ASTM B855-06

(Test Method)Standard Test Method for Volumetric Flow Rate of Metal Powders Using Arnold Meter and Hall Funnel

Standard Test Method for Volumetric Flow Rate of Metal Powders Using Arnold Meter and Hall Funnel

SIGNIFICANCE AND USE

The volumetric flow rate is a measure of the flow characteristics of a metal powder. Measuring flow by volume as compared with flow per unit mass eliminates the variable of the powder density.

The ability of a powder to flow and pack is a function of interparticle friction. As the surface area increases, the amount of friction in a powder mass also increases. Consequently, the friction between particles increases, giving less efficient flow and packing.

Knowledge of the volumetric flow permits the number of parts that can be made per hour to be estimated.

This test method may be part of the purchase agreement between powder manufacturers and powder metallurgy (P/M) part producers, or it can be an internal quality control test by either the producer or the end user.

SCOPE

1.1 This test method covers a procedure for measuring the flow characteristics of a given volume of powder.

1.2 The values stated in SI units are to be regarded as the standard (except for the Hall Flowmeter Funnel, which is produced in inch-pound units). The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B855–06

Standard Test Method for

Volumetric Flow Rate of Metal Powders Using Arnold Meter

1

and Hall Funnel

This standard is issued under the fixed designation B855; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* of the steel block is transferred to a Hall Flowmeter and the

3

flow rate reported in seconds per 20 cm .

1.1 This test method covers a procedure for measuring the

flow characteristics of a given volume of powder.

5. Significance and Use

1.2 The values stated in SI units are to be regarded as the

5.1 The volumetric flow rate is a measure of the flow

standard (except for the Hall Flowmeter Funnel, which is

characteristics of a metal powder. Measuring flow by volume

producedininch-poundunits).Thevaluesgiveninparentheses

as compared with flow per unit mass eliminates the variable of

are for information only.

the powder density.

1.3 This standard does not purport to address all of the

5.2 The ability of a powder to flow and pack is a function of

safety concerns, if any, associated with its use. It is the

interparticle friction.As the surface area increases, the amount

responsibility of the user of this standard to establish appro-

of friction in a powder mass also increases. Consequently, the

priate safety and health practices and determine the applica-

friction between particles increases, giving less efficient flow

bility of regulatory limitations prior to use.

and packing.

2. Referenced Documents 5.3 Knowledge of the volumetric flow permits the number

2

of parts that can be made per hour to be estimated.

2.1 ASTM Standards:

5.4 This test method may be part of the purchase agreement

B213 Test Method for Flow Rate of Metal Powders

between powder manufacturers and powder metallurgy (P/M)

B215 Practices for Sampling Metal Powders

part producers, or it can be an internal quality control test by

B243 Terminology of Powder Metallurgy

either the producer or the end user.

B703 Test Method for Apparent Density of Powders Using

Arnold Meter

6. Apparatus

3

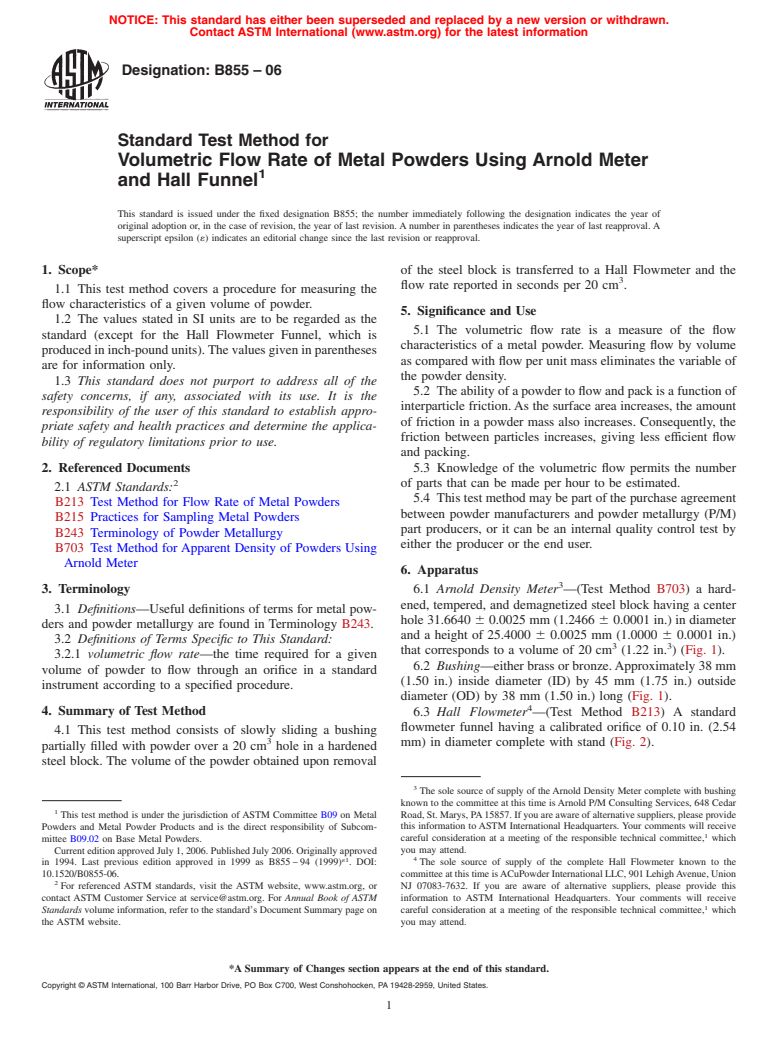

3. Terminology 6.1 Arnold Density Meter —(Test Method B703) a hard-

ened, tempered, and demagnetized steel block having a center

3.1 Definitions—Useful definitions of terms for metal pow-

hole 31.6640 6 0.0025 mm (1.2466 6 0.0001 in.) in diameter

ders and powder metallurgy are found in Terminology B243.

and a height of 25.4000 6 0.0025 mm (1.0000 6 0.0001 in.)

