ASTM G74-01

(Test Method)Standard Test Method for Ignition Sensitivity of Materials to Gaseous Fluid Impact

Standard Test Method for Ignition Sensitivity of Materials to Gaseous Fluid Impact

SIGNIFICANCE AND USE

This test evaluates the relative sensitivity of materials to dynamic pressure impacts by various gaseous fluid media (may include mixtures of gases).

Any change or variations in test specimen configurations, thickness, preparation, and cleanliness may cause a significant change in impact sensitivity/reaction.

A reaction is indicated by an abrupt increase in test specimen temperature or by obvious changes in odor, color, or material appearance, or a combination thereof, as observed during post test examinations. Odor alone is not considered positive evidence that a reaction has occurred.

Suggested criteria for test completion at a given pressure are:

4.4.1 Each specimen is subjected to five impacts.

4.4.2 A material passes if no reactions occur in 20 successive samples.

4.4.3 A material fails if one reaction occurs in a maximum of 20 or fewer successive samples.

Materials may be ranked by the maximum pressure (pressure threshold) at which they pass the test.

Material acceptance may be on the basis of passing at a selected pressure.

SCOPE

1.1 This method describes a technique to determine the relative sensitivity of materials to dynamic pressure impacts by gases such as oxygen, air, or blends of gases containing oxygen.

1.2 This method describes the test apparatus and test procedures that may be employed in the evaluation of materials for use in gases under dynamic pressure operating conditions up to gage pressures of 10 000 psi (69 MPa) at ambient temperature.

1.3 This method is primarily a test for ranking of materials. This method is not necessarily valid for determination of the sensitivity of the materials in an "as-used" configuration since the material sensitivity may be altered because of changes in material configuration, usage, and environment. This method can be employed to provide batch-to-batch acceptance data. Acceptability of any material may be based on its performance at a particular test pressure, or test pressure may be varied to determine the reaction threshold of a material, as specified by the user.

1.4 The criteria used for the acceptance, retest, and rejection of materials for any given application shall be determined by the user and are not fixed by this method.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautions see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G 74 – 01

Standard Test Method for

1

Ignition Sensitivity of Materials to Gaseous Fluid Impact

ThisstandardisissuedunderthefixeddesignationG 74;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope MNL36 Safe Use of Oxygen and Oxygen Systems: Guide-

lines for Oxygen System Design, Materials Selection,

1.1 This method describes a technique to determine the

4

Operations, Storage, and Transportation

relative sensitivity of materials to dynamic pressure impacts by

5

2.2 Military Standards:

gases such as oxygen, air, or blends of gases containing

MIL-D-16791-E Detergent, General Purpose (Liquid, Non-

oxygen.

ionic)

1.2 This method describes the test apparatus and test pro-

MIL-0-27210E, Amendment 1-Oxygen, Aviator’s Breath-

ceduresthatmaybeemployedintheevaluationofmaterialsfor

ing, Liquid and Gas

use in gases under dynamic pressure operating conditions up to

gage pressures of 10 000 psi (69 MPa) at ambient temperature.

