ASTM E1719-24

(Test Method)Standard Test Method for Vapor Pressure of Liquids by Ebulliometry

Standard Test Method for Vapor Pressure of Liquids by Ebulliometry

SIGNIFICANCE AND USE

5.1 Vapor pressure is a fundamental thermodynamic property of a liquid. Vapor pressure and boiling temperature data are required for safety data sheets (SDS), the estimation of volatile organic compounds (VOC), and other needs related to product safety. Vapor pressures are important for prediction of the transport of a chemical in the environment; see Test Method E1194.

SCOPE

1.1 This test method describes procedures for determination of the vapor pressure of liquids by ebulliometry (boiling point measurements). It applies to pure liquids and azeotropes with an atmospheric boiling point between 285 K and 575 K, which can be condensed completely and returned to the ebulliometer boiler, that is, all materials must be condensable at total reflux. Liquid mixtures may be studied if they do not contain non-condensable components. Liquid mixtures that contain trace amounts of volatile but completely condensable components may also be studied, but they will produce vapor pressure data of greater uncertainty. Boiling point temperatures are measured at applied pressures of 1.0 kPa to 100 kPa (7.5 torr to 760 torr).

1.2 SI units are the standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 8.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1719 − 24

Standard Test Method for

1

Vapor Pressure of Liquids by Ebulliometry

This standard is issued under the fixed designation E1719; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2879 Test Method for Vapor Pressure-Temperature Rela-

tionship and Initial Decomposition Temperature of Liq-

1.1 This test method describes procedures for determination

uids by Isoteniscope

of the vapor pressure of liquids by ebulliometry (boiling point

E1 Specification for ASTM Liquid-in-Glass Thermometers

measurements). It applies to pure liquids and azeotropes with

E177 Practice for Use of the Terms Precision and Bias in

an atmospheric boiling point between 285 K and 575 K, which

ASTM Test Methods

can be condensed completely and returned to the ebulliometer

E691 Practice for Conducting an Interlaboratory Study to

boiler, that is, all materials must be condensable at total reflux.

Determine the Precision of a Test Method

Liquid mixtures may be studied if they do not contain

E1142 Terminology Relating to Thermophysical Properties

non-condensable components. Liquid mixtures that contain

E1194 Test Method for Vapor Pressure

trace amounts of volatile but completely condensable compo-

E1970 Practice for Statistical Treatment of Thermoanalytical

nents may also be studied, but they will produce vapor pressure

Data

data of greater uncertainty. Boiling point temperatures are

measured at applied pressures of 1.0 kPa to 100 kPa (7.5 torr to

3. Terminology

760 torr).

3.1 Definitions:

1.2 SI units are the standard. No other units of measurement

3.1.1 The following terms apply to this test method and can

are included in this standard.

be found in Terminology E1142; boiling temperature and

vapor pressure.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.1.2 For definitions of other terms used in this test method,

refer to Terminology E1142.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- 3.2 Definitions of Terms Specific to This Standard:

3.2.1 ebulliometer—a one-stage, total-reflux boiler designed

mine the applicability of regulatory limitations prior to use.

For specific hazard statements, see Section 8. to minimize superheating of the boiling liquid.

1.4 This international standard was developed in accor-

3.2.2 manostat—a device for maintaining constant vacuum

dance with internationally recognized principles on standard-

or pressure.

ization established in the Decision on Principles for the

3.2.3 superheating—act of heating a liquid above the equi-

Development of International Standards, Guides and Recom-

librium boiling temperature for a particular applied pressure.

mendations issued by the World Trade Organization Technical

3.3 Symbols:

Barriers to Trade (TBT) Committee.

A, B, C = Antoine vapor pressure equation constants (log ,

10

2. Referenced Documents

kPa, K) for the Antoine vapor pressure equation:

2

2.1 ASTM Standards:

log P = A − B /(T + C),

10

D1193 Specification for Reagent Water

P = vapor pressure, kPa, and

T = absolute temperature, K.

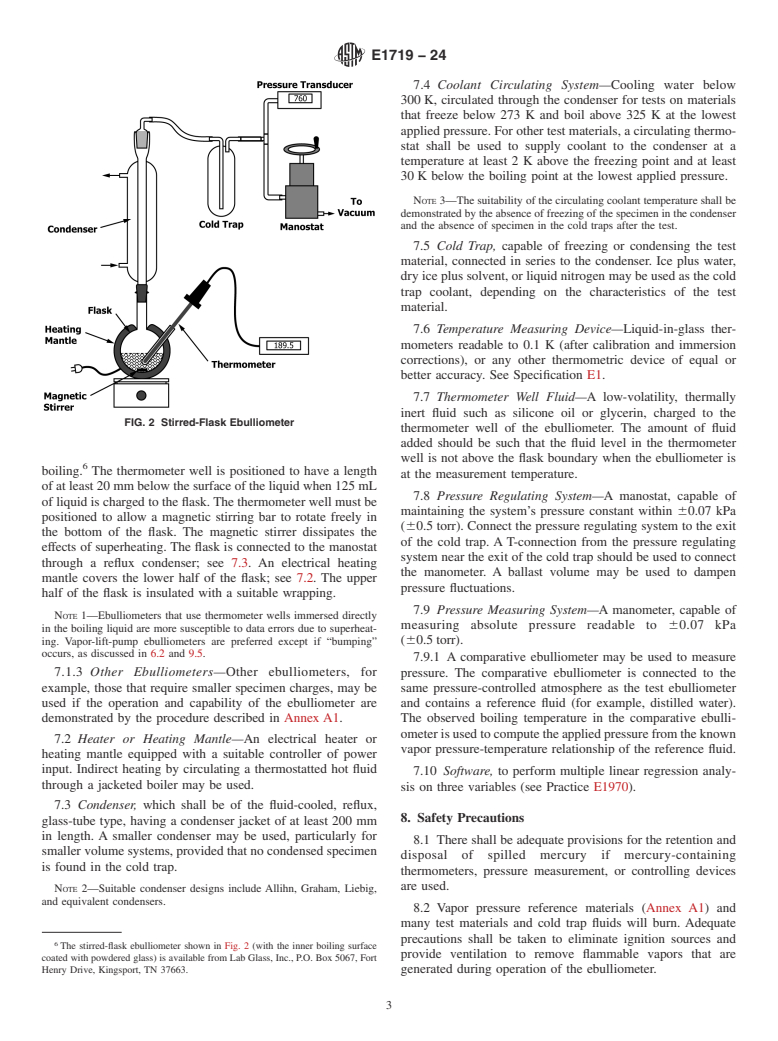

4. Summary of Test Method

1

This test method is under the jurisdiction of ASTM Committee E37 on Thermal

Measurements and is the direct responsibility of Subcommittee E37.01 on Calo-

4.1 A specimen is charged to the ebulliometer boiler. The

rimetry and Mass Loss.

ebulliometer is connected to a manostat, and coolant is

Current edition approved March 1, 2024. Published March 2024. Originally

circulated through the ebulliometer condenser. The manostat is

approved in 1995. Last previous edition approved in 2018 as E1719 – 12 (2018)

set at a low pressure, and the specimen is heated to the boiling

which was withdrawn in April 2023 and reinstated in March 2024. DOI: 10.1520/

E1719-24.

temperature. The boiling temperature and manostat pressure

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

are recorded upon reaching a steady-state, and the manostat

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

pressure is raised to a higher value. A suitable number (usually

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. five or more) of boiling temperature points are recorded at

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United State

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.