ASTM A262-02a(2008)

(Practice)Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

ABSTRACT

This specification covers the standard practices for detecting susceptibility to intergranular attack in austenitic stainless steels. These practices include five intergranular corrosion tests, namely: (1) oxalic acid etch test for classification of etch structures of austenitic stainless steels; (2) ferric sulfate-sulfuric acid test, (3) nitric acid test and (4) copper-copper sulfate-sulfuric acid test for detecting susceptibility to intergranular attack in austenitic stainless steels; and (5) copper-copper sulfate-50% sulfuric acid test for detecting susceptibility to intergranular attack in molybdenum-bearing cast austenitic stainless steels. Methods for preparing the test specimens, rapid screening tests, apparatus setup and testing procedures, and calculations and report contents are described for each testing practice. The etch structure types used to classify the specimens are: step structure, dual structure, ditch structure, isolated ferrite, interdendritic ditches, end-grain pitting I, and end-grain pitting II.

SCOPE

1.1 These practices cover the following five tests:

1.1.1 Practice A—Oxalic Acid Etch Test for Classification of Etch Structures of Austenitic Stainless Steels (Sections 3 to 7, inclusive),

1.1.2 Practice B—Ferric Sulfate–Sulfuric Acid Test for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels (Sections 8 to 14, inclusive),

1.1.3 Practice C—Nitric Acid Test for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels (Sections 15 to 21, inclusive),

1.1.4 Practice E—Copper–Copper Sulfate–Sulfuric Acid Test for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels (Sections 22 to 31, inclusive), and

1.1.5 Practice F—Copper–Copper Sulfate–50 % Sulfuric Acid Test for Detecting Susceptibility to Intergranular Attack in Molybdenum-Bearing Cast Austenitic Stainless Steels (Sections 32 to 38, inclusive).

1.2 The following factors govern the application of these practices:

1.2.1 Susceptibility to intergranular attack associated with the precipitation of chromium carbides is readily detected in all six tests.

1.2.2 Sigma phase in wrought chromium-nickel-molybdenum steels, which may or may not be visible in the microstructure, can result in high corrosion rates only in nitric acid.

1.2.3 Sigma phase in titanium or columbium stabilized alloys and cast molybdenum-bearing stainless alloys, which may or may not be visible in the microstructure, can result in high corrosion rates in both the nitric acid and ferric sulfate–sulfuric acid solutions.

1.3 The oxalic acid etch test is a rapid method of identifying, by simple etching, those specimens of certain stainless steel grades that are essentially free of susceptibility to intergranular attack associated with chromium carbide precipitates. These specimens will have low corrosion rates in certain corrosion tests and therefore can be eliminated (screened) from testing as “acceptable.”

1.4 The ferric sulfate–sulfuric acid test, the copper–copper sulfate–50 % sulfuric acid test, and the nitric acid test are based on weight loss determinations and, thus, provide a quantitative measure of the relative performance of specimens evaluated. In contrast, the copper–copper sulfate–16 % sulfuric acid test is based on visual examination of bend specimens and, therefore, classifies the specimens only as acceptable or nonacceptable.

1.5 In most cases either the 15-h copper–copper sulfate–16 % sulfuric acid test or the 120-h ferric sulfate–sulfuric acid test, combined with the oxalic acid etch test, will provide the required information in the shortest time. All stainless grades listed in the accompanying table may be evaluated in these combinations of screening and corrosion tests, except those specimens of molybdenum-bearing grades (for example 316, 316L, 317, and 317L), which represent steel intended for use in nitric acid environments.

1.6 The 240...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A262 – 02a (Reapproved 2008)

Standard Practices for

Detecting Susceptibility to Intergranular Attack in Austenitic

Stainless Steels

This standard is issued under the fixed designation A262; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope intergranular attack associated with chromium carbide precipi-

tates. These specimens will have low corrosion rates in certain

1.1 These practices cover the following five tests:

corrosion tests and therefore can be eliminated (screened) from

1.1.1 Practice A—Oxalic Acid Etch Test for Classification

testing as “acceptable.”

of Etch Structures of Austenitic Stainless Steels (Sections 3 to

1.4 The ferric sulfate–sulfuric acid test, the copper–copper

7, inclusive),

sulfate–50 %sulfuricacidtest,andthenitricacidtestarebased

1.1.2 Practice B—Ferric Sulfate–Sulfuric Acid Test for

on weight loss determinations and, thus, provide a quantitative

Detecting Susceptibility to Intergranular Attack in Austenitic

measureoftherelativeperformanceofspecimensevaluated.In

Stainless Steels (Sections 8 to 14, inclusive),

contrast, the copper–copper sulfate–16 % sulfuric acid test is

1.1.3 Practice C—Nitric Acid Test for Detecting Suscepti-

based on visual examination of bend specimens and, therefore,

bility to Intergranular Attack in Austenitic Stainless Steels

classifies the specimens only as acceptable or nonacceptable.

