ASTM C143/C143M-05a

(Test Method)Standard Test Method for Slump of Hydraulic-Cement Concrete

Standard Test Method for Slump of Hydraulic-Cement Concrete

SIGNIFICANCE AND USE

This test method is intended to provide the user with a procedure to determine slump of plastic hydraulic-cement concretes.

Note 1—This test method was originally developed to provide a technique to monitor the consistency of unhardened concrete. Under laboratory conditions, with strict control of all concrete materials, the slump is generally found to increase proportionally with the water content of a given concrete mixture, and thus to be inversely related to concrete strength. Under field conditions, however, such a strength relationship is not clearly and consistently shown. Care should therefore be taken in relating slump results obtained under field conditions to strength.

This test method is considered applicable to plastic concrete having coarse aggregate up to 1½ in. [37.5 mm] in size. If the coarse aggregate is larger than 1½ in. [37.5 mm] in size, the test method is applicable when it is performed on the fraction of concrete passing a 1½-in. [37.5-mm] sieve, with the larger aggregate being removed in accordance with the section titled “Additional Procedure for Large Maximum Size Aggregate Concrete” in Practice C 172.

This test method is not considered applicable to non-plastic and non-cohesive concrete.

Note 2—Concretes having slumps less than ½ in. [15 mm] may not be adequately plastic and concretes having slumps greater than about 9 in. [230 mm] may not be adequately cohesive for this test to have significance. Caution should be exercised in interpreting such results.

SCOPE

1.1 This test method covers determination of slump of hydraulic-cement concrete, both in the laboratory and in the field.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Warning-Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C143/C143M–05a

Standard Test Method for

1

Slump of Hydraulic-Cement Concrete

This standard is issued under the fixed designation C 143/C 143M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* The vertical distance between the original and displaced

position of the center of the top surface of the concrete is

1.1 This test method covers determination of slump of

measured and reported as the slump of the concrete.

hydraulic-cement concrete, both in the laboratory and in the

field.

4. Significance and Use

1.2 The values stated in either inch-pound units or SI units

4.1 This test method is intended to provide the user with a

are to be regarded separately as standard. Within the text, the

procedure to determine slump of plastic hydraulic-cement

SI units are shown in brackets. The values stated in each

concretes.

system are not exact equivalents; therefore, each system shall

be used independently of the other. Combining values from the

NOTE 1—This test method was originally developed to provide a

two systems may result in nonconformance with the standard. technique to monitor the consistency of unhardened concrete. Under

laboratory conditions, with strict control of all concrete materials, the

1.3 The text of this standard references notes and footnotes

slump is generally found to increase proportionally with the water content

which provide explanatory material. These notes and footnotes

of a given concrete mixture, and thus to be inversely related to concrete

(excluding those in tables and figures) shall not be considered

strength. Under field conditions, however, such a strength relationship is

as requirements of the standard.

not clearly and consistently shown. Care should therefore be taken in

1.4 This standard does not purport to address all of the

relating slump results obtained under field conditions to strength.

safety concerns, if any, associated with its use. It is the

4.2 This test method is considered applicable to plastic

responsibility of the user of this standard to establish appro-

1

concrete having coarse aggregate up to 1 ⁄2 in. [37.5 mm] in

priate safety and health practices and determine the applica-

1

size. If the coarse aggregate is larger than 1 ⁄2 in. [37.5 mm] in

bility of regulatory limitations prior to use. (Warning—Fresh

size, the test method is applicable when it is performed on the

hydraulic cementitious mixtures are caustic and may cause

1

fraction of concrete passing a 1 ⁄2-in. [37.5-mm] sieve, with the

2

chemical burns to skin and tissue upon prolonged exposure. )

larger aggregate being removed in accordance with the section

titled “Additional Procedure for Large Maximum Size Aggre-

2. Referenced Documents

gate Concrete” in Practice C 172.

3

2.1 ASTM Standards:

4.3 This test method is not considered applicable to non-

C 172 Practice for Sampling Freshly Mixed Concrete

plastic and non-cohesive concrete.

C 670 Practice for Preparing Precision and Bias Statements

1

for Test Methods for Construction Materials NOTE 2—Concretes having slumps less than ⁄2 in. [15 mm] may not be

adequately plastic and concretes having slumps greater than about 9 in.

