ASTM B213-13

(Test Method)Standard Test Methods for Flow Rate of Metal Powders Using the Hall Flowmeter Funnel

Standard Test Methods for Flow Rate of Metal Powders Using the Hall Flowmeter Funnel

SIGNIFICANCE AND USE

5.1 The rate and uniformity of die cavity filling are related to flow properties, which thus influence production rates and uniformity of compacted parts.

5.2 The ability of a powder to flow is a function of interparticle friction. As interparticle friction increases, flow is slowed. Fine powders may not flow. Some powders, often fine powders and lubricated powder mixtures, may not flow through the Hall Flowmeter funnel. Nevertheless, if a larger orifice is provided, such as in the Carney Flowmeter funnel of Test Method B964, a meaningful flow rate may be determined, providing specific information for certain applications.

5.3 Test Method B213, using the Hall Flowmeter funnel, is the preferred method for determining the flowability of metal powders and powder mixtures. The Carney Flowmeter funnel of Method B964 should only be used when powder will not flow through the Hall Flowmeter funnel.

5.4 Humidity and moisture content influence flow rate. Wet or moist powders may not flow.

5.5 These test methods are based on flow of a specified mass of powder. If flow of a specific volume of powder is preferred, Test Method B855 may be used for powders that flow readily through the Hall Flowmeter funnel.

5.6 This test method may be part of the purchase agreement between powder manufacturers and powder metallurgy (PM) part producers, or it can be an internal quality control test by either the producer or the end user.

SCOPE

1.1 This test method covers the determination of a flow rate, by the use of the Hall Flowmeter funnel of metal powders and powder mixtures. It is suitable only for those powders that will flow unaided through the Hall Flowmeter funnel.

1.2 With the exception of the values for density and the mass used to determine density, for which the use of the gram per cubic centimeter (g/cm3) and gram (g) units is the longstanding industry practice, the values in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only, and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B213 − 13

Standard Test Methods for

Flow Rate of Metal Powders Using the Hall Flowmeter

1

Funnel

This standard is issued under the fixed designation B213; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 3. Terminology

1.1 This test method covers the determination of a flow rate, 3.1 Definitions—Definitions of powder metallurgy terms

by the use of the Hall Flowmeter funnel of metal powders and can be found in Terminology B243.

powder mixtures. It is suitable only for those powders that will 3.2 Definitions of Terms Specific to This Standard:

flow unaided through the Hall Flowmeter funnel. 3.2.1 Hall flow rate (FR ), n—the time required for a metal

H

powder sample of specified mass to flow through the orifice in

1.2 With the exception of the values for density and the

a Hall Flowmeter funnel according to a specified procedure.

mass used to determine density, for which the use of the gram

3

per cubic centimeter (g/cm ) and gram (g) units is the long-

4. Summary of Test Method

standingindustrypractice,thevaluesininch-poundunitsareto

4.1 Aweighed mass (50.0 g) of metal powder is timed as it

be regarded as standard. The values given in parentheses are

flowsthroughthecalibratedorificeofaHallFlowmeterfunnel.

mathematical conversions to SI units that are provided for

information only, and are not considered standard. 5. Significance and Use

1.3 This standard does not purport to address all of the

5.1 The rate and uniformity of die cavity filling are related

safety concerns, if any, associated with its use. It is the

to flow properties, which thus influence production rates and

responsibility of the user of this standard to establish appro- uniformity of compacted parts.

priate safety and health practices and determine the applica-

5.2 The ability of a powder to flow is a function of

bility of regulatory limitations prior to use.

interparticle friction.As interparticle friction increases, flow is

slowed. Fine powders may not flow. Some powders, often fine

2. Referenced Documents

powders and lubricated powder mixtures, may not flow

2

2.1 ASTM Standards:

through the Hall Flowmeter funnel. Nevertheless, if a larger

B215 Practices for Sampling Metal Powders

orifice is provided, such as in the Carney Flowmeter funnel of

B243 Terminology of Powder Metallurgy Test Method B964, a meaningful flow rate may be determined,

B855 Test Method for Volumetric Flow Rate of Metal

providing specific information for certain applications.

