ASTM D4530-15(2020)

(Test Method)Standard Test Method for Determination of Carbon Residue (Micro Method)

Standard Test Method for Determination of Carbon Residue (Micro Method)

SIGNIFICANCE AND USE

5.1 The carbon residue value of the various petroleum materials serves as an approximation of the tendency of the material to form carbonaceous type deposits under degradation conditions similar to those used in the test method, and can be useful as a guide in manufacture of certain stocks. However, care needs to be exercised in interpreting the results.

5.2 This test method offers advantages of better control of test conditions, smaller samples, and less operator attention compared to Test Method D189, to which it is equivalent.

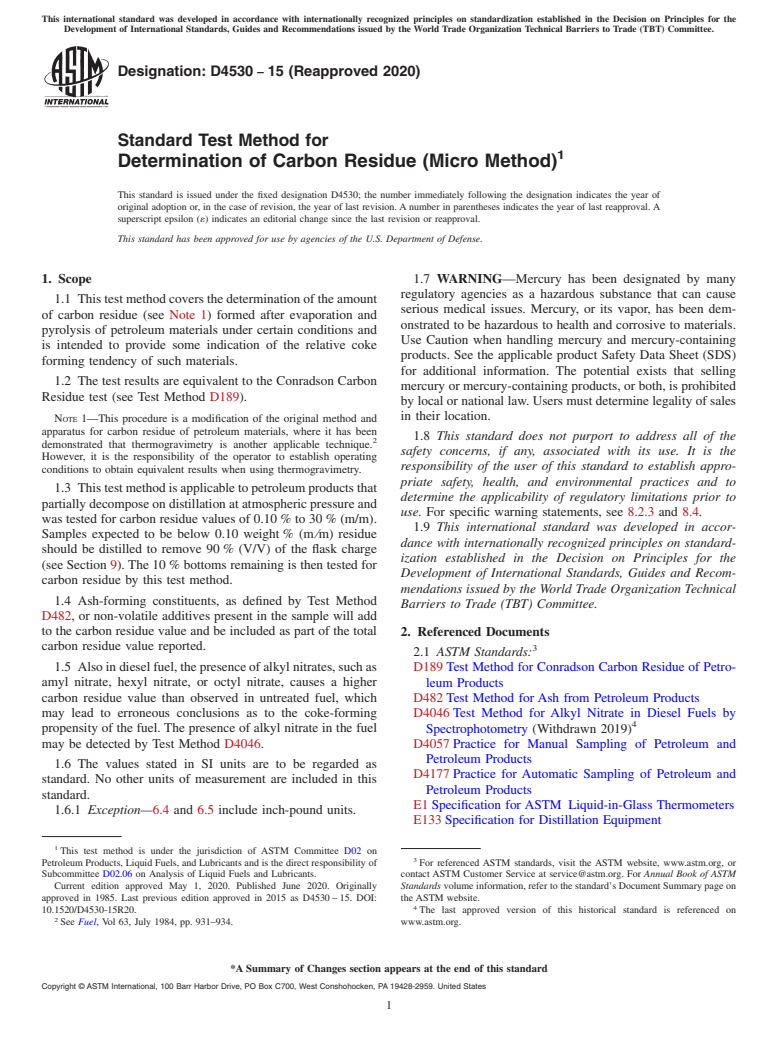

5.3 Up to twelve samples may be run simultaneously, including a control sample when the vial holder shown in Fig. 1 is used exclusively for sample analysis.

FIG. 1 Sample Vial Holder and Vial

SCOPE

1.1 This test method covers the determination of the amount of carbon residue (see Note 1) formed after evaporation and pyrolysis of petroleum materials under certain conditions and is intended to provide some indication of the relative coke forming tendency of such materials.

1.2 The test results are equivalent to the Conradson Carbon Residue test (see Test Method D189).

Note 1: This procedure is a modification of the original method and apparatus for carbon residue of petroleum materials, where it has been demonstrated that thermogravimetry is another applicable technique.2 However, it is the responsibility of the operator to establish operating conditions to obtain equivalent results when using thermogravimetry.

