ASTM D2245-90(2011)

(Test Method)Standard Test Method for Identification of Oils and Oil Acids in Solvent-Reducible Paints (Withdrawn 2016)

Standard Test Method for Identification of Oils and Oil Acids in Solvent-Reducible Paints (Withdrawn 2016)

SIGNIFICANCE AND USE

This test method provides a procedure to identify the fatty acids present in the vehicle of a paint.

SCOPE

1.1 This test method covers the identification of oils and oil acids in vehicles that have been separated from solvent-reducible paints. The test method is based on a gas chromatographic technique (of the methyl esters) applicable to products containing both saturated and unsaturated, animal and vegetable, unpolymerized or partially polymerized fatty acids having 8 to 20 carbon atoms.

1.2 This test method is not applicable to products containing fatty acids that have been polymerized or oxidized to such an extent that no characteristic monomeric fatty acids remain.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the identification of oils and oil acids in vehicles that have been separated from solvent-reducible paints. The test method is based on a gas chromatographic technique (of the methyl esters) applicable to products containing both saturated and unsaturated, animal and vegetable, unpolymerized or partially polymerized fatty acids having 8 to 20 carbon atoms.

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this test method was withdrawn in April 2016. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2245 −90(Reapproved 2011)

Standard Test Method for

Identification of Oils and Oil Acids in Solvent-Reducible

Paints

This standard is issued under the fixed designation D2245; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3. Summary of Test Method

1.1 This test method covers the identification of oils and oil 3.1 This test method is based upon the differential migration

acids in vehicles that have been separated from solvent- and partitioning of constituent fatty acids in the form of

reducible paints. The test method is based on a gas chromato- vaporized methyl esters between a flowing gas phase and a

graphic technique (of the methyl esters) applicable to products supported liquid phase in a gas chromatographic column. The

containing both saturated and unsaturated, animal and test method is based on isothermal operation of the gas

vegetable, unpolymerized or partially polymerized fatty acids chromatograph and a hot wire, thermal conductivity detector.

having 8 to 20 carbon atoms.

3.2 The test method consists in the separation of the vehicle

1.2 Thistestmethodisnotapplicabletoproductscontaining from the paint by centrifugation, extraction of fatty acids from

fatty acids that have been polymerized or oxidized to such an the vehicle after saponification, conversion of fatty acids and a

extent that no characteristic monomeric fatty acids remain. measured addition of margaric acid (internal standard) into

methyl esters, preparation of the gas chromatogram, and

1.3 This standard does not purport to address all of the

interpretation of the chromatogram. The amount of each

safety concerns, if any, associated with its use. It is the

monomeric fatty acid ester is calculated, totaled, subtracted

responsibility of the user of this standard to establish appro-

from100 %toyieldpolymerizedfattyacids,reportedasis,and

priate safety and health practices and determine the applica-

interpreted by comparison with standards as being from

bility of regulatory limitations prior to use.

specific oils or oil acids.

2. Referenced Documents

4. Significance and Use

2.1 ASTM Standards:

4.1 This test method provides a procedure to identify the

D1398 Test Method for Fatty Acid Content of Alkyd Resins

fatty acids present in the vehicle of a paint.

and Alkyd Resin Solutions (Withdrawn 2007)

D1983 Test Method for Fatty Acid Composition by Gas-

5. Apparatus

Liquid Chromatography of Methyl Esters (Withdrawn

2003) 5.1 Centrifuge,

D2372 Practice for Separation of Vehicle From Solvent-

5.2 Separatory Funnels, with PTFE-fluorocarbon stop-

Reducible Paints

cocks.

D2800 Test Method for Preparation of Methyl Esters From

5.3 Gas Chromatograph and Accessories, suitable for

Oils for Determination of Fatty Acid Composition by

analysis of fatty acids as methyl esters (see Test Method

Gas-Liquid Chromatography (Withdrawn 2007)

D1983).

6. Reagent

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

6.1 Hydroquinone.

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

Current edition approved June 1, 2011. Published June 2011. Originally

7. Calibration and Standardization

approved in 1964. Last previous edition approved in 2005 as D2245 – 90 (2005).

DOI: 10.1520/D2245-90R11.

7.1 Establish optimum operating conditions on the gas

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

chromatograph with known samples of methyl esters as de-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on scribed in Test Method D1983.

the ASTM website.