Powders Using the Arnold Meter and Hall Flowmeter

5.3 Test Method B213, using the Hall Flowmeter funnel, is

Funnel

the preferred method for determining the flowability of metal

B964 Test Methods for Flow Rate of Metal Powders Using

powders and powder mixtures. The Carney Flowmeter funnel

the Carney Funnel

of Method B964 should only be used when powder will not

flow through the Hall Flowmeter funnel.

5.4 Humidity and moisture content influence flow rate. Wet

1

This test method is under the jurisdiction of ASTM Committee B09 on Metal

or moist powders may not flow.

Powders and Metal Powder Products and is the direct responsibility of B09.02 on

Base Metal Powders.

5.5 Thesetestmethodsarebasedonflowofaspecifiedmass

Current edition approved April 1, 2013. Published June 2013. Originally

of powder. If flow of a specific volume of powder is preferred,

approved in 1946. Last previous edition approved in 2011 as B213 – 11. DOI:

Test Method B855 may be used for powders that flow readily

10.1520/B0213-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or through the Hall Flowmeter funnel.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.6 This test method may be part of the purchase agreement

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. between powder manufacturers and powder metallurgy (PM)

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B213 − 13

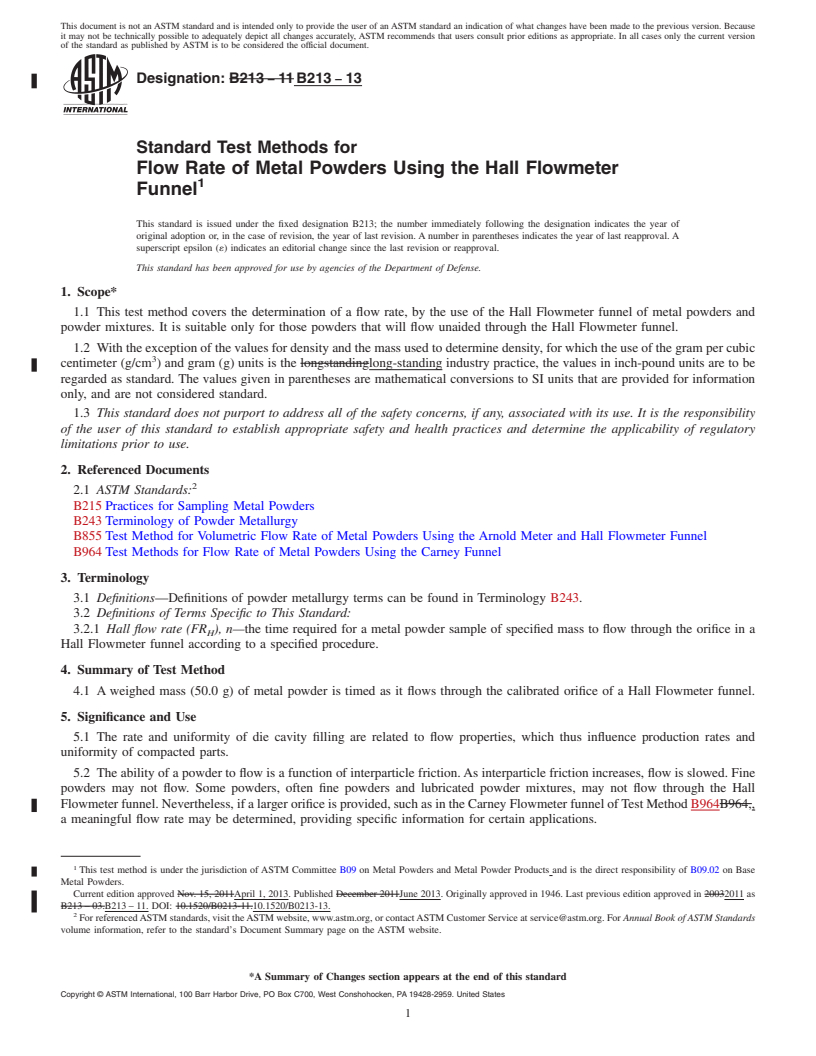

FIG. 2 Stand

Calibration with emery, as specified in Section 9, determines

the working flow rate of the funnel.

