ASTM D242-95(2000)e1

(Specification)Standard Specification for Mineral Filler For Bituminous Paving Mixtures

Standard Specification for Mineral Filler For Bituminous Paving Mixtures

SCOPE

1.1 This specification covers mineral filler added as a separate ingredient for use in bituminous paving mixtures.

1.2 The values stated in SI units are to be regarded as the standard. Inch-pound units, shown in parentheses, are for information only.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

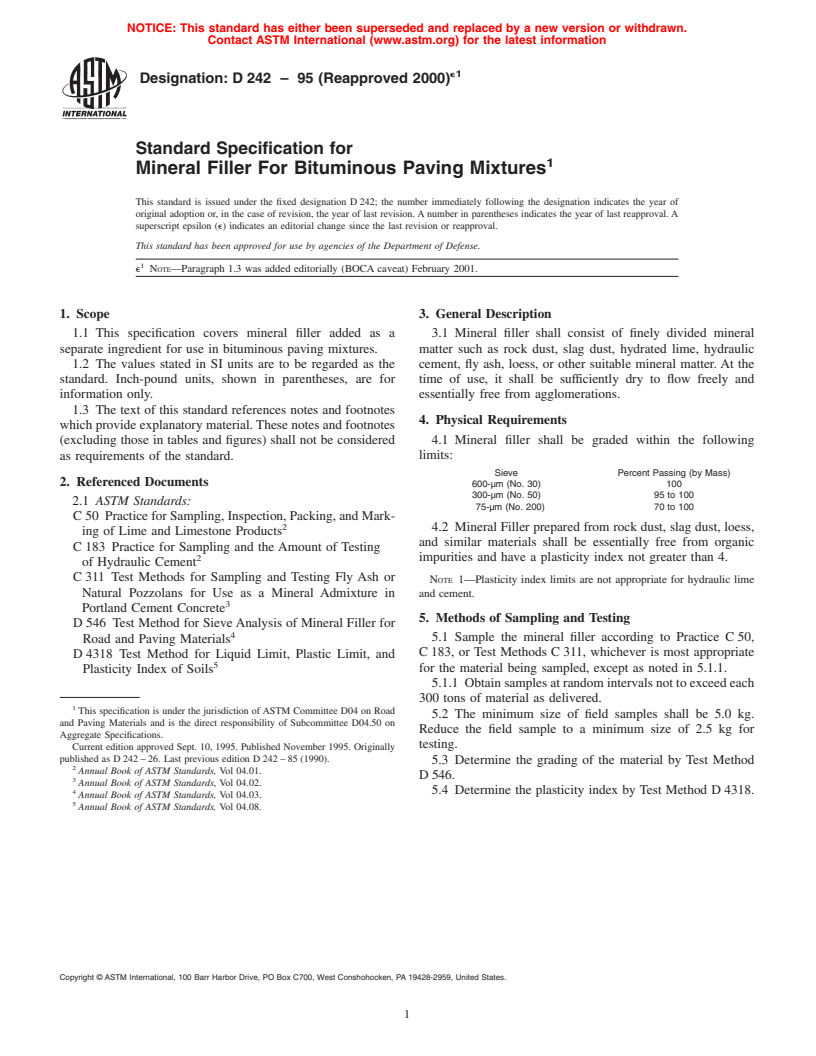

Designation: D 242 – 95 (Reapproved 2000)

Standard Specification for

Mineral Filler For Bituminous Paving Mixtures

This standard is issued under the fixed designation D 242; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Paragraph 1.3 was added editorially (BOCA caveat) February 2001.

1. Scope 3. General Description

1.1 This specification covers mineral filler added as a 3.1 Mineral filler shall consist of finely divided mineral

separate ingredient for use in bituminous paving mixtures. matter such as rock dust, slag dust, hydrated lime, hydraulic

1.2 The values stated in SI units are to be regarded as the cement, fly ash, loess, or other suitable mineral matter. At the

standard. Inch-pound units, shown in parentheses, are for time of use, it shall be sufficiently dry to flow freely and

information only. essentially free from agglomerations.

1.3 The text of this standard references notes and footnotes

4. Physical Requirements

which provide explanatory material. These notes and footnotes

4.1 Mineral filler shall be graded within the following

(excluding those in tables and figures) shall not be considered

as requirements of the standard. limits:

Sieve Percent Passing (by Mass)

2. Referenced Documents

600-µm (No. 30) 100

300-µm (No. 50) 95 to 100

2.1 ASTM Standards:

75-µm (No. 200) 70 to 100

C 50 Practice for Sampling, Inspection, Packing, and Mark-

4.2 Mineral Filler prepared from rock dust, slag dust, loess,

ing of Lime and Limestone Products

and similar materials shall be essentially free from organic

C 183 Practice for Sampling and the Amount of Testing

impurities and have a plasticity index not greater than 4.

of Hydraulic Cement

C 311 Test Methods for Sampling and Testing Fly Ash or

NOTE 1—Plasticity index limits are not appropriate for hydraulic lime

Natural Pozzolans for Use as a Mineral Admixture in and cement.

