ASTM E259-98(2003)

(Practice)Standard Practice for Preparation of Pressed Powder White Reflectance Factor Transfer Standards for Hemispherical and Bi-Directional Geometries

Standard Practice for Preparation of Pressed Powder White Reflectance Factor Transfer Standards for Hemispherical and Bi-Directional Geometries

SCOPE

1.1 This practice covers procedures for preparing pressed powder transfer standards. These standards can be used in the near-ultraviolet, visible and near-infrared region of the electromagnetic spectrum. Procedures for calibrating the reflectance factor of materials on an absolute basis are contained in CIE Publication No. 44. Pressed powder standards are used as transfer standards for such calibrations because they have a high reflectance factor that is nearly constant with wavelength, and because the geometric distribution of reflected flux resembles that from the perfect reflecting diffuser.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 259 – 98 (Reapproved 2003)

Standard Practice for

Preparation of Pressed Powder White Reflectance Factor

Transfer Standards for Hemispherical and Bi-Directional

Geometries

This standard is issued under the fixed designation E259; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The internationally accepted standard of reflectance is the perfect reflecting diffuser. This ideal

reflecting surface reflects 100% of the incident radiant power such that the radiance is the same for

all directions within the hemisphere above the surface. No physical realization of this standard exists.

Optical properties of standards prepared from pressed plaques of magnesium carbonate (MgCO ),

barium sulfate (BaSO ), or polytetrafluoroethylene (PTFE) can approximate an ideal standard. For

further information see CIE Publication No. 46 (1). The principal use of a white reflectance factor

standard is to transfer an absolute scale of reflectance to a more durable material or from one

instrument to another. In theory, it should be easy to do this transfer from first principles. In practice,

one is likely to need values for parameters that are unknown, proprietary, or require a high level of

skill. Some, but not all, of those parameters are discussed in this practice.

1. Scope 2. Referenced Documents

1.1 This practice covers procedures for preparing pressed 2.1 ASTM Standards:

powder transfer standards. These standards can be used in the E284 Terminology of Appearance

near-ultraviolet, visible and near-infrared region of the electro-

3. Terminology

magnetic spectrum. Procedures for calibrating the reflectance

3.1 Terms and definitions in Terminology E284 are appli-

factor of materials on an absolute basis are contained in CIE

Publication No. 44 (2). Pressed powder standards are used as cable to this practice.

3.2 Definitions—The following definitions are particularly

transfer standards for such calibrations because they have a

high reflectance factor that is nearly constant with wavelength, important to this practice:

3.2.1 perfect reflecting diffuser—idealreflectingsurfacethat

and because the geometric distribution of reflected flux re-

sembles that from the perfect reflecting diffuser. neither absorbs nor transmits light, but reflects diffusely, with

the radiance of the reflecting surface being the same for all

1.2 The values stated in SI units are to be regarded as the

standard. The values in parentheses are for information only. reflecting angles, regardless of the angular distribution of the

incident light. (1990)

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.2.2 reflectance, r, n—ratio of the reflected radiant or

responsibility of the user of this standard to establish appro- luminous flux to the incident flux in the given conditions.

A

[CIE]

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 3.2.3 Theterm reflectanceisoftenusedinageneralsenseor

as an abbreviation for reflectance factor. Such usage may be

assumed unless the above definition is specifically required by

This practice is under the jurisdiction ofASTM Committee E12 on Color and

the context. (1989b)

Appearance and is the direct responsibility of Subcommittee E12.02 on Spectro-

3.2.4 reflectance factor, R, n—ratio of the flux reflected

photometry and Colorimetry.

from the specimen to the flux reflected from the perfect

Current edition approved July 10, 2003. Published July 2003. Originally

approved in 1965. Last previous edition approved in 1998 as E259–98.

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this practice. Annual Book of ASTM Standards, Vol 06.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

