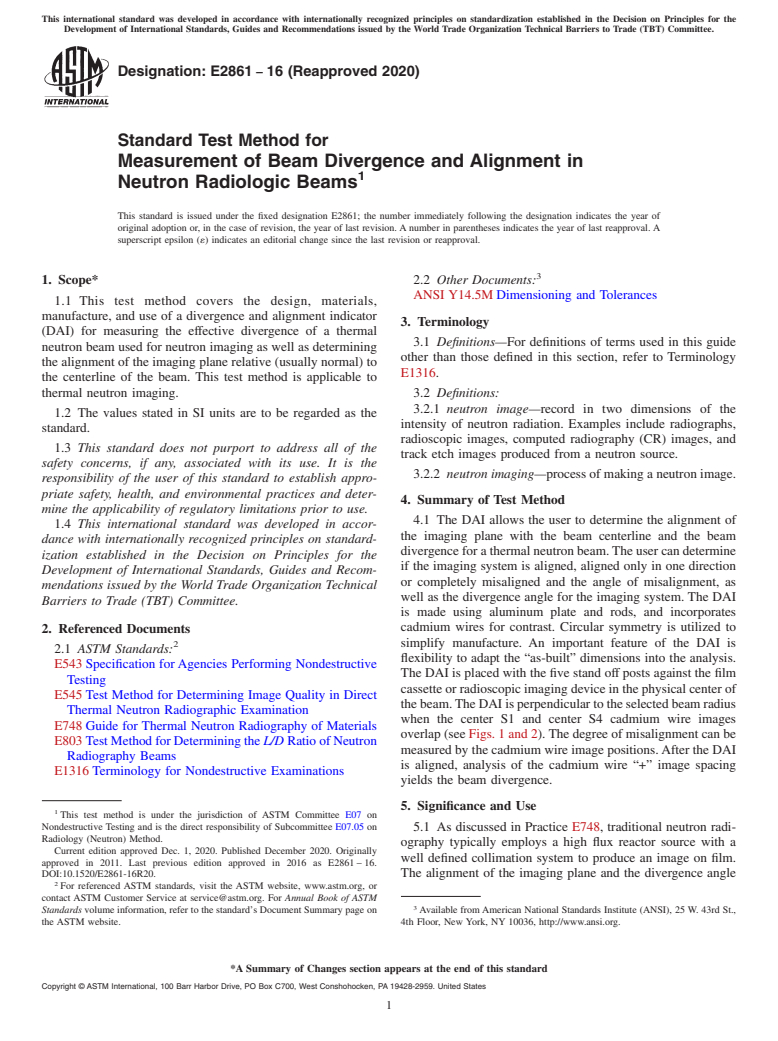

FIG. 1 Image of the DAI device with added labels to label the S2 surface as the un-grooved side of the plate, the S3 surface as the end

of the stand off post that is mounted to surface S2, and S4, the end of the stand off post to be positioned at the imaging plane.

