ASTM F1883-98

(Practice)Standard Practice for Selection of Wire and Cable Size in AWG or Metric Units

Standard Practice for Selection of Wire and Cable Size in AWG or Metric Units

SCOPE

1.1 This practice is intended as a guide to shipbuilders, shipowners, and design agents for use in the selection of conductor size for single conductor or multiple conductor cable sizes either in American Wire Gauge (AWG) or metric designations for commercial ship design and construction.

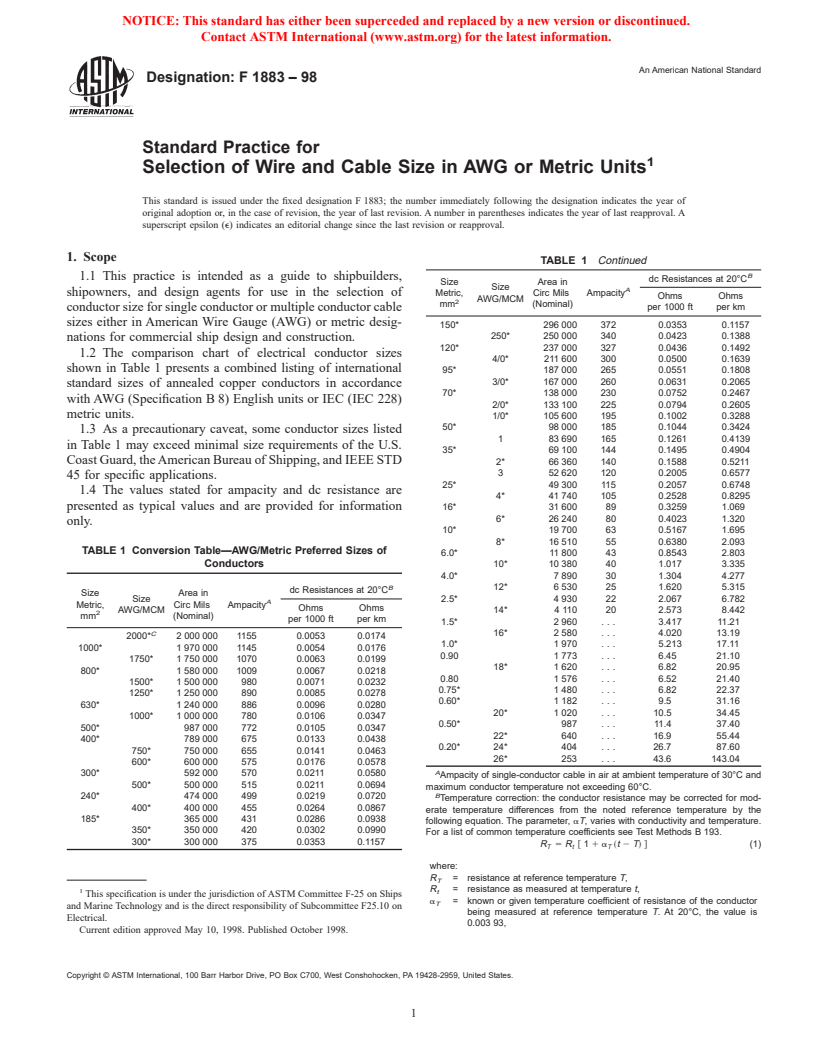

1.2 The comparison chart of electrical conductor sizes shown in Table 1 presents a combined listing of international standard sizes of annealed copper conductors in accordance with AWG (Specification B 8) English units or IEC (IEC 228) metric units.

1.3 As a precautionary caveat, some conductor sizes listed in Table 1 may exceed minimal size requirements of the U.S. Coast Guard, the American Bureau of Shipping, and IEEE STD 45 for specific applications

1.4 The values stated for ampacity and dc resistance are presented as typical values and are provided for information only.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: F 1883 – 98

Standard Practice for

Selection of Wire and Cable Size in AWG or Metric Units

This standard is issued under the fixed designation F 1883; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

TABLE 1 Continued

B

1.1 This practice is intended as a guide to shipbuilders,

dc Resistances at 20°C

Size Area in

Size

A

shipowners, and design agents for use in the selection of

Metric, Circ Mils Ampacity

Ohms Ohms

AWG/MCM

mm (Nominal)

per 1000 ft per km

conductor size for single conductor or multiple conductor cable

sizes either in American Wire Gauge (AWG) or metric desig-

150* 296 000 372 0.0353 0.1157

250* 250 000 340 0.0423 0.1388

nations for commercial ship design and construction.

