ASTM G63-99(2007)

(Guide)Standard Guide for Evaluating Nonmetallic Materials for Oxygen Service

Standard Guide for Evaluating Nonmetallic Materials for Oxygen Service

SIGNIFICANCE AND USE

The purpose of this guide is to furnish qualified technical personnel with pertinent information for use in selecting materials for oxygen service in order to minimize the probability of ignition and the risk of explosion or fire. It is not intended as a specification for approving materials for oxygen service.

SCOPE

1.1 This guide applies to nonmetallic materials, (hereinafter called materials) under consideration for oxygen or oxygen-enriched fluid service, direct or indirect, as defined below. It is intended for use in selecting materials for applications in connection with the production, storage, transportation, distribution, or use of oxygen. It is concerned primarily with the properties of a material associated with its relative susceptibility to ignition and propagation of combustion; it does not involve mechanical properties, potential toxicity, outgassing, reactions between various materials in the system, functional reliability, or performance characteristics such as aging, shredding, or sloughing of particles, except when these might contribute to an ignition.

1.2 When this document was originally published in 1980, it addressed both metals and nonmetals. Its scope has been narrowed to address only nonmetals and a separate standard Guide G 94 has been developed to address metals.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—The American Society for Testing and Materials takes no position respecting the validity of any evaluation methods asserted in connection with any item mentioned in this guide. Users of this guide are expressly advised that determination of the validity of any such evaluation methods and data and the risk of use of such evaluation methods and data are entirely their own responsibility.

Note 2—In evaluating materials, any mixture with oxygen exceeding atmospheric concentration at pressures higher than atmospheric should be evaluated from the hazard point of view for possible significant increase in material combustibility.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G63 − 99 (Reapproved2007)

Standard Guide for

Evaluating Nonmetallic Materials for Oxygen Service

ThisstandardisissuedunderthefixeddesignationG63;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This guide applies to nonmetallic materials, (hereinafter 2.1 ASTM Standards:

called materials) under consideration for oxygen or oxygen- D217Test Methods for Cone Penetration of Lubricating

enriched fluid service, direct or indirect, as defined below. It is Grease

intended for use in selecting materials for applications in D566TestMethodforDroppingPointofLubricatingGrease

connection with the production, storage, transportation, D1264Test Method for Determining the Water Washout

distribution, or use of oxygen. It is concerned primarily with Characteristics of Lubricating Greases

the properties of a material associated with its relative suscep- D1743Test Method for Determining Corrosion Preventive

tibility to ignition and propagation of combustion; it does not Properties of Lubricating Greases

involve mechanical properties, potential toxicity, outgassing, D1748Test Method for Rust Protection by Metal Preserva-

reactions between various materials in the system, functional tives in the Humidity Cabinet

reliability, or performance characteristics such as aging, D2512Test Method for Compatibility of Materials with

shredding, or sloughing of particles, except when these might Liquid Oxygen (Impact Sensitivity Threshold and Pass-

contribute to an ignition. Fail Techniques)

D2863Test Method for Measuring the Minimum Oxygen

1.2 Whenthisdocumentwasoriginallypublishedin1980,it

Concentration to Support Candle-Like Combustion of

addressed both metals and nonmetals. Its scope has been

Plastics (Oxygen Index)

narrowed to address only nonmetals and a separate standard

D4809Test Method for Heat of Combustion of Liquid

Guide G94 has been developed to address metals.

Hydrocarbon Fuels by Bomb Calorimeter (Precision

1.3 This standard does not purport to address all of the

Method)

safety concerns, if any, associated with its use. It is the

G72Test Method for Autogenous Ignition Temperature of

responsibility of the user of this standard to establish appro-

Liquids and Solids in a High-Pressure Oxygen-Enriched

priate safety and health practices and determine the applica-

Environment

bility of regulatory limitations prior to use.

G74Test Method for Ignition Sensitivity of Materials to

Gaseous Fluid Impact

NOTE 1—The American Society for Testing and Materials takes no

position respecting the validity of any evaluation methods asserted in

G86Test Method for Determining Ignition Sensitivity of

connection with any item mentioned in this guide. Users of this guide are

Materials to Mechanical Impact in Ambient Liquid Oxy-

expresslyadvisedthatdeterminationofthevalidityofanysuchevaluation

gen and Pressurized Liquid and Gaseous Oxygen Envi-

methods and data and the risk of use of such evaluation methods and data

ronments

are entirely their own responsibility.