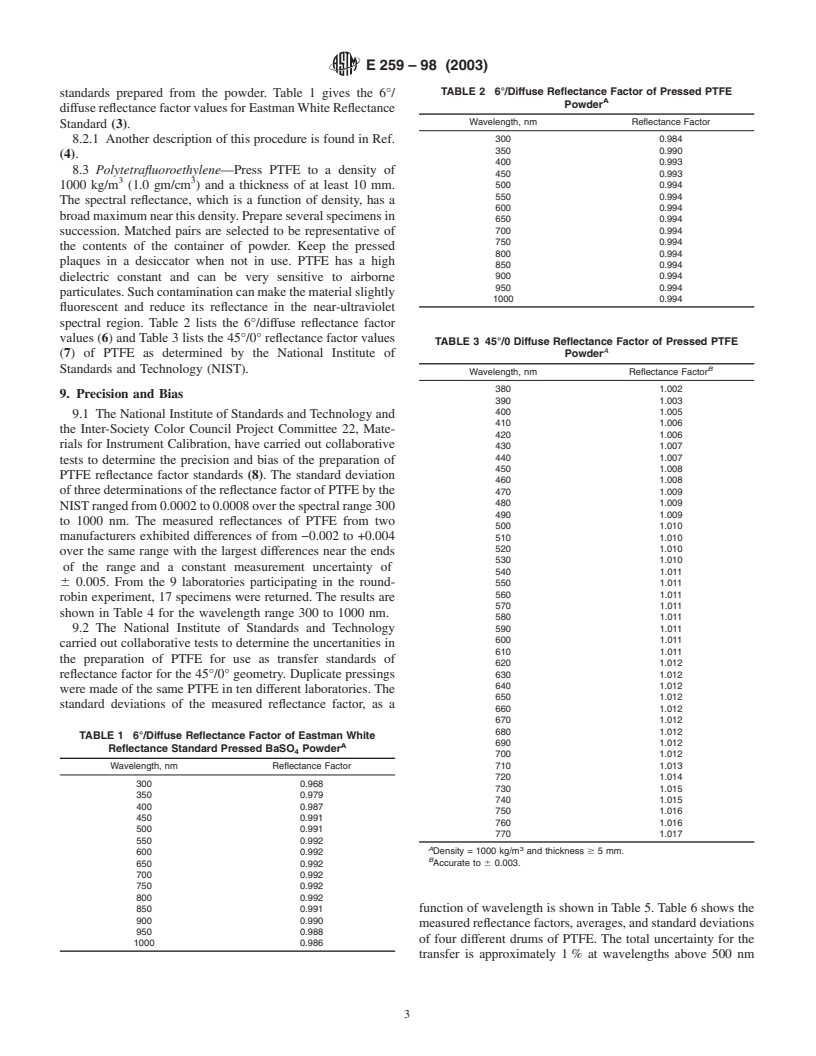

E 259 – 98 (2003)

reflecting diffuser under the same geometric and spectral Fig. 1. The optical surface of the plaque should be pressed

B

conditions of measurement. [CIE] (1988) against a surface of ground glass or poly(methyl methacrylate)

to provide a matte finish on the pressed plaque. Powder

4. Summary of Practice

receptaclesshouldbeatleast5mmdeepforBaSO andatleast

10 mm deep for PTFE.

4.1 Procedures are given for the preparation of white

reference standards of diffuse reflectance factor and diffuse

7. Reagents and Materials

radiancefactor.Therecommendedmaterialsarewhitepowders

7.1 Barium Sulfate—the barium sulfate should be of the

that are pressed into plaques. These plaques provide close

highest purity. It should be specially refined for optical and

approximations to the optical properties of the perfect reflect-

spectroscopic use (3).

ing diffuser, and may be used to transfer a scale of absolute

7.2 Polytetrafluoroethylene—the PTFE (4) should also be

reflectance to another material or to an instrument.

specially refined for optical and spectroscopic use but some

5. Significance and Use commercial grades have been found to be acceptable substi-

tutes. (5) There is currently no commercial source for small

5.1 All commercial reflectometers measure relative reflec-

quantities of optical grade PTFE powder. Large quantities

tance.Theinstrumentreadingisthereflectancefactor,theratio

(drums) of commercial grade PTFE can be obtained from

of the light reflected by a reference specimen to that reflected

manufacturers.

by a test specimen. That ratio is dependent on specific

instrument parameters.

8. Procedure

5.2 National standardizing laboratories and some research

8.1 Store all powdered reflectance standards in tightly

laboratories measure reflectance on instruments calibrated

capped glass containers. If the powder is purchased in plastic

from basic principles, thereby establishing a scale of absolute

containers, transfer it to a glass container as soon as possible.

reflectance as described in CIE Publication No. 44 (2). These

Before using the powder, place it in a glass blender equipped

measurementsaresufficientlydifficultthattheyareusuallyleft

with stainless-steel or PTFE-coated blades and pulverize to a

to laboratories that specialize in them.

uniform consistency. Transfer the quantity of powder to be

5.3 Astandard that has been measured on an absolute scale

used with stainless steel or PTFE-coated spoons. Perform the

could be used to transfer that scale to a reflectometer. While

whole operation in a draft-free location, away from sources of

suchproceduresexist,theconstraintsplacedonthemechanical

small particulate contamination, filters, sweaters, windows,

properties restrict the suitability of some optical properties,

ovens, etc. Perform all measurements (weight, height, width,

especiallythosepropertiesrelatedtothegeometricdistribution

depth, volume, area, etc.) with adequate precision to ensure

of the reflected light. Thus, reflectance factor standards which

that the final density is within 5% of the specified value. The

are sufficiently rugged and able to be cleaned, depart consid-

most reproducible standards are made by pressing the powder

erablyfromtheperfectdiffuserinthegeometricdistributionof

toaspecificdensity.Thus,determinethemassofthepowderto

reflected radiance.

be used from the volume of the receptacle.

5.4 The geometric distribution of reflected radiance from a

8.2 Barium Sulfate—Press BaSO to a density of 2000

pressed powder plaque is sufficiently diffuse to provide a 4

3 3

kg/m (2.0 gm/cm ) and a thickness of at least 5 mm. Press

dependable calibration of a directional-hemispherical reflecto-

several specimens in succession. Select matched pairs to be

meter. Although pressed powder standards are subject to

representativeofthecontentsofthebottleofpowder.Keepthe

contamination and breakage, the directional-hemispherical re-

pressed plaques in a covered desiccator when not in use. Some

flectancefactorofpressedpowderstandardscanbesufficiently

suppliers of BaSO provide calibration values with each bottle

reproduciblefromspecimentospecimenmadefromagivenlot 4

ofpowder,othersuppliersprovideonly3or4qualityreference

of powder, so as to allow one to assign absolute reflectance

checks and a reference to published values of reference

factor values to all the powder in a lot.

5.5 Thispracticedescribeshowtopreparewhitereflectance

factor standards from a powder in a manner that allows a

standardizing laboratory to assign the absolute scale of reflec-

tance to the plaque.

6. Apparatus

6.1 The basic apparatus for producing a pressed powder

standard includes a powder press, powder containers and a

balance. There are presently two commercial suppliers of

powderpresses. Thepressandreceptaclescanalsobemadein

a local machine sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.