(Sections 15 to 21, inclusive),

1.5 In most cases either the 15-h copper–copper sul-

1.1.4 Practice E—Copper–Copper Sulfate–Sulfuric Acid

fate–16 % sulfuric acid test or the 120-h ferric sulfate–sulfuric

Test for Detecting Susceptibility to Intergranular Attack in

acid test, combined with the oxalic acid etch test, will provide

Austenitic Stainless Steels (Sections 22 to 31, inclusive), and

the required information in the shortest time. All stainless

1.1.5 Practice F—Copper–Copper Sulfate–50 % Sulfuric

grades listed in the accompanying table may be evaluated in

Acid Test for Detecting Susceptibility to Intergranular Attack

these combinations of screening and corrosion tests, except

in Molybdenum-Bearing CastAustenitic Stainless Steels (Sec-

those specimens of molybdenum-bearing grades (for example

tions 32 to 38, inclusive).

316, 316L, 317, and 317L), which represent steel intended for

1.2 The following factors govern the application of these

use in nitric acid environments.

practices:

1.6 The 240-h nitric acid test must be applied to stabilized

1.2.1 Susceptibility to intergranular attack associated with

and molybdenum-bearing grades intended for service in nitric

theprecipitationofchromiumcarbidesisreadilydetectedinall

acidandtoallstainlesssteelgradesthatmightbesubjecttoend

six tests.

grain corrosion in nitric acid service.

1.2.2 Sigma phase in wrought chromium-nickel-

1.7 Only those stainless steel grades are listed inTable 1 for

molybdenum steels, which may or may not be visible in the

whichdataontheapplicationoftheoxalicacidetchtestandon

microstructure, can result in high corrosion rates only in nitric

their performance in various quantitative evaluation tests are

acid.

available.

1.2.3 Sigma phase in titanium or columbium stabilized

1.8 Extensive test results on various types of stainless steels

alloys and cast molybdenum-bearing stainless alloys, which

evaluated by these practices have been published in Ref (1).

may or may not be visible in the microstructure, can result in

1.9 The values stated in SI units are to be regarded as

high corrosion rates in both the nitric acid and ferric sulfate-

standard. The inch-pound equivalents are in parentheses and

–sulfuric acid solutions.

may be approximate.

1.3 The oxalic acid etch test is a rapid method of identify-

1.10 This standard does not purport to address all of the

ing, by simple etching, those specimens of certain stainless

safety problems, if any, associated with its use. It is the

steel grades that are essentially free of susceptibility to

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. (Specific precau-

These practices are under the jurisdiction of ASTM Committee A01 on Steel,

tionary statements are given in 5.6, 11.1.1, 11.1.9, and 35.1.)

Stainless Steel and RelatedAlloys and are the direct responsibility of Subcommittee

A01.14 on Methods of Corrosion Testing.

Current edition approved March 1, 2008. Published March 2008. Originally

´3 2

approved in 1943. Last previous edition approved in 2002 as A262 – 02a . DOI: The boldface numbers in parentheses refer to the list of references found at the

10.1520/A0262-02AR08. end of these practices.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A262 – 02a (2008)

TABLE 1 Application of Evaluation Tests for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

NOTE 1—For each corrosion test, the types of susceptibility to intergranular attack detected are given along with the grades of stainless steels in which

they may be found.These lists may contain grades of steels in addition to those given in the rectangles. In such cases, the acid corrosion test is applicable,

but not the oxalic acid etch test.

NOTE 2—Theoxalicacidetchtestmaybeappliedtothegradesofstainlesssteelslistedintherectangleswhenusedinconnectionwiththetestindicated

by the arrow.

