ASTM D5656-01

(Test Method)Standard Test Method for Thick-Adherend Metal Lap-Shear Joints for Determination of the Stress-Strain Behavior of Adhesives in Shear by Tension Loading

Standard Test Method for Thick-Adherend Metal Lap-Shear Joints for Determination of the Stress-Strain Behavior of Adhesives in Shear by Tension Loading

SCOPE

1.1 This test method covers the preparation and testing of thick-adherend lap-shear samples for the determination of the stress-strain behavior of adhesives.

1.2 This test method covers data reduction and analysis of stress-strain curves obtained using thick-adherend lap-shear samples.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound units in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 7.3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5656 – 01

Standard Test Method for

Thick-Adherend Metal Lap-Shear Joints for Determination of

the Stress-Strain Behavior of Adhesives in Shear by

1

Tension Loading

This standard is issued under the fixed designation D 5656; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.2 panel—two plates of a rigid material having the same

dimensions that are adhesively bonded together on one face

1.1 This test method covers the preparation and testing of

such that the thickness of the panel is approximately twice the

thick-adherend lap-shear samples for the determination of the

thickness of each individual plate.

stress-strain behavior of adhesives.

1.2 This test method covers data reduction and analysis of

4. Summary of Test Method

stress-strain curves obtained using thick-adherend lap-shear

4.1 This test method consists of testing thick-adherend

samples.

lap-shear samples whereby a tensile load is applied to the

1.3 The values stated in SI units are to be regarded as the

sample but the adhesive is placed in shear. Since the adherends

standard. The inch-pound units in parentheses are for informa-

used are thick and rigid, peel forces are minimized and the

tion only.

shear stress-strain properties of the adhesive are obtained.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

NOTE 1—The peel forces generated during testing are a function of the

responsibility of the user of this standard to establish appro- bending deformation in the adherends. Greater adherend stiffness results

in less bending and smaller peel forces.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific precau-

5. Significance and Use

tionary statements are given in 7.3.

5.1 This test method can be used to determine the stress-

2. Referenced Documents

strain properties of an adhesive in shear and to establish the

proportional-limit of the stress-stain relationship. This data

2.1 ASTM Standards:

2

may be useful for the design and analysis of adhesively bonded

D 907 Terminology of Adhesives

joints.

D 2651 Guide for Preparation of Metal Surfaces for Adhe-

2

5.2 This test method is not intended to determine adhesion

sive Bonding

3

characteristics of an adhesive to a particular substrate; rather

E 4 Practices for Force Verification of Testing Machines

this test method is intended to characterize the adhesive

3. Terminology

properties that may be relevant for design considerations.

5.3 This test method has been developed and applied using

3.1 Definitions:

bonded aluminum adherends. At this time no assumptions

3.1.1 Many terms in this test method are defined in Termi-

regarding the validity of this test method with non-aluminum

nology D 907.

adherends can be made.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 knee—inflection point on a load-deflection curve; the

