ASTM D5833-12(2020)

(Guide)Standard Guide for Source Reduction Reuse, Recycling, or Disposal of Steel Cans

Standard Guide for Source Reduction Reuse, Recycling, or Disposal of Steel Cans

SIGNIFICANCE AND USE

4.1 This guide will familiarize public officials and business and industry managers with source reduction, reuse, recycling, or disposal of steel cans.

SCOPE

1.1 This guide provides general information to public officials and business and industry managers regarding the source reduction, reuse, recycling, or disposal of steel cans under 5-gal (wet) or 40-lb (dry) capacity. It presents a comprehensive overview of the steel can life cycle. Five-gallon pails and larger containers, up to 55-gal drums, will be in a separate guide due to their inherently different use and management when empty.

1.2 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5833 − 12 (Reapproved 2020)

Standard Guide for

Source Reduction Reuse, Recycling, or Disposal of Steel

Cans

This standard is issued under the fixed designation D5833; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E702 Specification for Municipal Ferrous Scrap

E1134 Specification for Source-Separated Steel Cans (With-

1.1 This guide provides general information to public offi-

drawn 2001)

cials and business and industry managers regarding the source

reduction, reuse, recycling, or disposal of steel cans under

3. Summary of Guide

5-gal (wet) or 40-lb (dry) capacity. It presents a comprehensive

overview of the steel can life cycle. Five-gallon pails and larger 3.1 Steel can container applications are described, including

containers, up to 55-gal drums, will be in a separate guide due food, beverage, and general purpose. The processes for

to their inherently different use and management when empty. steelmaking, steel sheet production, and steel can manufactur-

ing are discussed. The methods of source reduction, reuse,

1.2 The values stated in inch-pound units are to be regarded

recycling, or disposal of steel cans are explained.

as standard. No other units of measurement are included in this

standard.

4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 This guide will familiarize public officials and business

safety concerns, if any, associated with its use. It is the

and industry managers with source reduction, reuse, recycling,

responsibility of the user of this standard to establish appro-

or disposal of steel cans.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

5. Typical Steel Can Container Applications

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard- 5.1 Food Cans—More than 90 % of metal food containers,

ization established in the Decision on Principles for the also known as sanitary cans, are made of steel (1). While they

Development of International Standards, Guides and Recom- have been commonly called “tin” cans, the tin coating on steel

mendations issued by the World Trade Organization Technical

sheet has become extremely thin as technology advanced. It

Barriers to Trade (TBT) Committee. has been supplemented or replaced by other alternative coat-

ings and treatments so that about one third of all steel cans are

2. Referenced Documents

now made with tin-free steel (2). Steel food cans contain many

types of food products, such as meat, fruit, vegetables, soup,

2.1 ASTM Standards:

infant formula, and pet food. (See Fig. 1.)

A623 Specification for Tin Mill Products, General Require-

5.1.1 Single-Serving or Home-Use Container—Steel food

ments

cans vary in size and style, in accordance with product and

D5488 Terminology of Environmental Labeling of Packag-

consumer requirements. Can size may range from a few ounces

ing Materials and Packages (Withdrawn 2002)

to the typical one-pound net weight container used in the home.

E701 Test Methods for Municipal Ferrous Scrap

They are normally opened with an ordinary manual or electric

can opener, but some have aluminum or steel easy-open lids for

greater convenience to the consumer.

This guide is under the jurisdiction of ASTM Committee D34 on Waste

5.1.2 Multi-Serving or Commercial/Institutional

Management and is the direct responsibility of Subcommittee D34.03 on Treatment,

Recovery and Reuse.

