ASTM D3792-05(2009)

(Test Method)Standard Test Method for Water Content of Coatings by Direct Injection Into a Gas Chromatograph

Standard Test Method for Water Content of Coatings by Direct Injection Into a Gas Chromatograph

SIGNIFICANCE AND USE

In order to calculate volatile organic content (VOC) in waterborne paints, it is necessary to know the water content. This gas chromatographic test method provides a relatively simple and direct way to determine water content.

SCOPE

1.1 This test method is for the determination of the total water content of waterborne paints. It has been evaluated for latex systems (styrene-butadiene, poly(vinylacetate)-acrylic, acrylic), epoxy acrylic resin systems and acrylic systems. The established working range of this test method is from 15 to 90 %. There is no reason to believe that it will not work outside of this range.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3792 − 05(Reapproved 2009)

Standard Test Method for

Water Content of Coatings by Direct Injection Into a Gas

Chromatograph

This standard is issued under the fixed designation D3792; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 4. Significance and Use

1.1 This test method is for the determination of the total 4.1 In order to calculate volatile organic content (VOC) in

water content of waterborne paints. It has been evaluated for waterborne paints, it is necessary to know the water content.

latex systems (styrene-butadiene, poly(vinylacetate)-acrylic, This gas chromatographic test method provides a relatively

acrylic), epoxy acrylic resin systems and acrylic systems. The simple and direct way to determine water content.

established working range of this test method is from 15 to

5. Apparatus

90 %.Thereisnoreasontobelievethatitwillnotworkoutside

5.1 Gas Chromatography—Any gas-liquid chromato-

of this range.

graphic instrument equipped with a thermoconductivity detec-

1.2 The values stated in SI units are to be regarded as the

tor may be used. Temperature programming capability is

standard. The values given in parentheses are for information

preferable, but isothermal operations may be adequate. See

only.

Table 1.

1.3 This standard does not purport to address all of the

5.2 Column—The column should be at least 1.22 m (4 ft) of

safety concerns, if any, associated with its use. It is the

3.2-mm ( ⁄8-in.) outside diameter tubing of stainless steel, or

responsibility of the user of this standard to establish appro-

other suitable material, lined with a TFE-fluorocarbon coating

priate safety and health practices and determine the applica-

packed with 60/80 mesh (180 to 250 µm) porous polymer

bility of regulatory limitations prior to use.

packing material. A longer 1.83 m (6-ft) column can be used

2. Referenced Documents to improve resolution.

2.1 ASTM Standards:

5.3 Integrator—Any electronic integrator that can accu-

D1193 Specification for Reagent Water

rately quantify a gas chromatographic peak is acceptable.

E180 Practice for Determining the Precision of ASTM Alternatively, a recording potentiometer with a full-scale

Methods for Analysis and Testing of Industrial and Spe-

deflectionof1-10mV,fullscaleresponsetimeof2sorlessand

cialty Chemicals (Withdrawn 2009) sufficient sensitivity and stability to meet the requirements of

5.1.

3. Summary of Test Method

5.4 Liquid Charging Devices—Micro syringes of 5–10-µL

3.1 A suitable aliquot of whole paint is internally

capacity with a precision of 60.01 µL. Automatic injection of

standardized, diluted with dimethylformamide, and then in-

samples improves the precision of this test method.

jected into a gas chromatographic column containing a porous

polymer packing that separates water from other volatile 6. Column Conditioning

components.

6.1 Procedure—Install the packed column in the gas chro-

matographic unit leaving the exit end disconnected from the

This test method is under the jurisdiction of ASTM Committee D01 on Paint

detector. This will prevent any contamination of the detector

and Related Coatings, Materials, andApplications and is the direct responsibility of

with the column bleed.

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

6.1.1 Set the carrier gas flow rate at 20 to 30 mL/min if a

Current edition approved June 1, 2009. Published June 2009. Originally

approved in 1979. Last previous edition approved in 2005 as D3792 – 05. DOI:

3.2-mm ( ⁄8-in.) outside diameter column is used. Purge the

10.1520/D3792-05R09.

column 5 or 10 min before heating.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on HayeSep R (silanized), was used in the round robin.Any other porous polymer

the ASTM website. packing or other column giving equivalent or superior performance may be used.

