ASTM A197/A197M-00(2019)

(Specification)Standard Specification for Cupola Malleable Iron

Standard Specification for Cupola Malleable Iron

ABSTRACT

This specification covers malleable irons for castings made by the cupola process. The chemical composition of the iron shall be such as to produce materials that meet the mechanical property requirements. The tensile test methods for malleable iron are presented in details. At least three tensile test specimens shall be cast from a representative ladle of iron from each 4-h pour period during the purchaser's castings were poured. Only one test specimen need be tested to qualify each pour period and heat treatment batch provided the requirements of this specification are met by the test specimen. The microstructure of the malleable iron shall consist of temper carbon nodules uniformly distributed in a ferritic matrix and shall be free from excessive pearlite, massive carbides, and primary graphite. All castings, on visual examination shall be sound and free from obvious shrinkage and porosity.

SCOPE

1.1 This specification covers malleable irons for castings made by the cupola process.

1.2 Without knowledge of casting geometry and process details, quantitative relationships cannot be stated between the properties of the iron in the various locations of a casting and those of a test bar cast from the same iron.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A197/A197M −00 (Reapproved 2019)

Standard Specification for

Cupola Malleable Iron

This standard is issued under the fixed designationA197/A197M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 4. Classification

1.1 This specification covers malleable irons for castings 4.1 Iron produced for castings ordered under this specifica-

made by the cupola process. tion is classified in a single grade and is qualified by tests on

separately cast test bars. Separately cast test bars shall be

1.2 Without knowledge of casting geometry and process

poured from the same lot of iron as the castings they represent

details, quantitative relationships cannot be stated between the

and shall be heat treated with those castings.

properties of the iron in the various locations of a casting and

those of a test bar cast from the same iron.

5. Ordering Information

1.3 The values stated in either inch-pound units or SI units

5.1 The purchase order for castings ordered under this

are to be regarded separately as standard. Within the text, the

specification shall state the specification designation and the

SI units are shown in brackets. The values stated in each

year in which the specification was issued.

system are not exact equivalents; therefore, each system shall

be used independently of the other. Combining values from the 5.2 Any options or special additions to the basic require-

ments of this specification shall be clearly and fully stipulated.

two systems may result in nonconformance with the specifi-

cation.

6. Chemical Composition

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

6.1 The chemical composition of the iron shall be such as to

ization established in the Decision on Principles for the produce the mechanical properties required by this specifica-

Development of International Standards, Guides and Recom-

tion.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 7. Mechanical Requirements

7.1 Factors influencing the properties of castings and their

2. Referenced Documents

relationship to those of test specimens and separate test

2.1 ASTM Standards:

castings are discussed in Appendix X1.

A247 Test Method for Evaluating the Microstructure of

7.2 Tensile Test:

Graphite in Iron Castings

7.2.1 Tensile Test Specimens:

A644 Terminology Relating to Iron Castings

7.2.1.1 The tensile test specimens shall be cast to the form

E8/E8M Test Methods for Tension Testing of Metallic Ma-

and dimensions shown in Figs. 1 and 2 using the same kind of

terials

molding material used for the production castings.

7.2.1.2 All test specimens shall be suitably identified with

3. Terminology

the designation of the pour period.

3.1 Definitions—Definitions for many terms common to

7.2.1.3 All test specimens shall be heat treated in the same

iron castings are found in Terminology A644.

production furnace and for the same cycles as the castings they

represent.

This specification is under the jurisdiction of ASTM Committee A04 on Iron

7.2.2 Tensile Test Method:

Castings and is the direct responsibility of Subcommittee A04.02 on Malleable and

7.2.2.1 Perform the tensile test on unmachined specimens.

Ductile Iron Castings.

7.2.2.2 Gage Length—The gage length of the standard

Current edition approved Nov. 1, 2019. Published November 2019. Originally

tensile specimen shall be 2.00 6 0.01 in. [50.0 6 0.03 mm].

approved in 1936. Last previous edition approved in 2015 as A197/A197M – 00

(2015). DOI: 10.1520/A0197_A0197M-00R19.

