ASTM A623-00

(Specification)Standard Specification for Tin Mill Products, General Requirements

Standard Specification for Tin Mill Products, General Requirements

SCOPE

1.1 This specification covers a group of common requirements which, unless otherwise specified in the purchase order or in an individual specification, shall apply to tin mill products.

1.2 In case of any conflict in requirements, the requirements of the purchase order, the individual material specification, and this general specification shall prevail in the sequence named.

Note 1—A complete metric companion to Specification A 623 has been developed-Specification A 623M; therefore no metric equivalents are presented in this specification.

1.3 The following safety caveat pertains to through of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 623 – 00

Standard Specification for

Tin Mill Products, General Requirements

This standard is issued under the fixed designation A 623; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope MIL-STD-129 Marking for Shipment and Storage

MIL-STD-163 Steel Mill Products, Preparation for Marking

1.1 This specification covers a group of common require-

and Storage

ments which, unless otherwise specified in the purchase order

2.3 U.S. Federal Standard:

or in an individual specification, shall apply to tin mill

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

products.

1.2 In case of any conflict in requirements, the requirements

3. Terminology

of the purchase order, the individual material specification, and

3.1 Definitions:

this general specification shall prevail in the sequence named.

3.1.1 base box, n—a unit of area equivalent to 112 sheets 14

2 2

NOTE 1—A complete metric companion to Specification A 623 has

by 20 in. or 31 360 in. (217.78 ft ) (see Annex A1).

been developed—Specification A 623M; therefore no metric equivalents

3.1.2 base weight, n—a term used to describe the thickness

are presented in this specification.

of tin mill products. The designated base weight multiplied by

1.3 The following safety caveat pertains to Annex A3

a factor of 0.00011 is the nominal decimal thickness, in inches

through Annex A10 of this specification: This standard does

of the material. Although it is customary industry-wide to use

not purport to address all of the safety concerns, if any,

the term“ pound” (for example, 75 lb), following the base

associated with its use. It is the responsibility of the user of this

weight designation, base weight is correctly used only to define

standard to establish appropriate safety and health practices

material thickness, and is not a measure of the weight of a base

and determine the applicability of regulatory limitations prior

box.

to use.

3.1.3 black plate, n—light-gage, low-carbon, cold-reduced

steel intended for use in the untinned state or for the production

2. Referenced Documents

of other tin mill products. It is supplied only in a dry or oiled

2.1 ASTM Standards:

condition.

A 370 Test Methods and Definitions for Mechanical Testing

3.1.4 box annealing, n—a process involving slow heating of

of Steel Products

coils to a subcritical temperature, holding, and cooling there-

A 700 Practices for Packaging, Marking, and Loading

from, to soften the strip and relieve stresses produced during

Methods for Steel Products for Domestic Shipment

cold reduction. It is accomplished in a sealed container. By

D 1125 Test Methods for Electrical Conductivity and Re-

introducing and maintaining an inert or slightly reducing

sistivity of Water

atmosphere during the cycle, a relatively bright surface is

E 18 Test Methods for Rockwell Hardness and Rockwell

obtained.

Superficial Hardness of Metallic Materials

3.1.5 bright finish, n—a surface that has a melted tin

E 112 Test Methods for Determining the Average Grain

coating.

Size

3.1.6 bundle, n—a unit containing two or more packages of

2.2 U.S. Military Standards:

a cut size, supported by a platform, generally consisting of ten

or more packages. (Also commonly referred to as a multiple-

package lift containing two or more packages.)

3.1.7 burr, n—metal displaced beyond the plane of the

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

surface by slitting or shearing (see 9.1.7 and 9.2.6).

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

A01.20 on Tin Mill Products. 3.1.8 camber, n—the greatest deviation of an edge from a

Current edition approved September 10, 2000. Published November 2000.

straight line, the measurement being taken along the concave

Originally published as A 623 – 68. Last previous edition A 623 – 99.

edge using a taut line or straightedge (see 9.1.9 and 9.2.7).

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 01.05.

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 03.01.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 623

3.1.9 chemical treatment, electrolytic tin plate, n—a passi- from a flat plane other than at the edges. The term “buckle” is

vating chemical treatment applied to the surface of electrolytic often applied to form of fullness.

tin plate to stabilize the plate surface characteristics compatible 3.1.20 length dimension—the longer dimension of a cut

with a specified end use (see Annex A8 and Annex A10). size.