Container—Steel food cans are widely used in business and

Current edition approved Nov. 1, 2020. Published November 2020. Originally

institutional food service facilities and food manufacturing

approved in 1995. Last previous edition approved in 2012 as D5833 – 12. DOI:

plants. This includes 1-gal (#10) cans and oblong cans, such as

10.1520/D5833-12R20.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or for olive oil.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on The boldface numbers in parentheses refer to a list of references at the end of

www.astm.org. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5833 − 12 (2020)

scrap charge for future production. Prompt scrap is leftover or

unused scrap material from industrial fabricating processes,

such as trimmings from steel can manufacturing. Obsolete

scrap is any product collected for scrap metal at the end of its

useful life, such as major appliances, tools, automobiles,

construction and demolition salvage, and steel cans. Steel scrap

is collected, processed, and shipped to the closest melting

location.

6.2 Basic Oxygen-Furnace Production—About 60 % of the

steel produced in the United States in 1994 was made in the

basic oxygen furnace by the integrated mills (3). This highest-

quality steel is required for cans, appliances, automobiles, and

other flat-rolled steel products. Domestic mills use an average

of 75 % molten iron and 25 % scrap steel in the furnace charge.

Thus, this steel has about 25 % recycled content.

6.2.1 The basic oxygen process is very large in scale,

making 200 to 300 tons of steel per melt (batch) (4). Hot metal

(or molten iron) is first made separately in the blast furnace,

using iron ore, coke, and limestone. Then the basic oxygen

furnace is loaded with a charge of steel scrap and molten iron.

Limestone is also added as flux. An oxygen lance is lowered

into the furnace to blow oxygen onto the surface of the molten

FIG. 1 Steel Container Applications

iron. The blow of oxygen continues until the impurities and a

certain amount of carbon in the molten iron have been reduced

5.2 Beverage Cans—Steel cans are widely used for juices through oxidation and the desired composition of steel has

and other non-carbonated beverage applications. They may been made. These chemical reactions take place very rapidly so

also be used for beer or soft drinks. (See Fig. 1) the process is completed in about 20 min.

5.2.1 Single-Serving Container—Steel beverage cans vary 6.2.2 Due to technological limitations, the maximum

in size and style. The 6-oz juice can, commonly used for school amount of scrap used relative to the hot metal is approximately

lunches, has a foil peel-off closure on the lid, although some

30 % in the basic oxygen furnace. Any higher percentage of

now have an all-steel stay-on tab. scrap would require supplemental energy to the chemical

5.2.2 Multi-Serving or Commercial/Institutional

reaction process (5). In 1994, the North American integrated

Container—Larger beverage containers, from 46 oz (#5) to steel producers averaged more than 25 % total scrap steel use,

1 gal (#10), are used for home, business, institutions, and food

with about 10 to 15 % being obsolete scrap and the balance

manufacturing. from home scrap and prompt scrap.

6.2.3 The modern method of continuous casting transforms

5.3 General Purpose Cans—Steel cans have many non-food

the liquid steel into solidified semifinished steel. This is done

and non-beverage applications, wet or dry, for the household,

by delivering the liquid steel in a ladle to the casting floor,

business, and industry. (See Fig. 1)

where it is poured into a special mold arrangement that allows

5.3.1 Single-Serving or Home-Use Container—Smaller

the steel to flow and form directly into a red-hot continuous

cans up to 1 gal are typical. Numerous styles and sizes of cans

ribbon of solidified steel which is cut automatically into

are required because of the wide array of products and

specified slab lengths.

applications, including liquid products (such as paint), powders

(such as talc), semisolids (such as paste wax), aerosols (such as 6.3 Manufacture of Can Sheet:

hair spray), and dry goods (such as adhesive bandages or roller

6.3.1 Steel slab destined for steel can application is rolled or

bearings). Many have replaceable lids that are pried off to open

flattened into an intermediate gage in the hot strip mill (6). The

the container. Aerosol cans are sealed and release product

hot band is then cleaned before going through a cold reduction

through a spray valve until empty.

mill to strengthen and form it into the desired sheet gage. It

5.3.2 Industrial or Commercial/Institutional Container—

then passes through an annealing furnace, which softens it in

Larger general purpose containers, including 5-gal pails and

preparation for other processing. The sheet steel, in the form of

steel drums of various capacities will be covered in a separate

very large coils (rolls), goes either to a temper mill for final

guide.