1.3 This test method is applicable to petroleum products that partially decompose on distillation at atmospheric pressure and was tested for carbon residue values of 0.10 % to 30 % (m/m). Samples expected to be below 0.10 weight % (m/m) residue should be distilled to remove 90 % (V/V) of the flask charge (see Section 9). The 10 % bottoms remaining is then tested for carbon residue by this test method.

1.4 Ash-forming constituents, as defined by Test Method D482, or non-volatile additives present in the sample will add to the carbon residue value and be included as part of the total carbon residue value reported.

1.5 Also in diesel fuel, the presence of alkyl nitrates, such as amyl nitrate, hexyl nitrate, or octyl nitrate, causes a higher carbon residue value than observed in untreated fuel, which may lead to erroneous conclusions as to the coke-forming propensity of the fuel. The presence of alkyl nitrate in the fuel may be detected by Test Method D4046.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6.1 Exception—6.4 and 6.5 include inch-pound units.

1.7 WARNING—Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Use Caution when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for additional information. The potential exists that selling mercury or mercury-containing products, or both, is prohibited by local or national law. Users must determine legality of sales in their location.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and to determine the applicability of regulatory limitations prior to use. For specific warning statements, see 8.2.3 and 8.4.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4530 − 15 (Reapproved 2020)

Standard Test Method for

Determination of Carbon Residue (Micro Method)

This standard is issued under the fixed designation D4530; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.7 WARNING—Mercury has been designated by many

regulatory agencies as a hazardous substance that can cause

1.1 Thistestmethodcoversthedeterminationoftheamount

serious medical issues. Mercury, or its vapor, has been dem-

of carbon residue (see Note 1) formed after evaporation and

onstrated to be hazardous to health and corrosive to materials.

pyrolysis of petroleum materials under certain conditions and

Use Caution when handling mercury and mercury-containing

is intended to provide some indication of the relative coke

products. See the applicable product Safety Data Sheet (SDS)

forming tendency of such materials.

for additional information. The potential exists that selling

1.2 The test results are equivalent to the Conradson Carbon

mercury or mercury-containing products, or both, is prohibited

Residue test (see Test Method D189).

by local or national law. Users must determine legality of sales

in their location.

NOTE 1—This procedure is a modification of the original method and

apparatus for carbon residue of petroleum materials, where it has been

1.8 This standard does not purport to address all of the

demonstrated that thermogravimetry is another applicable technique.

safety concerns, if any, associated with its use. It is the

However, it is the responsibility of the operator to establish operating

responsibility of the user of this standard to establish appro-

conditions to obtain equivalent results when using thermogravimetry.

priate safety, health, and environmental practices and to

1.3 Thistestmethodisapplicabletopetroleumproductsthat

determine the applicability of regulatory limitations prior to

partially decompose on distillation at atmospheric pressure and

use. For specific warning statements, see 8.2.3 and 8.4.

was tested for carbon residue values of 0.10 % to 30 % (m/m).

1.9 This international standard was developed in accor-

Samples expected to be below 0.10 weight % (m⁄m) residue

dance with internationally recognized principles on standard-

should be distilled to remove 90 % (V/V) of the flask charge

ization established in the Decision on Principles for the

(see Section 9). The 10 % bottoms remaining is then tested for

Development of International Standards, Guides and Recom-

carbon residue by this test method.

mendations issued by the World Trade Organization Technical

1.4 Ash-forming constituents, as defined by Test Method

Barriers to Trade (TBT) Committee.

D482, or non-volatile additives present in the sample will add

to the carbon residue value and be included as part of the total

2. Referenced Documents

carbon residue value reported. 3

2.1 ASTM Standards:

1.5 Alsoindieselfuel,thepresenceofalkylnitrates,suchas

D189 Test Method for Conradson Carbon Residue of Petro-

amyl nitrate, hexyl nitrate, or octyl nitrate, causes a higher leum Products

carbon residue value than observed in untreated fuel, which

D482 Test Method for Ash from Petroleum Products

may lead to erroneous conclusions as to the coke-forming D4046 Test Method for Alkyl Nitrate in Diesel Fuels by

propensity of the fuel. The presence of alkyl nitrate in the fuel

Spectrophotometry (Withdrawn 2019)

may be detected by Test Method D4046. D4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

1.6 The values stated in SI units are to be regarded as

D4177 Practice for Automatic Sampling of Petroleum and

standard. No other units of measurement are included in this

Petroleum Products

standard.

