ASTM D3949-99

(Specification)Standard Specification for Coated Glass Fabrics Used for Electrical Insulation

Standard Specification for Coated Glass Fabrics Used for Electrical Insulation

SCOPE

1.1 This specification covers woven glass fabric coated with fully cured oleoresinous varnish, epoxy resin, polyurethane resin, or polyester resin. Excluded are coated polyester-glass fabric and glass fabric coated with silicone resins and silicone elastomers.

1.2 It is recognized that several properties, notably breaking strength and dielectric strength, are related to the style of base fabric used for any particular thickness. This specification has been developed for materials using fabrics woven from relatively coarse-filament yarns and in some cases from relatively open-weave constructions, and property values are frequently somewhat lower than if finer filament yarns or closer weave constructions were used. The user is therefore alerted that significantly higher levels of performance test values may be obtained through the use of these latter types of alternate base constructions.

1.3 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 3949 – 99

Standard Specification for

Coated Glass Fabrics Used for Electrical Insulation

This standard is issued under the fixed designation D 3949; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Classification

1.1 This specification covers woven glass fabric coated with 4.1 The materials of this specification are identified accord-

fully cured oleoresinous varnish, epoxy resin, polyurethane ing to the type of coating applied, as follows:

resin, or polyester resin. Excluded are coated polyester-glass 4.1.1 Type 1—Black oleoresinous varnish,

fabric and glass fabric coated with silicone resins and silicone 4.1.2 Type 2—Yellow oleoresinous varnish,

elastomers. 4.1.3 Type 3—Epoxy resin,

1.2 It is recognized that several properties, notably breaking 4.1.4 Type 4—Polyurethane (isocyanate) resin, and

strength and dielectric strength, are related to the style of base 4.1.5 Type 5—Polyester resin.

fabric used for any particular thickness. This specification has

5. Ordering Information

been developed for materials using fabrics woven from rela-

5.1 Orders for material covered by this specification shall

tively coarse-filament yarns and in some cases from relatively

open-weave constructions, and property values are frequently include the following:

5.1.1 Type of coating,

somewhat lower than if finer filament yarns or closer weave

constructions were used. The user is therefore alerted that 5.1.2 Nature of finish, if any (waxy, greasy, dry, oily,

mica-dusted, and so forth),

significantly higher levels of performance test values may be

obtained through the use of these latter types of alternate base 5.1.3 Color of coating (oleoresinous only),

5.1.4 Nominal coated thickness and base fabric thickness,

constructions.

1.3 The values stated in inch-pound units are to be regarded 5.1.5 Put-up,

5.1.5.1 Full-Width Rolls—core size, trimmed or untrimmed,

as the standard.

length and width,

2. Referenced Documents

5.1.5.2 Sheets—length and width,

2.1 ASTM Standards: 5.1.5.3 Tapes—core size, length, width,

D 902 Test Methods for Flexible Resin-Coated Glass Fab- 5.1.6 Number of units per package,

rics and Glass Fabric Tapes Used for Electrical Insulation 5.1.7 Type of packaging (sealed unit packages, carton size,

D 1711 Terminology Relating to Electrical Insulation pallet size), and

D 1830 Test Method for Thermal Endurance of Flexible 5.1.8 Marking on unit packages and cartons.

Sheet Materials Used for Electrical Insulation by the

2 6. Materials and Manufacture

Curved Electrode Method

6.1 Materials—The base fabric for all thicknesses shall be

D 2518 SpecificationforWovenGlassFabricsforElectrical

Insulation woven from continuous-filament yarns and shall be in con-

formance with the requirements of Specification D 2518.

D 3636 Practice for Sampling and Judging Quality of Solid

Electrical Insulating Materials 6.2 Splices—The material shall not be spliced unless agreed

upon by the purchaser and seller. If it is necessary to splice

3. Terminology

rolls, splices shall occur not more than once in each 100 yd (92

3.1 Definitions: For definitions of terms used in this speci- m) or less, except that rolls having a length of 10 yd (9 m) or

fication refer to Terminology D 1711. less shall contain no splices. Sheet materials shall contain no

splices.

This specification is under the jurisdiction of ASTM Committee D-9 on

7. Electrical and Mechanical Requirements

Electrical and Electronic Insulating Materials and is the direct responsibility of

7.1 The electrical and mechanical requirements shall be in

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

Current edition approved Oct. 10, 1999. Published November 1999. Originally

accordance with the values shown in Tables 1-3.

published as D 3949 – 80. Last previous edition D 3949 – 94.

Annual Book of ASTM Standards, Vol 10.01.

Annual Book of ASTM Standards, Vol 10.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

