ASTM D5101-99

(Test Method)Standard Test Method for Measuring the Soil-Geotextile System Clogging Potential by the Gradient Ratio

Standard Test Method for Measuring the Soil-Geotextile System Clogging Potential by the Gradient Ratio

SCOPE

1.1 This test method covers a performance test applicable for determining the soil-geotextile system permeability and clogging behavior under unidirectional flow conditions.

1.2 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5101 – 99

Standard Test Method for

Measuring the Soil-Geotextile System Clogging Potential by

the Gradient Ratio

This standard is issued under the fixed designation D 5101; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope nology D 123. For definitions of other terms related to geotex-

tiles, refer to Terminology D 4439 and Terminology D 653.

1.1 This test method covers a performance test applicable

3.2 Symbols and Acronyms:

for determining the soil-geotextile system permeability and

3.2.1 CO —the chemical formula for carbon dioxide gas.

clogging behavior under unidirectional flow conditions.

3.2.2 CHD—the acronym for constant head device.

1.2 The values stated in SI units are to be regarded as

standard. The values in parentheses are for information only.

4. Summary of Test Method

1.3 This standard does not purport to address all of the

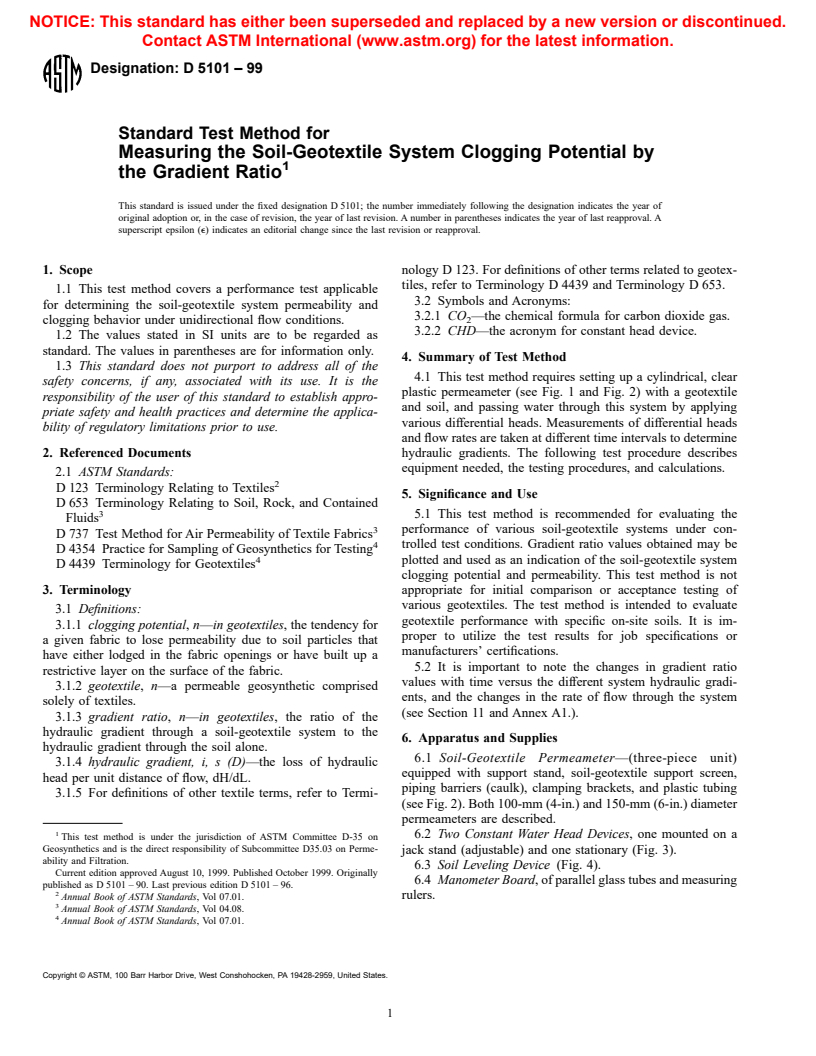

4.1 This test method requires setting up a cylindrical, clear

safety concerns, if any, associated with its use. It is the

plastic permeameter (see Fig. 1 and Fig. 2) with a geotextile

responsibility of the user of this standard to establish appro-

and soil, and passing water through this system by applying

priate safety and health practices and determine the applica-

various differential heads. Measurements of differential heads

bility of regulatory limitations prior to use.

and flow rates are taken at different time intervals to determine

2. Referenced Documents hydraulic gradients. The following test procedure describes

equipment needed, the testing procedures, and calculations.

