ASTM F1704-09

(Test Method)Standard Test Method for Capture and Containment Performance of Commercial Kitchen Exhaust Ventilation Systems

Standard Test Method for Capture and Containment Performance of Commercial Kitchen Exhaust Ventilation Systems

SIGNIFICANCE AND USE

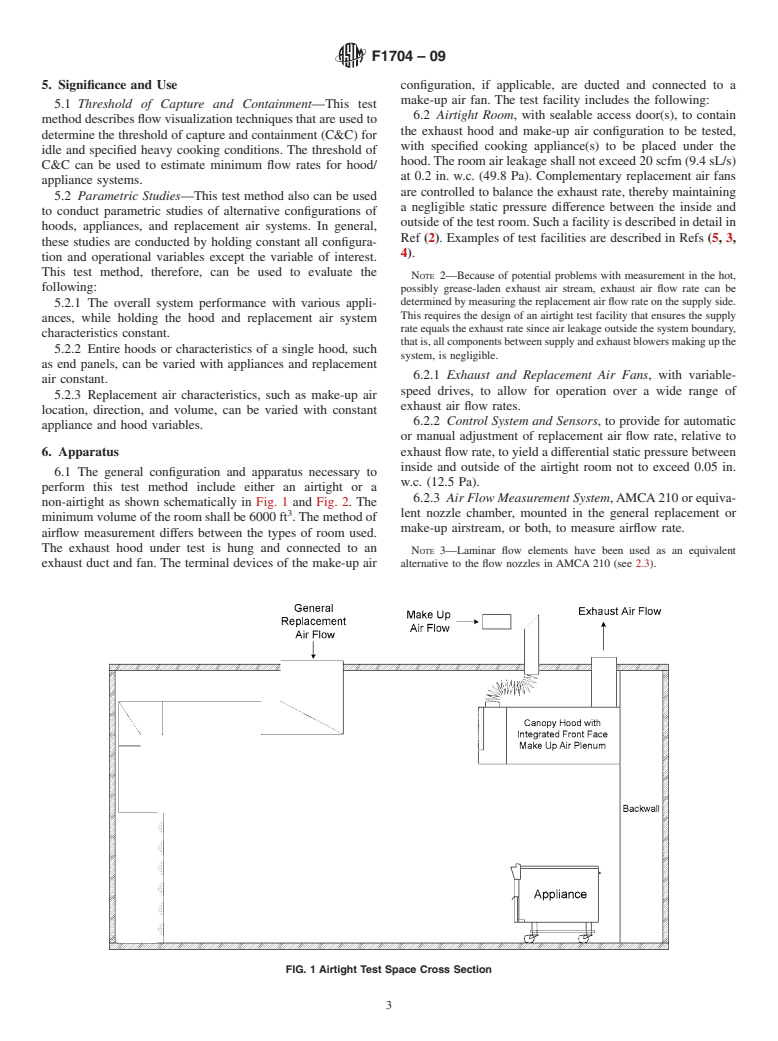

Threshold of Capture and Containment—This test method describes flow visualization techniques that are used to determine the threshold of capture and containment (C&C) for idle and specified heavy cooking conditions. The threshold of C&C can be used to estimate minimum flow rates for hood/appliance systems.

Parametric Studies—This test method also can be used to conduct parametric studies of alternative configurations of hoods, appliances, and replacement air systems. In general, these studies are conducted by holding constant all configuration and operational variables except the variable of interest. This test method, therefore, can be used to evaluate the following:

The overall system performance with various appliances, while holding the hood and replacement air system characteristics constant.

Entire hoods or characteristics of a single hood, such as end panels, can be varied with appliances and replacement air constant.

Replacement air characteristics, such as make-up air location, direction, and volume, can be varied with constant appliance and hood variables.

SCOPE

1.1 Characterization of capture and containment performance of hood, appliance(s), and replacement air system during cooking and non-cooking conditions (idle):

1.2 Parametric evaluation of operational or design variations in appliances, hoods, or replacement air configurations.

1.3 The test method to determine heat gain to space from commercial kitchen ventilation/appliance systems has been re-designated as Test Method F2474.

1.4 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F1704 – 09

Standard Test Method for

Capture and Containment Performance of Commercial

1

Kitchen Exhaust Ventilation Systems

This standard is issued under the fixed designation F1704; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F1785 Test Method for Performance of Steam Kettles

F1787 Test Method for Performance of Rotisserie Ovens

1.1 Characterization of capture and containment perfor-

F1817 Test Method for Performance of Conveyor Ovens

mance of hood, appliance(s), and replacement air system

F1991 Test Method for Performance of Chinese (Wok)

during cooking and non-cooking conditions (idle):

Ranges

1.2 Parametric evaluation of operational or design varia-

F1964 Test Method for Performance of Pressure and Kettle

tions in appliances, hoods, or replacement air configurations.

Fryers

1.3 The test method to determine heat gain to space from

F1965 Test Method for Performance of Deck Ovens

commercial kitchen ventilation/appliance systems has been

F2093 Test Method for Performance of Rack Ovens

re-designated as Test Method F2474.

F2144 Test Method for Performance of Large Open Vat

1.4 The values stated in inch-pound units are to be regarded

Fryers

as standard. No other units of measurement are included in this

F2237 Test Method for Performance of Upright Overfired

standard.

Broilers

1.5 This standard does not purport to address all of the

F2239 Test Method for Performance of Conveyor Broilers

safety concerns, if any, associated with its use. It is the

F2474 Test Method for Heat Gain to Space Performance of

responsibility of the user of this standard to establish appro-

Commercial Kitchen Ventilation/Appliance Systems

priate safety and health practices and determine the applica-

3

2.2 ASHRAE Standards:

bility of regulatory limitations prior to use.

