ASTM D664-95(2001)e1

(Test Method)Standard Test Method for Acid Number of Petroleum Products by Potentiometric Titration

Standard Test Method for Acid Number of Petroleum Products by Potentiometric Titration

SCOPE

1.1 This test method covers procedures for the determination of acidic constituents in petroleum products and lubricants soluble or nearly soluble in mixtures of toluene and propan-2-ol (Note 1). It is applicable for the determination of acids whose dissociation constants in water are larger than 10-9; extremely weak acids whose dissociation constants are smaller than 10-9 do not interfere. Salts react if their hydrolysis constants are larger than 10-9.

Note 1—In new and used oils, the constituents that may be considered to have acidic characteristics include organic and inorganic acids, esters, phenolic compounds, lactones, resins, salts of heavy metals, salts of ammonia and other weak bases, acid salts of polybasic acids, and addition agents such as inhibitors and detergents.

1.2 The test method may be used to indicate relative changes that occur in an oil during use under oxidizing conditions regardless of the color or other properties of the resulting oil. Although the titration is made under definite equilibrium conditions, the test method is not intended to measure an absolute acidic property that can be used to predict performance of an oil under service conditions. No general relationship between bearing corrosion and acid number is known.

Note 2—The acid number obtained by this standard may or may not be numerically the same as that obtained in accordance with Test Methods D974 and D3339.

1.3 The values stated in acceptable SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

An American National Standard

e1

Designation:D664–95 (Reapproved 2001) British Standard 4457

Designation 177/96

Standard Test Method for

Acid Number of Petroleum Products by Potentiometric

Titration

This standard is issued under the fixed designation D664; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This test method was adopted as a joint ASTM-IP standard in 1964.

This test method has been adopted for use by government agencies to replace Method 5106 of Federal Test Method Standard No. 791b.

ASTM Test Method D 4739 has been developed as an alternative to the base number portion of D 664.

e NOTE—Warning notes were placed in the text editorially in January 2001.

1. Scope 1.3 The values stated in acceptable SI units are to be

regarded as the standard.

1.1 This test method covers procedures for the determina-

1.4 This standard does not purport to address all of the

tionofacidicconstituentsinpetroleumproductsandlubricants

safety concerns, if any, associated with its use. It is the

soluble or nearly soluble in mixtures of toluene and propan-

responsibility of the user of this standard to establish appro-

2-ol (Note 1). It is applicable for the determination of acids

−9

priate safety and health practices and determine the applica-

whose dissociation constants in water are larger than 10 ;

bility of regulatory limitations prior to use.

extremely weak acids whose dissociation constants are smaller

−9

than 10 do not interfere. Salts react if their hydrolysis

2. Referenced Documents

−9

constants are larger than 10 .

2.1 ASTM Standards:

NOTE 1—In new and used oils, the constituents that may be considered

D974 Test Method for Acid and Base Number by Color-

to have acidic characteristics include organic and inorganic acids, esters,

Indicator Titration

phenolic compounds, lactones, resins, salts of heavy metals, salts of

D1193 Specification for Reagent Water

ammoniaandotherweakbases,acidsaltsofpolybasicacids,andaddition

D3339 Test Method for Acid Number of Petroleum Prod-

agents such as inhibitors and detergents.

ucts by Semi-Micro Color Indicator Titration

1.2 The test method may be used to indicate relative

changes that occur in an oil during use under oxidizing

3. Terminology

conditions regardless of the color or other properties of the

3.1 Definitions:

resulting oil. Although the titration is made under definite

3.1.1 acid number, n—the quantity of base, expressed as

equilibrium conditions, the test method is not intended to

milligrams of potassium hydroxide per gram of sample, re-

measure an absolute acidic property that can be used to predict

quired to titrate a sample to a specified end point.

performance of an oil under service conditions. No general

3.1.1.1 Discussion—Thistestmethodexpressesthequantity

relationship between bearing corrosion and acid number is

of base as milligrams of potassium hydroxide per gram of

known.

sample, that is required to titrate a sample in the solvent from

NOTE 2—Theacidnumberobtainedbythisstandardmayormaynotbe its initial meter reading in millivolts to a meter reading in

numerically the same as that obtained in accordance with Test Methods

millivolts corresponding to a freshly prepared non-aqueous

D974 and D3339.

basic buffer solution or a well-defined inflection point as

specified in the test method.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.06 on Analysis of Lubricants. Annual Book of ASTM Standards, Vol 05.01.