2.1 ASTM Standards:

D 123 Terminology Relating to Textiles

5. Significance and Use

D 653 Terminology Relating to Soil, Rock, and Contained

3 5.1 This test method is recommended for evaluating the

Fluids

3 performance of various soil-geotextile systems under con-

D 737 Test Method for Air Permeability of Textile Fabrics

trolled test conditions. Gradient ratio values obtained may be

D 4354 Practice for Sampling of Geosynthetics for Testing

4 plotted and used as an indication of the soil-geotextile system

D 4439 Terminology for Geotextiles

clogging potential and permeability. This test method is not

3. Terminology appropriate for initial comparison or acceptance testing of

various geotextiles. The test method is intended to evaluate

3.1 Definitions:

geotextile performance with specific on-site soils. It is im-

3.1.1 clogging potential, n—in geotextiles, the tendency for

proper to utilize the test results for job specifications or

a given fabric to lose permeability due to soil particles that

manufacturers’ certifications.

have either lodged in the fabric openings or have built up a

5.2 It is important to note the changes in gradient ratio

restrictive layer on the surface of the fabric.

values with time versus the different system hydraulic gradi-

3.1.2 geotextile, n—a permeable geosynthetic comprised

ents, and the changes in the rate of flow through the system

solely of textiles.

(see Section 11 and Annex A1.).

3.1.3 gradient ratio, n—in geotextiles, the ratio of the

hydraulic gradient through a soil-geotextile system to the

6. Apparatus and Supplies

hydraulic gradient through the soil alone.