OXALIC ACID ETCH TEST

↓

↓↓↓ ↓

A

AISI : 304, 304L AISI: 304, 304L, 316, 316L, AISI: 201, 202, 301, 304, ACI: CF-3M, CF-8M,

317, 317L 304L, 304H, 316, 316L,

316H, 317, 317L, 321, 347

B

ACI : CF-3, CF-8 ACI: CF-3, CF-8, CF-3M,

CF-8M

C

Nitric Acid Test (240hin Ferric Sulfate–Sulfuric Acid Test Copper–Copper Sulfate– Copper–Copper Sulfate–

boiling solution) (120 h in boiling solution) Sulfuric Acid Test (15 h† 50 % Sulfuric Acid

in boiling solution) Testing Boiling Solution

Chromium carbide in: 304, Chromium carbide in: 304, Chromium carbide in: 201, Chromium carbide in: CF-3M,

304L, CF-3, CF-8 304L, 316, 316L, 317, 317L, 202, 301, 304, 304L, 316, CF-8M

Chromium carbide and sigma CF-3, CF-8 316L, 317, 317L, 321, 347

D

phase in: 316, 316L, 317, Chromium carbide and sigma

E

317L, 321, 347, CF-3M, CF- phase in: 321, CF-3M, CF-8M

8M

End-grain in: all grades

A

AISI: American Iron and Steel Institute designations for austenitic stainless steels.

B

ACI: Alloy Casting Institute designations.

C

The nitric acid test may be also applied to AISI 309, 310, 348, and AISI 410, 430, 446, and ACI CN-7M.

D

Must be tested in nitric acid test when destined for service in nitric acid.

E

To date, no data have been published on the effect of sigma phase on corrosion of AISI 347 in this test.

2. Referenced Documents 3.2 The oxalic acid etch test may be used to screen

specimens intended for testing in Practice B—Ferric Sulfate-

2.1 ASTM Standards:

–Sulfuric Acid Test, Practice C—Nitric Acid Test, Practice

A370 Test Methods and Definitions for Mechanical Testing

E—Copper–Copper Sulfate–16 % Sulfuric Acid Test, and

of Steel Products

Practice F—Copper–Copper Sulfate–50 % Sulfuric Acid Test.

2.2 ISO Standard:

3.2.1 Each practice contains a table showing which classi-

ISO 3651-2 Determination of Resistance to Intergranular

fications of etch structures on a given stainless steel grade are

Corrosion of Stainless Steels—Part 2: Ferritic,Austenitic,

equivalent to acceptable, or possibly nonacceptable perfor-

and Ferritic-Austenitic (Duplex) Stainless Steels—

mance in that particular test. Specimens having acceptable etch

Corrosion Test in Media Containing Sulfuric Acid

structures need not be subjected to the hot acid test. Specimens

PRACTICE A—OXALIC ACID ETCH TEST FOR having nonacceptable etch structures must be tested in the

CLASSIFICATION OF ETCH STRUCTURES OF specified hot acid solution.

AUSTENITIC STAINLESS STEELS 2

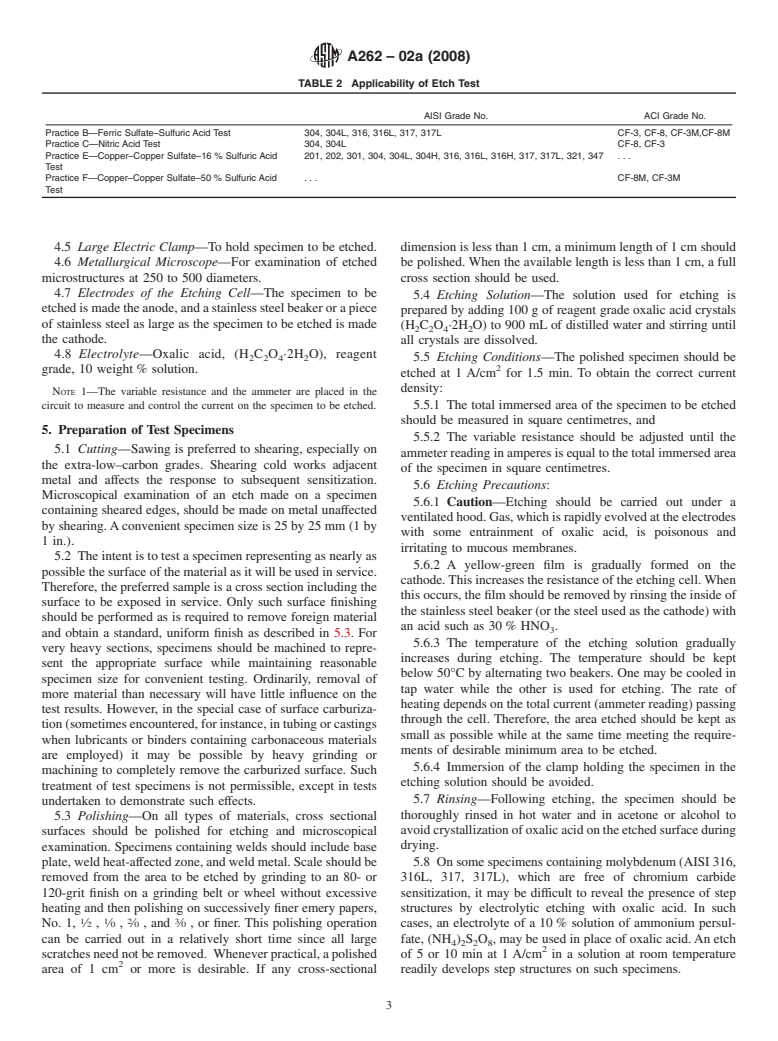

3.3 The grades of stainless steels and the hot acid tests for

which the oxalic acid etch test is applicable are listed in Table

3. Scope

2.