3

6.3 Stand —A stand (Fig. 2) to support the powder flow-

meter funnel.

6.4 Workbench—A level, vibration free table or workbench

to support the powder flowmeter stand.

6.5 Timing Device—A stopwatch or other suitable device

capable of measuring to the nearest 0.1 s.

3

6.6 Chinese Emery —An em

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B213 − 11 B213 − 13

Standard Test Methods for

Flow Rate of Metal Powders Using the Hall Flowmeter

1

Funnel

This standard is issued under the fixed designation B213; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This test method covers the determination of a flow rate, by the use of the Hall Flowmeter funnel of metal powders and

powder mixtures. It is suitable only for those powders that will flow unaided through the Hall Flowmeter funnel.

1.2 With the exception of the values for density and the mass used to determine density, for which the use of the gram per cubic

3

centimeter (g/cm ) and gram (g) units is the longstandinglong-standing industry practice, the values in inch-pound units are to be

regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information

only, and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B215 Practices for Sampling Metal Powders

B243 Terminology of Powder Metallurgy

B855 Test Method for Volumetric Flow Rate of Metal Powders Using the Arnold Meter and Hall Flowmeter Funnel

B964 Test Methods for Flow Rate of Metal Powders Using the Carney Funnel

3. Terminology

3.1 Definitions—Definitions of powder metallurgy terms can be found in Terminology B243.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 Hall flow rate (FR ), n—the time required for a metal powder sample of specified mass to flow through the orifice in a

H

Hall Flowmeter funnel according to a specified procedure.

4. Summary of Test Method

4.1 A weighed mass (50.0 g) of metal powder is timed as it flows through the calibrated orifice of a Hall Flowmeter funnel.

5. Significance and Use

5.1 The rate and uniformity of die cavity filling are related to flow properties, which thus influence production rates and

uniformity of compacted parts.

5.2 The ability of a powder to flow is a function of interparticle friction. As interparticle friction increases, flow is slowed. Fine

powders may not flow. Some powders, often fine powders and lubricated powder mixtures, may not flow through the Hall

Flowmeter funnel. Nevertheless, if a larger orifice is provided, such as in the Carney Flowmeter funnel of Test Method B964B964,,

a meaningful flow rate may be determined, providing specific information for certain applications.

1

This test method is under the jurisdiction of ASTM Committee B09 on Metal Powders and Metal Powder Products and is the direct responsibility of B09.02 on Base

Metal Powders.

Current edition approved Nov. 15, 2011April 1, 2013. Published December 2011June 2013. Originally approved in 1946. Last previous edition approved in 20032011 as

B213 – 03.B213 – 11. DOI: 10.1520/B0213-11.10.1520/B0213-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B213 − 13

5.3 Test Method B213B213,, using the Hall Flowmeter funnel, is the preferred method for determining the flowability of metal

powders and powder mixtures. The Carney Flowmeter funnel of Method B964 should only be used when powder will not flow

through the Hall Flowmeter funnel.

5.4 Humidity and moisture content influence flow rate. Wet or moist powders may not flow.

5.5 These test methods are based on flow of a specified mass of powder. If flow of a specific volume of powder is preferred,

Test Method B855 may be used for powders that flow readily through the Hall Flowmeter funnel.

5.6 This test method may be part of the purchase agreement between powder manufacturers and powder metallurgy (PM) part

produce

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.