finish or to a double cold-reduction mill, where it becomes

even thinner and stronger. Called“ black plate” up to now, the

6. Manufacture of Steel and Can Sheet for Steel Cans

single- or double-reduced product is ready for coating with tin

6.1 Scrap steel is used in making new steel in the basic or chromium.

oxygen furnace, electric arc furnace, and foundry. Scrap steel is 6.3.2 As the steel goes through the coating line, it is washed

categorized as “home,” “prompt,” or “obsolete” scrap. Home and cleaned. It is electroplated in a bath employing soluble tin

scrap is unsalable steel scrap generated from the steelmaking anodes. If coated with tin, the steel sometimes is passed

process. It is “run-around” in the mill to be used as part of the through a high-frequency induction or resistance heater. There,

D5833 − 12 (2020)

the tin melts and flows to form a lustrous coating that is cooled prompt scrap.) Can bodies are made by cutting can sheet into

in water, treated electrochemically, rinsed, then electrostati- the desired size and rolling it into a cylinder. The side seams

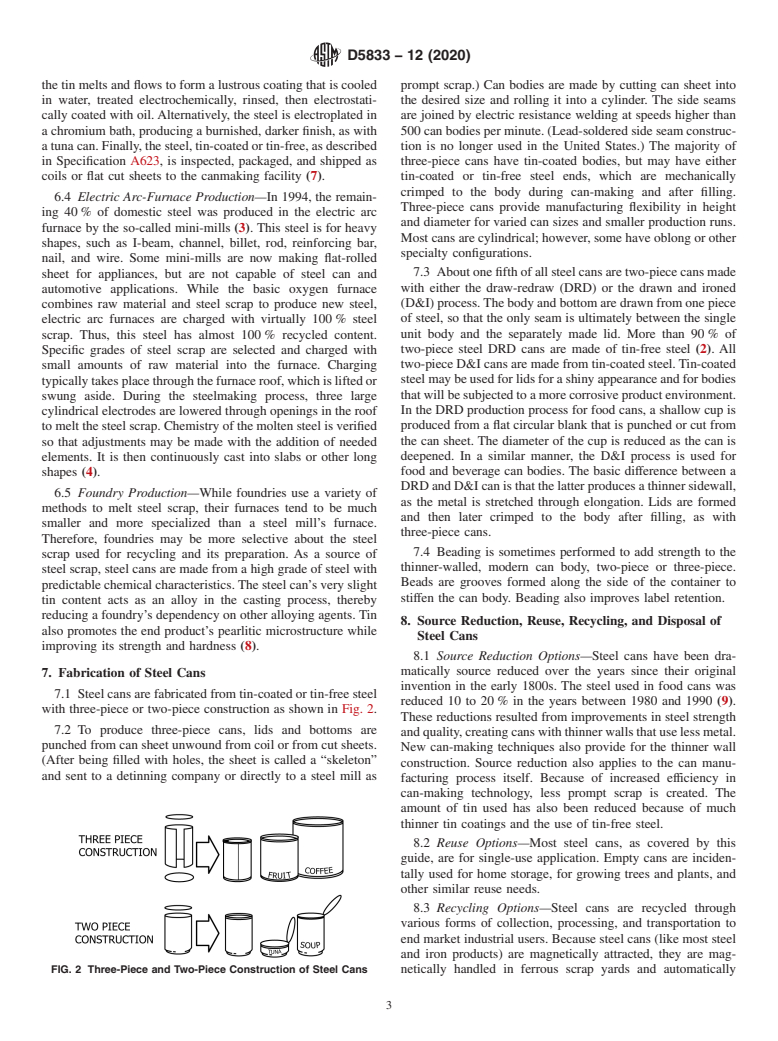

cally coated with oil. Alternatively, the steel is electroplated in are joined by electric resistance welding at speeds higher than

a chromium bath, producing a burnished, darker finish, as with 500 can bodies per minute. (Lead-soldered side seam construc-

a tuna can. Finally, the steel, tin-coated or tin-free, as described tion is no longer used in the United States.) The majority of

in Specification A623, is inspected, packaged, and shipped as three-piece cans have tin-coated bodies, but may have either

coils or flat cut sheets to the canmaking facility (7). tin-coated or tin-free steel ends, which are mechanically

crimped to the body during can-making and after filling.

