ASTM D1461-85(2006)

(Test Method)Standard Test Method for Moisture or Volatile Distillates in Bituminous Paving Mixtures

Standard Test Method for Moisture or Volatile Distillates in Bituminous Paving Mixtures

SIGNIFICANCE AND USE

This test method is used for determining either the amount of moisture or the amount of volatile petroleum distillates in bituminous paving mixtures.

SCOPE

1.1 This test method covers the determination, by direct measurement, of moisture or volatile fractions of the bitumen in bituminous paving mixtures.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1461–85(Reapproved 2006)

Standard Test Method for

Moisture or Volatile Distillates in Bituminous Paving

1

Mixtures

This standard is issued under the fixed designation D1461; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope head shall be of metal, preferably of copper or brass, and shall

be provided with a tubulation 25.4 mm (1 in.) in inside

1.1 This test method covers the determination, by direct

diameter.

measurement, of moisture or volatile fractions of the bitumen

4.2 Condenser, of the water-cooled reflux glass-tube type,

in bituminous paving mixtures.

3

havingacondenserjacketnotlessthan400mm(15 ⁄4in.)long

1.2 The values stated in SI units are to be regarded as the

3 1

with an inner tube 9.5 to 12.7 mm ( ⁄8 to ⁄2 in.) in outside

standard. The values given in parentheses are for information

diameter. The end of the condenser inserted in the trap shall be

only.

ground off at an angle of 30° from the vertical axis of the

1.3 This standard does not purport to address all of the

condenser. For mixtures with very volatile solvents, it may be

safety concerns, if any, associated with its use. It is the

necessary to supplement this water-cooled condenser with a

responsibility of the user of this standard to establish appro-

second water-cooled condenser of approximately the same

priate safety and health practices and determine the applica-

dimensions.

bility of regulatory limitations prior to use.

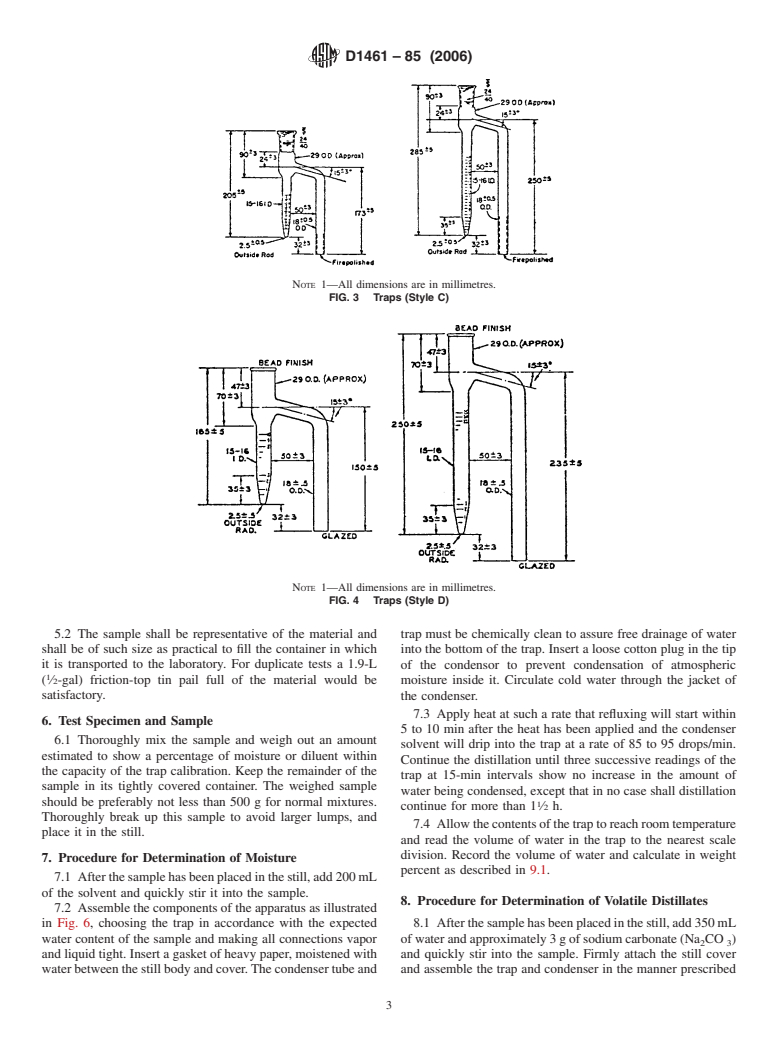

4.3 Trap, of well-annealed glass, of one of the following

2. Referenced Documents types depending upon the purpose of the test:

2

4.3.1 For determination of water in bituminous paving

2.1 ASTM Standards:

mixtures, a glass trap of 10 or 25-mL capacity shall be used.