3. Summary of Method

1.3 This method is primarily a test for ranking of materials.

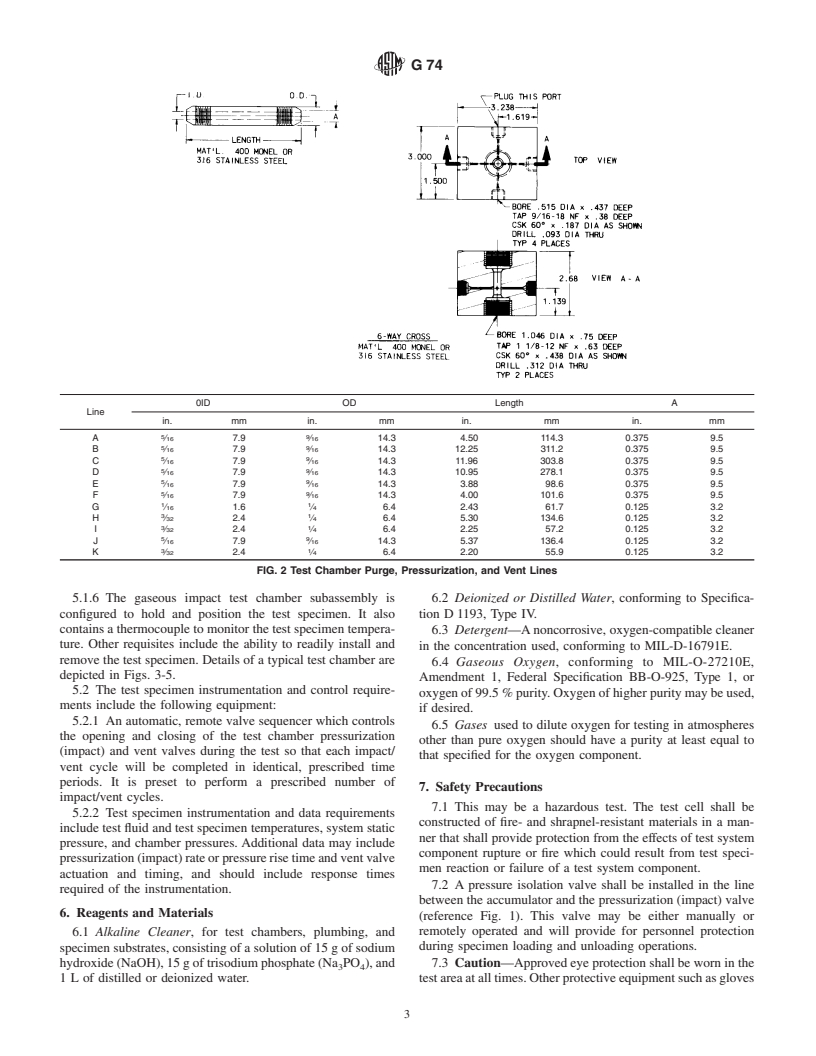

3.1 The gaseous impact test system is designed to expose

This method is not necessarily valid for determination of the

material specimens or small components/elements to high-

sensitivity of the materials in an “as-used” configuration since

velocity (dynamic) gaseous impact environments. The basic

the material sensitivity may be altered because of changes in

configuration consists of a high-pressure accumulator, a high-

material configuration, usage, and environment. This method

speed pressurization (impact) valve, test system pressurization

can be employed to provide batch-to-batch acceptance data.

lines, test chamber/fixture, test chamber purge and vent sys-

Acceptability of any material may be based on its performance

tems, and a valve sequencer/control device. Fig. 1 is a

at a particular test pressure, or test pressure may be varied to

schematic of a typical test system.

determine the reaction threshold of a material, as specified by

3.2 The general procedure is to prepare the test specimen,

the user.

record significant pretest data, and place the test specimen in

1.4 The criteria used for the acceptance, retest, and rejection

the test chamber. The test specimen is then subjected to

of materials for any given application shall be determined by

sequential gaseous impacts by alternately opening and closing

the user and are not fixed by this method.

the test chamber pressurization (impact) and vent valves. The

1.5 This standard does not purport to address all of the

test data obtained may include test chamber pressures and

safety concerns, if any, associated with its use. It is the

temperatures, test chamber pressure rise times, pressurization

responsibility of the user of this standard to establish appro-

and vent valve actuation times, and sequence times. The test

priate safety and health practices and determine the applica-

specimen is then removed and examined for any significant

bility of regulatory limitations prior to use. For specific

changes and evidence of reactions. Pertinent data are recorded.

precautions see Section 7.

The test is repeated using a fresh specimen for each impact test

2. Referenced Documents cycle until the desired user-selected criteria are met.

2.1 ASTM Standards:

4. Significance and Use

2

D 1193 Specification for Reagent Water

4.1 This test evaluates the relative sensitivity of materials to

G 63 GuideforEvaluatingNon-MetallicMaterialsforOxy-

3 dynamic pressure impacts by various gaseous fluid media (may

gen Service

include mixtures of gases).

G 93 Practice for Cleaning Methods and Cleanliness Levels

4.2 Any change or variations in test specimen configura-

for Material and Equipment Used in Oxygen-Enriched

3 tions, thickness, preparation, and cleanliness may cause a

Environments

significant change in impact sensitivity/reaction.

4.3 A reaction is indicated by an abrupt increase in test

1 specimen temperature or by obvious changes in odor, color, or

ThismethodisunderthejurisdictionofASTMCommitteeG4onCompatibility

and Sensitivity of Materials in Oxygen Enriched Atmospheres and is the direct

responsibility of Subcommittee G04.01 on Test Methods.

Current edition approved Sept. 10, 2001. Published January 2002. Originally

e1 4

published as G74–82. Last previous edition G74–82(1996) . AvailablefromASTM,100BarrHarborDrive,WestConshohocken,PA19428.

2 5

Annual Book of ASTM Standards, Vol 11.01. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

3

Annual Book of ASTM Standards, Vol 14.04. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Bar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.