7.2.2.3 Cross-Sectional Area—The diameter used to com-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

pute the cross-sectional area shall be the average between the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

largest and smallest diameters in that section of the 2-in.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. [50-mm] gage length having the smallest diameter and shall be

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A197/A197M − 00 (2019)

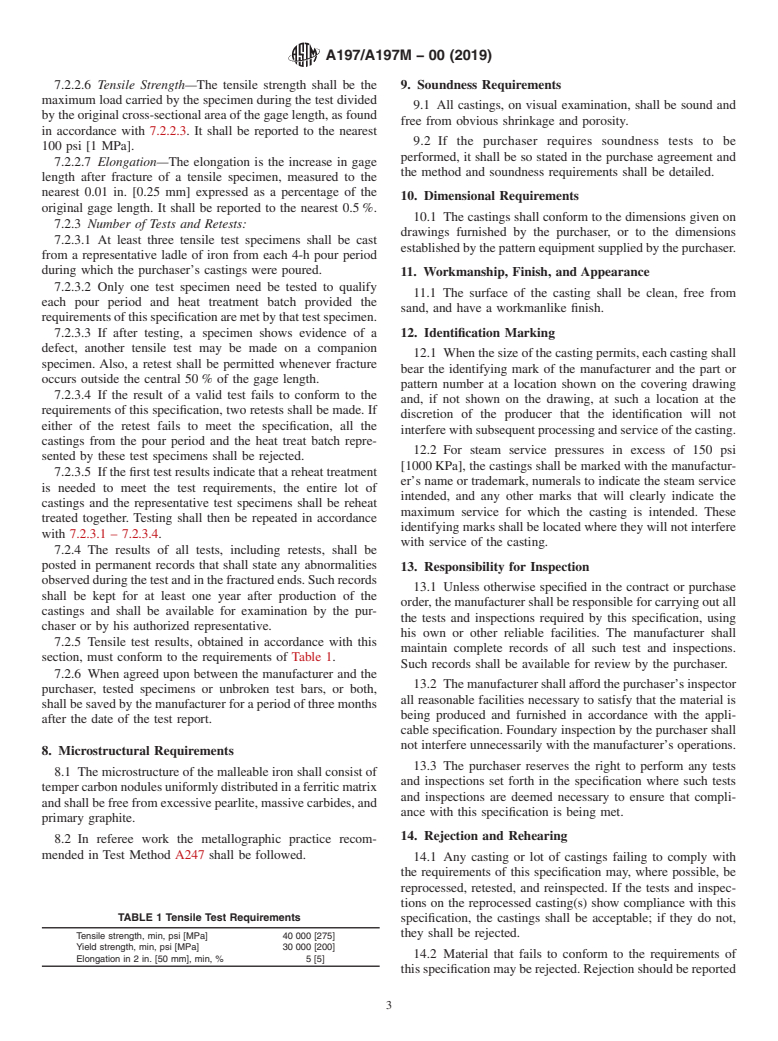

FIG. 1 Tension Test Specimen

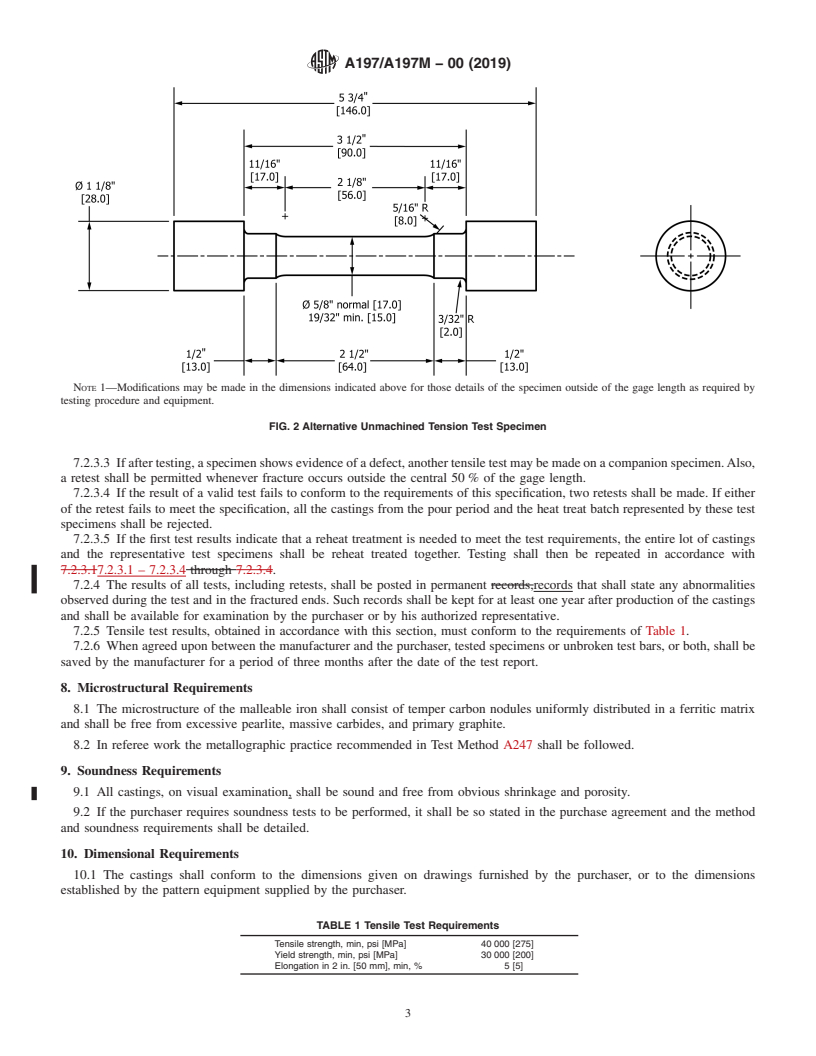

NOTE 1—Modifications may be made in the dimensions indicated above for those details of the specimen outside of the gage length as required by

testing procedure and equipment.

FIG. 2 Alternative Unmachined Tension Test Specimen

measured to the nearest 0.001 in. [0.02 mm]. No cast bar determined by an approved technique described in Test Meth-

having a mean diameter less than 0.590 in. [15 mm] shall be odsE8/E8Morbyanequivalentmethod.Ifdeterminedasyield

accepted for test. strength, that stress producing an extension under load of

7.2.2.4 Speed of Testing—After reaching a stress equivalent 0.01 in. [0.25 mm] over the 2-in. [50-mm] gage length (for

to approximately half of the anticipated yield stress, the speed example, 0.5 % extension) or an offset of 0.2 % shall be taken

of the moving head of the testing machine shall not exceed astheyieldstress,whichshallbeconvertedtoyieldstrengthby

0.50 in./min [12.5 mm/min] through the breaking load. dividing by the original cross-sectional area of the gage length