3.1.10 chemically treated steel, n—light-gage, low-carbon, 3.1.21 lot—each 20 000 sheets or part thereof or the

equivalent in coils, of an item in a specific shipment having the

cold-reduced steel that has a passivating or chemical treatment

applied to the surface to provide rust resistance or retard same order specifications.

underfilm corrosion, or both. 3.1.22 matte finish—a surface that has an unmelted tin

3.1.11 coil set (longitudinal or line bow)—a curvature of the coating, generally on a shot-blast finish (SBF) base steel.

3.1.23 mechanical designation—an arbitrary number to

strip running parallel to the rolling direction.

3.1.12 cold reduction—the process of reducing the thick- designate Rockwell hardness and ultimate tensile strength

characteristics for double-reduced plate (see 8.2).

ness of the strip cold, generally accomplished by one rolling

through a series of four-high mills arranged in tandem. 3.1.24 oiling—a lubricant film applied to both surfaces of

the plate.

3.1.13 continuous annealing—a process consisting of pass-

ing the cold-reduced strip continuously and in a single thick- 3.1.25 package—a unit quantity of 112 sheets.

3.1.26 passivating treatment—a surface chemical treatment

ness through a series of vertical passes within a furnace

consisting of heating, soaking, and cooling zones to soften the (see 3.1.9).

3.1.27 ratio—the number of base boxes in a package of a

strip and relieve stresses produced during cold reduction. An

inert or slightly reducing atmosphere is maintained in the given size (see 3.1.1 and Annex A1).

3.1.28 Rockwell hardness test—a test for determining hard-

furnace to obtain a relatively bright strip.

ness (see Annex A2).

3.1.14 cross bow (transverse)—a curvature of the strip

3.1.29 rolling width—the dimension of the sheet perpen-

running perpendicular to the rolling direction.

dicular to the rolling direction.

3.1.15 differentially coated tin plate—electrolytic tin plate

3.1.30 single-reduced plate—plate produced with one major

with a different weight of tin coating on each surface.

cold reduction.

3.1.16 double-reduced plate—plate given a second major

3.1.31 steel Type D—base-metal steel aluminum killed,

cold reduction following annealing.

sometimes required to minimize severe fluting and stretcher-

3.1.17 electrolytic chromium-coated steel—light-gage, low-

strain hazards or for severe drawing applications (see Table 1).

carbon, cold-reduced steel on which chromium and oxides

3.1.32 steel Type L—base-metal steel, low in metalloids and

have been electrodeposited.

residual elements, sometimes used for improved internal cor-

3.1.18 electrolytic tin plate—light-gage, low-carbon, cold-

rosion resistance for certain food-product containers (see Table

reduced steel on which tin has been electrodeposited by an acid

1).

or alkaline process.

3.1.33 steel Type MR—base-metal steel, similar in metalloid

3.1.18.1 J Plate—electrolytic tin plate, No. 50 or heavier tin

content to Type L but less restrictive in residual elements,

coating, with improved corrosion performance for some gal-

commonly used for most tin mill products (see Table 1).

vanic detinning food products as specified in the table follow-

3.1.34 surface appearance—visual characteristics deter-

ing 3.1.18.2 and as measured by the Special Property Tests for

mined primarily by the steel surface finish. For electrolytic tin

Pickle Lag (PL) (see Annex A3), Iron Solution Values (ISV)

plate, the appearance is also influenced by the weight of

(see Annex A5), Tin Crystal Size (TCS) (see Annex A4). The

coating and by melting or not melting the tin coating.

alloy layer is normally light in color, characteristic of the acid

3.1.35 surface finishes—steel surface finishes for tin mill

tinning process.

3.1.18.2 K Plate—electrolytic tin plate, No. 50 or heavier

TABLE 1 Chemical Requirements for Tin Mill Products

tin coating, with improved corrosion performance for some

Cast Composition, max %

galvanic detinning food products as specified in the following

Element

Type D Type L Type MR

table and as measured by the Special Property Tests for Pickle

Carbon 0.12 0.13 0.13

Lag ( PL) (see Annex A3), Iron Solution Value ( ISV) (see

Manganese 0.60 0.60 0.60

Annex A5), Tin Crystal Size ( TCS) (see Annex A4), and Alloy

Phosphorus 0.020 0.015 0.020

Tin Couple ( ATC) (see Annex A6) and Aerated Media

Sulfur 0.03 0.03 0.03

A,B

Silicon 0.020 0.020 0.020

Polarization (AMP) (see Annex A9).

