ASTM D7245-09(2021)

(Test Method)Standard Test Method for Measuring Total Water and Volatiles in Liquid Coatings Which Produce Cure Water Upon Heating

Standard Test Method for Measuring Total Water and Volatiles in Liquid Coatings Which Produce Cure Water Upon Heating

SIGNIFICANCE AND USE

5.1 In the determination of VOC, cure water is treated as a VOC in other test methods, as these methods are unable to account for cure water. This test method allows taking credit for cure water as total water is measured, a value which includes cure water.

5.2 Total water content and volatile content results obtained with this method may be used in Practice D3960 to calculate VOC of the coating.

SCOPE

1.1 This test method is designed to measure total water which includes cure water resulting from the heat induced condensation reaction of coatings. Cure water cannot be measured directly by Test Method D4017. This task is accomplished by measuring water content in the vapors evolved during heating. This test method will yield total water content. This test method also permits for the simultaneous determination of total volatile content. The results of this test method may be used to calculate VOC content. Although this test method was designed for phenolic coatings, it can be used with other types of coatings.

1.2 Materials used for method development and evaluation had total water values from 20 to 37 %. Use of this test method on coatings outside these values will need to be validated by the user.

1.3 Sample heating is accomplished with a Brinkmann Instruments Model 832 drying oven,2 or other mutually agreed upon alternative, passing all of the evolved vapors into a Karl Fischer titration vessel.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

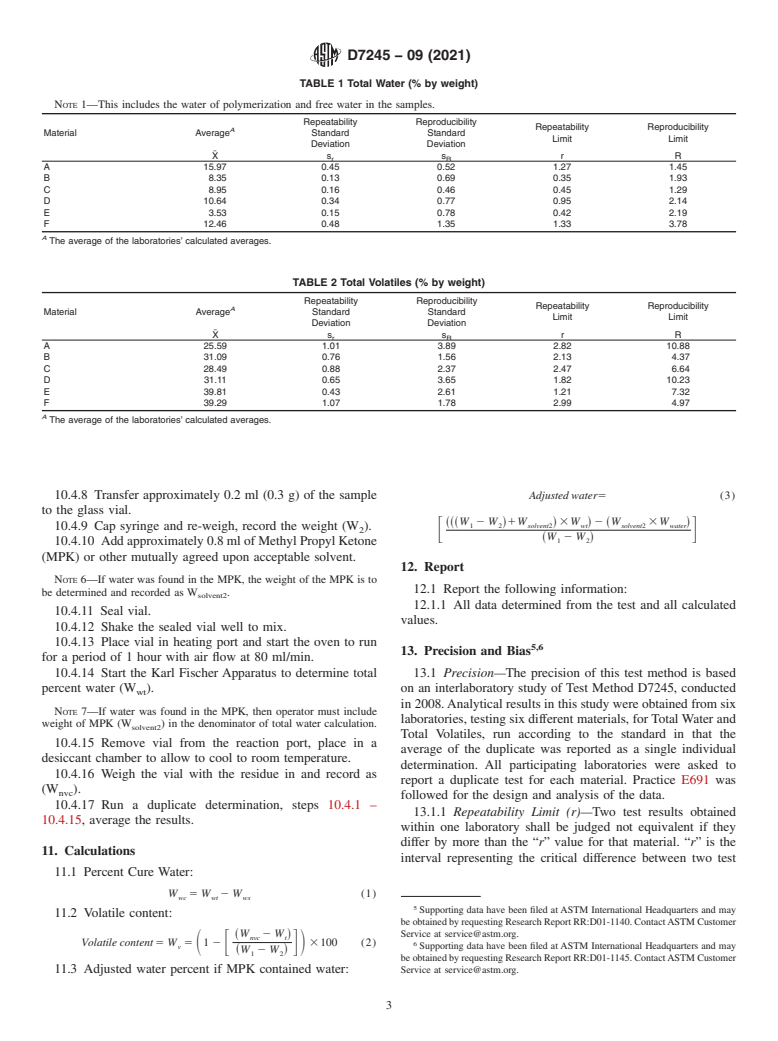

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7245 − 09 (Reapproved 2021)

Standard Test Method for

Measuring Total Water and Volatiles in Liquid Coatings

Which Produce Cure Water Upon Heating

This standard is issued under the fixed designation D7245; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This test method is designed to measure total water

which includes cure water resulting from the heat induced

2. Referenced Documents

condensation reaction of coatings. Cure water cannot be

2.1 ASTM Standards:

measured directly by Test Method D4017. This task is accom-

D1193 Specification for Reagent Water

plished by measuring water content in the vapors evolved

D3925 Practice for Sampling Liquid Paints and Related

during heating. This test method will yield total water content.

Pigmented Coatings

This test method also permits for the simultaneous determina-

D3960 PracticeforDeterminingVolatileOrganicCompound

tion of total volatile content. The results of this test method

(VOC) Content of Paints and Related Coatings

may be used to calculate VOC content. Although this test

D4017 Test Method for Water in Paints and Paint Materials

method was designed for phenolic coatings, it can be used with

by Karl Fischer Method

other types of coatings.

E177 Practice for Use of the Terms Precision and Bias in

1.2 Materials used for method development and evaluation

ASTM Test Methods

had total water values from 20 to 37 %. Use of this test method

E691 Practice for Conducting an Interlaboratory Study to

on coatings outside these values will need to be validated by

Determine the Precision of a Test Method

the user.