The last approved version of this historical standard is referenced on These products are available from most gas chromatography suppliers and distribu-

www.astm.org. tors.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3792 − 05 (2009)

TABLE 1 Suggested Instrument Conditions

where such specifications are available. Other grades may be

Detector thermal conductivity used, provided it is first ascertained that the reagent is of

Column 1.22m×3.2 mm TFE-fluorocarbon coating

sufficiently high purity to permit its use without lessening the

coated stainless steel

accuracy of the determination.

Packing 60/80 mesh porous polymer

Temperatures, °C

7.2 Purity of Water—Unless otherwise indicated, reference

Sample inlet 240

Detector 250 to water shall be understood to mean reagent water conforming

Column

to Type II of Specification D1193.

Initial 140

Final 240

7.3 Carrier Gas—Helium of 99.995 % or higher purity.

Program rate 40/min

High-purity nitrogen may also be used.

Carrier gas helium

Flow rate, ml/min 22.0-22.5

NOTE 1—Care should be taken that any moisture that may be present in

Detector current 150 mA

the carrier gas is eliminated through the use of a suitable carrier gas

Specimen size 1-2 µl

purifier. Trace levels of water will accumulate on the column at low oven

temperatures and may affect the reproducibility as well as the accuracy of

the determination.

7.4 Dimethylformamide (DMF) (Anhydrous) gas

chromatography, spectrophotometric quality (See Note 2).

7.5 2-Propanol (Anhydrous) (Isopropanol)—See Note 2.

7.6 Methanol (Anhydrous)—See Note 2.

7.7 Septum Sample Vials, 10-mL capacity with

fluorocarbon-faced septa are preferred.

7.8 Molecular Sieve, 2A-3A, 8-12, mesh.

NOTE 2—Dry the DMF, 2-propanol and methanol with the molecular

sieve. Verify the absence of water by analysis of the solvents by this GC

method.

8. Hazards

8.1 Dimethylformamide is hazardous. Check the supplier’s

Material Safety Data Sheet (MSDS) before use.