E1 Specification for ASTM Liquid-in-Glass Thermometers

1.6.1 Exception—6.4 and 6.5 include inch-pound units.

E133 Specification for Distillation Equipment

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Subcommittee D02.06 on Analysis of Liquid Fuels and Lubricants. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved May 1, 2020. Published June 2020. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1985. Last previous edition approved in 2015 as D4530 – 15. DOI: the ASTM website.

10.1520/D4530-15R20. The last approved version of this historical standard is referenced on

See Fuel, Vol 63, July 1984, pp. 931–934. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4530 − 15 (2020)

2.2 Energy Institute Standard: useful as a guide in manufacture of certain stocks. However,

Specification for IP Standard Thermometers care needs to be exercised in interpreting the results.

5.2 This test method offers advantages of better control of

3. Terminology

test conditions, smaller samples, and less operator attention

3.1 Definitions:

compared to Test Method D189, to which it is equivalent.

3.1.1 carbon residue, n—the residue formed by evaporation

5.3 Up to twelve samples may be run simultaneously,

and thermal degradation of a carbon containing material.

including a control sample when the vial holder shown in Fig.

3.1.1.1 Discussion—Theresidueisnotcomposedentirelyof

1 is used exclusively for sample analysis.

carbon but is a coke that can be further changed by carbon

pyrolysis.

6. Apparatus

6.1 Glass Sample Vials, 2 mL capacity, 12 mm outside

4. Summary of Test Method

diameter by approximately 35 mm high.

4.1 A weighed quantity of sample is placed in a glass vial

6.2 Larger 4-dram Glass Sample Vials, 15 mL capacity

and heated to 500 °C under an inert (nitrogen) atmosphere in a

(20.5 mmto21 mmoutsidediameterby70 mm 61 mmhigh),

controlled manner for a specific time. The sample undergoes

may be used for samples that are expected to yield residues

coking reactions, and volatiles formed are swept away by the

<0.10 % (m/m) so that a more appreciable mass difference can

nitrogen. The carbonaceous-type residue remaining is reported

be determined. It should be noted the precision statements for

as a percent of the original sample as “carbon residue (micro).”

the test method were determined using the 2 mLcapacity vials

4.1.1 When the test result is expected to be below 0.10 %

only(withsampleresiduesbetween0.3 %and26%(m/m)and

(m/m), the sample can be distilled to produce a 10 % (V/V)

that the precision associated with using the larger sample vials

bottoms, prior to performing the test.

has not been determined.