6.4 Electric Arc-Furnace Production—In 1994, the remain-

Three-piece cans provide manufacturing flexibility in height

ing 40 % of domestic steel was produced in the electric arc

and diameter for varied can sizes and smaller production runs.

furnace by the so-called mini-mills (3). This steel is for heavy

Most cans are cylindrical; however, some have oblong or other

shapes, such as I-beam, channel, billet, rod, reinforcing bar,

specialty configurations.

nail, and wire. Some mini-mills are now making flat-rolled

7.3 About one fifth of all steel cans are two-piece cans made

sheet for appliances, but are not capable of steel can and

with either the draw-redraw (DRD) or the drawn and ironed

automotive applications. While the basic oxygen furnace

(D&I) process. The body and bottom are drawn from one piece

combines raw material and steel scrap to produce new steel,

electric arc furnaces are charged with virtually 100 % steel of steel, so that the only seam is ultimately between the single

unit body and the separately made lid. More than 90 % of

scrap. Thus, this steel has almost 100 % recycled content.

Specific grades of steel scrap are selected and charged with two-piece steel DRD cans are made of tin-free steel (2). All

two-piece D&I cans are made from tin-coated steel. Tin-coated

small amounts of raw material into the furnace. Charging

steel may be used for lids for a shiny appearance and for bodies

typically takes place through the furnace roof, which is lifted or

that will be subjected to a more corrosive product environment.

swung aside. During the steelmaking process, three large

In the DRD production process for food cans, a shallow cup is

cylindrical electrodes are lowered through openings in the roof

produced from a flat circular blank that is punched or cut from

to melt the steel scrap. Chemistry of the molten steel is verified

the can sheet. The diameter of the cup is reduced as the can is

so that adjustments may be made with the addition of needed

deepened. In a similar manner, the D&I process is used for

elements. It is then continuously cast into slabs or other long

food and beverage can bodies. The basic difference between a

shapes (4).

DRD and D&I can is that the latter produces a thinner sidewall,

6.5 Foundry Production—While foundries use a variety of

as the metal is stretched through elongation. Lids are formed

methods to melt steel scrap, their furnaces tend to be much

and then later crimped to the body after filling, as with

smaller and more specialized than a steel mill’s furnace.

three-piece cans.

Therefore, foundries may be more selective about the steel

7.4 Beading is sometimes performed to add strength to the

scrap used for recycling and its preparation. As a source of

thinner-walled, modern can body, two-piece or three-piece.

steel scrap, steel cans are made from a high grade of steel with

Beads are grooves formed along the side of the container to

predictable chemical characteristics. The steel can’s very slight

stiffen the can body. Beading also improves label retention.

tin content acts as an alloy in the casting process, thereby

reducing a foundry’s dependency on other alloying agents. Tin

8. Source Reduction, Reuse, Recycling, and Disposal of

also promotes the end product’s pearlitic microstructure while

Steel Cans

improving its strength and hardness (8).

8.1 Source Reduction Options—Steel cans have been dra-

matically source reduced over the years since their original

7. Fabrication of Steel Cans

invention in the early 1800s. The steel used in food cans was

7.1 Steel cans are fabricated from tin-coated or tin-free steel

reduced 10 to 20 % in the years between 1980 and 1990 (9).

with three-piece or two-piece construction as shown in Fig. 2.

These red

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.