9. Preparation of Apparatus

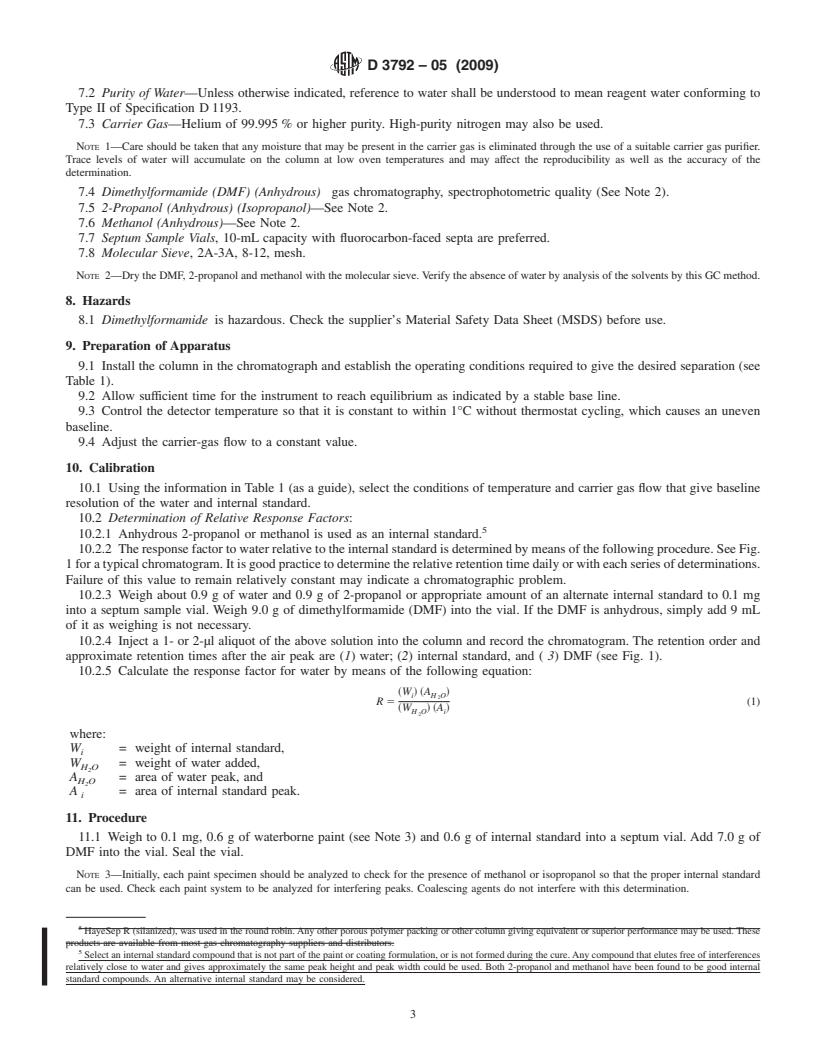

FIG. 1 Typical Chromatogram

9.1 Install the column in the chromatograph and establish

the operating conditions required to give the desired separation

(see Table 1).

9.2 Allow sufficient time for the instrument to reach equi-

6.1.2 Heat the column from room temperature to 200°C at

librium as indicated by a stable base line.

5°C/min and hold this temperature for at least 12 h (overnight).

9.3 Control the detector temperature so that it is constant to

At the end of this time, heat the column at 5°C/min to 250°C

within 1°C without thermostat cycling, which causes an

(the maximum temperature for this packing) and hold for

uneven baseline.

several hours. Cool the column to room temperature and

connect to the detector.

9.4 Adjust the carrier-gas flow to a constant value.

6.1.3 Reheat the column to 250°C at 5°C/min to observe if

there is column bleed. Optimum conditioning of this column

10. Calibration

may take several cycles of the heating program before a flat

10.1 UsingtheinformationinTable1(asaguide),selectthe

recorder baseline is achieved.

conditions of temperature and carrier gas flow that give

6.2 Before each calibration and series of determinations (or

baseline resolution of the water and internal standard.

daily) condition the column at 200°C for 1 h with carrier gas

flow and to eliminate any residual

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3792–99 Designation:D3792–05(Reapproved2009)

Standard Test Method for

Water Content of Coatings by Direct Injection Into a Gas

Chromatograph

This standard is issued under the fixed designation D 3792; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method is for the determination of the total water content of waterborne paints. It has been evaluated for latex

systems (styrene-butadiene, poly(vinylacetate)-acrylic, acrylic), epoxy acrylic resin systems and acrylic systems. The established

working range of this test method is from 15 to 90 %. There is no reason to believe that it will not work outside of this range.

1.2 The values givenstated in inch/poundSI units are to be regarded as the preferred unit of measurement.standard. The values

given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 1193 Specification for Reagent Water

D1364Test Method for Water in Volatile Solvents (Karl Fischer Reagent Titration Method) Specification for Reagent Water

E 180 Practice for Determining the Precision Data of ASTM Methods for Analysis and Testing of Industrial and Specialty

Chemicals

3. Summary of Test Method

3.1 A suitable aliquot of whole paint is internally standardized, diluted with dimethylformamide, and then injected into a gas

chromatographic column containing a porous polymer packing that separates water from other volatile components.

4. Significance and Use

4.1 In order to calculate volatile organic content (VOC) in waterborne paints, it is necessary to know the water content. This

gas chromatographic test method provides a relatively simple and direct way to determine water content.

5. Apparatus

5.1 Gas Chromatography—Any gas-liquid chromatographic instrument equipped with a thermoconductivity detector may be

used. Temperature programming capability is preferable, but isothermal operations may be adequate. See Table 1.

5.2 Column—The column should be at least 4 ft (1.22 m)1.22 m (4 ft) of 3.2-mm ( ⁄8-in. (3.2-mm) -in.) outside diameter tubing

ofstainlesssteel,orothersuitablematerial,linedwithaTFE-fluorocarboncoatingpackedwith60/80mesh(180to250µm)porous

polymer packing material. A longer 6-ft (1.83 m)1.83 m (6-ft) column can be used to improve resolution.