3. Terminology

1.3 Sample heating is accomplished with a Brinkmann

Instruments Model 832 drying oven, or other mutually agreed 3.1 Definitions:

3.1.1 cure water, n—water produced as a product of con-

upon alternative, passing all of the evolved vapors into a Karl

Fischer titration vessel. densation reaction during cure.

3.1.2 total water, n—water in the liquid coating plus cure

1.4 The values stated in SI units are to be regarded as

water produced by the condensation reaction.

standard. No other units of measurement are included in this

standard.

4. Summary of Test Method

1.5 This standard does not purport to address all of the

4.1 Ameasured quantity of coating is added to a tared glass

safety concerns, if any, associated with its use. It is the

vial which is sealed and then placed into a preheated oven

responsibility of the user of this standard to establish appro-

chamber for the required test duration. Sample is heated at

priate safety, health, and environmental practices and deter-

110°Cforonehour.ThevolatilesarepassedintoaKarlFischer

mine the applicability of regulatory limitations prior to use.

titration vessel and total water determined. By subtracting the

1.6 This international standard was developed in accor-

percent water found in regular Karl Fischer titration, Test

dance with internationally recognized principles on standard-

Method D4017, from total water, the percent of cure water can

ization established in the Decision on Principles for the

be determined. With the weights being known and vial sealed,

Development of International Standards, Guides and Recom-

total volatile content is obtained with this method.

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee D01 on Paint

5.1 In the determination of VOC, cure water is treated as a

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

VOC in other test methods, as these methods are unable to

Current edition approved Feb. 1, 2021. Published March 2021. Originally

approved in 2007. Last previous edition approved in 2014 as D7245 – 09 (2014).

DOI: 10.1520/D7245-09R21. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Round-robin collaborators used the Model 832 drying oven which were loaned contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

to them by Brinkmann Instruments Westbury, New York 11590. It is not known Standards volume information, refer to the standard’s Document Summary page on

whether this method is applicable to other similar instruments. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7245 − 09 (2021)

7.4 Methyl Propyl Ketone (MPK), or other appropriate

solvent—Technical Grade.

8. Preparation of Apparatus

8.1 ConnecttransferlinefromtheovenintotheKarlFischer

unit so the end of the tubing is beneath the level of the liquid

in the Karl Fischer titration vessel.

NOTE1—Equipmenttestedcameequippedwithataperedplugdesigned

for the tubing to fit through and which was tapered to fit into the Karl

Fischer unit.

NOTE 2—Transfer line should be insulated to avoid condensation of

vapors in the line. The use of a heated transfer line is preferred.

FIG. 1 Drying Oven

8.2 The air-inlet port shall be attached to a source of

desiccant-dried air or nitrogen.

NOTE 3—Testing found no appreciable difference between the two.

account for cure water. This test method allows taking credit

for cure water as total water is measured, a value which

8.3 Check equipment for leaks.

includes cure water.

8.4 Precondition the glass vials and septum by heating in an

5.2 Total water content and volatile content results obtained

oven at 110ºC for 30 minutes and storing in a desiccator until

with this method may be used in Practice D3960 to calculate

needed.

VOC of the coating.

9. Calibration and Standardization

6. Apparatus

9.1 Use the procedure specified in Test Method D4017 for

6.1 Glass Vial—A glass vial measuring 22 mm in diameter,

calibration and standardization of the Karl Fischer apparatus.

38 mm in height having a capacity of 6 ml capable of being

9.2 Run a blank on the Methyl Propyl Ketone (MPK) to

sealed with a TFE-fluorocarbon septum.

determine if it contains water. If there is water present in the

6.2 Analytical Balance—Capable of weighing to 60.0001

solvent, proceed to 9.2.1.

g.

9.2.1 Weigh a sample of MPK, record as W ,tothe

solvent

6.3 Drying Oven—This instrument is essentially a closed nearest 0.1 mg.

9.2.2 Perform Test Method D4017, record the weight per-

system in which the sample is heated within the heating

chamber and the vapors passed to the titration vessel through a cent water results as W .

water

connecting tube. See Fig. 1.

10. Procedure

6.4 Karl Fischer Apparatus—See Test Method D4017.

10.1 Take a representative sample of the liquid coating in

6.5 Syringe—Minimum of 1 ml but no more than 5 ml

accordance with Practice D3925.

capacity equipped without a needle, but with a cap, capable of

properly dispensing the coating. 10.2 Thoroughly mix the sample to be analyzed.

4 NOTE 4—Mixing time of 5 minutes has proven adequate for most

7. Reagents

samples.

7.1 Purity of Reagent—Reagent grade chemicals shall be

10.3 Should amount of cure water need to be known,

used in all tests unless otherwise indicated; it is intended that

determine percent water content on the coating in accordance

all reagents conform to the specifications of the committee on

with Test Method D4017 (W ).

ws

Analytical Reagents of the American Chemical Society where

10.4 Determine Total Water (W ) and Volatile content

wt

such specifications are available. Other grades may be used,

(W ).

v

provided it is first ascertained that the reagent is of sufficiently

10.4.1 Preheat the Drying oven to 110 6 2ºC.

high purity to permit use.

10.4.2 Set the Airflow to 80 ml/min.

7.2 Purity of Water—Unless otherwise indicated references

10.4.3 Purge transfer line for a period of 5 min

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.