5. Significance and Use

6.3 Eyedropper, Syringe, or Small Rod, for sample transfer.

5.1 The carbon residue value of the various petroleum

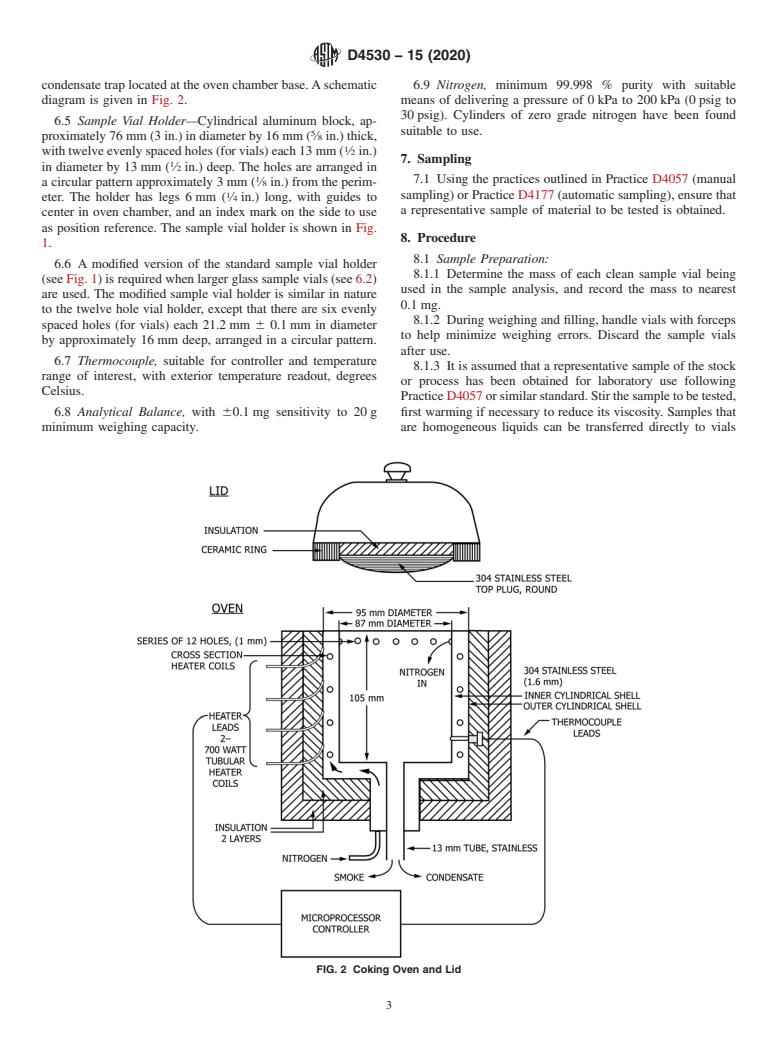

6.4 Coking Oven with circular heating chamber approxi-

materials serves as an approximation of the tendency of the

mately85 mm(3 ⁄8 in.)indiameterby100 mm(4 in.)deep,for

material to form carbonaceous type deposits under degradation

top loading, with heating capability from 10 °C⁄min to

conditions similar to those used in the test method, and can be 1

40 °C⁄min rate to 500 °C, with exhaust port 13 mm ( ⁄2 in.)

inside diameter for nitrogen purge of oven chamber (inlet near

top, exhaust at bottom center) with thermocouple sensor

located in oven chamber next to but not touching sample vials,

“Methods for Analysis and Testing,” Institute of Petroleum Standard Methods

for Petroleum and Its Products, Part I, Vol 2. Available from Energy Institute, 61

with lid capable of sealing out air, and with removable

New Cavendish St., London, WIM 8AR, UK.

FIG. 1 Sample Vial Holder and Vial

D4530 − 15 (2020)

condensate trap located at the oven chamber base.Aschematic 6.9 Nitrogen, minimum 99.998 % purity with suitable

diagram is given in Fig. 2. means of delivering a pressure of 0 kPa to 200 kPa (0 psig to

30 psig). Cylinders of zero grade nitrogen have been found

6.5 Sample Vial Holder—Cylindrical aluminum block, ap-

suitable to use.

proximately 76 mm (3 in.) in diameter by 16 mm ( ⁄8 in.) thick,

withtwelveevenlyspacedholes(forvials)each13 mm( ⁄2 in.)

7. Sampling

in diameter by 13 mm ( ⁄2 in.) deep. The holes are arranged in

1 7.1 Using the practices outlined in Practice D4057 (manual

a circular pattern approximately 3 mm ( ⁄8 in.) from the perim-

sampling) or Practice D4177 (automatic sampling), ensure that

eter. The holder has legs 6 mm ( ⁄4 in.) long, with guides to

a representative sample of material to be tested is obtained.

center in oven chamber, and an index mark on the side to use

as position reference. The sample vial holder is shown in Fig.

8. Procedure

1.

8.1 Sample Preparation:

6.6 A modified version of the standard sample vial holder

8.1.1 Determine the mass of each clean sample vial being

(see Fig. 1) is required when larger glass sample vials (see 6.2)

used in the sample analysis, and record the mass to nearest

are used. The modified sample vial holder is similar in nature

0.1 mg.

to the twelve hole vial holder, except that there are six evenly

8.1.2 During weighing and filling, handle vials with forceps

spaced holes (for vials) each 21.2 mm 6 0.1 mm in diameter

to help minimize weighing errors. Discard the sample vials

by approximately 16 mm deep, arranged in a circular pattern.

after use.

6.7 Thermocouple, suitable for controller and temperature

8.1.3 It is assumed that a representative sample of the stock

range of interest, with exterior temperature readout, degrees

or process has been obtained for laboratory use following

Celsius.

