ASTM E1019-08

(Test Method)Standard Test Methods for Determination of Carbon, Sulfur, Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt Alloys by Various Combustion and Fusion Techniques

Standard Test Methods for Determination of Carbon, Sulfur, Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt Alloys by Various Combustion and Fusion Techniques

SIGNIFICANCE AND USE

These test methods for the chemical analysis of metals and alloys are primarily intended to test such materials for compliance with compositional specifications. It is assumed that all who use these test methods will be trained analysts, capable of performing common laboratory procedures skillfully and safely. It is expected that work will be performed in a properly equipped laboratory.

SCOPE

1.1 These test methods cover the determination of carbon, sulfur, nitrogen, and oxygen, in steel and in iron, nickel, and cobalt alloys having chemical compositions within the following limits:

ElementConcentration Range, % Aluminum0.001 to 18.00 Antimony0.002 to 0.03 Arsenic 0.0005 to 0.10 Beryllium0.001 to 0.05 Bismuth 0.001 to 0.50 Boron 0.0005 to 1.00 Cadmium 0.001 to 0.005 Calcium 0.001 to 0.05 Carbon 0.001 to 4.50 Cerium 0.005 to 0.05 Chromium0.005 to 35.00 Cobalt 0.01 to 75.0 Columbium0.002 to 6.00 Copper 0.005 to 10.00 Hydrogen0.0001 to 0.0030 Iron 0.01 to 100.0 Lead 0.001 to 0.50 Magnesium0.001 to 0.05 Manganese0.01 to 20.0 Molybdenum0.002 to 30.00 Nickel 0.005 to 84.00 Nitrogen0.0005 to 0.50 Oxygen 0.0005 to 0.03 Phosphorus0.001 to 0.90 Selenium0.001 to 0.50 Silicon 0.001 to 6.00 Sulfur (Metal Reference

Materials)0.002 to 0.35 Sulfur (Potassium Sulfate)0.001 to 0.600 Tantalum0.001 to 10.00 Tellurium0.001 to 0.35 Tin 0.002 to 0.35 Titanium0.002 to 5.00 Tungsten0.005 to 21.00 Vanadium0.005 to 5.50 Zinc 0.005 to 0.20 Zirconium0.005 to 2.500

1.2 The test methods appear in the following order:

Sections Carbon, Total, by the Combustion–Instrumental Measurement

Test Method

10-20 Nitrogen by the Inert Gas Fusion–Thermal Conductivity

Test Method32-42 Oxygen by the Inert Gas Fusion Test Method43-54 Sulfur by the Combustion-Infrared Absorption Test Method

(Calibration with Metal Reference Materials)

55-65 Sulfur by the Combustion–Infrared Absorption Test Method

(Potassium Sulfate Calibration)

21-31

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in Section 6.

10.1 This test method covers the determination of carbon in concentrations from 0.005 % to 4.5 %.

21.1 This test method covers the determination of sulfur in the range of 0.001 % to 0.01 %. As written, this test method is not applicable to cast iron samples.

32.1 This test method covers the determination of nitrogen (N) in concentrations from 0.0010 % to 0.2 % (Note 12).

Note 12—The upper limit of the scope has been set at 0.2 % because sufficient numbers of test materials containing higher nitrogen contents were unavailable for testing in accordance with Practice E 173. However, recognizing that commercial nitrogen determinators are capable of handling higher concentrations, this test method provides a calibration procedure up to 0.5 %. Users of this test method are cautioned that use of it above 0.2 % is not supported by interlaboratory testing. In this case, laboratories should perform method validation using reference materials.

43.1 This test method covers the determination of oxygen in the range 0.001 % to 0.005 % in steel.

Note 22—The upper limit of the scope has been set at 0.005 % because sufficient numbers of test materials containing higher oxygen contents were unavailable for testing in accordance with Practice E 173. However, recognizing that commercial oxygen determinators are capable of handling higher concentrations, it may be that this test method can be used for oxygen concentrations outside of the scope. In this case, laboratories should perform method validation using refer...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1019–08

Standard Test Methods for

Determination of Carbon, Sulfur, Nitrogen, and Oxygen in

Steel, Iron, Nickel, and Cobalt Alloys by Various

1

Combustion and Fusion Techniques

This standard is issued under the fixed designation E1019; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

Vanadium 0.005 to 5.50

Zinc 0.005 to 0.20

2

1.1 These test methods cover the determination of carbon,

Zirconium 0.005 to 2.500

sulfur, nitrogen, and oxygen, in steel and in iron, nickel, and

1.2 The test methods appear in the following order:

cobalt alloys having chemical compositions within the follow-

Sections

ing limits:

