ASTM B385-74

(Specification)Specification for Molybdenum and Molybdenum Alloy Billets for Reforging (Withdrawn 1985)

Specification for Molybdenum and Molybdenum Alloy Billets for Reforging (Withdrawn 1985)

General Information

Standards Content (Sample)

m 900927b OOL3L28 7T7 m

Designation: B 385 - 74 American National Standard 21 79.5-1975

Approved Oct 7.1975

4CTb

By American National Standards Institute

Standard Specification for

MOLYBDENUM AND MOLYBDENUM ALLOY BILLETS

FOR REFORGING'

This Standard is issued under the fixed designation B 385; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval.

1. Scope 2.1.7 Marking (Section 14),

2.1.8 Workmanship and quality level re-

1.1 Materials-This specification covers

quirements (Section 9),

unalloyed molybdenum and molybdenum alloy

2.1.9 Certification and reports (Section l2),

billets as follows:

and

1. I. 1 Molybdenum 360-Unalloyed arc-cast

2. I. 10 Disposition of rejected material (Sec-

molybdenum.

tion I i).

I. I .2 Molybdenum 361 -Unalloyed powder

metallurgy molybdenum.

3. Manufacture

1.1.3 Molybdenum Alloy 362-Arc-cast

3.1 The various molybdenum mill products

molybdenum-0.5 % titanium.

covered by this specification shall be formed

I. 1.4 Molybdenum Alloy 363-Arc-cast

with the conventional extrusion, forging, or

molybdenum-0.5 % titanium-0.1 7% zirconium

rolling equipment normally found in primary

(TZM) alloy.

ferrous and nonferrous plants. The ingot metal

1.1.5 Molybdenum Alloy 364-Powder met-

for Materials 360, 362, 363, and 365 is arc

allurgy molybdenum-0.5 % titanium-0.1 %

melted in furnaces of a type suitable for reac-

zirconium (TZM type) alloy.

tive, refractory metals, and for Materials 361

1.1.6 Molybdenum 365-Unalloyed arc-cast

and 364 it is consolidated by powder metallurgy

molybdenum, low carbon.

methods. '

1.2 Use-These billets are primarily in-

tended for further processing by forging to

4. Product Limitations

semifinished shapes.

4.1 Billets for reforging are greater than 3 ?h

NOTE-The values stated in U.S. customary units

in. (88.9 mm) in diameter or in equivalent

are to be regarded as the standard.

cross-sectional area. Reforging billet stock

2. Basis of Purchase

with a smaller cross-sectional area is consid-

or rod. As-sintered alloys 361 and

ered as bar

2.1 Orders for material under this specifica-

364 material, of any dimension, are classified

tion shall include the following information as

under reforging billets.

applicable:

2.1.1 Material number and structure (Sec-

5. Metallurgical Structure

tions 1 and 5),

5.1 Billets of Materials 360, 362, 363, and

2.1.2 Product limitations (Section 4),

365 shall be furnished in the recrystallized

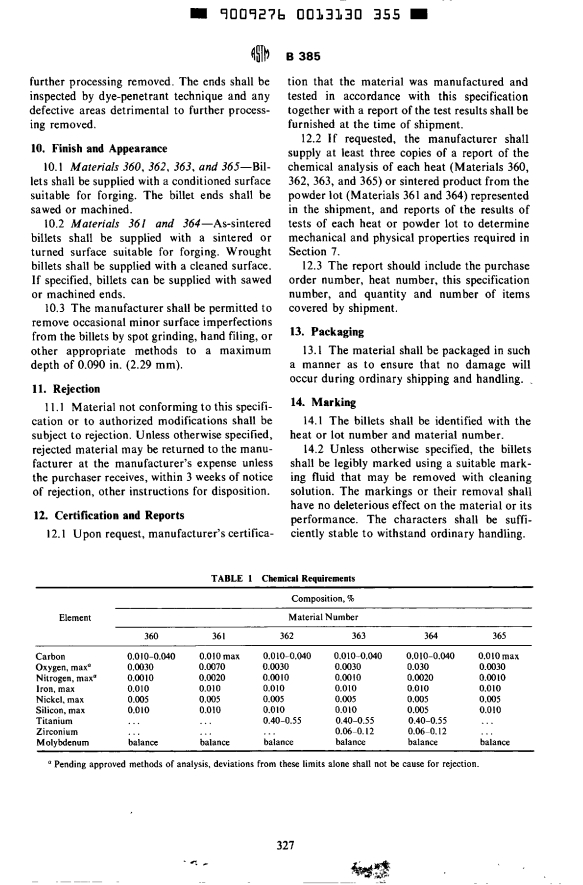

2.1.3 Restrictive chemistry (Tables 1 and 2),

2.1.4 Mechanical and physical requirements

'This specification is under the jurisdiction of ASTM

(Section 7 and Table 3),

Committee B-10 on Reactive and Refractory Metals and

2.1.5 Dimensions, weights, and tolerances

Alloys.

Current edition approved March 27. 1974. Published May

(Section 8),

1974. Originally published as B 385 - 62 T. Last previous

2. I .6 Finish and appearance (Section IO),

edition B 385 ~ 69.

---------------------- Page: 1 ----------------------

900927b OOL3L29 633 m

B 385

recrystallized condition shall not exceed the

condition as defined in 7.1.

values shown in Table 3.

5.2 Billets also can be furnished in the as-

7.2 Density:

worked or stress-relieved condition upon re-

7.2.1 Material 361-The density in the as-

quest of the purchaser.

sintered condition shall be at least 9.59 g/cm3

5.3 Billets of Materials 361 and 364 shall be

furnished in the as-sintered condition, as de- (Mg/mS), unless otherwise specified (theoreti-

fined in Section 7, unless requested otherwise cal density-10.20 g/cm3 (Mg/m3)).

7.2.2 Material 364-The density in the as-

by the purchaser.

sintered condition shall be at least 9.52 g/cm3

6. Chemical Requirements

( Mg/m3), unless otherwise specified (theoreti-

6. I The molybdenum and molybdenum alloy cal density-IO. 13 g/cm3 (Mg/m3)).

ingots and billets for conversion to finished

8. Dimensions, Weights, and Tolerances

products covered by this specification shall

conform to the requirements as to chemical 8.1 Uniformity of Diameter-Each billet

shall display a uniform section along the entire

composition specified in Table 1.

6.2 Check Analysis: length within A!& in. (1.59 mm) of the mean

6.2.1 Check analysis is an analysis made by diameter for Materials 360, 362, and 365 and

for Materials 361 and 364 with a turned

the purchaser or the manufacturer of the metal

after it has been processed into finished mill surface; for Materials 361 and 364 with an

as-sintered surface, the tolerance shall be A L/s

forms, and is either for the purpose of verifying

the composition of heat or lot or to determine in. (3.18 mm); for Material 363 the tolerance

variations in the composition within a heat or shall be +2 % of the mean diameter.

8.2 Billet to Billet Uniformity-The mean

lot.

diameter of Material 363 billet supplied sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.