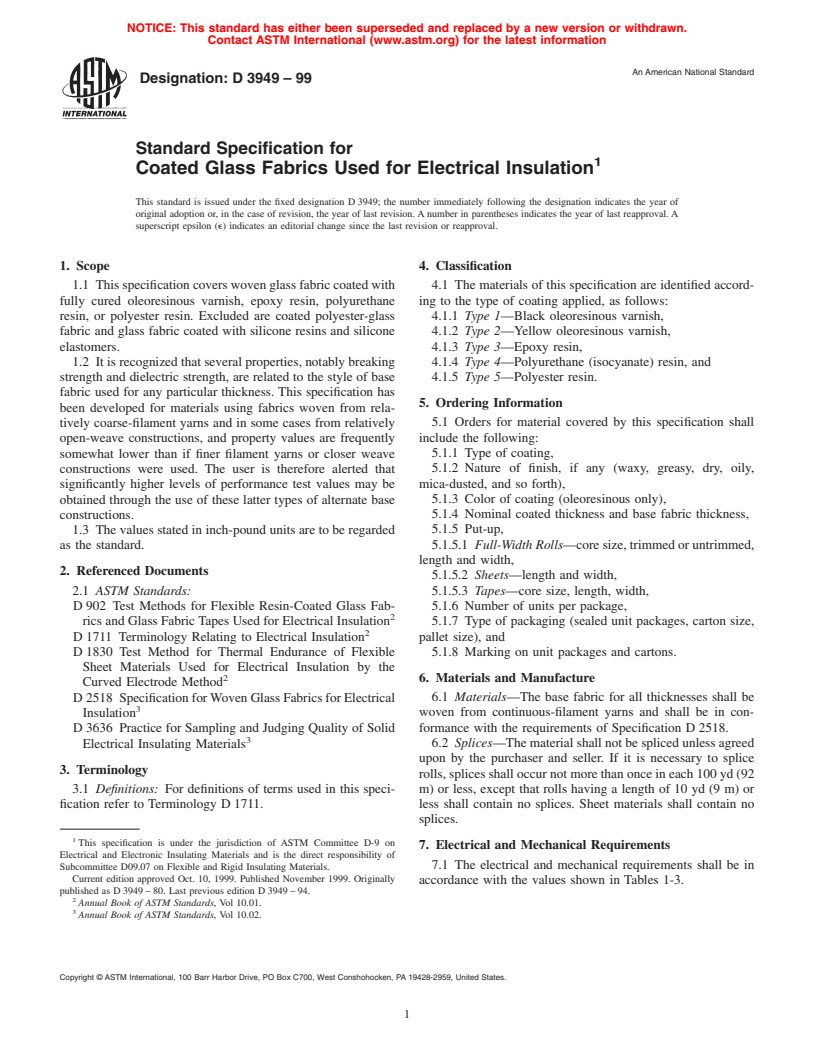

D 3949

TABLE 1 Breaking Strength Requirements

Types 1 and 2 130

Types 3 and 4 155

Base Fabric Thickness, in. (mm) Breaking Strength, warp, lbf/in. (kN/m)

Type 5 180

0.002 (.051) 70 (12.2)

0.003 (0.08) 100 (17.5) NOTE 2—In the case of materials for special applications, some of the

0.004 (0.10) 130 (22.8)

preceding types may have temperature indices below those stated, or may

0.005 (0.13) 150 (26.2)

have life values less than 20 000 h. Use of these materials shall be agreed

0.007 (0.18) 220 (38.6)

upon between the purchaser and the seller.

0.010 (0.25) 300 (52.6)

0.015 (0.38) 350 (61.3)

11.2 The seller shall, at the request of the purchaser, provide

a thermal life graph (Arrhenius plot) showing the nominal

temperature indices of the types of materials purchased.

8. Dimensional Requirements

12. Sampling

8.1 Thickness shall be in accordance with the values shown

12.1 Lot Definition—Refer to Terminology Section of Prac-

in Table 4.

tice D 3636.

8.2 Width—Individual measurements on all samples se-

12.2 Unit of Sample—Theunitofsampleshallbetheunitof

lected shall not vary from the nominal by more than 6 ⁄32 in.

product (rolls or sheets).

(0.8 mm) for widths up to 1 in. (25 mm) and by more than

12.3 Sampling the Lot—Randomly select, to the nearest

6 ⁄16in. (1.6 mm) for widths 1 in. and over. Rolls trimmed to

integral package, a number of packages equal to N from

=

36 in. or 1 m shall not be less than that amount. Sheets shall be

each lot, where N is the total number of packages in the

within 6 ⁄8 in. (3.2 mm) of the nominal width and length

shipment.Theseshallconstitutethesourceoftheunitsampling

specified.

in 12.4 and 12.5.

8.3 Length—The length in yards or metres per roll shall not

12.4 Sampling for Visual and Dimensional Examination—

be less than specified.

Select a random sample of rolls or sheets from material of 12.3

in accordance with Inspection Level I of Practice D 3636.

9. Workmanship and Appearance

Acceptance shall be determined in accordance with 11.1 and

Table 4 on the basis of AQL 5 2.5. Take as the test sample 5

9.1 Visual Nonconformities—The material shall be free

yd (4.5 m) from each sampled roll or sheet.

from the following nonconformities to the extent specified in

12.5 Sampling for Performance Tests—Select a random

12.4:

sample of rolls or sheets from the material of 12.3 in accor-

9.1.1 Weave distortion in base fabric,

dance with Inspection Level S-2 of Practice D 3636. Take an

9.1.2 Wrinkles, creases, tears,

2 2

amount corresponding to about 0.5 yd (0.3 m ) from each

9.1.3 Dirt in coating,

sampled roll or sheet.

9.1.4 Nonuniform application of coating (runs, drains,

wrinkles, uncoated spots),

13. Tests and Retests

9.1.5 Poor adhesion of coating to fabric,

13.1 Iftheresultsofanytesttodetermineconformancewith

9.1.6 Roughness caused by broken glass filaments, gels in

coating, 7.1 and 10.1 do not conform to the requirements prescribed in

this specification, make two additional tests on different

9.1.7 Unevenly wound rolls,

specimensofthesamesample.Ifeitheroftheseadditionaltests

9.1.8 Ragged cut edges of rolls,

fail, or if the average of all tests computed including the retests

9.1.9 Collapsed cores, and

fail, the lot of material shall be subject to rejection. Notice of

9.1.10 Unmarked s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.