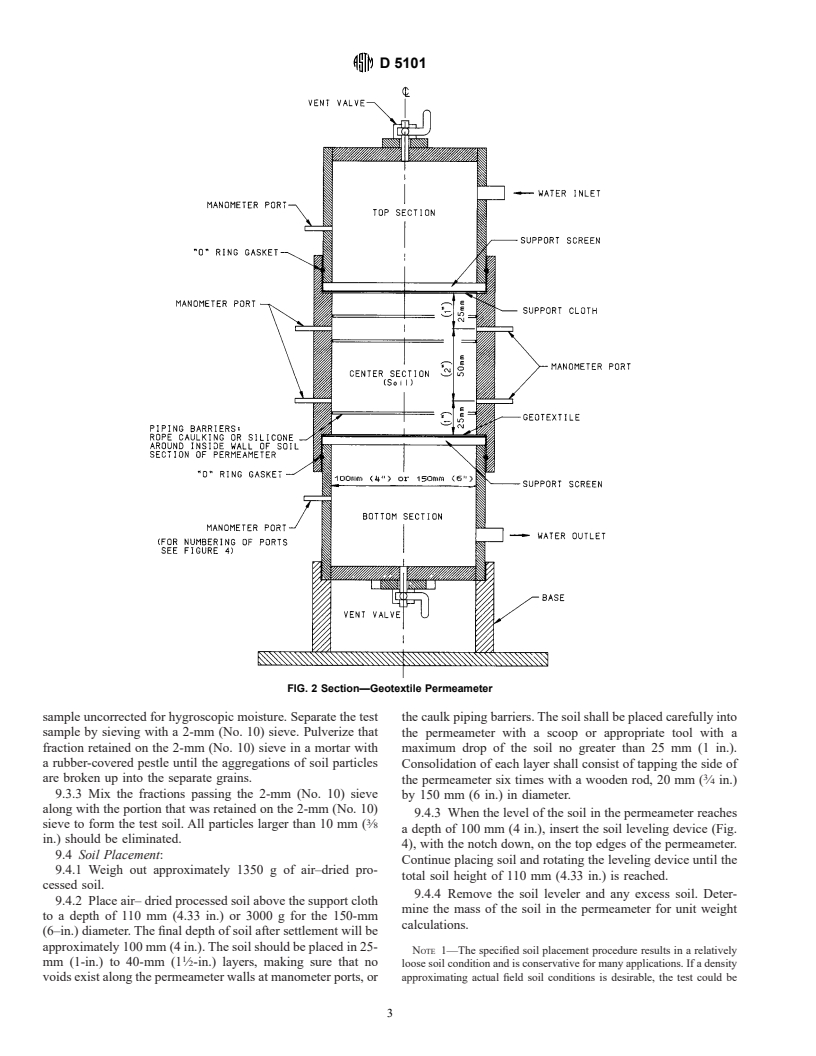

6.1 Soil-Geotextile Permeameter—(three-piece unit)

3.1.4 hydraulic gradient, i, s (D)—the loss of hydraulic

equipped with support stand, soil-geotextile support screen,

head per unit distance of flow, dH/dL.

piping barriers (caulk), clamping brackets, and plastic tubing

3.1.5 For definitions of other textile terms, refer to Termi-

(see Fig. 2). Both 100-mm (4-in.) and 150-mm (6-in.) diameter

permeameters are described.

6.2 Two Constant Water Head Devices, one mounted on a

This test method is under the jurisdiction of ASTM Committee D-35 on

Geosynthetics and is the direct responsibility of Subcommittee D35.03 on Perme-

jack stand (adjustable) and one stationary (Fig. 3).

ability and Filtration.

6.3 Soil Leveling Device (Fig. 4).

Current edition approved August 10, 1999. Published October 1999. Originally

6.4 Manometer Board, of parallel glass tubes and measuring

published as D 5101 – 90. Last previous edition D 5101 – 96.

rulers.

Annual Book of ASTM Standards, Vol 07.01.

Annual Book of ASTM Standards, Vol 04.08.

Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5101

and laboratory samples as directed in Practice D 4354. For

laboratory samples, take a full width swatch of geotextile from

each roll of material in the lot sample at least1m(3ft) long

cut from the end of the roll after discarding the first metre of

material from the outside of the roll.

7.2 Test Specimens—Cut three circular specimens from

each swatch in the laboratory sample with each specimen

having a diameter of 110 mm (4.33 in.) or 165 mm (6.50 in.).

Locate two specimens no less than 300 mm (11.8 in.) from

each edge of the swatch and one at the center of the swatch

width.

8. Conditioning

8.1 Test Water Preparation:

8.1.1 Test water should be maintained at room temperature

about 16 to 27°C (60 to 80°F), and deaired to a dissolved

oxygen content of 6 parts per million (ppm) or less before

introducing it to permeameter system. This will reduce or

eliminate the problems associated with air bubbles forming

within the test apparatus.

8.1.2 An algae inhibitor or micro screen should be used to

eliminate any algae buildup in the system.

8.2 Specimen Conditions:

8.2.1 Condition the specimen by soaking it in a container of

deaired water for a period of 2 h. Dry the surface of the

specimen by blotting prior to inserting in the permeameter.

9. Procedure

9.1 Preparation of Apparatus:

9.1.1 Thoroughly clean and dry permeameter sections.

9.1.2 Close all valves and cover the inside openings of all

manometer ports with fine wire mesh or lightweight nonwoven

fabric (the equivalent of No. 100 mesh).

FIG. 1 Geotextile Permeameter

9.1.3 Lubricate all O-ring gaskets.

9.2 Permeameter Preassembly:

6.5 Two Soil Support Screens, of approximately 5 mm (No.

9.2.1 Stand center section of the permeameter on end and

4) mesh.

place a soil support cloth 110 mm (4.33 in.) or 165 mm (6.5 in.)

6.6 Soil Support Cloth, of 150 μm (No. 100) mesh, or

in diameter on recessed permeameter flanges.

equivalent geotextile.