3.2 Definitions of Terms Specific to This Standard:

3 3

that corresponds to a volume of 20 cm (1.22 in.)(Fig. 1).

3.2.1 volumetric flow rate—the time required for a given

6.2 Bushing—either brass or bronze.Approximately 38 mm

volume of powder to flow through an orifice in a standard

(1.50 in.) inside diameter (ID) by 45 mm (1.75 in.) outside

instrument according to a specified procedure.

diameter (OD) by 38 mm (1.50 in.) long (Fig. 1).

4

4. Summary of Test Method

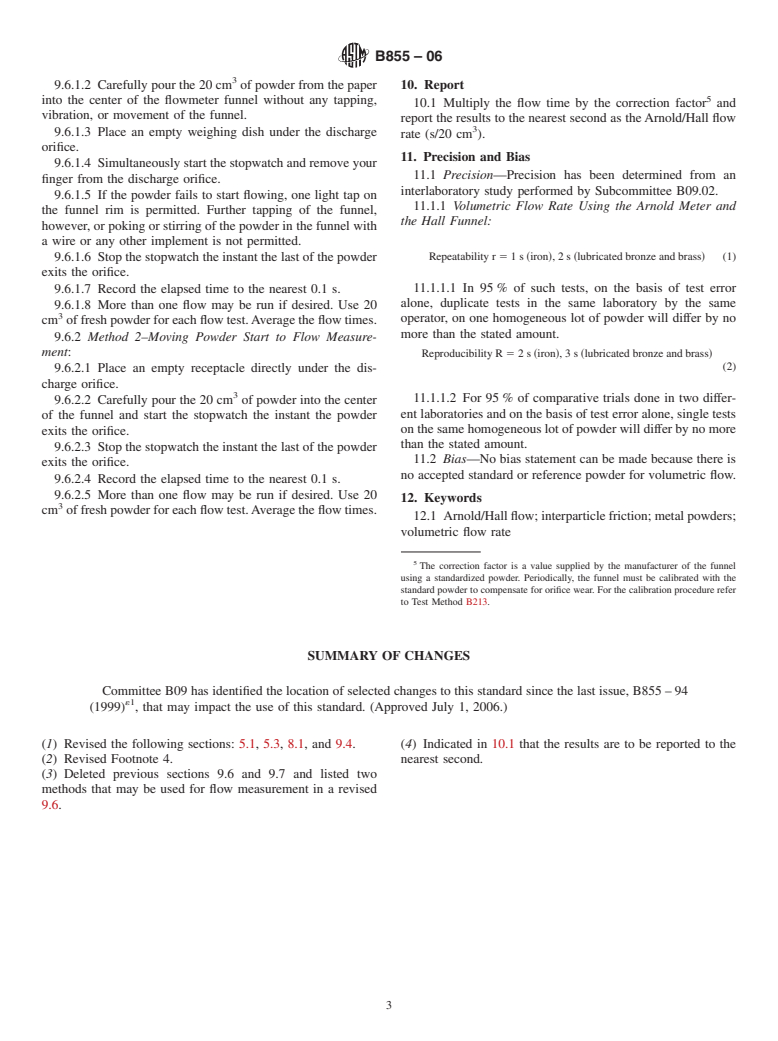

6.3 Hall Flowmeter —(Test Method B213) A standard

flowmeter funnel having a calibrated orifice of 0.10 in. (2.54

4.1 This test method consists of slowly sliding a bushing

3

mm) in diameter complete with stand (Fig. 2).

partially filled with powder over a 20 cm hole in a hardened

steel block. The volume of the powder obtained upon removal

3

The sole source of supply of theArnold Density Meter complete with bushing

known to the committee at this time isArnold P/M Consulting Services, 648 Cedar

1

This test method is under the jurisdiction of ASTM Committee B09 on Metal Road, St. Marys, PA15857. If you are aware of alternative suppliers, please provide

Powders and Metal Powder Products and is the direct responsibility of Subcom- this information to ASTM International Headquarters. Your comments will receive

1

mittee B09.02 on Base Metal Powders. careful consideration at a meeting of the responsible technical committee, which

Current edition approved July 1, 2006. Published July 2006. Originally approved you may attend.

´1 4

in 1994. Last previous edition approved in 1999 as B855 – 94 (1999) . DOI: The sole source of supply of the complete Hall Flowmeter known to the

10.1520/B0855-06. committeeatthistimeisACuPowderInternationalLLC,901LehighAvenue,Union

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or NJ 07083-7632. If you are aware of alternative suppliers, please provide this

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM information to ASTM International Headquarters. Your comments will receive

1

Standards volume information, refer to the standard’s Document Summary page on careful consideration at a meeting of the responsible technical committee, which

the ASTM website. you may atten

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.