Carbon, Total, by the Combustion–Instrumental Measurement

Element Concentration Range, %

Test Method 10-20

Aluminum 0.001 to 18.00

Nitrogen by the Inert Gas Fusion–Thermal Conductivity 32-42

Antimony 0.002 to 0.03

Test Method

Arsenic 0.0005 to 0.10

Oxygen by the Inert Gas Fusion Test Method 43-54

Beryllium 0.001 to 0.05

Sulfur by the Combustion-Infrared Absorption Test Method

Bismuth 0.001 to 0.50

(Calibration with Metal Reference Materials) 55-65

Boron 0.0005 to 1.00

Sulfur by the Combustion–Infrared Absorption Test Method

Cadmium 0.001 to 0.005

(Potassium Sulfate Calibration) 21-31

Calcium 0.001 to 0.05

Carbon 0.001 to 4.50

Cerium 0.005 to 0.05 1.3 The values stated in SI units are to be regarded as

Chromium 0.005 to 35.00

standard. No other units of measurement are included in this

Cobalt 0.01 to 75.0

standard.

Columbium 0.002 to 6.00

Copper 0.005 to 10.00

1.4 This standard does not purport to address all of the

Hydrogen 0.0001 to 0.0030

safety concerns, if any, associated with its use. It is the

Iron 0.01 to 100.0

responsibility of the user of this standard to establish appro-

Lead 0.001 to 0.50

Magnesium 0.001 to 0.05

priate safety and health practices and determine the applica-

Manganese 0.01 to 20.0

bility of regulatory limitations prior to use. Specific hazards

Molybdenum 0.002 to 30.00

statements are given in Section 6.

Nickel 0.005 to 84.00

Nitrogen 0.0005 to 0.50

Oxygen 0.0005 to 0.03 2. Referenced Documents

Phosphorus 0.001 to 0.90

3

2.1 ASTM Standards:

Selenium 0.001 to 0.50

Silicon 0.001 to 6.00 E29 Practice for Using Significant Digits in Test Data to

Sulfur (Metal Reference 0.002 to 0.35

Determine Conformance with Specifications

Materials)

E50 Practices for Apparatus, Reagents, and Safety Consid-

Sulfur (Potassium Sulfate) 0.001 to 0.600

Tantalum 0.001 to 10.00

erations for Chemical Analysis of Metals, Ores, and

Tellurium 0.001 to 0.35

Related Materials

Tin 0.002 to 0.35

E135 Terminology Relating to Analytical Chemistry for

Titanium 0.002 to 5.00

Tungsten 0.005 to 21.00

Metals, Ores, and Related Materials

E173 Practice for Conducting Interlaboratory Studies of

4

Methods for Chemical Analysis of Metals

1

These test methods are under the jurisdiction of ASTM Committee E01 on

Analytical Chemistry for Metals, Ores, and Related Materials and are the direct

responsibility of Subcommittee E01.01 on Iron, Steel, and Ferroalloys.

3

Current edition approved Nov. 1, 2008. Published November 2008. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1984. Last previous edition approved in 2003 as E1019 – 03. DOI: contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

10.1520/E1019-08. Standards volume information, refer to the standard’s Document Summary page on

2

Some of these test methods represent revisions of test methods covered by Test the ASTM website.

4

Methods E350, E351, E352, E353, and E354, which appear in the Annual Book of Withdrawn. The last approved version of this historical standard is referenced

ASTM Standards, Vol 03.05. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1019–08