7.2.2.5 Yield Strength—While the values for yield point and found in accordance with 7.2.2.3. It shall be reported to the

yield strength are not identical, they are sufficiently close for nearest100psi[1MPa].Inrefereework,yieldstrengthshallbe

most applications to be used interchangeably. They shall be determined at an offset of 0.2 % from the stress strain curve.

A197/A197M − 00 (2019)

7.2.2.6 Tensile Strength—The tensile strength shall be the 9. Soundness Requirements

maximum load carried by the specimen during the test divided

9.1 All castings, on visual examination, shall be sound and

by the original cross-sectional area of the gage length, as found

free from obvious shrinkage and porosity.

in accordance with 7.2.2.3. It shall be reported to the nearest

9.2 If the purchaser requires soundness tests to be

100 psi [1 MPa].

performed, it shall be so stated in the purchase agreement and

7.2.2.7 Elongation—The elongation is the increase in gage

the method and soundness requirements shall be detailed.

length after fracture of a tensile specimen, measured to the

nearest 0.01 in. [0.25 mm] expressed as a percentage of the

10. Dimensional Requirements

original gage length. It shall be reported to the nearest 0.5 %.

10.1 The castings shall conform to the dimensions given on

7.2.3 Number of Tests and Retests:

drawings furnished by the purchaser, or to the dimensions

7.2.3.1 At least three tensile test specimens shall be cast

establishedbythepatternequipmentsuppliedbythepurchaser.

from a representative ladle of iron from each 4-h pour period

during which the purchaser’s castings were poured.