ASHRAE Guideline 2-1986 (RA90) Engineering Analysis

2. Referenced Documents

of Experimental Data

4

2

2.3 ANSI Standard:

2.1 ASTM Standards:

ANSI/ASHRAE41.2 StandardMethodsforLaboratoryAir-

F1275 Test Method for Performance of Griddles

Flow Measurement

F1361 Test Method for Performance of Open Deep Fat

ANSI/ASHRAE 51 and ANSI/AMCA 210 Laboratory

Fryers

Method of Testing Fans for Rating

F1484 Test Methods for Performance of Steam Cookers

F1496 Test Method for Performance of Convection Ovens

NOTE 1—The replacement air and exhaust system terms and their

F1521 Test Methods for Performance of Range Tops

definitions are consistent with terminology used by theAmerican Society

5

of Heating, Refrigeration, and Air Conditioning Engineers, see Ref (1).

F1605 Test Method for Performance of Double-Sided

Where there are references to cooking appliances, an attempt has been

Griddles

made to be consistent with terminology used in the test methods for

F1639 Test Method for Performance of Combination Ovens

commercial cooking appliances. For each energy rate defined as follows,

F1695 Test Method for Performance of Underfired Broilers

there is a corresponding energy consumption that is equal to the average

F1784 Test Method for Performance of a Pasta Cooker

energy rate multiplied by elapsed time. Electric energy and rates are

expressed in W, kW, and kWh. Gas Energy consumption quantities and

rates are expressed in Btu, kBtu, and kBtu/h. Energy rates for natural

1

This test method are under the jurisdiction of ASTM Committee F26 on Food

Service Equipment and are the direct responsibility of Subcommittee F26.07 on

Commercial Kitchen Ventilation.

3

Current edition approved Oct. 1, 2009. Published November 2009. Originally Available from American Society of Heating, Refrigerating, and Air-

approved in 1996. Last previous edition approved in 2005 as F1704 – 05. DOI: Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA

10.1520/F1704-09. 30329.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036.

5

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to the list of references at the end of

the ASTM website. these test methods.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1704 – 09

gas-fueled appliances are based on the higher heating value of natural gas.

3.1.12.1 air curtain supply, n—replacement air delivered

directly to

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F1704–05 Designation: F1704 – 09

Standard Test Method for

Capture and Containment Performance of Commercial

1

Kitchen Exhaust Ventilation Systems

This standard is issued under the fixed designation F1704; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Characterization of capture and containment performance of hood, appliance(s), and replacement air system during cooking

and non-cooking conditions (idle):

1.2 Parametric evaluation of operational or design variations in appliances, hoods, or replacement air configurations.

1.3 The test method to determine heat gain to space from commercial kitchen ventilation/appliance systems has been

re-designated as Test Method F2474.

1.4The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.4 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this

standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

F1275 Test Method for Performance of Griddles

F1361 Test Method for Performance of Open Deep Fat Fryers

F1484 Test Methods for Performance of Steam Cookers

F1496 Test Method for Performance of Convection Ovens

F1521 Test Methods for Performance of Range Tops

F1605 Test Method for Performance of Double-Sided Griddles

F1639 Test Method for Performance of Combination Ovens

F1695 Test Method for Performance of Underfired Broilers

F1784 Test Method for Performance of a Pasta Cooker

F1785 Test Method for Performance of Steam Kettles

F1787 Test Method for Performance of Rotisserie Ovens

F1817 Test Method for Performance of Conveyor Ovens

F1991 Test Method for Performance of Chinese (Wok) Ranges

F1964 Test Method for Performance of Pressure and Kettle Fryers

F1965 Test Method for Performance of Deck Ovens

F2093 Test Method for Performance of Rack Ovens

F2144 Test Method for Performance of Large Open Vat Fryers

F2237 Test Method for Performance of Upright Overfired Broilers

F2239 Test Method for Performance of Conveyor Broilers

F2474 Test Method for Heat Gain to Space Performance of Commercial Kitchen Ventilation/Appliance Systems

3

2.2 ASHRAE Standards:

1

ThistestmethodareunderthejurisdictionofASTMCommitteeF26onFoodServiceEquipmentandarethedirectresponsibilityofSubcommitteeF26.07onCommercial

Kitchen Ventilation.

Current edition approved MarchOct. 1, 2005.2009. Published March 2005.November 2009. Originally approved in 1996. Last previous edition approved in 19992005 as

F1704–99.F1704 – 05. DOI: 10.1520/F1704-059.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA 30329.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1704 – 09

ASHRAE Guideline 2-1986 (RA90) Engineering Analysis of Experimental Data

4

2.3 ANSI Standard: ANSI Standard:

ANSI/ASHRAE 41.2 Standard Methods for Laboratory Air-Flow Measurement

ANSI/ASHRAE 51 and ANSI/AMCA 210 Laboratory Method of Testing Fans for Rating

NOTE 1—The replacement air and exhaust system terms and their definitions are consistent with terminology used by theAmerican Society of Heating,

5

Refrigeration, andAir Conditioning Engineers, see Ref (1). Where there are references to cooking appliances, an attempt has been made to be consistent

with terminology used in the test methods for commercial cooking appliances. For each energy rate defined as follows, there is a corresponding energy

consumption that is equal to the average energy rate multiplied by elapsed time. Electric energy and rates are expressed in W, kW, and kWh. Gas Energy

consu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.