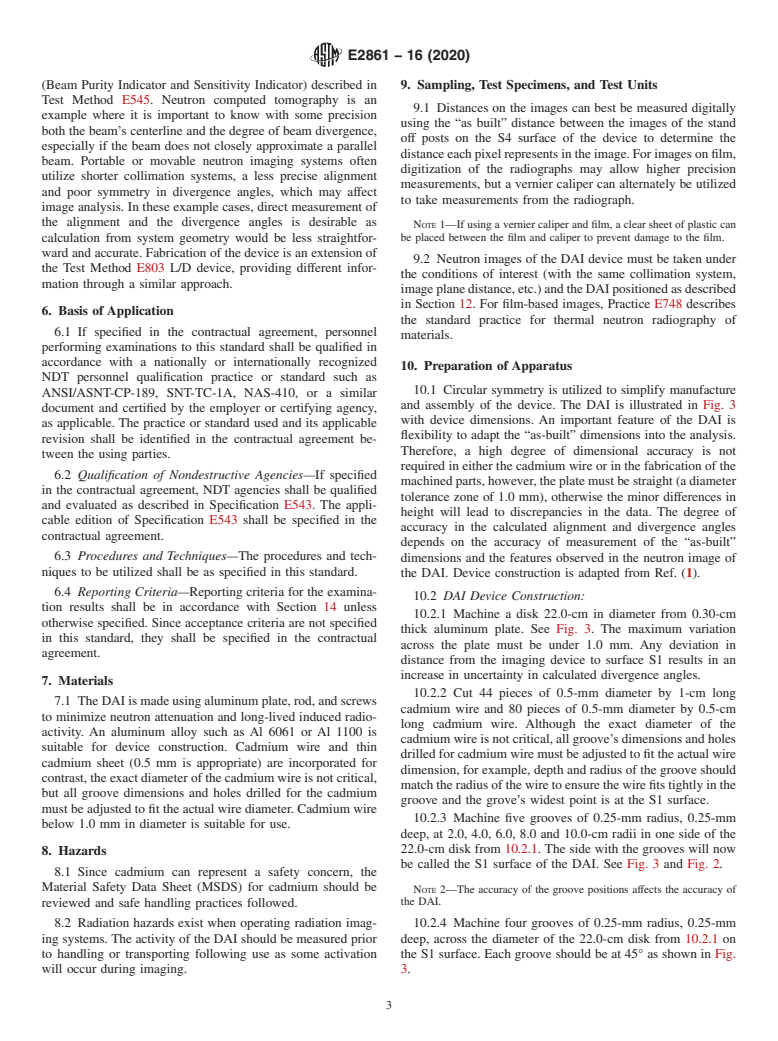

FIG. 2 Image of the S1 surface of a DAI device (with added S1 label), showing grooves, cadmium crosses, and aluminum screw heads.

This device used tape to hold the cadmium wire crosses in place. The surfaces S1, S2, S3, and S4 shown in Figs. 1 and 2 are all paral-

lel.

are generally well defined and a small degree of misalignment final image. These systems are well characterized by their

or uncertainty in divergence angle makes little difference in the physical dimension, the L/D ratio, and image quality indicators

E2861 − 16 (2020)

(Beam Purity Indicator and Sensitivity Indicator) described in 9. Sampling, Test Specimens, and Test Units

Test Method E545. Neutron computed tomography is an

9.1 Distances on the images can best be measured digitally

example where it is important to know with some precision

using the “as built” distance between the images of the stand

both the beam’s centerline and the degree of beam divergence,

off posts on the S4 surface of the device to determine the

especially if the beam does not closely approximate a parallel

distanceeachpixelrepresentsintheimage.Forimagesonfilm,

beam. Portable or movable neutron imaging systems often

digitization of the radiographs may allow higher precision

utilize shorter collimation systems, a less precise alignment

measurements, but a vernier caliper can alternately be utilized

and poor symmetry in divergence angles, which may affect

to take measurements from the radiograph.

image analysis. In these example cases, direct measurement of

the alignment and the divergence angles is desirable as

NOTE 1—If using a vernier caliper and film, a clear sheet of plastic can

be placed between the film and caliper to prevent damage to the film.

calculation from system geometry would be less straightfor-

ward and accurate. Fabrication of the device is an extension of

9.2 Neutron images of the DAI device must be taken under

the Test Method E803 L/D device, providing different infor-

the conditions of interest (with the same collimation system,

mation through a similar approach.

imageplanedistance,etc.)andtheDAIpositionedasdescribed

in Section 12. For film-based images, Practice E748 describes

6. Basis of Application

the standard practice for thermal neutron radiography of

6.1 If specified in the contractual agreement, personnel

materials.

performing examinations to this standard shall be qualified in

accordance with a nationally or internationally recognized

10. Preparation of Apparatus

NDT personnel qualification practice or standard such as

10.1 Circular symmetry is utilized to simplify manufacture

ANSI/ASNT-CP-189, SNT-TC-1A, NAS-410, or a similar

and assembly of the device. The DAI is illustrated in Fig. 3

document and certified by the employer or certifying agency,

with device dimensions. An important feature of the DAI is

as applicable. The practice or standard used and its applicable

flexibility to adapt the “as-built” dimensions into the analysis.

revision shall be identified in the contractual agreement be-

Therefore, a high degree of dimensional accuracy is not

tween the using parties.

required in either the cadmium wire or in the fabrication of the

6.2 Qualification of Nondestructive Agencies—If specified

machinedparts,however,theplatemustbestraight(adiameter

in the contractual agreement, NDT agencies shall be qualified

tolerance zone of 1.0 mm), otherwise the minor differences in

and evaluated as described in Specification E543. The appli-

height will lead to discrepancies in the data. The degree of

cable edition of Specification E543 shall be specified in the

accuracy in the calculated alignment and divergence angles

contractual agreement.

depends on the accuracy of measurement of the “as-built”

6.3 Procedures and Techniques—The procedures and tech-

dimensions and the features observed in the neutron image of

niques to be utilized shall be as specified in this standard.

the DAI. Device construction is adapted from Ref. (1).

6.4 Reporting Criteria—Reporting criteria for the examina-

10.2 DAI Device Construction:

tion results shall be in accordance with Section 14 unless

10.2.1 Machine a disk 22.0-cm in diameter from 0.30-cm

otherwise specified. Since acceptance criteria are not specified

thick aluminum plate. See Fig. 3. The maximum variation

in this standard, they shall be specified in the contractual

across the plate must be under 1.0 mm. Any deviation in

agreement.

distance from the imaging device to surface S1 results in an

increase in uncertainty in calculated divergence angles.