PracticeD4057orsimilarstandard.Stirthesampletobetested,

6.8 Analytical Balance, with 60.1 mg sensitivity to 20 g first warming if necessary to reduce its viscosity. Samples that

minimum weighing capacity. are homogeneous liquids can be transferred directly to vials

FIG. 2 Coking Oven and Lid

D4530 − 15 (2020)

usingarod,syringe,oreyedropper.Solidmaterialsmayalsobe 8.3 Final Weighing—Transfer sample vials (maintained in

heated; or frozen with liquid nitrogen, and then shattered to place in the vial holder) to desiccator and allow vials to cool to

provide manageable pieces. roomtemperature.Weighthecooledvialstothenearest0.1 mg

8.1.4 Transfer an appropriate mass of the sample (see Table and record. Handle the vials with forceps. Discard the used

1) into a tared-sample vial, reweigh to nearest 0.1 mg, and glass sample vials.

record. Place the loaded sample vials into vial holder (up to

8.4 Occasionally examine the condensate trap at the bottom

twelve), noting position of each sample with respect to index

of the oven chamber; empty if necessary and replace.

mark.

(Warning—The condensate trap residue may have some

carcinogenic materials present. Avoid contact with the trap

NOTE 2—A control sample can be included in each batch of samples

being tested. This control sample should be a typical sample that has been

residue; dispose of it in accordance with local laboratory

testedatleast20timesinthesameequipmentinordertodefineanaverage

practice.)

percent carbon residue and standard deviation. Results for each batch are

deemed acceptable when results for the control sample fall within the

9. Procedure for Carbon Residue on 10 % (V/V)

average percent carbon residue 6 three standard deviations. Control

results that are outside these limits indicate problems with the procedure Distillation Residue

or the equipment.

9.1 This procedure is applicable to light distillate materials,

8.2 Processing of Samples:

such as ASTM No. 1 and No. 2 fuel oil or materials expected

8.2.1 Withtheovenatlessthan100 °C,placethevialholder

to have less than 0.1 % (m/m) carbon residue.

into the oven chamber and secure lid. Purge with nitrogen for

9.2 A distillation analysis using either a 100 mL or 200 mL

at least 10 min at 600 mL⁄min. Then decrease the purge to

starting volume is required in order to collect a sufficient

150 mL⁄min and heat the oven slowly to 500 °C at 10 °C⁄min

amount of the 10 % (V/V) residue needed in this analysis. For

to 15 °C⁄min.

a 100 mL distillation, assemble the distillation apparatus de-

8.2.2 If the sample foams or spatters, causing loss of

scribed in Specification E133, using flask B (125 mL bulb

sample, discard and repeat the test.

volume), flask support board with 50 mm diameter opening,

NOTE 3—Spattering may be due to water that can be removed by prior

and graduated cylinder B (100 mL capacity). For a 200 mL

gentle heating in a vacuum, followed by a nitrogen sweep. Alternatively,

distillation, assemble the distillation apparatus described in

a smaller sample size can be used.

Specification E133, using flask D (250 mLbulb volume), flask

8.2.3 Hold oven at 500 °C 6 2 °C for 15 min. Then shut off

support board with 50 mm diameter opening, and graduated

furnace power and allow oven to cool freely while under

cylinder C (200 mL capacity). A thermometer is not required,

nitrogen purge of 600 mL⁄min. When oven temperature is less

but the use of theASTM High Distillation Thermometer 8F or

than 250 °C, remove the vial holder for further cooling in

8C, as prescribed in Specification E1, or the IP High Distilla-

desiccator. After the samples are removed from the oven, the

tion Thermometer 6C, as prescribed in the Specification for IP

nitrogen purge may be shut off. (Warning—Do not open oven

Thermometers, is recommended.

to air at any time during the heating cycle. The introduction of

9.3 Depending upon which distillation flask is used, place

air (oxygen) will likely cause the sample to ignite and spoil the

either 100 mL or 200 mL of sample (as measured at ambient

test. (Because of the oven design and materials, such an

temperature) into a distillation flask that is held at a tempera-

ignition is normally not a hazard to the operator.) Open the

ture between 13 °C and ambient. Maintain the condenser bath

ovenonlyafteroventemperaturefallsbelow250 °Cduringthe

temperature between 0 °C and 60 °C so as to provide a

cooling step. Maintain nitrogen flow until after the vial holder

sufficient temperature differential for sample condensation,

has been removed

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.