9.2.2 Insert the support screen 110 mm (4.33 in.) in diam-

6.7 Thermometer (0 to 50 6 1°C).

eter on top of the support cloth with the mesh side against the

6.8 Graduated Cylinder, 100 6 1cm capacity.

cloth.

6.9 Stopwatch.

9.2.3 Align and insert top section of the permeameter into

6.10 Balance, or scale of at least 2-kg capacity and accurate

center section and press until there is a tight fit to secure the

to 61g.

support cloth and screen in place. Ensure that all gasket edges

6.11 Carbon Dioxide, (CO ), gas supply and regulator.

secure against the support cloth, support bracket, and between

6.12 Geotextile.

the center and top permeameter sections.

6.13 Water Recirculation System.

9.2.4 Invert and place permeameter into holding stand.

6.14 Water Deairing System, with a capacity of approxi-

9.3 Process Soil:

mately 1700 L/day (500 gal/day).

9.3.1 Thoroughly air dry the soil sample as received from

6.15 Algae Inhibitor, or micro screen.

the field. This shall be done for a minimum of three days.

6.16 150-μm Mesh Screen, (No. 100), or equivalent geo-

Pulverize the sample in a mortar with a rubber-tipped pestle (or

textile for manometer ports.

in some other way that does not cause breakdown of individual

6.17 Soil Sample Splitter (optional).

grains), to reduce the particle size to a maximum of 10 mm ( ⁄8

6.18 Pan, for drying soil.

in.). Select a representative sample of the amount required

6.19 Mortar and Pestle, for pulverizing soil.

(approximately 1350 or 3000 g for the 150-mm (6-in.) diam-

6.20 Wooden rod, 20-mm ( ⁄4– in.) diameter by 150 mm (6

eter) to perform the test by the method of quartering or by the

in.) long.

use of a soil splitter.

7. Sampling and Test Specimens

9.3.2 Select that portion of the air-dried sample selected for

7.1 Lot Sample and Laboratory Sample—Take a lot sample purpose of tests and record the mass as the mass of the total test

D 5101

FIG. 2 Section—Geotextile Permeameter

sample uncorrected for hygroscopic moisture. Separate the test the caulk piping barriers. The soil shall be placed carefully into

sample by sieving with a 2-mm (No. 10) sieve. Pulverize that the permeameter with a scoop or appropriate tool with a

fraction retained on the 2-mm (No. 10) sieve in a mortar with

maximum drop of the soil no greater than 25 mm (1 in.).

a rubber-covered pestle until the aggregations of soil particles Consolidation of each layer shall consist of tapping the side of

are broken up into the separate grains.

the permeameter six times with a wooden rod, 20 mm ( ⁄4 in.)

9.3.3 Mix the fractions passing the 2-mm (No. 10) sieve

by 150 mm (6 in.) in diameter.

along with the portion that was retained on the 2-mm (No. 10)

9.4.3 When the level of the soil in the permeameter reaches

sieve to form the test soil. All particles larger than 10 mm ( ⁄8

a depth of 100 mm (4 in.), insert the soil leveling device (Fig.

in.) should be eliminated.

4), with the notch down, on the top edges of the permeameter.

9.4 Soil Placement:

Continue placing soil and rotating the leveling device until the

9.4.1 Weigh out approximately 1350 g of air–dried pro-

total soil height of 110 mm (4.33 in.) is reached.

cessed soil.

9.4.4 Remove the soil leveler and any excess soil. Deter-

9.4.2 Place air– dried processed soil above the support cloth

mine the mass of the soil in the permeameter for unit weight

to a depth of 110 mm (4.33 in.) or 3000 g for the 150-mm

calculations.