NOTE 2—In evaluating materials, any mixture with oxygen exceeding G88Guide for Designing Systems for Oxygen Service

atmosphericconcentrationatpressureshigherthanatmosphericshouldbe

G93Practice for Cleaning Methods and Cleanliness Levels

evaluated from the hazard point of view for possible significant increase

for Material and Equipment Used in Oxygen-Enriched

in material combustibility.

Environments

G94Guide for Evaluating Metals for Oxygen Service

ThisguideisunderthejurisdictionofASTMCommitteeG04onCompatibility

and Sensitivity of Materials in Oxygen Enriched Atmospheres and is the direct

responsibility of Subcommittee G04.02 on Recommended Practices. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 15, 2007. Published May 2007. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1980. Last previous edition approved in 1999 as G63–99. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/G0063-99R07. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G63 − 99 (2007)

2.2 Federal Standard: experience, know how to apply physical and chemical prin-

Fed.TestMethodStd.91BCorrosionProtectionbyCoating: ciples involved in the reactions between oxygen and other

Salt Spray (Fog) Test materials.

2.3 Other Standard:

3.2.11 reactioneffect—thepersonnelinjury,facilitydamage,

BS 3N:100: 1985Specification for General Design Require-

productloss,downtime,ormissionlossthatcouldoccurasthe

ments for Aircraft Oxygen Systems and Equipment

result of an ignition.

2.4 Other Documents:

CGA Pamphlet G4.4Industrial Practices for Gaseous Oxy- 4. Significance and Use

gen Transmission and Distribution Piping System

4.1 The purpose of this guide is to furnish qualified techni-

NSS 1740.15NASA Safety Standard for Oxygen and Oxy-

cal personnel with pertinent information for use in selecting

gen Systems

materialsforoxygenserviceinordertominimizetheprobabil-

ityofignitionandtheriskofexplosionorfire.Itisnotintended

3. Terminology

as a specification for approving materials for oxygen service.

3.1 Definitions:

3.1.1 autoignition temperature—the temperature at which a

5. Factors Affecting Selection of Material

materialwillspontaneouslyigniteinoxygenunderspecifictest

5.1 General—The selection of a material for use with

conditions (see Guide G88).

oxygen or oxygen-enriched atmospheres is primarily a matter

3.2 Definitions of Terms Specific to This Standard:

of understanding the circumstances that cause oxygen to react

3.2.1 direct oxygen service—in contact with oxygen during

with the material. Most materials in contact with oxygen will

normaloperations.Examples:oxygencompressorpistonrings,

not ignite without a source of ignition energy. When an

control valve seats.

energy-input rate, as converted to heat, is greater than the rate

of heat dissipation, and the temperature increase is continued

3.2.2 impact-ignition resistance—the resistance of a mate-

for sufficient time, ignition and combustion will occur. Thus

rial to ignition when struck by an object in an oxygen

considered: the material’s minimum ignition temperature, and

atmosphere under a specific test procedure.

the energy sources that will produce a sufficient increase in the

3.2.3 indirect oxygen service—not normally in contact with

temperature of the material. These should be viewed in the

oxygen, but which might be as a result of a reasonably

context of the entire system design so that the specific factors

foreseeablemalfunction,operatorerror,orprocessdisturbance.

listed below will assume the proper relative significance. To

Examples: liquid oxygen tank insulation, liquid oxygen pump

summarize: it depends on the application.

motor bearings.

5.2 Properties of the Material:

3.2.4 maximum use pressure—the maximum pressure to

5.2.1 Factors Affecting Ease of Ignition—Generally, in con-

which a material can be subjected due to a reasonably

sideringamaterialforaspecificoxygenapplication,oneofthe

foreseeable malfunction, operator error, or process upset.

most significant factors is its minimum ignition temperature in

3.2.5 maximum use temperature—the maximum tempera-

oxygen. Other factors that will affect its ignition are relative

ture to which a material can be subjected due to a reasonably

resistance to impact, geometry, configuration, specific heat,

foreseeable malfunction, operator error, or process upset.