Portland Cement Concrete

5. Methods of Sampling and Testing

D 546 Test Method for Sieve Analysis of Mineral Filler for

5.1 Sample the mineral filler according to Practice C 50,

Road and Paving Materials

C 183, or Test Meth

...

This May Also Interest You

SIGNIFICANCE AND USE

3.1 Recycling of deteriorated asphalt pavements is being used as a routine method of maintenance and rehabilitation. Utilization of existing materials as the major component of this procedure may yield benefits in quality, economy, and preservation of natural resources. Recycling takes many forms: hot, cold, in-situ, central plant, and surface. This practice may be used for various recycling methods.

3.2 This practice describes emulsified recycling (ER) agents as belonging to three groups: ER-1, ER-2, and ER-3 as shown in Table 1. The range of recycling methods demands several emulsified recycling agents. The groups should provide adequate freedom of selection for most recycling methods. (A) ER-1 shall be certified for dilution with potable water.(B) This specification allows a variety of emulsified asphalts. The engineer should take the steps necessary to keep incompatible materials from co-mingling in tanks or other vessels. It would be prudent to have the chemical charge nature certified by the supplier.(C) RTFO shall be the referee method. When approved by the engineer, the thin-film oven test (Test Method D1754/D1754M) may be substituted for compliance testing.

3.2.1 ER-1 is a material whose main function is to rejuvenate aged asphalt. The material is a petroleum derivative, and highly compatible with asphalts. It is classified by viscosity.

3.2.2 ER-2 and ER-3 are materials that combine rejuvenators and asphalt components in one emulsified asphalt. These soft residues are classified by low temperature penetration after aging. They are typically used in recycling where there is an increased demand for asphalt as when new aggregates are added, or where immediate cohesiveness is desired.

3.3 The choice of ER will be determined by the properties of the asphalt binder in the aged pavement, the methods of recycling planned, the amount, if any, of new aggregates, and other design needs.

SCOPE

1.1 This practice identifies emulsified petroleum products that may be used as recycling agents in recycled mixes. These materials are classified by viscosity or by low temperature penetration after aging.

1.2 This practice addresses emulsified materials designed specifically for use in recycling. The use of emulsified materials for recycling shall not be limited to this practice. For instance, the emulsified asphalts specified in Specifications D977 and D2397/D2397M may be used.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The flash point is one measure of the tendency of the test specimen to form a flammable mixture with air under controlled laboratory conditions. It is only one of a number of properties that should be considered in assessing the overall flammability hazard of a material.

5.2 Flash point is used in shipping and safety regulations to define flammable and combustible materials. Consult the particular regulation involved for precise definitions of these classifications.

5.3 Flash point can indicate the possible presence of highly volatile and flammable materials in a relatively nonvolatile or nonflammable material.

5.4 Skin prevention technique involves assembling a restraining ring over a centrally-holed qualitative filter paper that is laid at the bottom of the COC (Cleveland open cup) test cup, prior to introduction of the sample specimen into the cup. This allows a column of the hot sample specimen to move up constantly, through the hole, to the surface of the test specimen so that the surface is maintained in the hot condition to prevent skin formation. (See 9.6).

5.5 Skin-forming asphalts may not be limited to those which are air blown/oxidized, polymerized or non-homogeneous materials that, although infrequently, exhibit some unique behavior and characteristics, as far as manifestation of flash point is concerned. At the flash point stage, this behavior may involve flame propagation across the surface or just a flame appearing at one or more points on the surface.

5.6 This test method shall be used to measure and describe the properties of materials, products, or assemblies in response to heat and a test flame under controlled laboratory conditions and shall not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test method may be used as elements of a fire risk assessment that takes into account all of the factors that are pertinent to an ass...

SCOPE

1.1 This test method describes the determination of the flash point and fire point of asphalt by a manual Cleveland open cup apparatus or an automated Cleveland open cup apparatus.

Note 1: Apparatus is the same as described in Test Method D92 with the addition of the materials for the skin prevention technique.

1.2 This test method is applicable to asphalts that can form a skin, and those that do not form a skin during heat treatment.