3.1 The oxalic acid etch test is used for acceptance of

3.4 Extra-low–carbon grades, and stabilized grades, such as

material but not for rejection of material. This may be used in

304L, 316L, 317L, 321, and 347, are tested after sensitizing

connection with other evaluation tests to provide a rapid

heat treatments at 650 to 675°C (1200 to 1250°F), which is the

method for identifying those specimens that are certain to be

range of maximum carbide precipitation. These sensitizing

free of susceptibility to rapid intergranular attack in these other

treatments must be applied before the specimens are submitted

tests. Such specimens have low corrosion rates in the various

to the oxalic acid etch test. The most commonly used sensitiz-

hot acid tests, requiring from 4 to 240 h of exposure. These

ing treatment is1hat 675°C (1250°F).

specimens are identified by means of their etch structures,

which are classified according to the following criteria:

4. Apparatus

4.1 Source of Direct Current—Battery, generator, or recti-

3 fier capable of supplying about 15 V and 20 A.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4.2 Ammeter—Range 0 to 30 A (Note 1).

Standards volume information, refer to the standard’s Document Summary page on

4.3 Variable Resistance (Note 1).

the ASTM website.

4.4 Cathode—A cylindrical piece of stainless steel or,

Available from International Organization for Standardization (ISO), 1 rue de

Varembé, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch. preferably, a 1-qt (0.946-L) stainless steel beaker.

A262 – 02a (2008)

TABLE 2 Applicability of Etch Test

AISI Grade No. ACI Grade No.

Practice B—Ferric Sulfate–Sulfuric Acid Test 304, 304L, 316, 316L, 317, 317L CF-3, CF-8, CF-3M,CF-8M

Practice C—Nitric Acid Test 304, 304L CF-8, CF-3

Practice E—Copper–Copper Sulfate–16 % Sulfuric Acid 201, 202, 301, 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 347 . . .

Test

Practice F—Copper–Copper Sulfate–50 % Sulfuric Acid . CF-8M, CF-3M

Test

4.5 Large Electric Clamp—To hold specimen to be etched. dimension is less than 1 cm, a minimum length of 1 cm should

4.6 Metallurgical Microscope—For examination of etched be polished. When the available length is less than 1 cm, a full

microstructures at 250 to 500 diameters. cross section should be used.

4.7 Electrodes of the Etching Cell—The specimen to be

5.4 Etching Solution—The solution used for etching is

etchedismadetheanode,andastainlesssteelbeakerorapiece

prepared by adding 100 g of reagent grade oxalic acid crystals

of stainless steel as large as the specimen to be etched is made

(H C O ·2H O) to 900 mL of distilled water and stirring until

2 2 4 2

the cathode.

all crystals are dissolved.

4.8 Electrolyte—Oxalic acid, (H C O ·2H O), reagent

2 2 4 2 5.5 Etching Conditions—The polished specimen should be

grade, 10 weight % solution.

etched at 1 A/cm for 1.5 min. To obtain the correct current

density:

NOTE 1—The variable resistance and the ammeter are placed in the

circuit to measure and control the current on the specimen to be etched.

5.5.1 The total immersed area of the specimen to be etched

should be measured in square centimetres, and

5. Preparation of Test Specimens

5.5.2 The variable resistance should be adjusted until the

5.1 Cutting—Sawing is preferred to shearing, especially on

ammeter reading in amperes is equal to the total immersed area

the extra-low–carbon grades. Shearing cold works adjacent

of the specimen in square centimetres.

metal and affects the response to subsequent sensitization.

5.6 Etching Precautions:

Microscopical examination of an etch made on a specimen

5.6.1 Caution—Etching should be carried out under a

containing sheared edges, should be made on metal unaffected

ventilatedhood.Gas,whichisrapidlyevolvedattheelectrodes

by shearing.Aconvenient specimen size is 25 by 25 mm (1 by

with some entrainment of oxalic acid, is poisonous and

1 in.).

irritating to mucous membranes.

