ASTM D4975-96a

(Test Method)Standard Test Methods for Single-Filament Tire Bead Wire Made from Steel

Standard Test Methods for Single-Filament Tire Bead Wire Made from Steel

SCOPE

1.1 These test methods cover testing of single-filament steel wires that are components of tire beads used in the manufacture of pneumatic tires. By agreement, these test methods may be applied to similar filaments used for reinforcing other rubber products.

1.2 These test methods describe test procedures only and do not establish specifications and tolerances.

1.3 These test methods are written in SI units. The inch-pound units which are provided are not necessarily exact equivalents of the SI units. Either system of units may be used in these test methods. In case of referee decisions the SI units will prevail.

1.4 These test methods cover the determination of the mechanical properties listed below:

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4975 – 96a

Standard Test Methods for

Single-Filament Tire Bead Wire Made from Steel

This standard is issued under the fixed designation D 4975; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 These test methods cover testing of single-filament steel 3.1 Definitions:

wires that are components of tire beads used in the manufacture 3.1.1 breaking force, n—the maximum force applied to a

of pneumatic tires. By agreement, these test methods may be material carried to rupture.

applied to similar filaments used for reinforcing other rubber 3.1.2 percent elongation, n—the increase in length of a

products. specimen expressed as a percentage of the original length.

1.2 These test methods describe test procedures only and do 3.1.3 tire bead, n—that part of a tire that comes in contact

not establish specifications and tolerances. with the rim and that is shaped to secure the tire to the rim.

1.3 These test methods are written in SI units. The inch- 3.1.4 tire bead wire, n—a monofilament steel wire with a

pound units which are provided are not necessarily exact metallic coating, usually bronze, used in forming a tire bead.

equivalents of the SI units. Either system of units may be used 3.1.5 torsion resistance, n—in tire bead wire, the number of

in these test methods. In case of referee decisions the SI units turns of twist in a short length of wire that causes rupture.

will prevail. 3.1.6 yield strength, n—the stress at which a material

1.4 These test methods cover the determination of the exhibits a specified limiting deviation from the proportionality

mechanical properties listed below: of stress to strain.

1.5 This standard does not purport to address all of the 3.1.6.1 Discussion—It is customary in this instance to

safety problems, if any, associated with its use. It is the express the deviation in terms of strain and to determine yield

responsibility of the user of this standard to establish appro- strength by the offset method where a strain of 0.2 % is

priate safety and health practices and determine the applica- specified (see 10.9.1).

bility of regulatory limitations prior to use. 3.1.7 For definitions of other textile terms, refer to Termi-

nology D 123.

Property Section

Breaking Force (Strength) 7-13

4. Summary of Test Methods

Yield Strength 7-13

4.1 A summary of the directions prescribed for the determi-

Elongation 7-13

Torsion Resistance 14-20

nation of specific properties of tire bead wire is stated in the

Diameter (Gage) 21-27

appropriate sections of the specific test methods that follow.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards:

5.1 The procedures for the determination of properties of

A 370 Test Methods and Definitions for Mechanical Testing

single-filament bead wire made from steel are considered

of Steel Products

satisfactory for acceptance testing of commercial shipments of

D 76 Specification for Tensile Testing Machines for Tex-

this product since the procedures are the best available and

tiles

have been used extensively in the trade.

D 123 Terminology Relating to Textiles

5.1.1 In case of a dispute arising from differences in

D 2969 Test Method for Steel Tire Cords

reported test results when using these test methods for accep-

E 6 Terminology Relating to Methods of Mechanical Test-

tance testing of commercial shipments, the purchaser and

ing

supplier should conduct comparative tests to determine if there

E 558 Test Method for Torsion Testing of Wire

is a statistical bias between their laboratories. Competent

statistical assistance is recommended for the investigation of

bias. As a minimum, the two parties should take a group of test

These test methods are under the jurisdiction of ASTM Committee D-13 on

Textiles and are the direct responsibility of Subcommittee D13.19 on Tire Cord and

specimens which are as homogeneous as possible and which

Fabrics.

are from a lot of material of the type in question. The test

Current edition approved Aug. and Oct. 10, 1996. Published December 1997.

specimens then should be randomly assigned in equal numbers

Originally published as D 4975 – 89. Last previous edition D 4975 – 93.