11. Workmanship, Finish, and Appearance

7.2.3.2 Only one test specimen need be tested to qualify

11.1 The surface of the casting shall be clean, free from

each pour period and heat treatment batch provided the

sand, and have a workmanlike finish.

requirementsofthisspecificationaremetbythattestspecimen.

12. Identification Marking

7.2.3.3 If after testing, a specimen shows evidence of a

defect, another tensile test may be made on a companion

12.1 When the size of the casting permits, each casting shall

specimen. Also, a retest shall be permitted whenever fracture

bear the identifying mark of the manufacturer and the part or

occurs outside the central 50 % of the gage length.

pattern number at a location shown on the covering drawing

7.2.3.4 If the result of a valid test fails to conform to the

and, if not shown on the drawing, at such a location at the

requirements of this specification, two retests shall be made. If

discretion of the producer that the identification will not

either of the retest fails to

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A197/A197M − 00 (Reapproved 2019)

Standard Specification for

Cupola Malleable Iron

This standard is issued under the fixed designation A197/A197M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 4. Classification

1.1 This specification covers malleable irons for castings 4.1 Iron produced for castings ordered under this specifica-

made by the cupola process. tion is classified in a single grade and is qualified by tests on

separately cast test bars. Separately cast test bars shall be

1.2 Without knowledge of casting geometry and process

poured from the same lot of iron as the castings they represent

details, quantitative relationships cannot be stated between the

and shall be heat treated with those castings.

properties of the iron in the various locations of a casting and

those of a test bar cast from the same iron.

5. Ordering Information

1.3 The values stated in either inch-pound units or SI units

5.1 The purchase order for castings ordered under this

are to be regarded separately as standard. Within the text, the

specification shall state the specification designation and the

SI units are shown in brackets. The values stated in each

year in which the specification was issued.

system are not exact equivalents; therefore, each system shall

5.2 Any options or special additions to the basic require-

be used independently of the other. Combining values from the

two systems may result in nonconformance with the specifi- ments of this specification shall be clearly and fully stipulated.

cation.

6. Chemical Composition

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard- 6.1 The chemical composition of the iron shall be such as to

ization established in the Decision on Principles for the

produce the mechanical properties required by this specifica-

Development of International Standards, Guides and Recom- tion.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

7. Mechanical Requirements

7.1 Factors influencing the properties of castings and their

2. Referenced Documents

relationship to those of test specimens and separate test

2.1 ASTM Standards:

castings are discussed in Appendix X1.

A247 Test Method for Evaluating the Microstructure of

7.2 Tensile Test:

Graphite in Iron Castings

7.2.1 Tensile Test Specimens:

A644 Terminology Relating to Iron Castings

7.2.1.1 The tensile test specimens shall be cast to the form

E8/E8M Test Methods for Tension Testing of Metallic Ma-

and dimensions shown in Figs. 1 and 2 using the same kind of

terials

molding material used for the production castings.

7.2.1.2 All test specimens shall be suitably identified with

3. Terminology

the designation of the pour period.

3.1 Definitions—Definitions for many terms common to

7.2.1.3 All test specimens shall be heat treated in the same

iron castings are found in Terminology A644.

production furnace and for the same cycles as the castings they

represent.

This specification is under the jurisdiction of ASTM Committee A04 on Iron 7.2.2 Tensile Test Method:

Castings and is the direct responsibility of Subcommittee A04.02 on Malleable and

7.2.2.1 Perform the tensile test on unmachined specimens.

Ductile Iron Castings.

7.2.2.2 Gage Length—The gage length of the standard

Current edition approved Nov. 1, 2019. Published November 2019. Originally

tensile specimen shall be 2.00 6 0.01 in. [50.0 6 0.03 mm].

approved in 1936. Last previous edition approved in 2015 as A197/A197M – 00

(2015). DOI: 10.1520/A0197_A0197M-00R19.