relative porosity, thermal conductivity, preoxidation or

3.2.6 nonmetallic—any material, other than a metal, or any

passivity, and “heat-sink effect.” The latter is the heat-transfer

composite in which the metal is not the most easily ignited

aspect of the material to the mass in intimate contact with it,

componentandforwhichtheindividualconstituentscannotbe

with respect to both the amount and the physical arrangement

evaluated independently.

of each and to their respective physical properties. For

instance, a gasket material may have a relatively low ignition

3.2.7 operating pressure—the pressure expected under nor-

temperature but be extremely resistant to ignition when con-

mal operating conditions.

fined between two steel flanges. The presence of a small

3.2.8 operating temperature—the temperature expected un-

amount of an easily ignitable material, such as a hydrocarbon

der normal operating conditions.

oil or a grease film, can promote the ignition of the base

3.2.9 oxygen-enriched—appliestoafluid(gasorliquid)that

material.Accordingly, cleanliness is vital to minimize the risk

contains more than 25 mol % oxygen. 7

of ignition (1). See also Practice G93 and Refs. 2–3.

3.2.10 qualified technical personnel—persons such as engi-

5.2.2 Factors Affecting Propagation—After a material is

neers and chemists who, by virtue of education, training, or

ignited, combustion may be sustained or may halt.Among the

factors that affect whether fire will continue are the basic

composition of the material, the pressure, initial temperature,

AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

the geometric state of the matter, and whether the available

732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov. oxygen will be consumed or the accumulation of combustion

Available from British Standards Institute (BSI), 389 Chiswick High Rd.,

products reduce the availability of oxygen sufficiently to stop

London W4 4AL, U.K., http://www.bsi-global.com.

Available from Compressed Gas Association (CGA), 4221 Walney Rd., 5th

Floor, Chantilly, VA 20151-2923, http://www.cganet.com.

6 7

National Aeronautics and Space Administration, Office of Safety and Mission Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

Assurance, Washington, DC. this standard.

G63 − 99 (2007)

the reaction. Combustion may also be interrupted by the also decrease; therefore, greater latitude may be exercised in

presence of a heat sink. the selection of materials.

5.2.3 Properties and Conditions Affecting Potential Resul-

5.4 Ignition Mechanisms—For an ignition to occur, it is

tant Damage—A material’s heat of combustion, its mass, the

necessary to have three elements present: oxidizer, fuel, and

oxygen concentration, flow conditions before and after

ignition energy. The oxygen environment is obviously the

ignition, and the flame propagation characteristics affect the

oxidizer, and the material under consideration is the fuel.

potential damage if ignition should occur and should be taken

Several potential sources of ignition energy are listed below.

into account in estimating the reaction effect in 7.5.

The list is neither all-inclusive nor in order of importance nor

5.3 Operating Conditions—Conditions that affect the suit- in frequency of occurrence.

ability of a material include the other materials of construction 5.4.1 Friction—Therubbingoftwosolidmaterialsresultsin

and their arrangement in the equipment and pressure, the generation of heat. Example: the rub of a centrifugal

temperature, concentration, flow, and velocity of the oxygen. compressor rotor against its casing.

Pressure and temperature are generally the most significant, 5.4.2 Heat of Compression—Heat is generated from the

conversion of mechanical energy when a gas is compressed

and their effects show up in the estimate of ignition potential

(5.4) and reaction effect (5.5), as explained in Section 7. from a low to a high pressure. This can occur when high-

5.3.1 Pressure—Thepressureisimportant,notonlybecause pressure oxygen is released into a dead-ended tube or pipe,

it generally affects the generation of potential ignition quickly compressing the residual oxygen that was in the tube

mechanisms, but also because it usually significantly affects ahead of it. Example: a downstream valve in a dead-ended