Annual Book of ASTM Standards, Vol 01.03. to each laboratory for testing. The average results from the two

Annual Book of ASTM Standards, Vol 07.01.

laboratories should be compared using Student’s t-test for

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 4975

unpaired data and an acceptable probability level chosen by the computing equipment which may be programmed to calculate

two parties before testing is begun. If a bias is found, either its and print the results for each of these desired properties.

cause must be determined and corrected or the purchaser and Because of the variety of electronic equipment available and

the supplier must agree to interpret future test results in the the various possibilities for recording test data, use of this type

light of the known bias. of equipment is not covered in this test method.

9.3 Grips, of such design that failure of the specimen does

6. Sampling

not occur at the gripping point, and slippage of the specimen

6.1 Lot Sample—As a lot sample for acceptance testing,

within the jaws (grips) is prevented.

take at random the number of reels, coils, spools, or other

10. Procedure

shipping units of wire directed in an applicable material

specification or other agreement between the purchaser and the

10.1 Thermally age the specimen by placing it in a suitable

supplier. Consider reels, coils, spools, or other shipping units of

oven for1hat 150°C (300°F). Allow specimens to cool to

wire to be the primary sampling units.

room temperature before testing.

10.2 Select the proper force scale range on the tensile

NOTE 1—A realistic specification or other agreement between the

purchaser and the supplier requires taking into account the variability testing machine based on the estimated breaking force of the

between and within primary sampling units so as to provide a sampling

specimen being tested.

plan which at the specified level of the property of interest has a

10.3 Adjust the distance between the grips of the testing

meaningful producer’s risk, acceptable quality level, and desired limiting

machine, nip to nip, to a gage length of 250 mm (10 in.).

quality level.

10.4 Secure the specimen in the upper grip sufficiently to

6.2 Laboratory Sample—Use the primary sampling units in

prevent slippage during testing. While keeping the specimen

the lot sample as a laboratory sample.

straight and taut, place and secure the other end in the lower

6.3 Test Specimens—For each test procedure, take the

grip.

number of lengths of tire bead wire of the specified lengths

10.5 Apply a force of 1 N (0.2 lbf) on the clamped specimen

from each laboratory sample as directed in the test procedure.

to take out any residual slack before initiating the test. This will

be considered the zero reference point for elongation calcula-

BREAKING FORCE, YIELD STRENGTH, AND

tions.

ELONGATION

10.6 After setting the cross head speed at 25 mm (1 in.)/min

7. Summary of Test Method

and recorder chart speed at 250 mm (10 in.)/min, start the

testing machine and record the force-extension curve gener-

7.1 The two ends of a specimen are clamped in a tensile

ated.

testing machine; an increasing force is applied until the

10.6.1 If the specimen fractures at or within 5 mm (0.2 in.)

specimen breaks. The change in force is measured versus the

of the gripping point, discard the result and test another

increase in separation of the specimen clamps to form a

specimen. If such jaw breaks continue to occur, insert a jaw

force-extension curve. Breaking force is read directly from the

liner such as an abrasive cloth between the gripping surface

curve and is expressed in newtons (pounds-force). Percent

and the specimen in a manner so that the liner extends beyond

elongation at break is the extension at break divided by the

the grip edge where it comes in contact with the specimen.

original specimen length, 3 100. The yield strength, the inter-

10.7 Conduct this test procedure on two specimens from

section of the force-extension curve with a line at 0.2 % offset,

each laboratory sampling unit.

is read from the force-extension curve and is expressed in

10.8 Elongation, the increase in gage length of a tensile

newtons (pounds-force).

specimen, is usually expressed as a percentage of the original

8. Significance and Use

gage length and can be determined from the force-extension

8.1 The load-bearing ability of a reinforced rubber product

curve.