3. Summary of Test Method

[230 mm] may not be adequately cohesive for this test to have signifi-

cance. Caution should be exercised in interpreting such results.

3.1 A sample of freshly mixed concrete is placed and

compacted by rodding in a mold shaped as the frustum of a

5. Apparatus

cone. The mold is raised, and the concrete allowed to subside.

5.1 Mold—The test specimen shall be formed in a mold

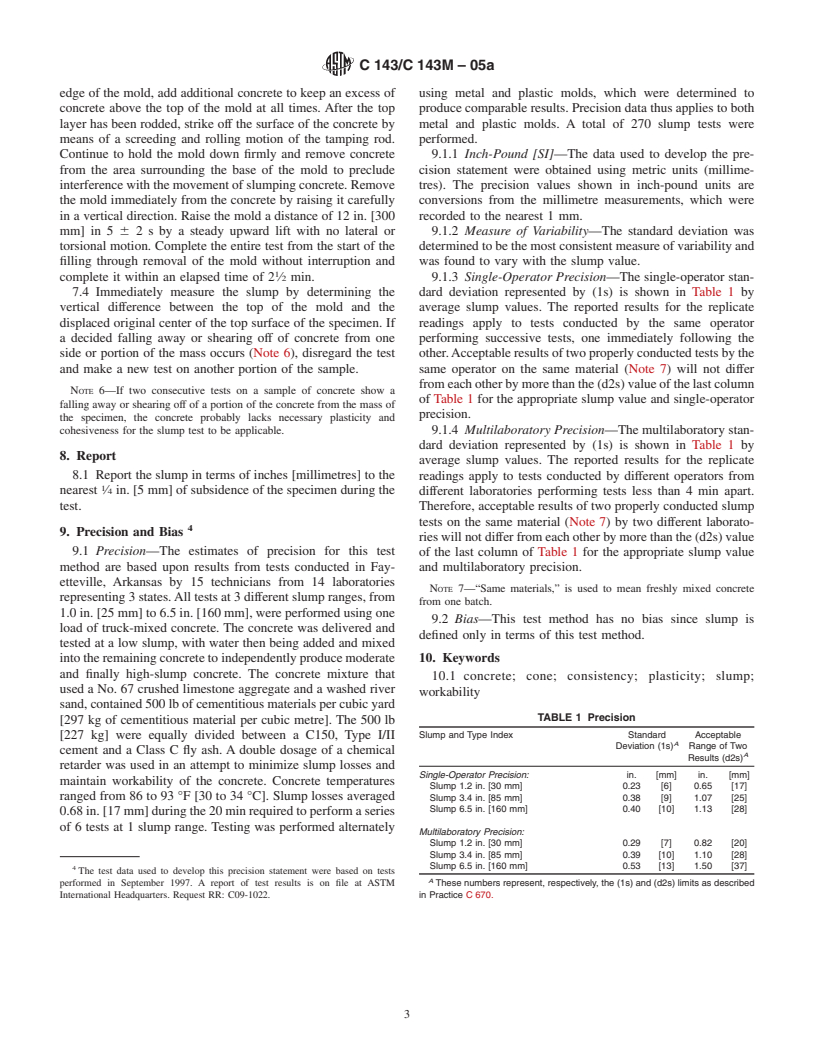

made of metal not readily attacked by the cement paste. The

1

metal shall not be thinner than 0.060 in. [1.5 mm] and if

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

formed by the spinning process, there shall be no point on the

C09.60 on Fresh Concrete Testing.

mold at which the thickness is less than 0.045 in. [1.15 mm].

Current edition approved Nov. 1, 2005. Published November 2005. Originally

The mold shall be in the form of the lateral surface of the

approved in 1922. Last previous edition approved in 2005 as C 143/C 143 – 05.

2

frustum of a cone with the base 8 in. [200 mm] in diameter, the

Section on Safety Precautions, Manual of Aggregate and Concrete Testing,

Annual Book of ASTM Standards, Vol. 04.02.

top 4 in. [100 mm] in diameter, and the height 12 in. [300 mm].

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.