(6–in.) diameter. The final depth of soil after settlement will be

approximately 100 mm (4 in.). The soil should be placed in 25-

NOTE 1—The specified soil placement procedure results in a relatively

mm (1-in.) to 40-mm (1 ⁄2-in.) layers, making sure that no

loose soil condition and is conservative for many applications. If a density

voids exist along the permeameter walls at manometer ports, or approximating actual field soil conditions is desirable, the test could be

D 5101

FIG. 3 Geotextile Permeameter “Set Up” Diagram

run at this specified soil density. It should be recognized, however, that

9.6.1 Open the top vent valve, and close off the permeame-

predicting field soil conditions may be very difficult due to construction

ter water outlet hose.

installation procedures that generally disturb and loosen soils adjacent to

9.6.2 Backfill permeameter with water through the outflow

the geotextile.

CHD until the water level is approximately 10 mm ( ⁄8 in.)

9.5 Permeameter Assembly and Setup:

below the open manometer port 6. Stop waterflow into the

9.5.1 Clean the inner flange of the center section of the

permeameter by clamping off the hose between outflow CHD

permeameter and insert the geotextile to be tested.

and permeameter.

9.5.2 Insert the support screen on top of the geotextile with

9.6.3 Expel oxygen and other gases in the permeameter and

the mesh side against the geotextile.

soil system by (1) attaching a carbon dioxide (CO ) line to

9.5.3 Align and insert the bottom section of the permeame-

manometer port 6, and (2) regulating the gas flow at 2 L/min

ter into the center section and press tightly to secure the

and purging the system for 5 min.

geotextile and support screen. The soil will compress from 110

NOTE 2—The permeameter may be backfilled without purging with

mm (4.33 in.) to approximately 100 mm (4 in.) when the

CO , however, the potential for air pockets within the soil to cause erratic

bottom section is secured. Check gaskets to ensure contact is

results for flow and pressure measurements will be greater without the

made between permeameter sections, support screen, and

purging.

geotextile.

9.6.4 After 5 min of gas saturation, seal off (plug) the open

9.5.4 Secure the permeameter sections together within

end of each manometer tube (1 through 5) and continue to

clamp brackets and tighten bolts on bracket rods evenly.

purge the system with CO for an additional 5 min with only

9.5.5 Invert permeameter into holding stand so that the 2

the top vent valve open.

geotextile will be below the soil level.

9.5.6 Connect the inflow and outflow constant head devices 9.6.5 Remove the CO gas line and replace the No. 6

manometer hose. Remove the seals (plugs or clamps) from all

(CHD) to their corresponding permeameter ports (see Fig. 3)

with plastic tubing. The outflow CHD is attached to the bottom manometer tubes (1 through 5).

permeameter port and the inflow CHD is attached to the top 9.6.6 Loosen the hose clamp between the outflow CHD and

permeameter port. permeameter, and fill the soil section of the permeameter with

9.5.7 Connect all manometer tubes (1 through 5) to their water. Filling is accomplished by adding water to and raising

corresponding permeameter manometer ports, and all overflow the level on outflow CHD slowly. Start with outflow CHD at 25

tubes to their corresponding outlet ports. mm (1 in.) above the geotextile level and raise 25 mm (1 in.)

9.6 Saturating the Soil/Geotextile System: every 30 min until water level is 50 mm (2 in.) above the top

D 5101

complete saturation of the system with water. The system

should be in a no-flow condition overnight.

9.6.9 Check for and remove air bubbles found in the tubes

or manometers by light vibration or tapping. It may be

necessary to disconnect tubing from the manometer board and

slowly lower the tubing, allowing water and entrapped air to

run out.

9.6.10 Place a thermometer into the inflow CHD to monitor

the temperature of water flowing into the permeameter.

9.7 Running the Test:

9.7.1 Check to make sure that all scales on the manometer

board are set to a common reference elevation.

9.7.2 Adjust the inflow CHD to a level so that a hydraulic

gradient (i) of 1 is obtained (see 10.1).

9.7.3 Unclamp hoses between the permeameter and CHDs

to allow flow, and record the initial starting time.

9.7.4 Record the following data (using Fig. 5) at 0, ⁄2,1,2,

4, 6, and 24 h from the initial starting time:

9.7.4.1 The time in hours (accumulated).

NOTE 3—Stabilization is defined as the point where the flow rate and

gradient ratio for three consecutive readings are within 10 % of their

apparent value. In some cases, the readings may continue to chan

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.