6. Apparatus

point at which plastic yielding of the adhesive begins to

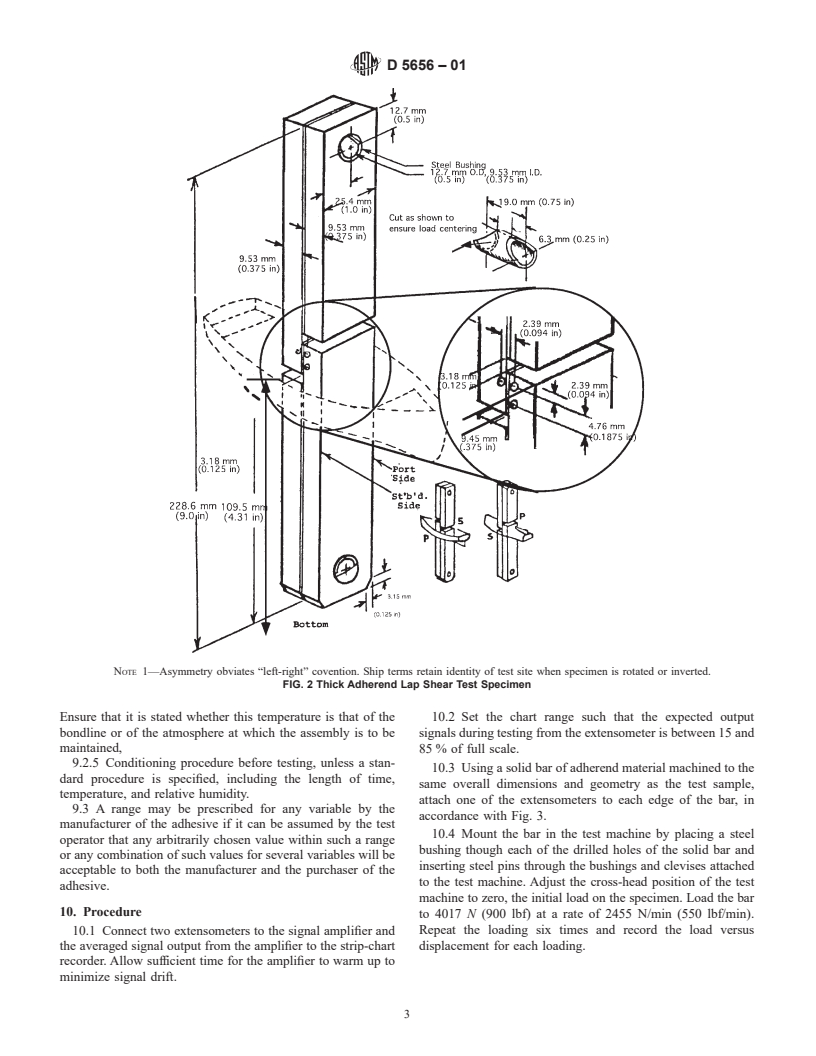

6.1 Testing machine conforming to the requirements of

dominate the deformation response of the load-deflection

Practices E 4. Select the testing machine so that the breaking

curve.

load of the specimens falls between 15 and 85 % of the

full-scale capacity. Ensure that the machine is capable of

1 maintaining a rate of loading of 2455 N (550 lbf)/min, or, if the

This test method is under the jurisdiction of ASTM Committee D14 on

rate is dependent on cross-head motion, set the machine to

Adhesives and is the direct responsibility of Subcommittee D14.80 on Metal

Bonding Adhesives.

approach this rate of loading. Use a suitable pair of self-

Current edition approved Oct. 10, 2001. Published December 2001. Originally

aligning grips to hold the specimen. Ensure that the grips and

published as D 5656 - 95. Last previous edition D 5656 - 95(2000).

2 attachments are so constructed that they will move into

Annual Book of ASTM Standards, Vol 15.06.

3

Annual Book of ASTM Standards, Vol 03.01. alignment with the test specimen as soon as the load is applied,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5656–01

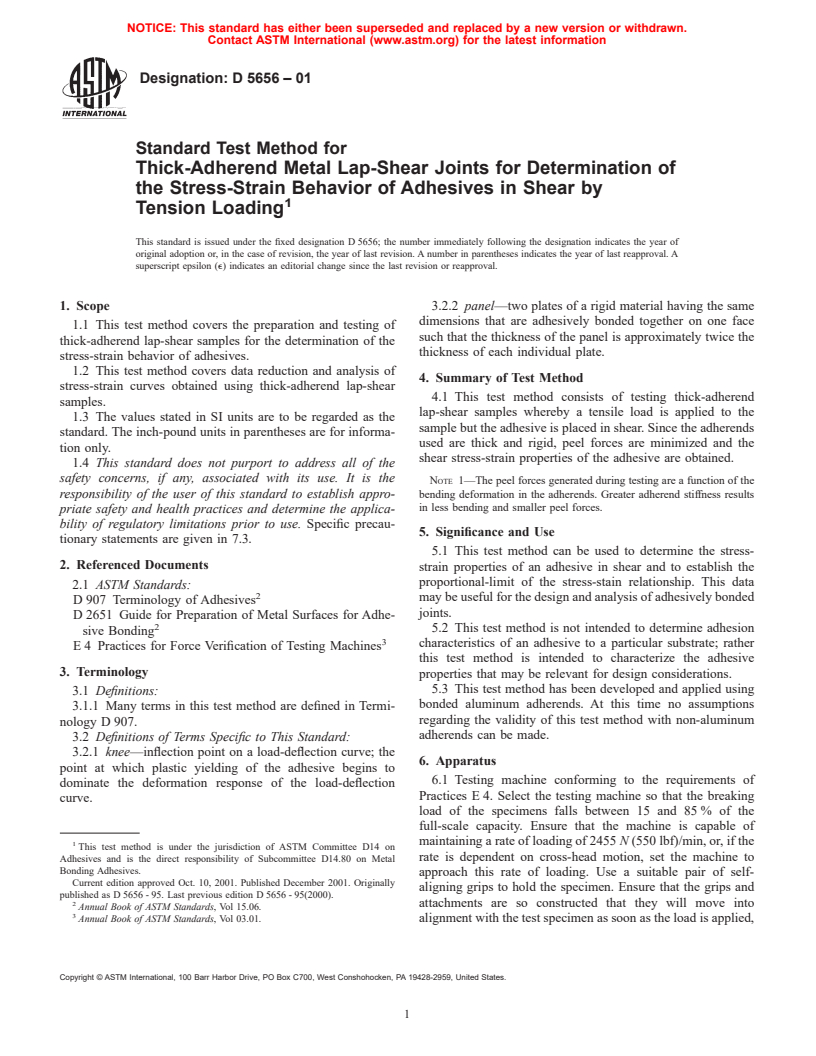

so that the long axis of the test specimen will coincide with the 7.3 After cure, saw-cut 25.4-mm (1.0-in.) wide test samples

direction of the applied pull through the center line of the grip from the bonded panel, or if machined edges are preferred

assembly. saw-cut the samples to 27.5-mm widths and machine the saw

cut edges to a sample width

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.