ASTM A564/A564M-13e1

(Specification)Standard Specification for Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes

Standard Specification for Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes

ABSTRACT

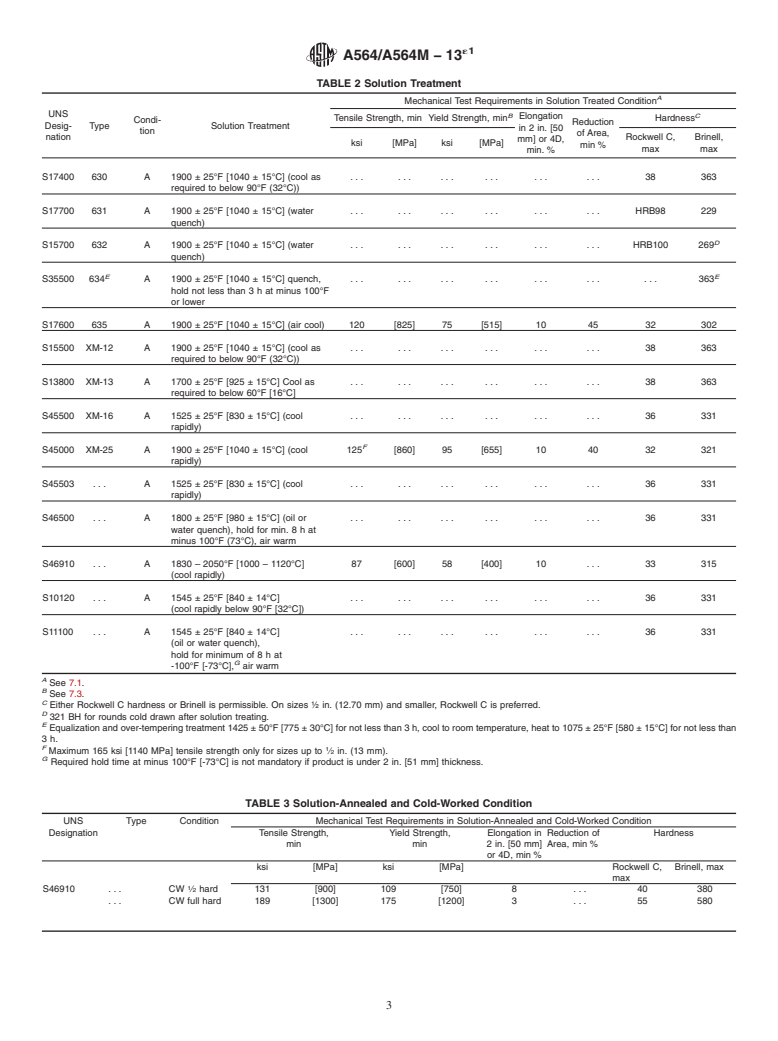

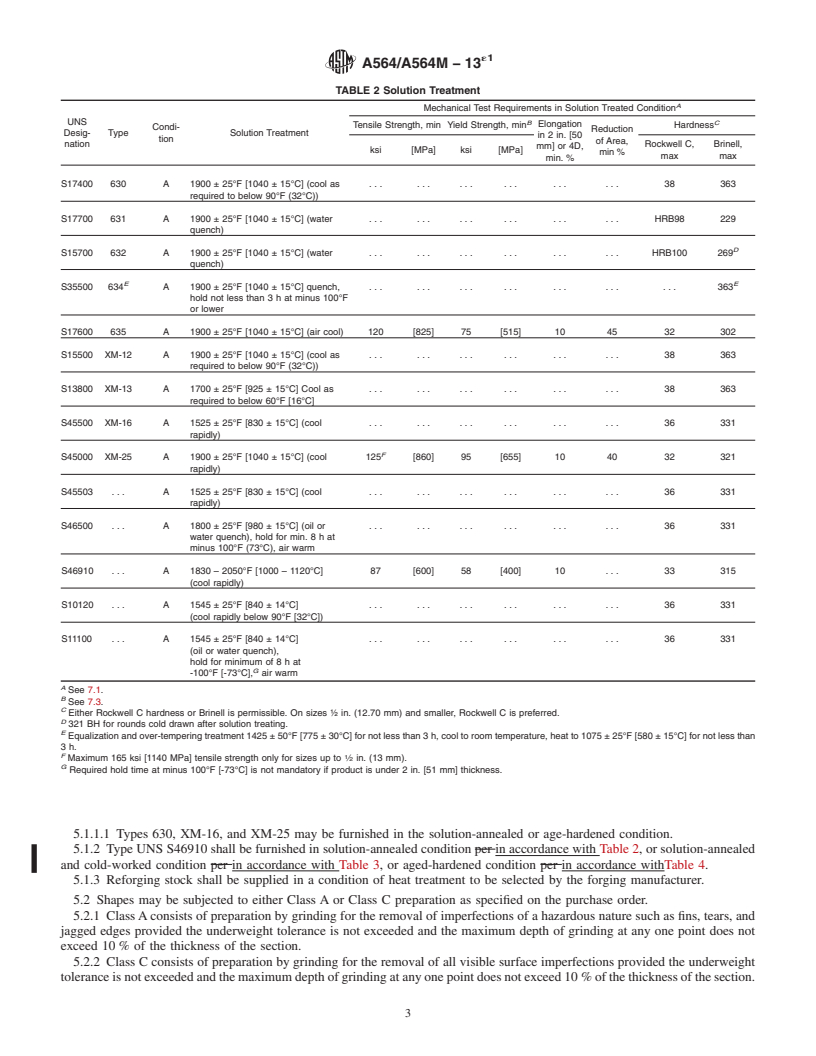

This specification covers bars and shapes of age-hardening stainless steels. Hot-finished or cold-finished rounds, squares, hexagons, bar shapes, angles, tees, and channels are included. These shapes may be produced by hot rolling, extruding, or forging. Type 631 and 632 stainless steels contain a large amount of ferrite in the microstructure and can have low ductility in forgings and large diameter bars. Material of types other than XM-16, XM-25, and Type 630 shall be furnished in the solution-annealed condition, or in the equalized and oven-tempered condition. Types 630, XM-16, and XM-25 may be furnished in the solution-annealed or age-hardened condition. Type UNS S46910 shall be furnished in solution annealed, cold-worked or aged-hardened condition. Shapes may be subjected to either Class A or Class C preparation for removal of visible surface imperfections. The material shall be subjected to tension, impact, and hardness tests.

SCOPE

1.1 This specification2 covers bars and shapes of age-hardening stainless steels. Hot-finished or cold-finished rounds, squares, hexagons, bar shapes, angles, tees, and channels are included; these shapes may be produced by hot rolling, extruding, or forging. Billets or bars for reforging may be purchased to this specification.

1.2 These steels are generally used for parts requiring corrosion resistance and high strength at room temperature, or at temperatures up to 600°F [315°C]; 700°F [370°C] for Type 632; 840°F [450°C] for Type UNS S46910. They are suitable for machining in the solution-annealed condition after which they may be age-hardened to the mechanical properties specified in Section 7 without danger of cracking or distortion. Type XM-25 is machinable in the as-received fully heat treated condition. Type UNS S46910 is suitable for machining in the solution-annealed, cold-worked, and aged-hardened condition.

1.3 Types 631 and 632 contain a large amount of ferrite in the microstructure and can have low ductility in forgings and larger diameter bars. Applications should be limited to small diameter bar.