Current edition approved Oct. 10, 1995. Published December 1995. Originally Annual Book of ASTM Standards, Vol 11.01.

published as D664–42T. Last previous edition D664–89. Annual Book of ASTM Standards, Vol 05.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

D664–95 (2001)

3.1.1.2 Discussion—This test method provides additional

information. The quantity of base, expressed as milligrams of

potassium hydroxide per gram of sample, required to titrate a

sampleinthesolventfromitsinitialmeterreadinginmillivolts

to a meter reading in millivolts corresponding to a freshly

prepared nonaqueous acidic buffer solution or a well-defined

inflectionpointasspecifiedinthetestmethodshallbereported

as the strong acid number.

3.1.1.3 Discussion—The causes and effects of the so-called

strongacidsandthecausesandeffectsoftheotheracidscanbe

very significantly different. Therefore, the user of this test

method shall differentiate and report the two, when they are

found.

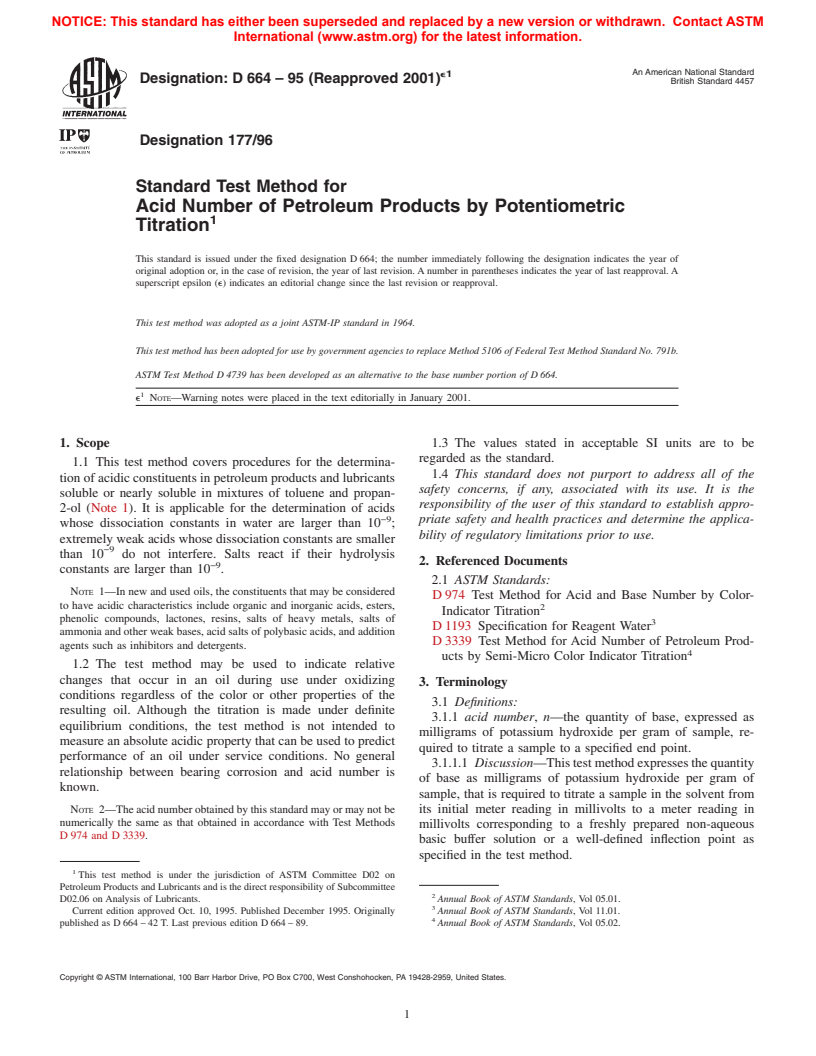

FIG. 1 Cell for Potentiometric Titration

4. Summary of Test Method

4.1 The sample is dissolved in a mixture of toluene and

grounded lead, any part of the exposed surface of the glass

propan-2-ol containing a small amount of water and titrated

electrode, the glass electrode lead, the titration stand, or the

potentiometrically with alcoholic potassium hydroxide using a

meter.

glass indicating electrode and a calomel reference electrode.