7.2.2.3 Cross-Sectional Area—The diameter used to com-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

pute the cross-sectional area shall be the average between the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

largest and smallest diameters in that section of the 2-in.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. [50-mm] gage length having the smallest diameter and shall be

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A197/A197M − 00 (2019)

FIG. 1 Tension Test Specimen

NOTE 1—Modifications may be made in the dimensions indicated above for those details of the specimen outside of the gage length as required by

testing procedure and equipment.

FIG. 2 Alternative Unmachined Tension Test Specimen

measured to the nearest 0.001 in. [0.02 mm]. No cast bar determined by an approved technique described in Test Meth-

having a mean diameter less than 0.590 in. [15 mm] shall be ods E8/E8M or by an equivalent method. If determined as yield

accepted for test. strength, that stress producing an extension under load of

7.2.2.4 Speed of Testing—After reaching a stress equivalent 0.01 in. [0.25 mm] over the 2-in. [50-mm] gage length (for

to approximately half of the anticipated yield stress, the speed example, 0.5 % extension) or an offset of 0.2 % shall be taken

of the moving head of the testing machine shall not exceed as the yield stress, which shall be converted to yield strength by

0.50 in./min [12.5 mm/min] through the breaking load. dividing by the original cross-sectional area of the gage length

7.2.2.5 Yield Strength—While the values for yield point and found in accordance with 7.2.2.3. It shall be reported to the

yield strength are not identical, they are sufficiently close for nearest 100 psi [1 MPa]. In referee work, yield strength shall be

most applications to be used interchangeably. They shall be determined at an offset of 0.2 % from the stress strain curve.

A197/A197M − 00 (2019)

7.2.2.6 Tensile Strength—The tensile strength shall be the 9. Soundness Requirements

maximum load carried by the specimen during the test divided

9.1 All castings, on visual examination, shall be sound and

by the original cross-sectional area of the gage length, as found

free from obvious shrinkage and porosity.

in accordance with 7.2.2.3. It shall be reported to the nearest

9.2 If the purchaser requires soundness tests to be

100 psi [1 MPa].

performed, it shall be so stated in the purchase agreement and

7.2.2.7 Elongation—The elongation is the increase in gage

the method and soundness requirements shall be detailed.

length after fracture of a tensile specimen, measured to the

nearest 0.01 in. [0.25 mm] expressed as a percentage of the

10. Dimensional Requirements

original gage length. It shall be reported to the nearest 0.5 %.

10.1 The castings shall conform to the dimensions given on

7.2.3 Number of Tests and Retests:

drawings furnished by the purchaser, or to the dimensions

7.2.3.1 At least three tensile test specimens shall be cast

established by the pattern equipment supplied by the purchaser.

from a representative ladle of iron from each 4-h pour period

during which the purchaser’s castings were poured.

11. Workmanship, Finish, and Appearance

7.2.3.2 Only one test specimen need be tested to qualify

11.1 The surface of the casting shall be clean, free from

each pour period and heat treatment batch provided the

sand, and have a workmanlike finish.

requirements of this specification are met by that test specimen.

7.2.3.3 If after testing, a specimen shows evidence of a 12. Identification Marking

defect, another tensile test may be made on a companion

12.1 When the size of the casting permits, each casting shall

specimen. Also, a retest shall be permitted whenever fracture

bear the identifying mark of the manufacturer and the part or

occurs outside the central 50 % of the gage length.

pattern number at a location shown on the covering drawing

7.2.3.4 If the result of a valid test fails to conform to the

and, if not shown on the drawing, at such a location at the

requirements of this specification, two retests shall be made. If

discretion of the producer that the identification will not

either of the retest fails to meet the specification, all the

interfere with subsequent processing and service of the casting.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A197/A197M − 00 (Reapproved 2015) A197/A197M − 00 (Reapproved 2019)

Standard Specification for

Cupola Malleable Iron

This standard is issued under the fixed designation A197/A197M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers malleable irons for castings made by the cupola process.

1.2 Without knowledge of casting geometry and process details, quantitative relationships cannot be stated between the

properties of the iron in the various locations of a casting and those of a test bar cast from the same iron.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

A247 Test Method for Evaluating the Microstructure of Graphite in Iron Castings

A644 Terminology Relating to Iron Castings

E8E8/E8M Test Methods for Tension Testing of Metallic Materials [Metric] E0008_E0008M

3. Terminology

3.1 Definitions—Definitions for many terms common to iron castings are found in Terminology A644.

4. Classification

4.1 Iron produced for castings ordered under this specification is classified in a single grade and is qualified by tests on

separately cast test bars. Separately cast test bars shall be poured from the same lot of iron as the castings they represent and shall

be heat treated with those castings.