5.3 Integrator—Any electronic integrator that can accurately quantify a gas chromatographic peak is acceptable.Alternatively,

a recording potentiometer with a full-scale deflection of 1-10mV, full scale response time of2sor less and sufficient sensitivity

and stability to meet the requirements of 5.1.

5.4 Liquid Charging Devices—Micro syringes of 5–10-µL capacity with a precision of 60.01 µL. Automatic injection of

This test method is under the jurisdiction of ASTM Committee D-1 D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials .

Current edition approved May 10, 1999. Published July 1999. Originally published as D3792–79. Last previous edition D3792–98.

Current edition approved June 1, 2009. Published June 2009. Originally approved in 1979. Last previous edition approved in 2005 as D 3792 – 05.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 11.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 06.04.

HayeSep R (silanized), was used in the round robin.Any other porous polymer packing or other column giving equivalent or superior performance may be used. These

products are available from most gas chromatography suppliers and distributors.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3792–05 (2009)

TABLE 1 Suggested Instrument Conditions

Detector thermal conductivity

Column 1.22 m 3 3.2 mm TFE-fluorocarbon coating

coated stainless steel

Packing 60/80 mesh porous polymer

Temperatures, °C

Sample inlet 240

Detector 250

Column

Initial 140

Final 240

Program rate 40/min

Carrier gas helium

Flow rate, ml/min 22.0-22.5

Detector current 150 mA

Specimen size 1-2 µl

FIG. 1 Typical Chromatogram

samples improves the precision of this test method.

6. Column Conditioning

6.1 Procedure—Install the packed column in the gas chromatographic unit leaving the exit end disconnected from the detector.

This will prevent any contamination of the detector with the column bleed.

6.1.1 Set the carrier gas flow rate at 20 to 30 mL/min if a -in. (3.2-mm)3.2-mm ( ⁄8-in.) outside diameter column is used. Purge

the column 5 or 10 min before heating.

6.1.2 Heat the column from room temperature to 200°C at 5°C/min and hold this temperature for at least 12 h (overnight). At

the end of this time, heat the column at 5°C/min to 250°C (the maximum temperature for this packing) and hold for several hours.

Cool the column to room temperature and connect to the detector.

6.1.3 Reheat the column to 250°C at 5°C/min to observe if there is column bleed. Optimum conditioning of this column may

take several cycles of the heating program before a flat recorder baseline is achieved.

6.2 Before each calibration and series of determinations (or daily) condition the column at 200°C for 1 h with carrier gas flow

and to eliminate any residual volatile compounds retained on the column.

7. Reagents and Materials

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

Annual Book of ASTM Standards, Vol 15.05.Reagent Chemicals, American Chemical Society Specifications , American Chemical Society, Washington, DC. For

suggestions on the testing of reagents not listed by the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and

the United States Pharmacopeia and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

D3792–05 (2009)

7.2 Purity of Water—Unless otherwise indicated, reference to water shall be understood to mean reagent water conforming to

Type II of Specification D 1193.

7.3 Carrier Gas—Helium of 99.995 % or higher purity. High-purity nitrogen may also be used.

NOTE 1—Care should be taken that any moisture that may be present in the carrier gas is eliminated through the use of a suitable carrier gas purifier.

Trace levels of water will accumulate on the column at low oven temperatures and may affect the reproducibility as well as the accuracy of the

determination.

7.4 Dimethylformamide (DMF) (Anhydrous) gas chromatography, spectrophotometric quality (See Note 2).

7.5 2-Propanol (Anhydrous) (Isopropanol)—See Note 2.

7.6 Methanol (Anhydrous)—See Note 2.

7.7 Septum Sample Vials, 10-mL capacity with fluorocarbon-faced septa are preferred.

7.8 Molecular Sieve, 2A-3A, 8-12, mesh.

NOTE 2—Dry the DMF, 2-propanol and methanol with the molecular sieve. Verify the absence o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.