1.4 The values stated in either inch-pound units or SI (metric) units are to be regarded separately as standards; within the text and tables, the SI units are shown in [brackets]. The values stated in each system are not exact equivalents; therefore, each system must be used independent of the other. Combining values from the two systems may result in nonconformance with the specification.

1.5 Unless the order specifies an “M'' designation, the material shall be furnished to inch-pound units.

Note 1: For forgings, see Specification A705/A705M.

Note 2: For billets and bars for forging see Specification A314.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:A564/A564M −13

Standard Specification for

Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel

1

Bars and Shapes

This standard is issued under the fixed designationA564/A564M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—Corrected incomplete sentence in 7.1 editorially in October 2017.

NOTE 1—For forgings, see Specification A705/A705M.

1. Scope*

NOTE 2—For billets and bars for forging see Specification A314.

2

1.1 This specification covers bars and shapes of age-

1.6 This international standard was developed in accor-

hardeningstainlesssteels.Hot-finishedorcold-finishedrounds,

dance with internationally recognized principles on standard-

squares, hexagons, bar shapes, angles, tees, and channels are

ization established in the Decision on Principles for the

included; these shapes may be produced by hot rolling,

Development of International Standards, Guides and Recom-

extruding, or forging. Billets or bars for reforging may be

mendations issued by the World Trade Organization Technical

purchased to this specification.

Barriers to Trade (TBT) Committee.

1.2 These steels are generally used for parts requiring

corrosion resistance and high strength at room temperature, or 2. Referenced Documents

at temperatures up to 600°F [315°C]; 700°F [370°C] for Type 3

2.1 ASTM Standards:

632; 840°F [450°C] for Type UNS S46910. They are suitable

A314 Specification for Stainless Steel Billets and Bars for

for machining in the solution-annealed condition after which

Forging

they may be age-hardened to the mechanical properties speci-

A370 Test Methods and Definitions for Mechanical Testing

fied in Section 7 without danger of cracking or distortion.Type

of Steel Products

XM-25 is machinable in the as-received fully heat treated

A484/A484M Specification for General Requirements for

condition. Type UNS S46910 is suitable for machining in the

Stainless Steel Bars, Billets, and Forgings

solution-annealed, cold-worked, and aged-hardened condition.