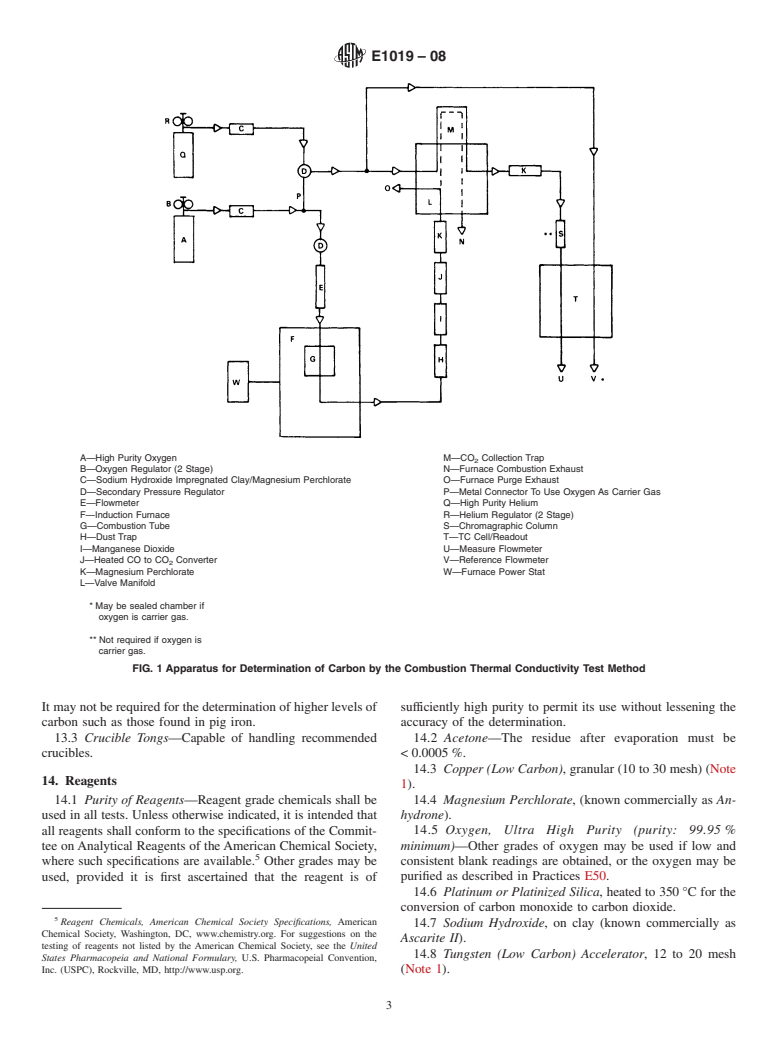

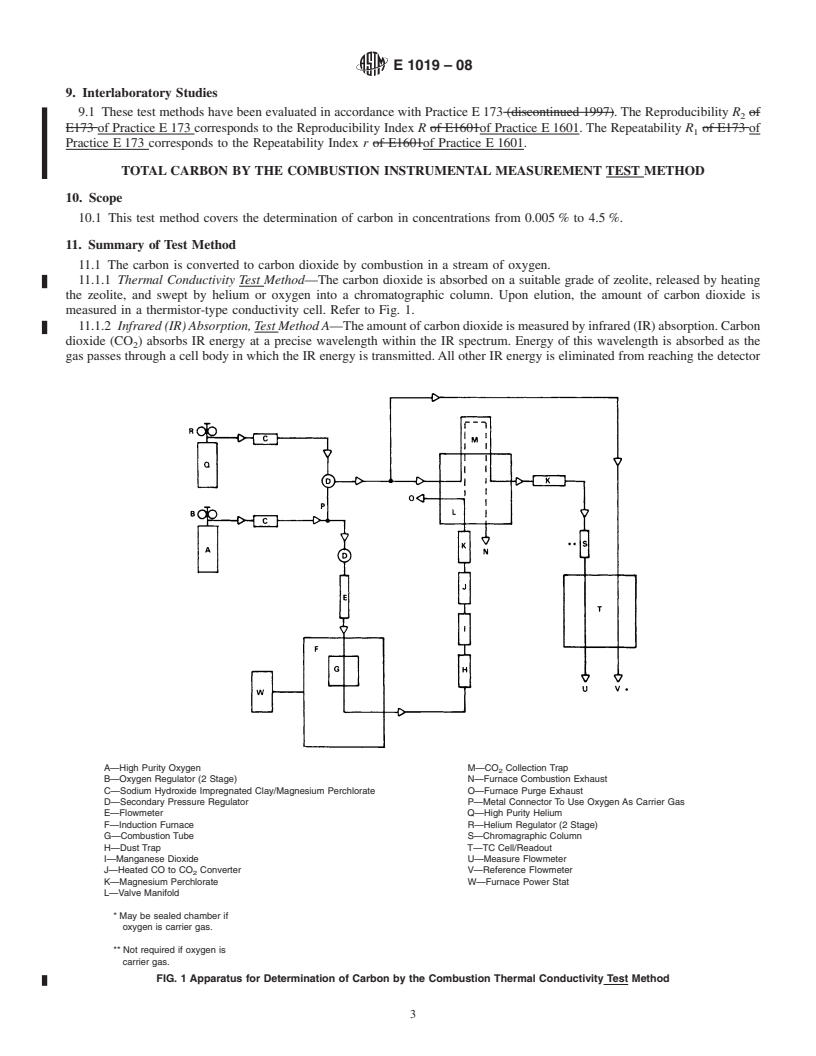

E1601 Practice for Conducting an Interlaboratory Study to chromatographic column. Upon elution, the amount of carbon

Evaluate the Performance of an Analytical Method dioxide is measured in a thermistor-type conductivity cell.