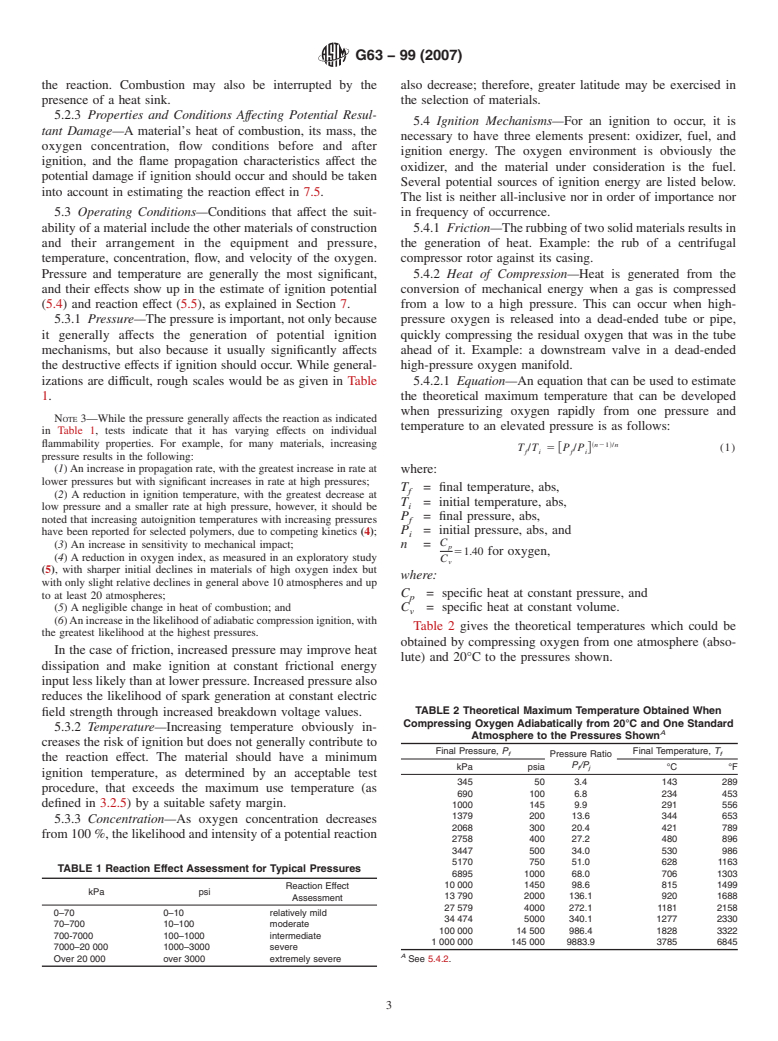

the destructive effects if ignition should occur. While general- high-pressure oxygen manifold.

izations are difficult, rough scales would be as given in Table 5.4.2.1 Equation—An equation that can be used to estimate

1. the theoretical maximum temperature that can be developed

when pressurizing oxygen rapidly from one pressure and

NOTE 3—While the pressure generally affects the reaction as indicated

temperature to an elevated pressure is as follows:

in Table 1, tests indicate that it has varying effects on individual

flammability properties. For example, for many materials, increasing ~n21!/n

T /T 5 @P /P # (1)

f i f i

pressure results in the following:

(1)An increase in propagation rate, with the greatest increase in rate at

where:

lower pressures but with significant increases in rate at high pressures;

T = final temperature, abs,

f

(2) A reduction in ignition temperature, with the greatest decrease at

T = initial temperature, abs,

i

low pressure and a smaller rate at high pressure, however, it should be

P = final pressure, abs,

noted that increasing autoignition temperatures with increasing pressures f

P = initial pressure, abs, and

have been reported for selected polymers, due to competing kinetics (4);

i

C

(3) An increase in sensitivity to mechanical impact; n =

p

51.40 for oxygen,

(4) A reduction in oxygen index, as measured in an exploratory study C

v

(5), with sharper initial declines in materials of high oxygen index but

where:

with only slight relative declines in general above 10 atmospheres and up

C = specific heat at constant pressure, and

to at least 20 atmospheres;

p

(5) A negligible change in heat of combustion; and C = specific heat at constant volume.

v

(6)Anincreaseinthelikelihoodofadiabaticcompressionignition,with

Table 2 gives the theoretical temperatures which could be

the greatest likelihood at the highest pressures.

obtained by compressing oxygen from one atmosphere (abso-

In the case of friction, increased pressure may improve heat

lute) and 20°C to the pressures shown.

dissipation and make ignition at constant frictional energy

inputlesslikelythanatlowerpressure.Increasedpressurealso

reduces the likelihood of spark generation at constant electric

TABLE 2 Theoretical Maximum Temperature Obtained When

field strength through increased breakdown voltage values.

Compressing Oxygen Adiabatically from 20°C and One Standard

5.3.2 Temperature—Increasing temperature obviously in-

A

Atmosphere to the Pressures Shown

creases the risk of ignition but does not generally contribute to

Final Pressure, P Final Temperature, T

f Pressure Ratio f

the reaction effect.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.