1.3 This test method is applicable to products with flash points above 79 °C (174 °F) and below 400 °C (752 °F), except fuel oils.

1.4 The precision has been determined over the temperature range of 300 °C to 370 °C (572 °F to 698 °F).

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 6.4, 7.1, 11.1, 11.2.3, and 11.3.4.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard8 pagesEnglish languagesale 15% off

SCOPE

1.1 This specification covers mineral filler added as a separate ingredient for use in asphalt mixtures.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification2 pagesEnglish languagesale 15% off

- Technical specification2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The carbon residue value of burner fuel serves as a rough approximation of the tendency of the fuel to form deposits in vaporizing pot-type and sleeve-type burners. Similarly, provided alkyl nitrates are absent (or if present, provided the test is performed on the base fuel without additive) the carbon residue of diesel fuel correlates approximately with combustion chamber deposits.

5.2 The carbon residue value of motor oil, while at one time regarded as indicative of the amount of carbonaceous deposits a motor oil would form in the combustion chamber of an engine, is now considered to be of doubtful significance due to the presence of additives in many oils. For example, an ash-forming detergent additive may increase the carbon residue value of an oil yet will generally reduce its tendency to form deposits.

5.3 The carbon residue value of gas oil is useful as a guide in the manufacture of gas from gas oil, while carbon residue values of crude oil residuums, cylinder and bright stocks, are useful in the manufacture of lubricants.

SCOPE

1.1 This test method covers the determination of the amount of carbon residue (Note 1) left after evaporation and pyrolysis of an oil, and is intended to provide some indication of relative coke-forming propensities. This test method is generally applicable to relatively nonvolatile petroleum products which partially decompose on distillation at atmospheric pressure. Petroleum products containing ash-forming constituents as determined by Test Method D482 or IP Method 4 will have an erroneously high carbon residue, depending upon the amount of ash formed (Note 2 and Note 4).

Note 1: The term carbon residue is used throughout this test method to designate the carbonaceous residue formed after evaporation and pyrolysis of a petroleum product under the conditions specified in this test method. The residue is not composed entirely of carbon, but is a coke which can be further changed by pyrolysis. The term carbon residue is continued in this test method only in deference to its wide common usage.

Note 2: Values obtained by this test method are not numerically the same as those obtained by Test Method D524. Approximate correlations have been derived (see Fig. X1.1), but need not apply to all materials which can be tested because the carbon residue test is applied to a wide variety of petroleum products.

Note 3: The test results are equivalent to Test Method D4530, (see Fig. X1.2).

Note 4: In diesel fuel, the presence of alkyl nitrates such as amyl nitrate, hexyl nitrate, or octyl nitrate causes a higher residue value than observed in untreated fuel, which can lead to erroneous conclusions as to the coke forming propensity of the fuel. The presence of alkyl nitrate in the fuel can be detected by Test Method D4046.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 WARNING—Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Use caution when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for additional information. The potential exists that selling mercury or mercury-containing products, or both, is prohibited by local or national law. Users must determine legality of sales in their location.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Prin...

- Standard7 pagesEnglish languagesale 15% off

- Standard7 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Many petroleum products, and some non-petroleum materials, are used as lubricants, and the correct operation of the equipment depends upon the appropriate viscosity of the liquid being used. In addition, the viscosity of many petroleum fuels is important for the estimation of optimum storage, handling, and operational conditions. Thus, the accurate determination of viscosity is essential to many product specifications.

SCOPE

1.1 This test method specifies a procedure for the determination of the kinematic viscosity, ν, of liquid petroleum products, both transparent and opaque, by measuring the time for a volume of liquid to flow under gravity through a calibrated glass capillary viscometer. The dynamic viscosity, η, can be obtained by multiplying the kinematic viscosity, ν, by the density, ρ, of the liquid.

Note 1: For the measurement of the kinematic viscosity and viscosity of bitumens, see also Test Methods D2170 and D2171.

Note 2: ISO 3104 corresponds to Test Method D445 – 03.

1.2 The result obtained from this test method is dependent upon the behavior of the sample and is intended for application to liquids for which primarily the shear stress and shear rates are proportional (Newtonian flow behavior). If, however, the viscosity varies significantly with the rate of shear, different results may be obtained from viscometers of different capillary diameters. The procedure and precision values for residual fuel oils, which under some conditions exhibit non-Newtonian behavior, have been included.

1.3 The range of kinematic viscosities covered by this test method is from 0.2 mm2/s to 300 000 mm2/s (see Table A1.1) at all temperatures (see 6.3 and 6.4). The precision has only been determined for those materials, kinematic viscosity ranges and temperatures as shown in the footnotes to the precision section.