Copper 0.20 0.06 0.20

Special Properties Aims

Nickel 0.15 0.04 0.15

Pickle Lag 10 s max

Chromium 0.10 0.06 0.10

Iron Solution Value 20 μg Iron max

Molybdenum 0.05 0.05 0.05

Tin Crystal Size ASTM No. 9 or larger C

Aluminum 0.20 0.10 0.20

A 2

Alloy Tin Couple 0.12 μA/cm max

Other elements, each 0.02 0.02 0.02

A

When steel produced by the silicon killed method is ordered, the silicon

A 2

Good mill practice has demonstrated the ability to average 0.05 μA/cm or less

maximum may be increased to 0.080 %.

over an extended period of production.

B

When strand cast steel produced by the aluminum killed method is ordered or

3.1.18.3 The production of J Plate and K Plate require

furnished, the silicon maximum may be increased to 0.030 % when approved by

the purchaser.

special processing and testing. In order to receive J Plate or K

C

Types L and MR may be supplied as non-killed or killed which would

Plate, this requirement must be specified on the order.

respectively be produced without and with aluminum additions. Minimum alumi-

3.1.19 fullness (center buckle)—a deviation of the strip num level for Type D is usually 0.02 %.

A 623

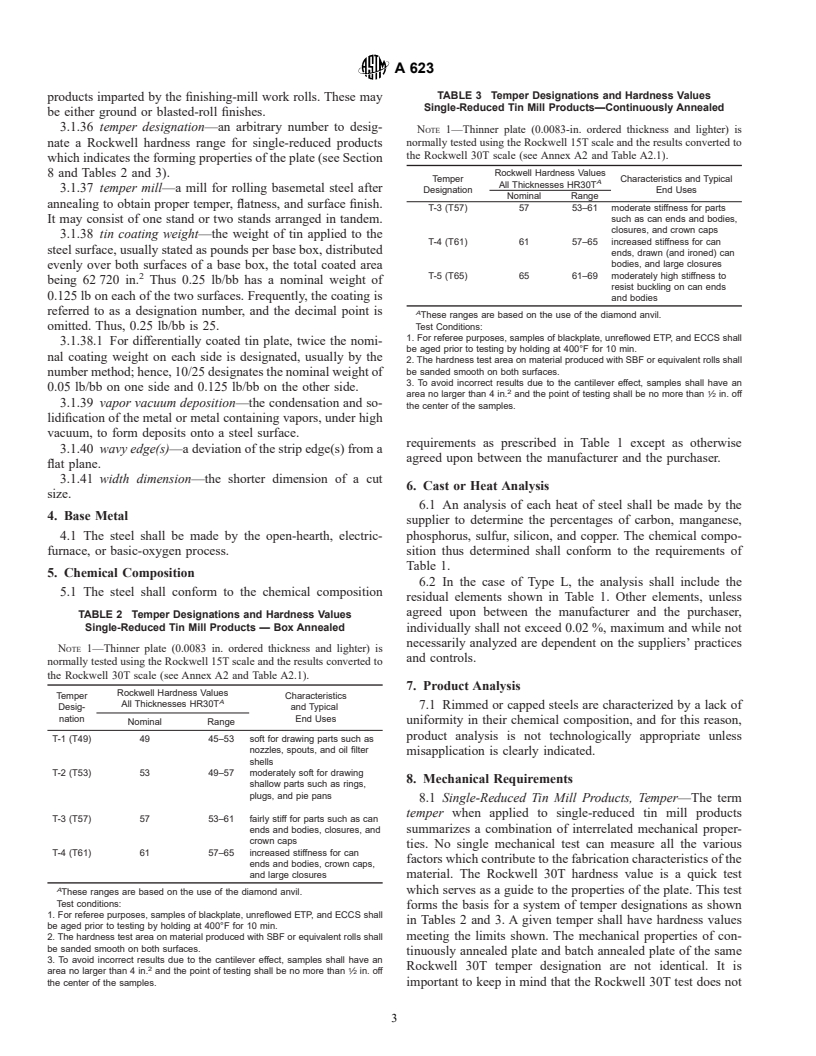

TABLE 3 Temper Designations and Hardness Values

products imparted by the finishing-mill work rolls. These may

Single-Reduced Tin Mill Products—Continuously Annealed

be either ground or blasted-roll finishes.