E1806 Practice for Sampling Steel and Iron for Determina- Refer to Fig. 1.

tion of Chemical Composition 11.1.2 Infrared (IR) Absorption, Test Method A—The

amount of carbon dioxide is measured by infrared (IR)

3. Terminology

absorption. Carbon dioxide (CO ) absorbs IR energy at a

2

precise wavelength within the IR spectrum. Energy of this

3.1 For definition of terms used in this tes

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E1019–03 Designation:E1019–08

Standard Test Methods for

Determination of Carbon, Sulfur, Nitrogen, and Oxygen in

Steel and in Iron, Nickel, and Cobalt AlloysDetermination of

Carbon, Sulfur, Nitrogen, and Oxygen in Steel, Iron, Nickel,

and Cobalt Alloys by Various Combustion and Fusion

1

Techniques

This standard is issued under the fixed designation E 1019; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

2

1.1 These test methods cover the determination of carbon, sulfur, nitrogen, and oxygen, in steel and in iron, nickel, and cobalt

alloys having chemical compositions within the following limits:

Element Concentration Range, %

Aluminum 0.001 to 18.00

Antimony 0.002 to 0.03

Arsenic 0.0005 to 0.10

Beryllium 0.001 to 0.05

Bismuth 0.001 to 0.50

Boron 0.0005 to 1.00

Cadmium 0.001 to 0.005

Calcium 0.001 to 0.05

Carbon 0.001 to 4.50

Cerium 0.005 to 0.05

Chromium 0.005 to 35.00

Cobalt 0.01 to 75.0

Columbium 0.002 to 6.00

Copper 0.005 to 10.00

Hydrogen 0.0001 to 0.0030

Iron 0.01 to 100.0

Lead 0.001 to 0.50

Magnesium 0.001 to 0.05

Manganese 0.01 to 20.0

Molybdenum 0.002 to 30.00

Nickel 0.005 to 84.00

Nitrogen 0.0005 to 0.50

Oxygen 0.0005 to 0.03

Phosphorus 0.001 to 0.90

Selenium 0.001 to 0.50

Silicon 0.001 to 6.00

Sulfur (Metal Reference 0.002 to 0.35

Materials)

Sulfur (Potassium Sulfate) 0.001 to 0.600

Tantalum 0.001 to 10.00

Tellurium 0.001 to 0.35

Tin 0.002 to 0.35

Titanium 0.002 to 5.00

Tungsten 0.005 to 21.00

Vanadium 0.005 to 5.50

Zinc 0.005 to 0.20

Zirconium 0.005 to 2.500

1.2 The test methods appear in the following order:

1

These test methods are under the jurisdiction ofASTM Committee E01 onAnalytical Chemistry for Metals, Ores, and Related Materials and are the direct responsibility

of Subcommittee E01.01 on Iron, Steel, and Ferroalloys.

Current edition approved Oct.Nov. 1, 2003.2008. Published November 2003.2008. Originally approved in 1984. Last previous edition approved in 20022003 as

E 1019 – 023.

2

Some of these test methods represent revisions of test methods covered byASTMTest Methods E 350, E 351, E 352, E 353, and E 354, which appear in the Annual Book

of ASTM Standards, Vol 03.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1019–08

Sections

Carbon, Total, by the Combustion–Instrumental Measurement

Method 10-20

Carbon, Total, by the Combustion–Instrumental Measurement

Test Method 10-20

Nitrogen by the Inert Gas Fusion–Thermal Conductivity Method 32-42

Nitrogen by the Inert Gas Fusion–Thermal Conductivity 32-42

Test Method

Oxygen by the Inert Gas Fusion Method 43-54

Oxygen by the Inert Gas Fusion Test Method 43-54

Sulfur by the Combustion-Infrared Absorption Method (Calibration

with Metal Reference Materials) 55-65

Sulfur by the Combustion-Infrared Absorption Test Method

(Calibration with Metal Reference Materials) 55-65

Sulfur by the Combustion–Infrared Absorption Method (Potassium

Sulfate Calibration) 21-31

Sulfur by the Combustion–Infrared Absorption Test Method

(Potassium Sulfate Calibration) 21-31

1.3

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific hazards statements are given in Section 6.

2. Referenced Documents

3

2.1 ASTM Standards:

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E 50Practices for Apparatus, Reagents, and Safety Precautions for Chemical Analysis of Metals

Practices for Apparatus, Reagents, and Safety Considerations for Chemical Analysis of Metals, Ores, and Related Materials

E 135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

4

E 173 Practice for Conducting Interlaboratory Studies of Methods for Chemical Analysis of Metals

E 1601 Practice for Conducting an Interlaboratory Study to Evaluate the Performance of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.