5.2 The intent is to test a specimen representing as nearly as

5.6.2 A yellow-green film is gradually formed on the

possible the surface of the material as it will be used in service.

cathode.This increases the resistance of the etching cell.When

Therefore, the preferred sample is a cross section including the

this occurs, the film should be removed by rinsing the inside of

surface to be exposed in service. Only such surface finishing

the stainless steel beaker (or the steel used as the cathode) with

should be performed as is required to remove foreign material

an acid such as 30 % HNO .

and obtain a standard, uniform finish as described in 5.3. For

5.6.3 The temperature of the etching solution gradually

very heavy sections, specimens should be machined to repre-

increases during etching. The temperature should be kept

sent the appropriate surface while maintaining reasonable

below 50°C by alternating two beakers. One may be cooled in

specimen size for convenient testing. Ordinarily, removal of

tap water while the other is used for etching. The rate of

more material than necessary will have little influence on the

heating depends on the total current (ammeter reading) passing

test results. However, in the special case of surface carburiza-

through the cell. Therefore, the area etched should be kept as

tion(sometimesencountered,forinstance,intubingorcastings

small as possible while at the same time meeting the require-

when lubricants or binders containing carbonaceous materials

ments of desirable minimum area to be etched.

are employed) it may be possible by heavy grinding or

5.6.4 Immersion of the clamp holding the specimen in the

machining to completely remove the carburized surface. Such

etching solution should be avoided.

treatment of test specimens is not permissible, except in tests

5.7 Rinsing—Following etching, the specimen should be

undertaken to demonstrate such effects.

thoroughly rinsed in hot water and in acetone or alcohol to

5.3 Polishing—On all types of materials, cross sectional

avoidcrystallizationofoxalicacidontheetchedsurfaceduring

surfaces should be polished for etching and microscopical

drying.

examination. Specimens containing welds should include base

plate, weld heat-affected zone, and weld metal. Scale should be 5.8 On some specimens containing molybdenum (AISI 316,

removed from the area to be etched by gr

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard Designation: A 262 – 02a (Reapproved 2008)

Designation:A 262–02

Standard Practices for

Detecting Susceptibility to Intergranular Attack in Austenitic

Stainless Steels

This standard is issued under the fixed designation A 262; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 These practices cover the following five tests:

1.1.1 Practice A—Oxalic Acid Etch Test for Classification of Etch Structures of Austenitic Stainless Steels (Sections 3 to 7,

inclusive),

1.1.2 Practice B—Ferric Sulfate–SulfuricAcid Test for Detecting Susceptibility to IntergranularAttack inAustenitic Stainless

Steels (Sections 8 to 14, inclusive),

1.1.3 Practice C—Nitric Acid Test for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels (Sections

15 to 21, inclusive),

1.1.4 Practice E—Copper–Copper Sulfate–SulfuricAcid Test for Detecting Susceptibility to IntergranularAttack inAustenitic

Stainless Steels (Sections 22 to 31, inclusive), and

1.1.5 Practice F—Copper–Copper Sulfate–50 % Sulfuric Acid Test for Detecting Susceptibility to Intergranular Attack in

Molybdenum-Bearing Cast Austenitic Stainless Steels (Sections 32 to 38, inclusive).

1.2 The following factors govern the application of these practices:

1.2.1 Susceptibility to intergranular attack associated with the precipitation of chromium carbides is readily detected in all six

tests.

1.2.2 Sigmaphaseinwroughtchromium-nickel-molybdenumsteels,whichmayormaynotbevisibleinthemicrostructure,can

result in high corrosion rates only in nitric acid.

1.2.3 Sigma phase in titanium or columbium stabilized alloys and cast molybdenum-bearing stainless alloys, which may or may

not be visible in the microstructure, can result in high corrosion rates in both the nitric acid and ferric sulfate–sulfuric acid

solutions.

1.3 Theoxalicacidetchtestisarapidmethodofidentifying,bysimpleetching,thosespecimensofcertainstainlesssteelgrades

that are essentially free of susceptibility to intergranular attack associated with chromium carbide precipitates. These specimens

will have low corrosion rates in certain corrosion tests and therefore can be eliminated (screened) from testing as “acceptable.”

1.4 The ferric sulfate–sulfuric acid test, the copper–copper sulfate–50 % sulfuric acid test, and the nitric acid test are based on

weight loss determinations and, thus, provide a quantitative measure of the relative performance of specimens evaluated. In

contrast, the copper–copper sulfate–16 % sulfuric acid test is based on visual examination of bend specimens and, therefore,

classifies the specimens only as acceptable or nonacceptable.