A705/A705M Specification for Age-Hardening Stainless

1.3 Types 631 and 632 contain a large amount of ferrite in Steel Forgings

the microstructure and can have low ductility in forgings and

A751 Test Methods, Practices, and Terminology for Chemi-

larger diameter bars. Applications should be limited to small cal Analysis of Steel Products

diameter bar.

E527 Practice for Numbering Metals and Alloys in the

Unified Numbering System (UNS)

1.4 The values stated in either inch-pound units or SI

2.2 Other Documents:

(metric)unitsaretoberegardedseparatelyasstandards;within

SAE J1086 Recommended Practice for Numbering Metals

the text and tables, the SI units are shown in [brackets]. The

4

and Alloys (UNS)

values stated in each system are not exact equivalents;

therefore, each system must be used independent of the other.

3. Ordering Information

Combining values from the two systems may result in noncon-

3.1 It is the responsibility of the purchaser to specify all

formance with the specification.

requirements that are necessary for material ordered under this

1.5 Unless the order specifies an “M’’ designation, the

specification. Such requirements may include but are not

material shall be furnished to inch-pound units.

limited to the following:

3.1.1 Quantity (weight or number of pieces),

1

'This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

3

A01.17 on Flat-Rolled and Wrought Stainless Steel. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedMay1,2013.PublishedJuly2013.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1966. Last previous edition approved in 2010 as A564/A564M – 10. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/A0564_A0564M-13E01. the ASTM website.

2 4

For ASME Boiler and Pressure Vessel Code applications, see related Specifi- Available from Society of Automotive Engineers (SAE), 400 Commonwealth

cation SA-564/SA-564M in Section II of that Code. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

A564/A564M−13

3.1.2 Type or UNS designation (Table 1), 5.1.1.1 Types 630, XM-16, and XM-25 may be fu

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: A564/A564M − 13 A564/A564M − 13

Standard Specification for

Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel

1

Bars and Shapes

This standard is issued under the fixed designation A564/A564M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—Corrected incomplete sentence in 7.1 editorially in October 2017.

1. Scope*

2

1.1 This specification covers bars and shapes of age-hardening stainless steels. Hot-finished or cold-finished rounds, squares,

hexagons, bar shapes, angles, tees, and channels are included; these shapes may be produced by hot rolling, extruding, or forging.

Billets or bars for reforging may be purchased to this specification.

1.2 These steels are generally used for parts requiring corrosion resistance and high strength at room temperature, or at

temperatures up to 600°F [315°C]; 700°F [370°C] for Type 632; 840°F [450°C] for Type UNS S46910. They are suitable for

machining in the solution-annealed condition after which they may be age-hardened to the mechanical properties specified in

Section 7 without danger of cracking or distortion. Type XM-25 is machinable in the as-received fully heat treated condition. Type

UNS S46910 is suitable for machining in the solution-annealed, cold-worked, and aged-hardened condition.

1.3 Types 631 and 632 contain a large amount of ferrite in the microstructure and can have low ductility in forgings and larger

diameter bars. Applications should be limited to small diameter bar.

1.4 The values stated in either inch-pound units or SI (metric) units are to be regarded separately as standards; within the text

and tables, the SI units are shown in [brackets]. The values stated in each system are not exact equivalents; therefore, each system

must be used independent of the other. Combining values from the two systems may result in nonconformance with the

specification.

1.5 Unless the order specifies an “M’’ designation, the material shall be furnished to inch-pound units.

NOTE 1—For forgings, see Specification A705/A705M.

NOTE 2—For billets and bars for forging see Specification A314.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

A314 Specification for Stainless Steel Billets and Bars for Forging

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A484/A484M Specification for General Requirements for Stainless Steel Bars, Billets, and Forgings

A705/A705M Specification for Age-Hardening Stainless Steel Forgings

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

1

'This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.17

on Flat-Rolled and Wrought Stainless Steel.

Current edition approved May 1, 2013. Published July 2013. Originally approved in 1966. Last previous edition approved in 2010 as A564/A564M – 10. DOI:

10.1520/A0564_A0564M-13.10.1520/A0564_A0564M-13E01.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specification SA-564/SA-564M in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

A564/A564M − 13

2.2 Other Documents:

4

SAE J1086 Recommended Practice for Numbering Metals and Alloys (UNS)

3. Ordering Information

3.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material ordered under this

sp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.