NOTE 3—A suitable apparatus could consist of a continuous-reading

The meter readings are plotted manually or automatically

−12

electronicvoltmeterdesignedtooperateonaninputoflessthan5 310

against the respective volumes of titrating solution and the end

A, when an electrode system having 1000-MV resistance is connected

pointsaretakenonlyatwelldefinedinflectionsintheresulting

across the meter terminals and provided with a metal shield connected to

curve.Whennodefiniteinflectionsareobtained,endpointsare the ground, as well as a satisfactory terminal to connect the shielded

connectionwirefromtheglasselectrodetothemeterwithoutinterference

taken at meter readings corresponding to those found for

from any external electrostatic field.

freshly prepared nonaqueous acidic and basic buffer solutions.

6.2.2 Glass Electrode, pencil type, 125 to 180 mm in length

5. Significance and Use

and 8 to 14 mm in diameter (C in Fig. 1).

6.2.2.1 The body of the electrode shall be made of a

5.1 New and used petroleum products may contain acidic

chemically resistant glass tube with a wall thickness of 1 to 3

constituents that are present as additives or as degradation

mm.

products formed during service, such as oxidation products.

6.2.2.2 The end dipping into the solution shall be closed

The relative amount of these materials can be determined by

with a hemisphere of glass sealed on to the electrode tube and

titrating with bases. The acid number is a measure of this

the radius of this hemisphere shall be about 7 mm. The

amount of acidic substance, in the oil-always under the

thickness of the glass in the hemisphere shall be great enough

conditionsofthetest.Theacidnumberisusedasaguideinthe

so that the resistance of the hemisphere is 100 to 1000 MV at

quality control of lubricating oil formulations. It is also

25°C.

sometimes used as a measure of lubricant degradation in

6.2.2.3 The electrode shall contain a reproducible, perma-

service. Any condemning limits must be empirically estab-

nently sealed liquid cell for making electrical connection with

lished.

the inner surface of the hemisphere.

5.2 Since a variety of oxidation products contribute to the

6.2.2.4 The entire electrical connection from the sealed

acid number and the organic acids vary widely in corrosion

contact cell to the meter terminal shall be surrounded by an

properties,thetestmethodcannotbeusedtopredictcorrosive-

electrical shield that will prevent electrostatic interference

ness of an oil under service conditions. No general correlation

when the shield is grounded.

is known between acid number and the corrosive tendency of

6.2.2.5 The shield shall be insulated from the electrical

oils toward metals.

connectionbyinsulatingmaterialofthehighestquality,suchas

rubber and glass, so that the resistance between the shield and

6. Apparatus

the entire length of the electrical connection is greater than

6.1 Thecellassemblyusedforthepotentiometrictitrationis

50000 MV.

shown in Fig. 1.

6.2.3 Calomel Reference Electrode, pencil type, 125 to 180

6.2 Manual Titration Apparatus:

mm in length and 8 to 14 mm in diameter (B in Fig. 1).

6.2.1 Meter,avoltmeterorapotentiometerthatwilloperate 6.2.3.1 This electrode shall be made of glass and shall be

with an accuracy of 60.005 V and a sensitivity of 60.002 V providedwithanexternal,removableglasssleeveonthesealed

overarangeofatleast 60.5Vwhenthemeterisusedwiththe end that is dipped into the titration solution.

electrodes specified in 6.1.2 and 6.1.3 and when the resistance 6.2.3.2 The glass sleeve shall be 8 to 25 mm in length, shall

between the electrodes falls within the range from 0.2 to 20 be slightly tapered, and shall be ground to fit the electrode so

MV.Themetershallbeprotectedfromstrayelectrostaticfields that the sealed end of the electrode protrudes 2 to 20 mm

so that no permanent change in the meter readings over the beyond the sleeve.The ground surface shall be continuous and

entire operating range is produced by touching, with a free of smooth spots.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

D664–95 (2001)

6.2.3.3 At a point between the extremities of the ground 7. Reagents

surface, the electrode tube shall be pierced by a hole or holes

7.1 Purity of Reagents—Reagent grade chemicals shall be

1 mm in diameter. The electrode shall contain the necessary

used in all tests. Unless otherwise indicated, it is intended that

mercury, calomel, and electrical connection to the mercury, all

all reagents shall conform to the specifications of the commit-

arranged in a permanent manner.

tee onAnalytical Reagents of theAmerican Chemical Society,

6.2.3.4 The electrode shall be filled almost to capacity with

where such specifications are available. Other grades may be

saturated KCl electrolyte and shall be equipped with a stop-

used, provided it is first ascertained that the reagent is of

pered port through which the electrolyte may be replenished.

sufficiently high purity to permit its use without lessening the

6.2.3.5 When suspended in the air and with the sleeve in accuracy of the determination.

place, the electrode shall not leak electrolyte at a rate greater

7.2 Purity of Water—Unlessotherwiseindicated,references

than one drop in 10 min. to water shall be understood to mean reagent water as defined

by Type III of Specification D1193.