1.5 In most cases either the 24-h15-h copper–copper sulfate–16 % sulfuric acid test or the 120-h ferric sulfate–sulfuric acid test,

combined with the oxalic acid etch test, will provide the required information in the shortest time. All stainless grades listed in

the accompanying table may be evaluated in these combinations of screening and corrosion tests, except those specimens of

molybdenum-bearing grades (for example 316, 316L, 317, and 317L), which represent steel intended for use in nitric acid

environments.

1.6 The 240-h nitric acid test must be applied to stabilized and molybdenum-bearing grades intended for service in nitric acid

and to all stainless steel grades that might be subject to end grain corrosion in nitric acid service.

1.7 Only those stainless steel grades are listed in Table 1 for which data on the application of the oxalic acid etch test and on

their performance in various quantitative evaluation tests are available.

1.8 Extensive test results on various types of stainless steels evaluated by these practices have been published in Ref (1).

These practices are under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and are the direct responsibility of SubcommitteeA01.14

on Methods of Corrosion Testing.

Current edition approved June 10, 2002. Published August 2002. Originally published as A262–43T. Last previous edition A262–01.

e3

Current edition approved March 1, 2008. Published March 2008. Originally approved in 1943. Last previous edition approved in 2002 as A 262 – 02a .

The boldface numbers in parentheses refer to the list of references found at the end of these practices.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 262 – 02a (2008)

1.9 The values stated in SI units are to be regarded as standard. The inch-pound equivalents are in parentheses and may be

approximate.

1.10 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. (Specific precautionary statements are given in 5.6, 11.1.1, 11.1.9, and 35.1.)

TABLE 1 Application of Evaluation Tests for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

NOTE 1—For each corrosion test, the types of susceptibility to intergranular attack detected are given along with the grades of stainless steels in which

they may be found.These lists may contain grades of steels in addition to those given in the rectangles. In such cases, the acid corrosion test is applicable,

but not the oxalic acid etch test.

NOTE 2—Theoxalicacidetchtestmaybeappliedtothegradesofstainlesssteelslistedintherectangleswhenusedinconnectionwiththetestindicated

by the arrow.

OXALIC ACID ETCH TEST

↓

↓↓↓ ↓

A

AISI : 304, 304L AISI: 304, 304L, 316, 316L, AISI: 201, 202, 301, 304, ACI: CF-3M, CF-8M,

317, 317L 304L, 304H, 316, 316L,

316H, 317, 317L, 321, 347

B

ACI : CF-3, CF-8 ACI: CF-3, CF-8, CF-3M,

CF-8M

C

Nitric Acid Test (240hin Ferric Sulfate–Sulfuric Acid Test Copper–Copper Sulfate– Copper–Copper Sulfate–

boiling solution) (120 h in boiling solution) Sulfuric Acid Test (2415 h† 50 % Sulfuric Acid

in boiling solution) Testing Boiling Solution

Chromium carbide in: 304, Chromium carbide in: 304, Chromium carbide in: 201, Chromium carbide in: CF-3M,

304L, CF-3, CF-8 304L, 316, 316L, 317, 317L, 202, 301, 304, 304L, 316, CF-8M

Chromium carbide and sigma CF-3, CF-8 316L, 317, 317L, 321, 347

D

phase in: 316, 316L, 317, Chromium carbide and sigma

E

317L, 321, 347, CF-3M, CF- phase in: 321, CF-3M, CF-8M

8M

End-grain in: all grades

A

AISI: American Iron and Steel Institute designations for austenitic stainless steels.

B

ACI: Alloy Casting Institute designations.

C

The nitric acid test may be also applied to AISI 309, 310, 348, and AISI 410, 430, 446, and ACI CN-7M.

D

Must be tested in nitric acid test when destined for service in nitric acid.

E

To date, no data have been published on the effect of sigma phase on corrosion of AISI 347 in this test.