1.4 The values stated in SI units are to be regarded as standard. The SI unit used in this test method for kinematic viscosity is mm2/s, and the SI unit used in this test method for dynamic viscosity is mPa·s. For user reference, 1 mm2/s = 10-6 m2/s = 1 cSt and 1 mPa·s = 1 cP = 0.001 Pa·s.

1.5 WARNING—Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Use Caution when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for additional information. The potential exists that selling mercury or mercury-containing products, or both, is prohibited by local or national law. Users must determine legality of sales in their location.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard16 pagesEnglish languagesale 15% off

- Standard16 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 Oil from one crude oil field is readily distinguishable from another, and differences in the makeup of oils from the same crude oil field can often be observed as well. Refined oils are fractions from crude oil stocks, usually derived from distillation processes. Two refined oils of the same type differ because of dissimilarities in the characteristics of their crude oil feed stocks as well as variations in refinery processes and any subsequent contact with other oils mixed in during transfer operations from residues in tanks, ships, pipes, hoses, and so forth. Thus, all petroleum oils, to some extent, have chemical compositions different from each other.

4.2 Identification of a recovered oil is determined by comparison with known oils selected because of their possible relationship to the particular recovered oil, for example, suspected sources. Thus, samples of such known oils must be collected and submitted along with the unknown for analysis. Identification of the source of an unknown oil by itself cannot be made without comparison to a known oil. The principles of oil spill identification are discussed in Ref (1).4

4.3 Many similarities (within uncertainties of sampling, analysis and weathering) will be needed to establish the identity beyond a reasonable doubt. The analyses described will distinguish many, but not all samples. Examples of weathering of various classes of oils are included in Ref (2).

4.4 This practice is a guide to the use of ASTM test methods for the analysis of oil samples for oil spill identification purposes. The evaluation of results from analytical methods and preparation of an Oil Spill Identification Report are discussed in this practice. Other analytical methods are described in Ref (3).

4.5 A quality assurance program for oil spill identification is specified.

SCOPE

1.1 This practice covers the broad concepts of sampling and analyzing waterborne oils for identification and comparison with suspected source oils. Detailed procedures are referenced in this practice. A general approach is given to aid the investigator in planning a program to solve the problem of chemical characterization and to determine the source of a waterborne oil sample.

1.2 This practice is applicable to all waterborne oils taken from water bodies, either natural or man-made, such as open oceans, estuaries or bays, lakes, rivers, smaller streams, canals; or from beaches, marshes, or banks lining or edging these water systems. Generally, the waterborne oils float on the surface of the waters or collect on the land surfaces adjoining the waters, but occasionally these oils, or portions, are emulsified or dissolved in the waters, or are incorporated into the sediments underlying the waters, or into the organisms living in the water or sediments.

1.3 This practice as presently written proposes the use of specific analytical techniques described in the referenced ASTM standards. As additional techniques for characterizing waterborne oils are developed and written up as test methods, this practice will be revised.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 Identification of a recovered oil is determined by comparison with known oils selected because of their possible relationship to the particular recovered oil, for example, suspected or questioned sources. Thus, samples of such known oils must be collected and submitted along with the unknown for analysis. It is unlikely that identification of the sources of an unknown oil by itself can be made without direct matching, that is, solely with a library of analyses.

SCOPE

1.1 This practice covers the preparation for analysis of waterborne oils recovered from water. The identification is based upon the comparison of physical and chemical characteristics of the waterborne oils with oils from suspect sources. These oils may be of petroleum or vegetable/animal origin, or both. Seven procedures are given as follows:

Sections

Procedure A (for samples of more than 50 mL volume containing significant quantities of hydrocarbons with boiling points above 280 °C)

8 to 12

Procedure B (for samples containing significant quantities of hydrocarbons with boiling points above 280 °C)

13 to 17

Procedure C (for waterborne oils containing significant amounts of components boiling below 280 °C and to mixtures of these and higher boiling components)

18 to 22

Procedure D (for samples containing both petroleum and vegetable/animal derived oils)

23 to 27

Procedure E (for samples of light crudes and medium distillate fuels)

28 to 34

Procedure F (for thin films of oil-on-water)

35 to 39

Procedure G (for oil-soaked samples)

40 to 44

1.2 Procedures for the analytical examination of the waterborne oil samples are described in Practice D3415 and Test Methods D3328, D3414, and D3650. Refer to the individual oil identification test methods for the sample preparation method of choice. The deasphalting effects of the sample preparation method should be considered in selecting the best methods.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific caution statements are given in Sections 6 and 32.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard8 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The pour point of a petroleum product is an index of the lowest temperature of its utility for certain applications. Flow characteristics, like pour point, can be critical for the correct operation of lubricating systems, fuel systems, and pipeline operations.