NOTE 4—Certain alternative electrode-electrolyte combinations have

7.3 Hydrochloric Acid (HCl)—Relative density 1.19

been shown to give satisfactory results although the precision using these

(Warning—Corrosive, causes burns.).

alternatives has not been determined. Combination electrodes can be used

7.4 Propan-2-ol, Anhydrous, (less than 0.1 % H O)

for this test method provided they have sufficiently fast response time. 2

(Warning—Flammable.). If adequately dry reagent cannot be

6.2.4 Variable-Speed Mechanical Stirrer, a suitable type,

procured,itcanbedriedbydistillationthroughamultipleplate

equipped with a glass, propeller-type stirring paddle (D in Fig.

column, discarding the first 5% of material distilling overhead

1).Apropeller with blades 6 mm in radius and set at a pitch of

and using the 95% remaining. Drying can also be accom-

30 to 45° is satisfactory.Amagnetic stirrer is also satisfactory.

plished using molecular sieves such as Linde Type 4A, by

6.2.4.1 If electrical stirring apparatus is used, it shall be

passing the solvent upward through a molecular sieve column

electrically correct and grounded so that connecting or discon-

using one part of molecular sieve per ten parts of solvent.

necting the power to the motor will not produce a permanent

7.5 2,4,6 Trimethyl Pyridine (g Collidine)—((CH ) C H N)

3 3 5 2

change in the meter reading during the course of the titration.

—(mol weight 121.18), (Warning—2,4,6-Trimethyl Pyridine

6.2.5 Burette, 10-mL capacity, graduated in 0.05-mL divi-

(g collidine) is hazardous if swallowed, breathed, or spilled on

sions and calibrated with an accuracy of6 0.02 mL (E in Fig.

skin or eyes. Warning—Wear chemical safety goggles, neo-

1).The burette shall have a glass stopcock and shall have a tip

preneorrubberglovesandapron.Useonlyinawell-ventilated

that extends 100 to 130 mm beyond the stopcock. The burette

hood, or wear an approved respirator for organic vapor or a

for KOH shall have a guard tube containing soda lime or other

supplied-air respirator. Do not take internally.) conforming to

CO -absorbing substance.

the following requirements:

6.2.6 Titration Beaker, 250-mL capacity, made of borosili-

Boiling range 168 to 170°C

Refractive index, n 1 498 2 6 0 000 5

cate glass (A in Fig. 1). D

Color colorless

6.2.7 Titration Stand, suitable for supporting the electrodes,

7.5.1 Storethereagentoveractivatedaluminaandkeepina

stirrer, and burette in the positions shown in Fig. 1.

brown glass bottle.

NOTE 5—Anarrangementthatallowstheremovalofthebeakerwithout

7.6 m-Nitrophenol—(NO C H OH)—(molweight139.11),

2 6 4

disturbing the electrodes, burette, and stirrer is desirable.

conforming to the following requirements (Warning—m-

Nitrophenol can be hazardous if swallowed, breathed, or

6.3 Automatic Titration Apparatus:

spilled on skin or eyes. Wear chemical-safety goggles, neo-

6.3.1 Automatic titration systems shall be generally in

prene or rubber gloves, and apron. Use only in a well-

accordance with 6.2 and provide the following technical

ventilated hood, or wear an approved respirator for organic

performance characteristics or features.

vapor or a supplied-air respirator. Do not take internally.):

6.3.1.1 Automatic adaptation of the titration speed in the

Melting point 96 to 97°C

continuous titrant delivery mode to the slope of the titration

Color pale yellow

curve with the capability of complying with the potential

7.6.1 Store the reagent in a brown glass bottle.

equilibrium specified and providing titration rates of less than

7.7 Potassium Chloride Electrolyte—Prepare a saturated

0.2 mL/min during titration and preferably 0.05 mL/min at

solution potassium chloride (KCl) in water.

inflections and at nonaqueous acid and base end points.

7.8 Potassium Hydroxide—(Warning—Causes severe

6.3.1.2 Interchangeable precision motor-driven burettes

burns.).

with a volume dispensing accuracy of 60.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.