D244 Test Methods and Practices for Emulsified Asphalts

The trap shall be graduated in 0.1-mL divisions with

D979 Practice for Sampling Bituminous Paving Mixtures

60.05-mL maximum error below 1 mL, and in 0.2-mL

3. Significance and Use

divisions with a 60.1-mL maximum error above 1 mL, as

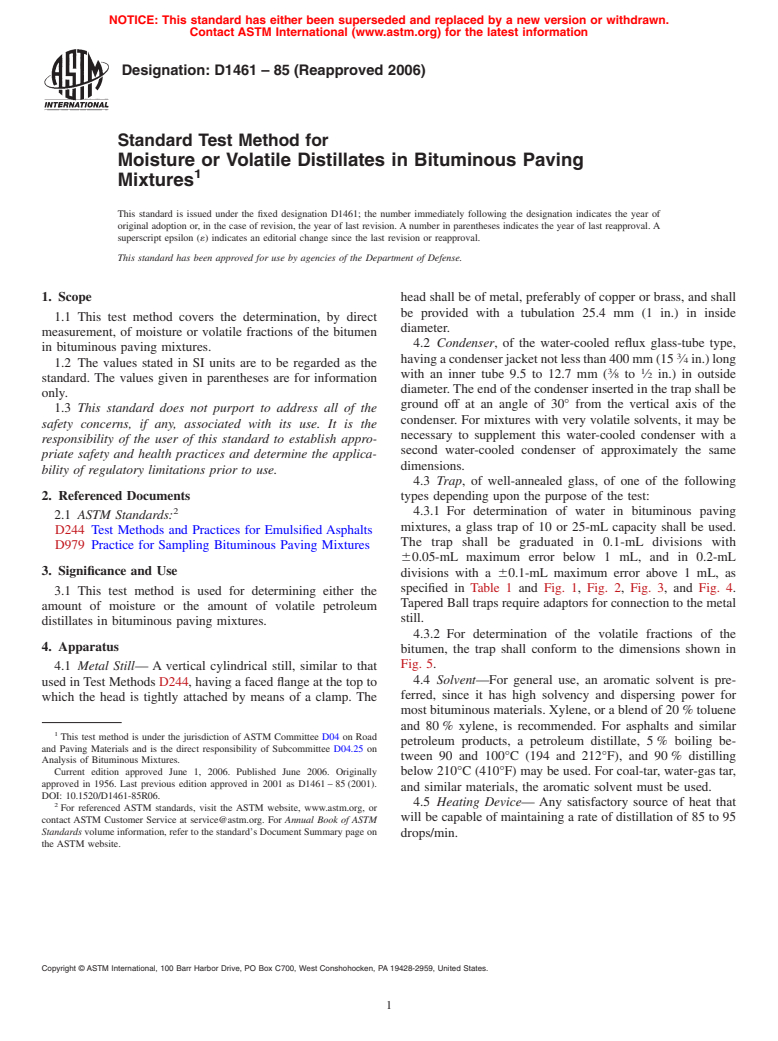

specified in Table 1 and Fig. 1, Fig. 2, Fig. 3, and Fig. 4.

3.1 This test method is used for determining either the

Tapered Ball traps require adaptors for connection to the metal

amount of moisture or the amount of volatile petroleum

still.

distillates in bituminous paving mixtures.

4.3.2 For determination of the volatile fractions of the

4. Apparatus

bitumen, the trap shall conform to the dimensions shown in

Fig. 5.

4.1 Metal Still— A vertical cylindrical still, similar to that

4.4 Solvent—For general use, an aromatic solvent is pre-

used in Test Methods D244, having a faced flange at the top to

ferred, since it has high solvency and dispersing power for

which the head is tightly attached by means of a clamp. The

most bituminous materials. Xylene, or a blend of 20 % toluene

and 80 % xylene, is recommended. For asphalts and similar

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

petroleum products, a petroleum distillate, 5 % boiling be-

and Paving Materials and is the direct responsibility of Subcommittee D04.25 on

tween 90 and 100°C (194 and 212°F), and 90 % distilling

Analysis of Bituminous Mixtures.

Current edition approved June 1, 2006. Published June 2006. Originally below 210°C (410°F) may be used. For coal-tar, water-gas tar,

approved in 1956. Last previous edition approved in 2001 as D1461 – 85 (2001).

and similar materials, the aromatic solvent must be used.

DOI: 10.1520/D1461-85R06.

4.5 Heating Device— Any satisfactory source of heat that

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

will be capable of maintaining a rate of distillation of 85 to 95

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

drops/min.

the ASTM website.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1461–85 (2006)

TABLE 1 Dimensions and Sizes of Traps

Description Small-

Size of est Scale

Top of Bottom of Bottom of

Style Figure Trap, Range, mL Scale Error

Graduated Graduated Vapor

mL Division, max, mL

Tube Tube Tube

mL

0to 1.0 0.1 0.05

A $ joint conical $ joint 7 10 over 1.0 to 10.0 0.2 0.1

B § joint conical § joint 8

C $ joint conical plain 9 0to 1.0 0.1 0.05

D plain conical plain 10 25 over 1.0 to 25 0.2 0.1

5 0to 5.0 0.1 0.05

E $ joint round $ joint 11 10 0to10.0 0.1 0.1

NOTE 1—All dimensions are in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.