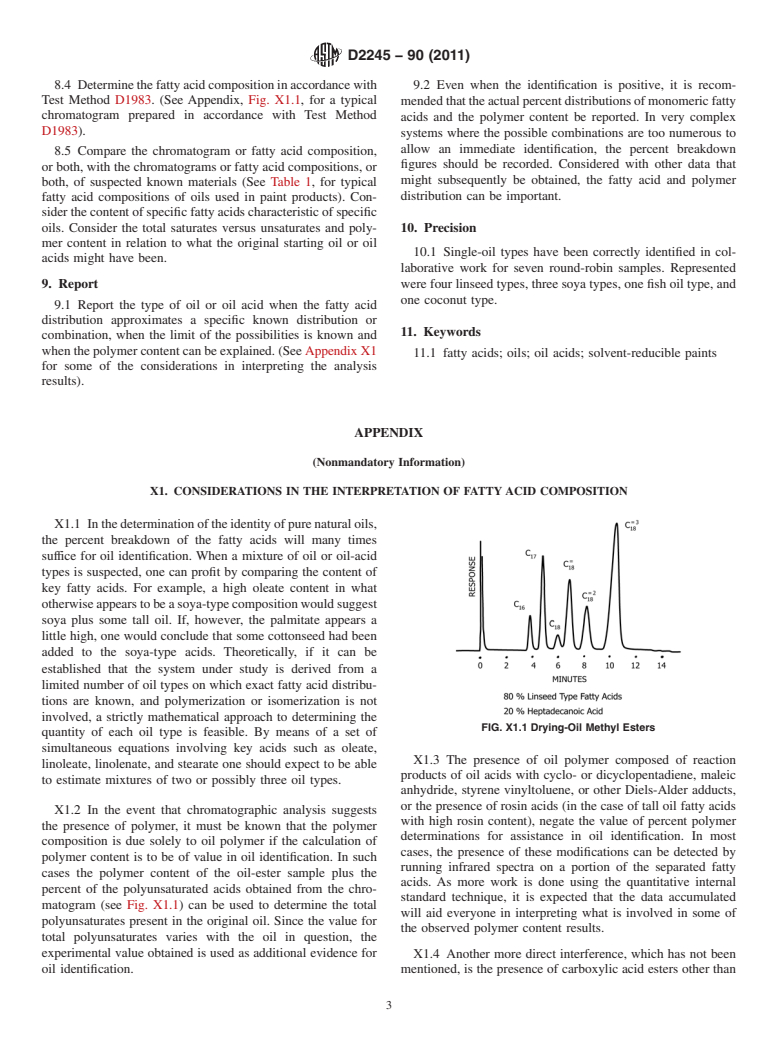

7.2 Prepare working standards by running known paints or

The last approved version of this historical standard is referenced on

www.astm.org. vehicles through the procedure described in Section 8. Include

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2245−90 (2011)

A

TABLE 1 Fatty Acid Composition of Oils Used in Paint Products

Caster Oil, % Oiticica Oil,%

Palmitic 2 Palmitic 7

Stearic 1 Stearic 5

Oleic 7 Oleic 6

Ricinoleic 87 Licanic 78

Linoleic 3 Hydroxy acids 4

Coconut Oil,% Perilla Oil,%

Caproic trace Palmitic 7

Caprylic 6 Stearic 2

Capric 6 Oleic 13

Lauric 44 Linoleic 14

Myristic 18 Linolenic 64

Palmitic 11 Safflower Oil,%

Stearic 6 Myristic trace

Oleic 7 Myristoleic trace

Linoleic 2 Palmitic 8

Linolenic trace Palmitoleic trace

Cottonseed Oil,% Stearic 3

Capric trace Oleic 13

Lauric trace Linoleic 75

Myristic 1 Linolenic 1

Myristoleic trace Arachidic trace

Palmitic 29 Gadoleic trace

Palmitoleic 2 Soybean Oil,%

Stearic 4 Myristic trace

Oleic 24 Palmitic 11

Linoleic 40 Stearic 4

Arachidic trace Oleic 25

Linseed Oil,% Linoleic 51

Palmitic 6 Linolenic 9

Palmitoleic trace Arachidic trace

Stearic 4 Gadoleic trace

B

Oleic 22 Tall Oil, %

Linoleic 16 Palmitic 5

Linolenic 52 Stearic 3

Arachidic trace Oleic 46

Gadoleic trace Linoleic 41

Menhaden Oil,% Linolenic 3

Lauric trace Arachidic 2

Myristic 7 Tung Oil,%

Myristoleic trace Palmitic 4

Palmitic 16 Stearic 1

Palmitoleic 16 Oleic 8

Stearic 2 Linoleic 4

Oleic 15 Linolenic 3

Linoleic 7 Eleostearic 80

Linolenic 2

Arachidonic 17

Clupanodonic 11

Nisinic 4

Shibic 1

Unidentified unsaturate 2

A

Theacidsandpercentspresentedinthistablearetakenfromthe“CompositionandConstantsofFattyAcids”chartandusedbypermissionoftheArcher-Daniels-Midland

Co.

B

The percent rosin acids in tall oil may vary from 0 to 42 %, the percent terpenes from 0 to 13 %. Both variations depend on the grade and refining of the oil.

particularly compositions with chemical or structural modifi- cocks when available. In cases involving unsaturated fatty

cations that might be expected to alter the fatty acid distribu- acids, add a crystal or diethyl ether solution of hydroquinone

tion or the apparent polymer content of the starting raw (equivalent to less than 0.05 weight % of the fatty acids to the

materials. fatty acid fractions obtained in the Procedure Section, Method

B, of Test Method D1398. Swirl the flask containing the fatty

8. Procedure

acids, some ether solvent, and the hydroquinone until the

8.1 Separate the vehicle from the paint by direct high-speed hydroquinone is well dispersed; evaporate off the remaining

ether carefully under vacuum as described in Test M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.