2. Referenced Documents

2.1 ASTM Standards:

A 370 Test Methods and Definitions for Mechanical Testing of Steel Products

2.2 ISO Standard:

ISO 5651-23651-2 Determination of Resistance to Intergranular Corrosion of Stainless Steels—Part 2: Ferritic,Austenitic, and

Ferritic-Austenitic (Duplex) Stainless Steels—Corrosion Test in Media Containing Sulfuric Acid

PRACTICE A—OXALIC ACID ETCH TEST FOR

CLASSIFICATION OF ETCH STRUCTURES OF AUSTENITIC STAINLESS STEELS 2

3. Scope

3.1 The oxalic acid etch test is used for acceptance of material but not for rejection of material. This may be used in connection

with other evaluation tests to provide a rapid method for identifying those specimens that are certain to be free of susceptibility

to rapid intergranular attack in these other tests. Such specimens have low corrosion rates in the various hot acid tests, requiring

from 4 to 240 h of exposure. These specimens are identified by means of their etch structures, which are classified according to

the following criteria:

3.2 The oxalic acid etch test may be used to screen specimens intended for testing in Practice B—Ferric Sulfate–SulfuricAcid

Test, Practice C—NitricAcidTest, Practice E—Copper–Copper Sulfate–16 %SulfuricAcidTest, and Practice F—Copper–Copper

Sulfate–50 % Sulfuric Acid Test.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 01.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from International Organization for Standardization (ISO), 1,1 rue de Varembé, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

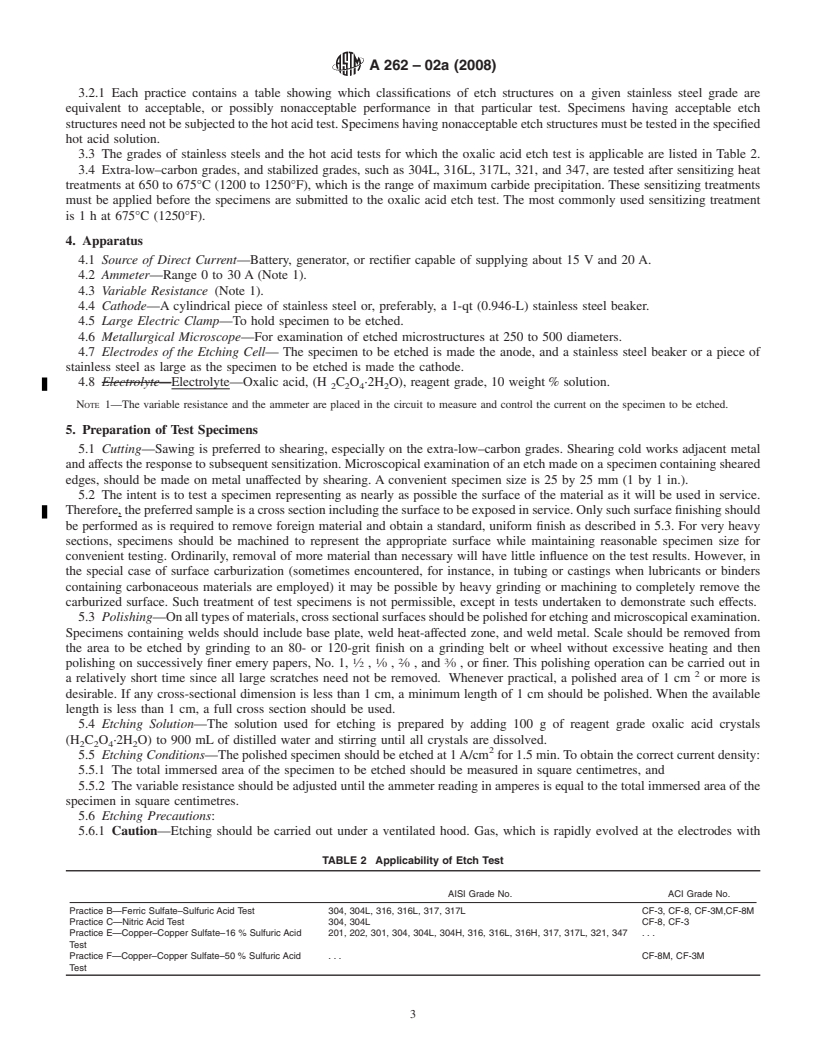

A 262 – 02a (2008)

3.2.1 Each practice contains a table showing which classifications of etch structures on a given stainless steel grade are

equivalent to acceptable, or possibly nonacceptable performance in that particular test. Specimens having acceptable etch

structures need not be subjected to the hot acid test. Specimens having nonacceptable etch structures must be tested in the specified

hot acid solution.

3.3 The grades of stainless steels and the hot acid tests for which the oxalic acid etch test is applicable are listed in Table 2.

3.4 Extra-low–carbon grades, and stabilized grades, such as 304L, 316L, 317L, 321, and 347, are tested after sensitizing heat

treatments at 650 to 675°C (1200 to 1250°F), which is the range of maximum carbide precipitation. These sensitizing treatments

must be applied before the specimens are submitted to the oxalic acid etch test. The most commonly used sensitizing treatment

is1hat 675°C (1250°F).

