ASTM D3987-85(2004)

(Test Method)Standard Test Method for Shake Extraction of Solid Waste with Water

Standard Test Method for Shake Extraction of Solid Waste with Water

SCOPE

1.1 This test method covers a procedure for leaching of solid waste to obtain an aqueous solution to be used to determine the materials leached under the specified testing conditions.

1.2 This test method provides for the shaking of a known weight of waste with water of specified composition and the separation of the aqueous phase for analysis.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3987–85 (Reapproved 2004)

Standard Test Method for

1

Shake Extraction of Solid Waste with Water

This standard is issued under the fixed designation D 3987; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers a procedure for leaching of 4.1 This test method is intended as a rapid means for

solid waste to obtain an aqueous solution to be used to obtaining an extract of solid waste. The extract may be used to

determine the materials leached under the specified testing estimate the release of certain constituents of the solid waste

conditions. under the laboratory conditions described in this procedure.

1.2 This test method provides for the shaking of a known 4.2 This test method is not intended to provide an extract

weight of waste with water of specified composition and the that is representative of the actual leachate produced from a

separation of the aqueous phase for analysis. solid waste in the field or to produce extracts to be used as the

1.3 This standard does not purport to address all of the sole basis of engineering design.

safety problems, if any, associated with its use. It is the 4.3 This test method is not intended to simulate site-specific

responsibility of the user of this standard to establish appro- leaching conditions. It has not been demonstrated to simulate

priate safety and health practices and determine the applica- actual disposal site leaching conditions.

bility of regulatory limitations prior to use. 4.4 The intent of this test method is that the final pH of the

extract reflect the interaction of the extractant with the buffer-

2. Referenced Documents

ing capacity of the solid waste.

2

2.1 ASTM Standards: 4.5 Theintentofthistestmethodisthatthewaterextraction

C 471 Test Methods for ChemicalAnalysis of Gypsum and

simulate conditions where the solid waste is the dominant

Gypsum Products factor in determining the pH of the extract.

D 75 Practice for Sampling Aggregates

4.6 The test method produces an extract that is amenable to

D 420 Practice for Investigating and Sampling Soil and the determination of both major and minor constituents. When

Rock for Engineering Purposes

minor constituents are being determined, it is especially

D 1129 Terminology Relating to Water

important that precautions are taken in sample storage and

D 1193 Specification for Reagent Water handling to avoid possible contamination of the samples.

D 2216 TestMethodforLaboratoryDeterminationofWater

4.7 This test method has been tested to determine its

(Moisture) Content of Soil and Rock applicability to certain inorganic components in the solid

D 2234 Test Methods for Collection of a Gross Sample of

waste. The test method has not been tested for applicability to

Coal organic substances and volatile matter (see 5.3).

D 3370 Practices for Sampling Water

4.8 The agitation technique, rate, and liquid-to-solid ratio

E 122 Practice for Choice of Sample Size to Estimate a specified in the procedure may not be suitable for extracting all

Measure of Quality for a Lot or Process

types of solid wastes. (See Sections 7, 8, and the discussion in

Appendix X1.)

3. Terminology Definitions

5. Apparatus

3.1 For definitions of terms used in this test method, see

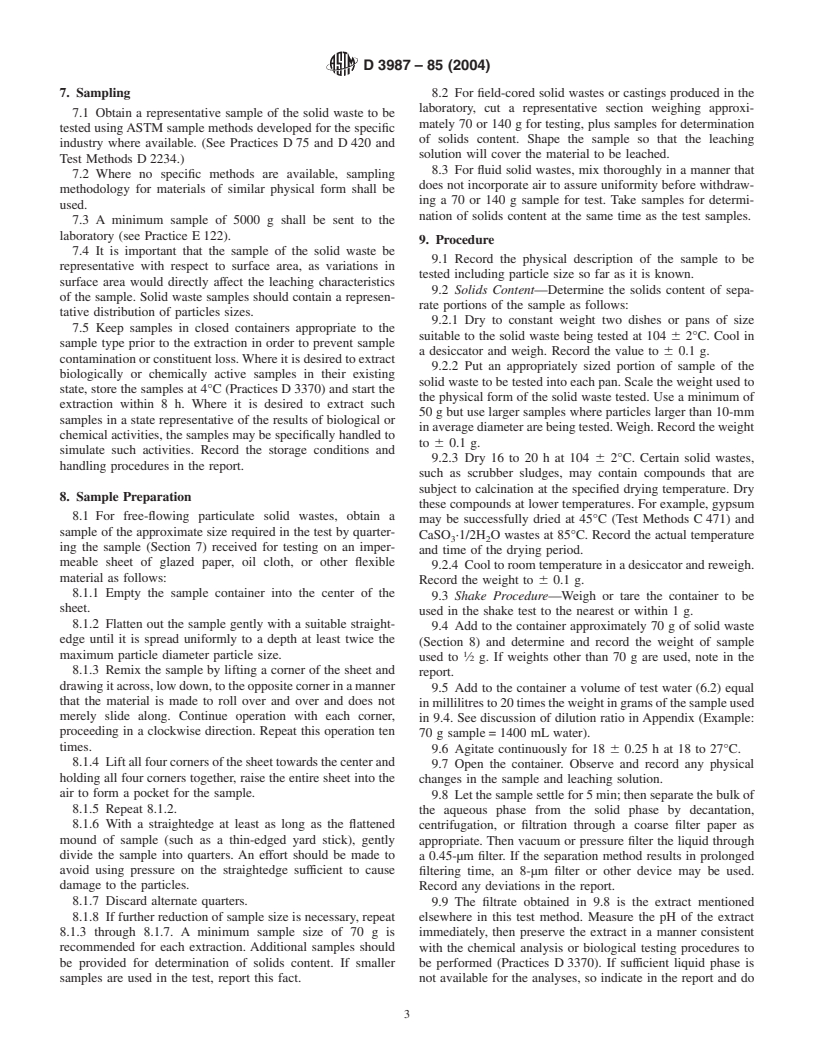

Terminology D 1129. 5.1 Agitation Equipment, of any type that rotates about a

central axis at a rate of 29 r/min, Fig. 1. (See discussion of

agitation in Appendix X1.)

1

This test method is under the jurisdiction of ASTM Committee D34 on Waste

5.2 Membrane Filter Assembly—A borosilicate glass or

Management and is the direct responsibility of Subcommittee D34.01.04 on Waste

stainless steel funnel with a flat, fritted base of the same

Leaching Techniques.

Current edition approved Oct. 21, 1985. Published March 1986. Originally material and membrane filters.

published as D 3987 – 81. Last previous edition D 3987 – 81.

5.3 Containers, round, wide-mouth, of a composition suit-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

able to the nature of the solid waste and the analyses to be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

performed, and constructed of materials that will not allow

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3987–85 (2004)

FIG. 1 Extractor

sorption of constituents of interest. One-gallon (or 4-L) con- all reagents sha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.