7. Materials

10.2.2 Cut 44 pieces of 0.5-mm diameter by 1-cm long

7.1 The DAI is made using aluminum plate, rod, and screws

cadmium wire and 80 pieces of 0.5-mm diameter by 0.5-cm

to minimize neutron attenuation and long-lived induced radio-

long cadmium wire. Although the exact diameter of the

activity. An aluminum alloy such as Al 6061 or Al 1100 is

cadmium wire is not critical, all groove’s dimensions and holes

suitable for device construction. Cadmium wire and thin

drilled for cadmium wire must be adjusted to fit the actual wire

cadmium sheet (0.5 mm is appropriate) are incorporated for

dimension, for example, depth and radius of the groove should

contrast, the exact diameter of the cadmium wire is not critical,

matchtheradiusofthewiretoensurethewirefitstightlyinthe

but all groove dimensions and holes drilled for the cadmium

groove and the grove’s widest point is at the S1 surface.

must be adjusted to fit the actual wire diameter. Cadmium wire

10.2.3 Machine five grooves of 0.25-mm radius, 0.25-mm

below 1.0 mm in diameter is suitable for use.

deep, at 2.0, 4.0, 6.0, 8.0 and 10.0-cm radii in one side of the

22.0-cm disk from 10.2.1. The side with the grooves will now

8. Hazards

be called the S1 surface of the DAI. See Fig. 3 and Fig. 2.

8.1 Since cadmium can represent a safety concern, the

Material Safety Data Sheet (MSDS) for cadmium should be

NOTE 2—The accuracy of the groove positions affects the accuracy of

the DAI.

reviewed and safe handling practices followed.

8.2 Radiation hazards exist when operating radiation imag- 10.2.4 Machine four grooves of 0.25-mm radius, 0.25-mm

ing systems. The activity of the DAI should be measured prior deep, across the diameter of the 22.0-cm disk from 10.2.1 on

to handling or transporting following use as some activation the S1 surface. Each groove should be at 45° as shown in Fig.

will occur during imaging. 3.

E2861 − 16 (2020)

FIG. 3 Diagram of the DAI Device Showing the Cadmium Pieces in Solid Black: (a) the S1 surface with machined grooves and dimen-

sions in centimetres, and (b) different orientation illustrates post positions.

NOTE 3—The accuracy of the groove positions affects the accuracy of

10.2.10 Cut five pieces of 0.5-mm diameter cadmium wire

the DAI.

each 0.3 cm long.

10.2.5 Machine four grooves of 0.25-mm radius, 0.25-mm

10.2.11 Drill a hole for the cadmium wire from 10.2.10 in

deep, on surface S1 to fit the cadmium wire from 10.2.2 of

the center of each post opposite the tapped hole, making sure

appropriate size to hold the “L” and “T” orientation markers as

theholesareperpendiculartothepostface.Thisendofthepost

depicted in Fig. 3a. The exact position and size are not

will be referred to as the S4 surface.

important as they are only for reference.

10.2.12 Mount the S3 surface of the posts to the S2 surface

10.2.6 Machine five aluminum posts 1.25 cm in diameter

of the 22.0-cm disk (the surface without the grooves) using the

and 5.0 cm in length, making sure the faces of the posts are

flat-head aluminum screws. Check that the posts are perpen-

finished perpendicular to the post length.

dicular to the S2 surface.

10.2.7 Obtain five flat-head aluminum machine screws

10.2.13 FromtheS1surfaceofthe22.0-cmdisk,drillahole

about 1.3 cm in length. The diameter of the screw is not

for a cadmium wire from 10.2.10 in the exact center of the

critical, but should be approximately 0.6 cm in diameter.

center post mounting screw, making sure the hole is drilled

10.2.8 Orient the S1 surface of the 22.0-cm diameter plate

perpendicular to the disk surface.

such that one groove machined in 10.2.4 is vertical relative to

10.2.14 Insert a piece of cadmium wire from 10.2.10 into

your position. The position of the posts and screws are

the hole drilled into the center post mounting screw in 10.2.13

illustrated in Fig. 3 and Fig. 2, respectively. Drill appropriate

(S1 surface) and four of the holes in the stand off posts (S4

through holes for the screws of 10.2.7 in the center of the plate

surface), leaving the center post empty. A small amount of

and at a radius of 7.07 cm in the 45°, 135°, 225°, and 315°

neutron transparent epoxy or glue can be used to secure the

grooves machined in 10.2.4. On surface S1 of the disk, counter

cadmium wire if it is loose.

sinktheholesforthescrewheadssuchthatthescrewheadsare

10.2.15 Cut a small piece of cadmium from a 0.5-mm thick

flush with the S1 surface.

sheet. Cut the piece such that its cross section is square and it

10.2.9 Drill and tap one end of each post from 10.2.6 for the

will fit into the unfilled center post hole from 10.2.11 (S4

screws from 10.2.7, making sure the tapped holes are perpen-

surface).

dicular to the post face. This end of the post will be referred to

as the S3 surface. NOTE 4—The square shape of the cadmium piece in the S4 surface will

E2861 − 16 (2020)

permit differentiation between S1 and S4 cadmium pieces in the radio-

determined. A vernier caliper can be utilized to determine

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.