4. Apparatus

4.1 Source of Direct Current—Battery, generator, or rectifier capable of supplying about 15 V and 20 A.

4.2 Ammeter—Range 0 to 30 A (Note 1).

4.3 Variable Resistance (Note 1).

4.4 Cathode—A cylindrical piece of stainless steel or, preferably, a 1-qt (0.946-L) stainless steel beaker.

4.5 Large Electric Clamp—To hold specimen to be etched.

4.6 Metallurgical Microscope—For examination of etched microstructures at 250 to 500 diameters.

4.7 Electrodes of the Etching Cell— The specimen to be etched is made the anode, and a stainless steel beaker or a piece of

stainless steel as large as the specimen to be etched is made the cathode.

4.8 Electrolyte—Electrolyte—Oxalic acid, (H C O ·2H O), reagent grade, 10 weight % solution.

2 2 4 2

NOTE 1—The variable resistance and the ammeter are placed in the circuit to measure and control the current on the specimen to be etched.

5. Preparation of Test Specimens

5.1 Cutting—Sawing is preferred to shearing, especially on the extra-low–carbon grades. Shearing cold works adjacent metal

and affects the response to subsequent sensitization. Microscopical examination of an etch made on a specimen containing sheared

edges, should be made on metal unaffected by shearing. A convenient specimen size is 25 by 25 mm (1 by 1 in.).

5.2 The intent is to test a specimen representing as nearly as possible the surface of the material as it will be used in service.

Therefore,thepreferredsampleisacrosssectionincludingthesurfacetobeexposedinservice.Onlysuchsurfacefinishingshould

be performed as is required to remove foreign material and obtain a standard, uniform finish as described in 5.3. For very heavy

sections, specimens should be machined to represent the appropriate surface while maintaining reasonable specimen size for

convenient testing. Ordinarily, removal of more material than necessary will have little influence on the test results. However, in

the special case of surface carburization (sometimes encountered, for instance, in tubing or castings when lubricants or binders

containing carbonaceous materials are employed) it may be possible by heavy grinding or machining to completely remove the

carburized surface. Such treatment of test specimens is not permissible, except in tests undertaken to demonstrate such effects.

5.3 Polishing—Onalltypesofmaterials,crosssectionalsurfacesshouldbepolishedforetchingandmicroscopicalexamination.

Specimens containing welds should include base plate, weld heat-affected zone, and weld metal. Scale should be removed from

the area to be etched by grinding to an 80- or 120-grit finish on a grinding belt or wheel without excessive heating and then

1 1 2 3

polishing on successively finer emery papers, No. 1, ⁄2 , ⁄0 , ⁄0 , and ⁄0 , or finer. This polishing operation can be carried out in

a relatively short time since all large scratches need not be removed. Whenever practical, a polished area of 1 cm or more is

desirable. If any cross-sectional dimension is less than 1 cm, a minimum length of 1 cm should be polished. When the available

length is less than 1 cm, a full cross section should be used.

5.4 Etching Solution—The solution used for etching is prepared by adding 100 g of reagent grade oxalic acid crystals

(H C O ·2H O) to 900 mL of distilled water and stirring until all crystals are dissolved.

2 2 4 2

5.5 EtchingConditions—The polished specimen should be etched at 1A/cm for 1.5 min.To obtain the correct current density:

5.5.1 The total immersed area of the specimen to be etched should be measured in square centimetres, and

5.5.2 The variable resistance should be adjusted until the ammeter reading in amperes is equal to the total immersed area of the

specimen in square centimetres.

5.6 Etching Precautions:

5.6.1 Caution—Etching should be carried out under a ventilated hood. Gas, which is rapidly evolved at the electrodes with

TABLE 2 Applicability of Etch Test

AISI Grade No. ACI Grade No.

Practice B—Ferric Sulfate–Sulfuric Acid Test 304, 304L, 316, 316L, 317, 317L CF-3, CF-8, CF-3M,CF-8M

Practice C—Nitric Acid Test 304, 304L CF-8, CF-3

Practice E—Copper–Copper Sulfate–16 % Sulfuric Acid 201, 202, 301, 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 347 . . .

Test

Practice F—Copper–Copper Sulfate–50 % Sulfuric Acid . CF-8M, CF-3M

Test

A 262 – 02a (2008)

some entrainment of oxalic acid, is poisonous and irritating to mucous membranes.

5.6.2 Ayellow-greenfilmisgraduallyformedonthecathode.Thisincreasestheresistanceoftheetchingcell.Whenthisoccurs,

the film should be removed by rinsing the inside of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.