5. Ordering Information

5.1 The purchase order for castings ordered under this specification shall state the specification designation and the year in

which the specification was issued.

5.2 Any options or special additions to the basic requirements of this specification shall be clearly and fully stipulated.

6. Chemical Composition

6.1 The chemical composition of the iron shall be such as to produce the mechanical properties required by this specification.

7. Mechanical Requirements

7.1 Factors influencing the properties of castings and their relationship to those of test specimens and separate test castings are

discussed in Appendix X1.

This specification is under the jurisdiction of ASTM Committee A04 on Iron Castings and is the direct responsibility of Subcommittee A04.02 on Malleable and Ductile

Iron Castings.

Current edition approved Nov. 1, 2015Nov. 1, 2019. Published November 2011November 2019. Originally approved in 1936. Last previous edition approved in 20112015

as A197/A197M – 00 (2011).(2015). DOI: 10.1520/A0197_A0197M-00R15.10.1520/A0197_A0197M-00R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A197/A197M − 00 (2019)

7.2 Tensile Test:

7.2.1 Tensile Test Specimens:

7.2.1.1 The tensile test specimens shall be cast to the form and dimensions shown in Fig. 1Figs. 1 and 2 and Fig. 2using the

same kind of molding material used for the production castings.

7.2.1.2 All test specimens shall be suitably identified with the designation of the pour period.

7.2.1.3 All test specimens shall be heat treated in the same production furnace and for the same cycles as the castings they

represent.

7.2.2 Tensile Test Method:

7.2.2.1 Perform the tensile test on unmachined specimens.

7.2.2.2 Gage Length—The gage length of the standard tensile specimen shall be 2.00 6 0.01 in. [50.0 6 0.03 mm].

7.2.2.3 Cross-Sectional Area—The diameter used to compute the cross-sectional area shall be the average between the largest

and smallest diameters in that section of the 2-in. [50 mm] [50-mm] gage length having the smallest diameter and shall be

measured to the nearest 0.001 in. [0.02 mm]. No cast bar having a mean diameter less than 0.590 in. [15 mm] shall be accepted

for test.

7.2.2.4 Speed of Testing—After reaching a stress equivalent to approximately half of the anticipated yield stress, the speed of

the moving head of the testing machine shall not exceed 0.50 in./min [12.5 mm/min] through the breaking load.

7.2.2.5 Yield Strength—While the values for yield point and yield strength are not identical, they are sufficiently close for most

applications to be used interchangeably. They shall be determined by an approved technique described in Test Methods E8E8/E8M

or by an equivalent method. If determined as yield strength, that stress producing an extension under load of 0.01 in. 0.01 in. [0.25

mm] over the 2-in. [50 mm] [50-mm] gage length (for example, 0.5 % extension) or an offset of 0.2 % shall be taken as the yield

stress, which shall be converted to yield strength by dividing by the original cross-sectional area of the gage length found in

accordance with 7.2.2.3. It shall be reported to the nearest 100 psi [1 MPa]. In referee work, yield strength shall be determined

at an offset of 0.2 % from the stress strain curve.

7.2.2.6 Tensile Strength—The tensile strength shall be the maximum load carried by the specimen during the test divided by the

original cross-sectional area of the gage length, as found in accordance with 7.2.2.3. It shall be reported to the nearest 100 psi [1

MPa].

7.2.2.7 Elongation—The elongation is the increase in gage length after fracture of a tensile specimen, measured to the nearest

0.01 in. [0.25 mm] expressed as a percentage of the original gage length. It shall be reported to the nearest 0.5 %.

7.2.3 Number of Tests and Retests:

7.2.3.1 At least three tensile test specimens shall be cast from a representative ladle of iron from each 4-h pour period during

which the purchaser’s castings were poured.

