ASTM D5859-96e1

(Test Method)Standard Test Method for Determining the Traction of Footwear on Painted Surfaces Using the Variable Incidence Tester (Withdrawn 2005)

Standard Test Method for Determining the Traction of Footwear on Painted Surfaces Using the Variable Incidence Tester (Withdrawn 2005)

SCOPE

1.1 This test method covers the measurement of the traction of footwear on painted walkway surfaces under both dry and wet conditions in the laboratory and the field.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI values given in parentheses are provided for information only.

1.3 This test method does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the measurement of the traction of footwear on painted walkway surfaces under both dry and wet conditions in the laboratory and the field.

Formerly under the jurisdiction of Committee F13 on Pedestrian/Walkway Safety and Footwear, this test method was withdrawn in January 2005 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation:D5859–96

Standard Test Method for

Determining the Traction of Footwear on Painted Surfaces

1

Using the Variable Incidence Tester

This standard is issued under the fixed designation D 5859; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Per Committee F13 Bylaws, editorially replaced term definitions with reference to Terminology F 1646 in January

2004.

1. Scope

1.1 This test method covers the measurement of the traction

of footwear on painted walkway surfaces under both dry and

wet conditions in the laboratory and the field.

1.2 The values stated in inch-pound units are to be regarded

as the standard. The SI values given in parentheses are

provided for information only.

1.3 This test method does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

F 1646 Terminology Relating to Safety and Traction for

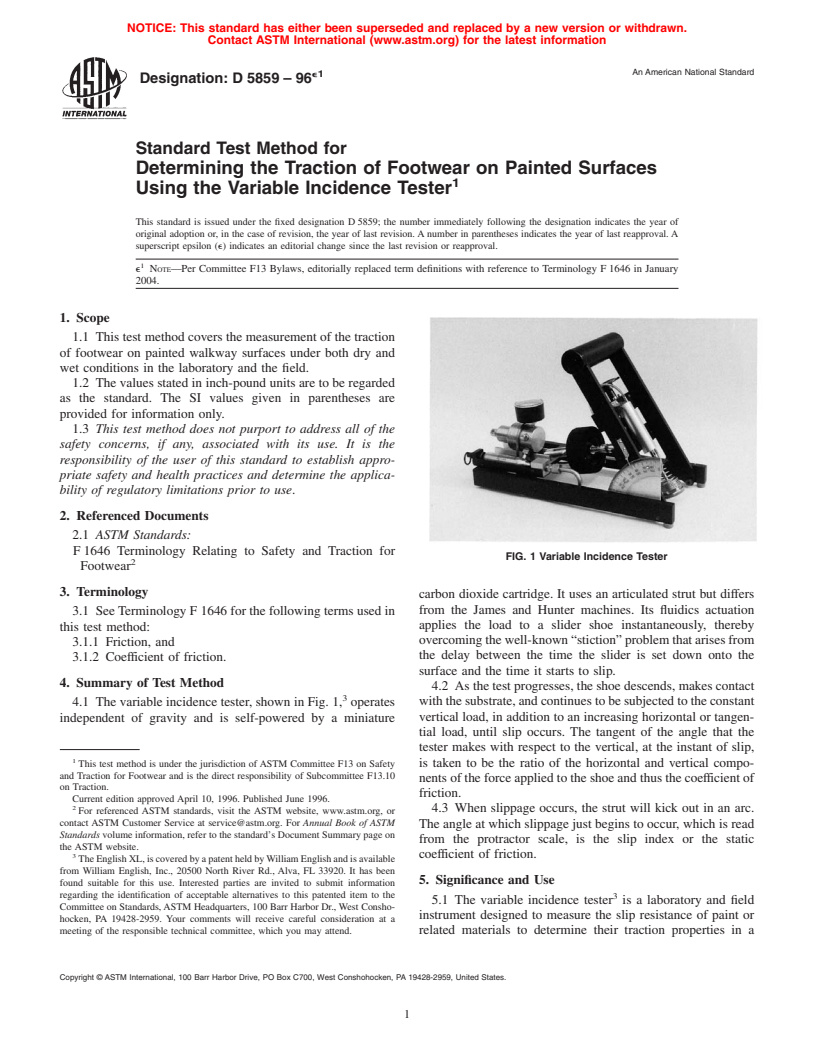

FIG. 1 Variable Incidence Tester

2

Footwear

3. Terminology

carbon dioxide cartridge. It uses an articulated strut but differs

from the James and Hunter machines. Its fluidics actuation

3.1 SeeTerminology F 1646 for the following terms used in

applies the load to a slider shoe instantaneously, thereby

this test method:

overcomingthewell-known“stiction”problemthatarisesfrom

3.1.1 Friction, and

the delay between the time the slider is set down onto the

3.1.2 Coefficient of friction.

surface and the time it starts to slip.

4. Summary of Test Method

4.2 As the test progresses, the shoe descends, makes contact

3

4.1 The variable incidence tester, shown in Fig. 1, operates withthesubstrate,andcontinuestobesubjectedtotheconstant

vertical load, in addition to an increasing horizontal or tangen-

independent of gravity and is self-powered by a miniature

tial load, until slip occurs. The tangent of the angle that the

tester makes with respect to the vertical, at the instant of slip,

1

This test method is under the jurisdiction of ASTM Committee F13 on Safety is taken to be the ratio of the horizontal and vertical compo-

and Traction for Footwear and is the direct responsibility of Subcommittee F13.10

nents of the force applied to the shoe and thus the coefficient of

on Traction.

friction.

Current edition approved April 10, 1996. Published June 1996.

2

4.3 When slippage occurs, the strut will kick out in an arc.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The angle at which slippage just begins to occur, which is read

Standards volume information, refer to the standard’s Document Summary page on

from the protractor scale, is the slip index or the static

the ASTM website.

3 coefficient of friction.

TheEnglishXL,iscoveredbyapatentheldbyWilliamEnglishandisavailable

from William English, Inc., 20500 North River Rd., Alva, FL 33920. It has been

5. Significance and Use

found suitable for this use. Interested parties are invited to submit information

regarding the identification of acceptable alternatives to this patented item to the 3

5.1 The variable incidence tester is a laboratory and field

Committee on Standards,ASTM Headquarters, 100 Barr Harbor Dr., West Consho-

instrument designed to measure the slip resistance of paint or

hocken, PA 19428-2959. Your comments will receive careful consideration at a

meeting of the responsible technical committee, which you may attend. related materials to determine their traction properties in a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

D5859–96

clean and dry state or in the presence of environmental 7. Test Sensor

4

contaminants encountered in situ.

7.1 The slider pad is prepared by cutting a disc of 1.25-in.

5.2 The indication of this test apparatus is believed to relate (3.2-cm) diameter elastomer and affixing it to the bottom of the

slip resistance of the surface tested in the test environment. It universal foot, sheen side exposed, using epoxy cement or

other suitable adhesive.

does not contemplate floor materials, characteristics of indi-

7.2 The slider pad is then prepared by sanding with 400-grit

vidual human gaits, and other factors besides the floor surface

wetordrysiliconcarbidepaperinthedrycondition,backedby

conditions.

a flat surface,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.