such as a tire bead is related to the strength of the single- 10.8.1 When a greater degree of accuracy is required in the

filament wire used as the reinforcing material. The breaking determination of elongation, an extensometer can be attached

force and yield strength of tire bead wire is used in engineering to the specimen.

calculations when designing this type of reinforced product. 10.9 Yield strength is the stress at which a material exhibits

8.2 Elongation of tire bead wire is taken into consideration a specified limiting deviation from the proportionality of stress

in the design and engineering of tire beads because of its effect to strain. Determine the yield strength by the 0.2 % offset

on uniformity and dimensional stability during service. method.

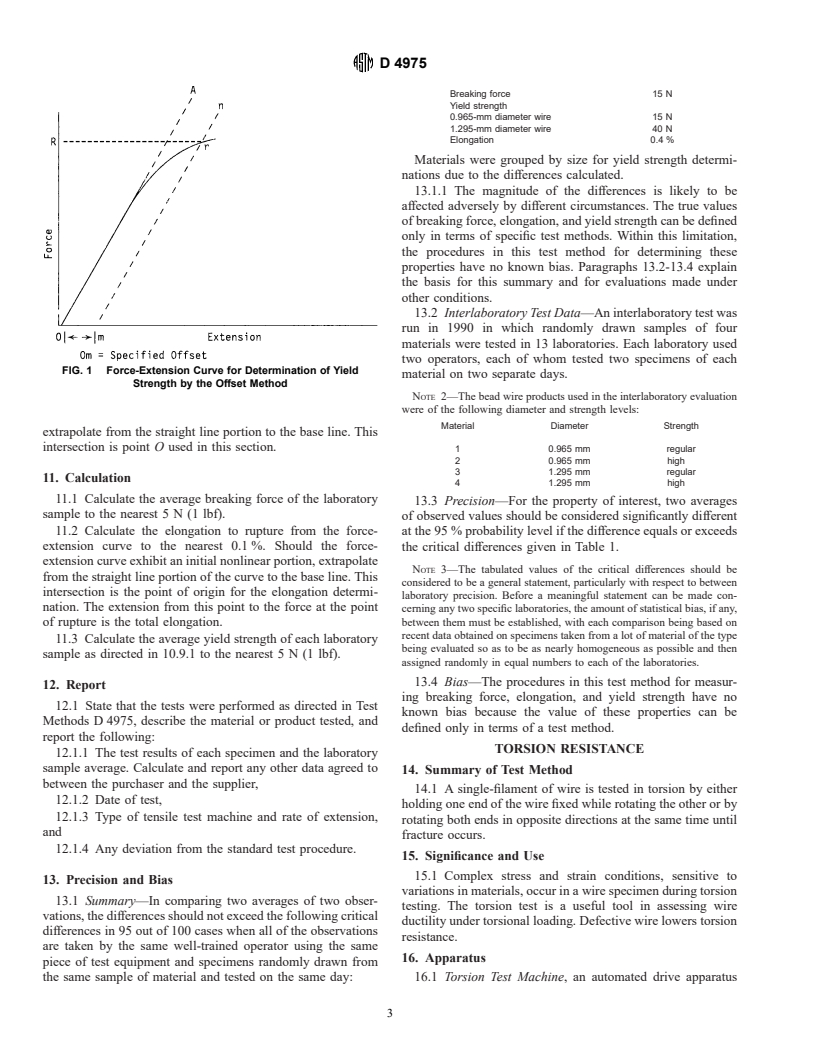

10.9.1 On the force-extension curve (Fig. 1) that has been

9. Apparatus

generated (see 10.6) lay off Om equal to the specified value of

9.1 Tensile Testing Machine, CRE (Constant-Rate-of-

the offset (0.2 % elongation); draw mn parallel to OA and

Extension) tensile testing machine of such capacity that the

locate r. This intersection of mn with the force-extension curve

maximum force required to fracture the wire shall not exceed

corresponds to force R which is the yield strength. Should the

90 % nor be of less than 10 % of the selected force measure-

force-extension curve exhibit an initial nonlinear portion,

ment range. The specifications and methods of calibration and

verification shall conform to Specification D 76.