7.2.3.2 Only one test specimen need be tested to qualify each pour period and heat treatment batch provided the requirements

of this specification are met by that test specimen.

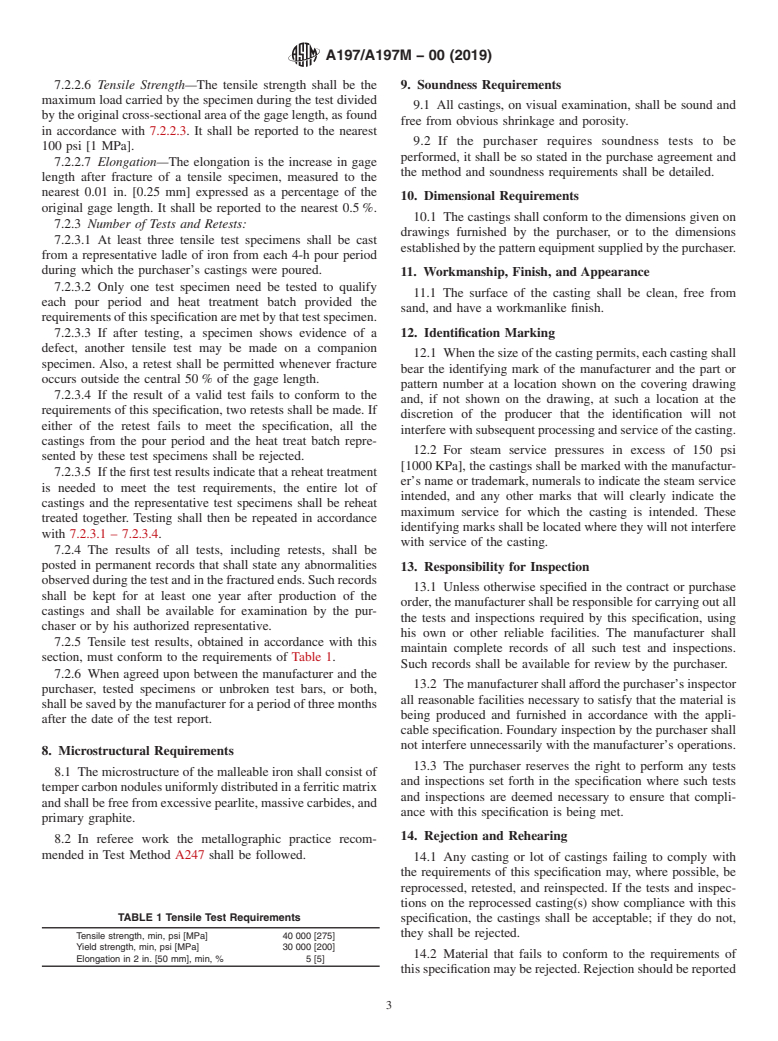

FIG. 1 Tension Test Specimen

A197/A197M − 00 (2019)

NOTE 1—Modifications may be made in the dimensions indicated above for those details of the specimen outside of the gage length as required by

testing procedure and equipment.

FIG. 2 Alternative Unmachined Tension Test Specimen

7.2.3.3 If after testing, a specimen shows evidence of a defect, another tensile test may be made on a companion specimen. Also,

a retest shall be permitted whenever fracture occurs outside the central 50 % of the gage length.

7.2.3.4 If the result of a valid test fails to conform to the requirements of this specification, two retests shall be made. If either

of the retest fails to meet the specification, all the castings from the pour period and the heat treat batch represented by these test

specimens shall be rejected.

7.2.3.5 If the first test results indicate that a reheat treatment is needed to meet the test requirements, the entire lot of castings

and the representative test specimens shall be reheat treated together. Testing shall then be repeated in accordance with

7.2.3.17.2.3.1 – 7.2.3.4 through 7.2.3.4.

7.2.4 The results of all tests, including retests, shall be posted in permanent records,records that shall state any abnormalities

observed during the test and in the fractured ends. Such records shall be kept for at least one year after production of the castings

and shall be available for examination by the purchaser or by his authorized representative.

7.2.5 Tensile test results, obtained in accordance with this section, must conform to the requirements of Table 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.