3.1.36 temper designation—an arbitrary number to desig-

NOTE 1—Thinner plate (0.0083-in. ordered thickness and lighter) is

nate a Rockwell hardness range for single-reduced products normally tested using the Rockwell 15T scale and the results converted to

the Rockwell 30T scale (see Annex A2 and Table A2.1).

which indicates the forming properties of the plate (see Section

8 and Tables 2 and 3). Rockwell Hardness Values

Temper Characteristics and Typical

A

All Thicknesses HR30T

3.1.37 temper mill—a mill for rolling basemetal steel after

Designation End Uses

Nominal Range

annealing to obtain proper temper, flatness, and surface finish.

T-3 (T57) 57 53–61 moderate stiffness for parts

such as can ends and bodies,

It may consist of one stand or two stands arranged in tandem.

closures, and crown caps

3.1.38 tin coating weight—the weight of tin applied to the

T-4 (T61) 61 57–65 increased stiffness for can

steel surface, usually stated as pounds per base box, distributed

ends, drawn (and ironed) can

bodies, and large closures

evenly over both surfaces of a base box, the total coated area

2 T-5 (T65) 65 61–69 moderately high stiffness to

being 62 720 in. Thus 0.25 lb/bb has a nominal weight of

resist buckling on can ends

0.125 lb on each of the two surfaces. Frequently, the coating is

and bodies

A

referred to as a designation number, and the decimal point is

These ranges are based on the use of the diamond anvil.

omitted. Thus, 0.25 lb/bb is 25. Test Conditions:

1. For referee purposes, samples of blackplate, unreflowed ETP, and ECCS shall

3.1.38.1 For differentially coated tin plate, twice the nomi-

be aged prior to testing by holding at 400°F for 10 min.

nal coating weight on each side is designated, usually by the

2. The hardness test area on material produced with SBF or equivalent rolls shall

be sanded smooth on both surfaces.

number method; hence, 10/25 designates the nominal weight of

3. To avoid incorrect results due to the cantilever effect, samples shall have an

0.05 lb/bb on one side and 0.125 lb/bb on the other side.

area no larger than 4 in. and the point of testing shall be no more than ⁄2 in. off

3.1.39 vapor vacuum deposition—the condensation and so-

the center of the samples.

lidification of the metal or metal containing vapors, under high

vacuum, to form deposits onto a steel surface.

requirements as prescribed in Table 1 except as otherwise

3.1.40 wavy edge(s)—a deviation of the strip edge(s) from a

agreed upon between the manufacturer and the purchaser.

flat plane.

3.1.41 width dimension—the shorter dimension of a cut

6. Cast or Heat Analysis

size.

6.1 An analysis of each heat of steel shall be made by the

4. Base Metal

supplier to determine the percentages of carbon, manganese,

4.1 The steel shall be made by the open-hearth, electric- phosphorus, sulfur, silicon, and copper. The chemical compo-

furnace, or basic-oxygen process. sition thus determined shall conform to the requirements of

Table 1.

5. Chemical Composition

6.2 In the case of Type L, the analysis shall include the

5.1 The steel shall conform to the chemical composition

residual elements shown in Table 1. Other elements, unless

agreed upon between the manufacturer and the purchaser,

TABLE 2 Temper Designations and Hardness Values

Single-Reduced Tin Mill Products — Box Annealed individually shall not exceed 0.02 %, maximum and while not

necessarily analyzed are dependent on the suppliers’ practices

NOTE 1—Thinner plate (0.0083 in. ordered thickness and lighter) is

and controls.

normally tested using the Rockwell 15T scale and the results converted to

the Rockwell 30T scale (see Annex A2 and Table A2.1).

7. Product Analysis

Rockwell Hardness Values

Temper Characteristics

A

All Thicknesses HR30T

7.1 Rimmed or capped steels are characterized by a lack of

Desig- and Typical

nation End Uses

Nominal Range uniformity in their chemical composition, and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.