ASTM D3763-10e1

(Test Method)Standard Test Method for High Speed Puncture Properties of Plastics Using Load and Displacement Sensors

Standard Test Method for High Speed Puncture Properties of Plastics Using Load and Displacement Sensors

SIGNIFICANCE AND USE

This test method is designed to provide load versus deformation response of plastics under essentially multiaxial deformation conditions at impact velocities. This test method further provides a measure of the rate sensitivity of the material to impact.

Multiaxial impact response, while partly dependent on thickness, does not necessarily have a linear correlation with specimen thickness. Therefore, results should be compared only for specimens of essentially the same thickness, unless specific responses versus thickness formulae have been established for the material.

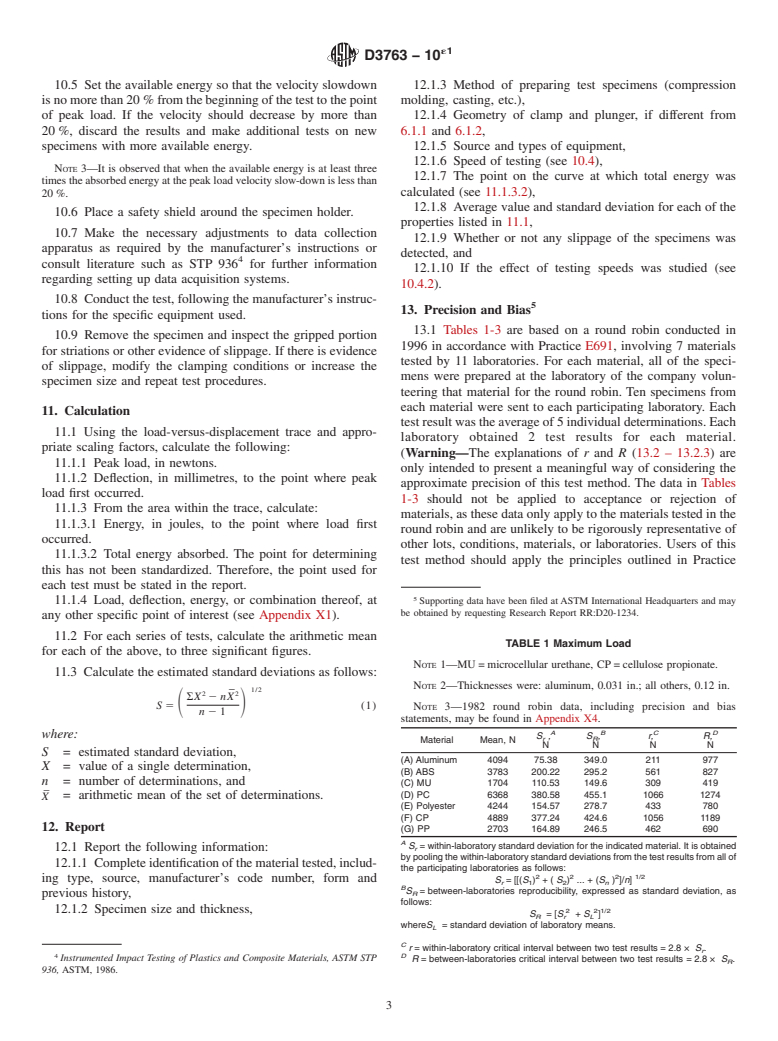

For many materials, there may be a specification that requires the use of this test method, but with some procedural modifications that take precedence when adhering to the specification. Therefore, it is advisable to refer to that material specification before using this test method. Table 1 of Classification System D4000 lists the ASTM materials standards that currently exist.

SCOPE

1.1 This test method covers the determination of puncture properties of rigid plastics over a range of test velocities.

1.2 Test data obtained by this test method are relevant and appropriate for use in engineering design.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—This specification does not closely conform to ISO 6603.2. The only similarity between the two tests is that they are both instrumented impact tests. The differences in striker, fixture, and specimen geometries and in test velocity can produce significantly different test results.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D3763 − 10

StandardTest Method for

High Speed Puncture Properties of Plastics Using Load and

1

Displacement Sensors

This standard is issued under the fixed designation D3763; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Added research report information to Section 13 editorially in September 2010.

3

1. Scope* 2.2 ISO Standard:

ISO 6603.2 Plastics—Determination of Multiaxial Impact

1.1 This test method covers the determination of puncture

Behavior of Rigid Plastics Part 2: Instrumented Puncture

properties of rigid plastics over a range of test velocities.

Test

1.2 Test data obtained by this test method are relevant and

appropriate for use in engineering design.

3. Terminology

1.3 The values stated in SI units are to be regarded as 3.1 Definitions—For definitions see Terminology D883 and

for abbreviations see Terminology D1600.

standard. No other units of measurement are included in this

standard.

4. Significance and Use

1.4 This standard does not purport to address all of the

4.1 This test method is designed to provide load versus

safety concerns, if any, associated with its use. It is the

deformation response of plastics under essentially multiaxial

responsibility of the user of this standard to establish appro-

deformation conditions at impact velocities. This test method

priate safety and health practices and determine the applica-

furtherprovidesameasureoftheratesensitivityofthematerial

bility of regulatory limitations prior to use.

to impact.

NOTE 1—This specification does not closely conform to ISO 6603.2.

4.2 Multiaxial impact response, while partly dependent on

The only similarity between the two tests is that they are both instru-

thickness, does not necessarily have a linear correlation with

mented impact tests. The differences in striker, fixture, and specimen

geometries and in test velocity can produce significantly different test

specimen thickness. Therefore, results should be compared

results.

only for specimens of essentially the same thickness, unless

specific responses versus thickness formulae have been estab-

2. Referenced Documents

lished for the material.

2

2.1 ASTM Standards:

4.3 For many materials, there may be a specification that

D618 Practice for Conditioning Plastics for Testing

requires the use of this test method, but with some procedural

D883 Terminology Relating to Plastics

modifications that take precedence when adhering to the

D1600 Terminology forAbbreviatedTerms Relating to Plas-

specification. Therefore, it is advisable to refer to that material

tics

specification before using this test method. Table 1 of Classi-

D4000 Classification System for Specifying Plastic Materi-

fication System D4000 lists theASTM materials standards that

als

currently exist.

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

5. Interferences

5.1 Inertial Effects— A loading function encountered when

performing an instrumented impact test that may, in some

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

cases, confuse the interpretation of the test data. For further

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

definition and examples of inertial effects, refer to Appendix

Current edition approved July 1, 2010. Published July 2010. Originally approved

X1.

in 1979. Last previous edition approved in 2008 as D3763 - 08. DOI: 10.1520/

D3763-10E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D3763 − 10

6. Apparatus 7.2 Specimens may be cut from injection-molded, extruded,

orcompressionmoldedsheet;ortheymaybecastormoldedto

6.1 Thetestingmachineshallconsistoftwoassemblies,one

size.

fixed and the other driven by a suitable method to achieve the

required impact velocity (that is, hydraulic, pneumatic,

8. Conditioning

mechanical, or gravity):

8.1 Conditioning— Condition the test specimens in accor-

6.1.1 Clamp Assembly, consisting of two parallel rigid

dance with Procedure A in Practice D618 unless otherwise

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.