120* 237 000 327 0.0436 0.1492

1.2 The comparison chart of electrical conductor sizes

4/0* 211 600 300 0.0500 0.1639

shown in Table 1 presents a combined listing of international

95* 187 000 265 0.0551 0.1808

3/0* 167 000 260 0.0631 0.2065

standard sizes of annealed copper conductors in accordance

70* 138 000 230 0.0752 0.2467

with AWG (Specification B 8) English units or IEC (IEC 228)

2/0* 133 100 225 0.0794 0.2605

metric units.

1/0* 105 600 195 0.1002 0.3288

50* 98 000 185 0.1044 0.3424

1.3 As a precautionary caveat, some conductor sizes listed

1 83 690 165 0.1261 0.4139

in Table 1 may exceed minimal size requirements of the U.S.

35* 69 100 144 0.1495 0.4904

Coast Guard, the American Bureau of Shipping, and IEEE STD

2* 66 360 140 0.1588 0.5211

3 52 620 120 0.2005 0.6577

45 for specific applications.

25* 49 300 115 0.2057 0.6748

1.4 The values stated for ampacity and dc resistance are

4* 41 740 105 0.2528 0.8295

presented as typical values and are provided for information 16* 31 600 89 0.3259 1.069

6* 26 240 80 0.4023 1.320

only.

10* 19 700 63 0.5167 1.695

8* 16 510 55 0.6380 2.093

TABLE 1 Conversion Table—AWG/Metric Preferred Sizes of

6.0* 11 800 43 0.8543 2.803

Conductors 10* 10 380 40 1.017 3.335

4.0* 7 890 30 1.304 4.277

B 12* 6 530 25 1.620 5.315

dc Resistances at 20°C

Size Area in

Size 2.5* 4 930 22 2.067 6.782

A

Metric, Circ Mils Ampacity

Ohms Ohms

AWG/MCM 14* 4 110 20 2.573 8.442

mm (Nominal)

per 1000 ft per km

1.5* 2 960 . . . 3.417 11.21

C 16* 2 580 . . . 4.020 13.19

2000* 2 000 000 1155 0.0053 0.0174

1.0* 1 970 . . . 5.213 17.11

1000* 1 970 000 1145 0.0054 0.0176

0.90 1 773 . . . 6.45 21.10

1750* 1 750 000 1070 0.0063 0.0199

18* 1 620 . . . 6.82 20.95

800* 1 580 000 1009 0.0067 0.0218

0.80 1 576 . . . 6.52 21.40

1500* 1 500 000 980 0.0071 0.0232

0.75* 1 480 . . . 6.82 22.37

1250* 1 250 000 890 0.0085 0.0278

0.60* 1 182 . . . 9.5 31.16

630* 1 240 000 886 0.0096 0.0280

20* 1 020 . . . 10.5 34.45

1000* 1 000 000 780 0.0106 0.0347

0.50* 987 . . . 11.4 37.40

500* 987 000 772 0.0105 0.0347

22* 640 . . . 16.9 55.44

400* 789 000 675 0.0133 0.0438

0.20* 24* 404 . . . 26.7 87.60

750* 750 000 655 0.0141 0.0463

26* 253 . . . 43.6 143.04

600* 600 000 575 0.0176 0.0578

A

300* 592 000 570 0.0211 0.0580

Ampacity of single-conductor cable in air at ambient temperature of 30°C and

500* 500 000 515 0.0211 0.0694

maximum conductor temperature not exceeding 60°C.

B

240* 474 000 499 0.0219 0.0720

Temperature correction: the conductor resistance may be corrected for mod-

400* 400 000 455 0.0264 0.0867

erate temperature differences from the noted reference temperature by the

185* 365 000 431 0.0286 0.0938

following equation. The parameter, aT, varies with conductivity and temperature.

350* 350 000 420 0.0302 0.0990

For a list of common temperature coefficients see Test Methods B 193.

300* 300 000 375 0.0353 0.1157

R 5 R @ 11a ~t 2 T! # (1)

T t T

where:

R = resistance at reference temperature T,

T

1 R = resistance as measured at temperature t,

t

This specification is under the jurisdiction of ASTM Committee F-25 on Ships

a = known or given temperature coefficient of resistance of the conductor

T

and Marine Technology and is the direct responsibility of Subcommittee F25.10 on

being measured at reference temperature T. At 20°C, the value is

Electrical.

0.003 93,

Current edition approved May 10, 1998. Published October 1998.

Co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.