9.2 In some laboratories, the output of CRE type of tensile

Suitable electric ovens are manufactured by Blue M Electric Company, Blue

testing machine is connected with electronic recording and Island, IL 60406.

D 4975

Breaking force 15 N

Yield strength

0.965-mm diameter wire 15 N

1.295-mm diameter wire 40 N

Elongation 0.4 %

Materials were grouped by size for yield strength determi-

nations due to the differences calculated.

13.1.1 The magnitude of the differences is likely to be

affected adversely by different circumstances. The true values

of breaking force, elongation, and yield strength can be defined

only in terms of specific test methods. Within this limitation,

the procedures in this test method for determining these

properties have no known bias. Paragraphs 13.2-13.4 explain

the basis for this summary and for evaluations made under

other conditions.

13.2 Interlaboratory Test Data—An interlaboratory test was

run in 1990 in which randomly drawn samples of four

materials were tested in 13 laboratories. Each laboratory used

two operators, each of whom tested two specimens of each

FIG. 1 Force-Extension Curve for Determination of Yield

material on two separate days.

Strength by the Offset Method

NOTE 2—The bead wire products used in the interlaboratory evaluation

were of the following diameter and strength levels:

Material Diameter Strength

extrapolate from the straight line portion to the base line. This

intersection is point O used in this section.

1 0.965 mm regular

2 0.965 mm high

3 1.295 mm regular

11. Calculation

4 1.295 mm high

11.1 Calculate the average breaking force of the laboratory

13.3 Precision—For the property of interest, two averages

sample to the nearest5N(1 lbf).

of observed values should be considered significantly different

11.2 Calculate the elongation to rupture from the force-

at the 95 % probability level if the difference equals or exceeds

extension curve to the nearest 0.1 %. Should the force- the critical differences given in Table 1.

extension curve exhibit an initial nonlinear portion, extrapolate

NOTE 3—The tabulated values of the critical differences should be

from the straight line portion of the curve to the base line. This

considered to be a general statement, particularly with respect to between

intersection is the point of origin for the elongation determi-

laboratory precision. Before a meaningful statement can be made con-

nation. The extension from this point to the force at the point

cerning any two specific laboratories, the amount of statistical bias, if any,

of rupture is the total elongation. between them must be established, with each comparison being based on

recent data obtained on specimens taken from a lot of material of the type

11.3 Calculate the average yield strength of each laboratory

being evaluated so as to be as nearly homogeneous as possible and then

sample as directed in 10.9.1 to the nearest5N(1 lbf).

assigned randomly in equal numbers to each of the laboratories.

13.4 Bias—The procedures in this test method for measur-

12. Report

ing breaking force, elongation, and yield strength have no

12.1 State that the tests were performed as directed in Test

known bias because the value of these properties can be

Methods D 4975, describe the material or product tested, and

defined only in terms of a test method.

report the following:

TORSION RESISTANCE

12.1.1 The test results of each specimen and the laboratory

sample average. Calculate and report any other data agreed to

14. Summary of Test Method

between the purchaser and the supplier,

14.1 A single-filament of wire is tested in torsion by either

12.1.2 Date of test,

holding one end of the wire fixed while rotating the other or by

12.1.3 Type of tensile test machine and rate of extension,

rotating both ends in opposite directions at the same time until

and

fracture occurs.

12.1.4 Any deviation from the standard test procedure.

15. Significance and Use

15.1 Complex stress and strain conditions, sensitive to

13. Precision and Bias

variations in materials, occur in a wire specimen during torsion

13.1 Summary—In comparing two averages of two obser-

testing. The torsion test is a useful tool in assessing wire

vations, the differences should not exceed the following critical

ductility under torsional loading. Defective wire lowers torsion

dif

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.