5.2 Petroleum blending operations require precise measurement of the pour point.

5.3 Test results from this test method can be determined at either 1 °C or 3 °C intervals.

5.4 This test method yields a pour point in a format similar to Test Method D97/IP 15 when the 3 °C interval results are reported. However, when specification requires Test Method D97/IP 15, do not substitute this test method.

Note 2: Since some users may wish to report their results in a format similar to Test Method D97/IP 15 (in 3 °C intervals), the precision data were derived for the 3 °C intervals. For statements on bias relative to Test Method D97/IP 15, see 13.3.1.

5.5 This test method has better repeatability and reproducibility relative to Test Method D97/IP 15 as measured in the 1998 interlaboratory test program (see Section 13).

SCOPE

1.1 This test method covers the determination of pour point of petroleum products by an automatic apparatus that applies a slightly positive air pressure onto the specimen surface while the specimen is being cooled.

1.2 This test method is designed to cover the range of temperatures from −57 °C to +51 °C; however, the range of temperatures included in the (1998) interlaboratory test program only covered the temperature range from −51 °C to −11 °C.

1.3 Test results from this test method can be determined at either 1 °C or 3 °C testing intervals.

1.4 This test method is not intended for use with crude oils.

Note 1: The applicability of this test method on residual fuel samples has not been verified. For further information on the applicability, refer to 13.4.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 Determination of the color of petroleum products is used mainly for manufacturing control purposes and is an important quality characteristic, since color is readily observed by the user of the product. In some cases, the color may serve as an indication of the degree of refinement of the material. When the color range of a particular product is known, a variation outside the established range may indicate possible contamination with another product. However, color is not always a reliable guide to product quality and should not be used indiscriminately in product specifications.

SCOPE

1.1 This test method covers the visual determination of the color of a wide variety of petroleum products, such as lubricating oils, heating oils, diesel fuel oils, and petroleum waxes.

Note 1: Test Method D156 is applicable to refined products that have an ASTM color lighter than 0.5.

Note 2: The color of some dyed products may extend outside color range defined by the glass reference standards employed in the testing procedure. Furthermore, samples used to determine the precision and bias did not include dyed products.

Note 3: It is up to the user to determine the suitability of this test method for their dyed products.

1.2 This test method reports results specific to the test method and recorded as “ASTM Color.”

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 ASTM test methods are frequently intended for use in the manufacture, selling, and buying of materials in accordance with specifications and therefore should provide such precision that when the test is properly performed by a competent operator, the results will be found satisfactory for judging the compliance of the material with the specification. Statements addressing precision and bias are required in ASTM test methods. These then give the user an idea of the precision of the resulting data and its relationship to an accepted reference material or source (if available). Statements addressing determinability are sometimes required as part of the test method procedure in order to provide early warning of a significant degradation of testing quality while processing any series of samples.

5.2 Repeatability and reproducibility are defined in the precision section of every Committee D02 test method. Determinability is defined above in Section 3. The relationship among the three measures of precision can be tabulated in terms of their different sources of variation (see Table 1).

5.2.1 When used, determinability is a mandatory part of the Procedure section. It will allow operators to check their technique for the sequence of operations specified. It also ensures that a result based on the set of determined values is not subject to excessive variability from that source.

5.3 A bias statement furnishes guidelines on the relationship between a set of test results and a related set of accepted reference values. When the bias of a test method is known, a compensating adjustment can be incorporated in the test method.

5.4 This practice is intended for use by D02 subcommittees in determining precision estimates and bias statements to be used in D02 test methods. Its procedures correspond with ISO 4259 and are the basis for the Committee D02 computer software, Calculation of Precision Data: Petroleum Test Methods. The use of this practice replaces that of Re...

SCOPE

1.1 This practice covers the necessary preparations and planning for the conduct of interlaboratory programs for the development of estimates of precision (determinability, repeatability, and reproducibility) and of bias (absolute and relative), and further presents the standard phraseology for incorporating such information into standard test methods.

1.2 This practice is generally limited to homogeneous petroleum products, liquid fuels, and lubricants with which serious sampling problems (such as heterogeneity or instability) do not normally arise.

1.3 This practice may not be suitable for products with sampling problems as described in 1.2, solid or semisolid products such as petroleum coke, industrial pitches, paraffin waxes, greases, or solid lubricants when the heterogeneous properties of the substances create sampling problems. In such instances, consult a trained statistician.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard42 pagesEnglish languagesale 15% off

- Standard42 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.