ASTM D5293-17e1

(Test Method)Standard Test Method for Apparent Viscosity of Engine Oils and Base Stocks Between –10 °C and –35 °C Using Cold-Cranking Simulator

Standard Test Method for Apparent Viscosity of Engine Oils and Base Stocks Between –10 °C and –35 °C Using Cold-Cranking Simulator

SIGNIFICANCE AND USE

5.1 The CCS apparent viscosity of automotive engine oils correlates with low temperature engine cranking. CCS apparent viscosity is not suitable for predicting low temperature flow to the engine oil pump and oil distribution system. Engine cranking data were measured by the Coordinating Research Council (CRC) L-495 test with reference oils that had viscosities between 600 mPa·s and 8400 mPa·s (cP) at –17.8 °C and between 2000 mPa·s and 20 000 mPa·s (cP) at –28.9 °C. The detailed relationship between this engine cranking data and CCS apparent viscosities is in Appendixes X1 and X2 of the 1967 T edition of Test Method D26026 and CRC Report 409.5 Because the CRC L-49 test is much less precise and standardized than the CCS procedures, CCS apparent viscosity need not accurately predict the engine cranking behavior of an oil in a specific engine. However, the correlation of CCS apparent viscosity with average CRC L-49 engine cranking results is satisfactory.

5.2 The correlation between CCS and apparent viscosity and engine cranking was confirmed at temperatures between –1 °C and –40 °C by work on 17 commercial engine oils (SAE grades 5W, 10W, 15W, and 20W). Both synthetic and mineral oil based products were evaluated. See ASTM STP 621.7

5.3 A correlation was established in a low temperature engine performance study between light duty engine startability and CCS measured apparent viscosity. This study used ten 1990s engines at temperatures ranging from –5 °C down to –40 °C with six commercial engine oils (SAE 0W, 5W, 10W, 15W, 20W, and 25W).8

5.4 The measurement of the cranking viscosity of base stocks is typically done to determine their suitability for use in engine oil formulations. A significant number of the calibration oils for this method are base stocks that could be used in engine oil formulations.

SCOPE

1.1 This test method covers the laboratory determination of apparent viscosity of engine oils and base stocks by cold cranking simulator (CCS) at temperatures between –10 °C and –35 °C at shear stresses of approximately 50 000 Pa to 100 000 Pa and shear rates of approximately 105 to 104 s–1 for viscosities of approximately 900 mPa·s to 25 000 mPa·s. The range of an instrument is dependent on the instrument model and software version installed. Apparent Cranking Viscosity results by this method are related to engine-cranking characteristics of engine oils.

1.2 A special procedure is provided for measurement of highly viscoelastic oils in manual instruments. See Appendix X2.

1.3 Procedures are provided for both manual and automated determination of the apparent viscosity of engine oils using the cold-cranking simulator.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in Section 8.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D5293 − 17

Standard Test Method for

Apparent Viscosity of Engine Oils and Base Stocks

1

Between –10 °C and –35 °C Using Cold-Cranking Simulator

This standard is issued under the fixed designation D5293; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

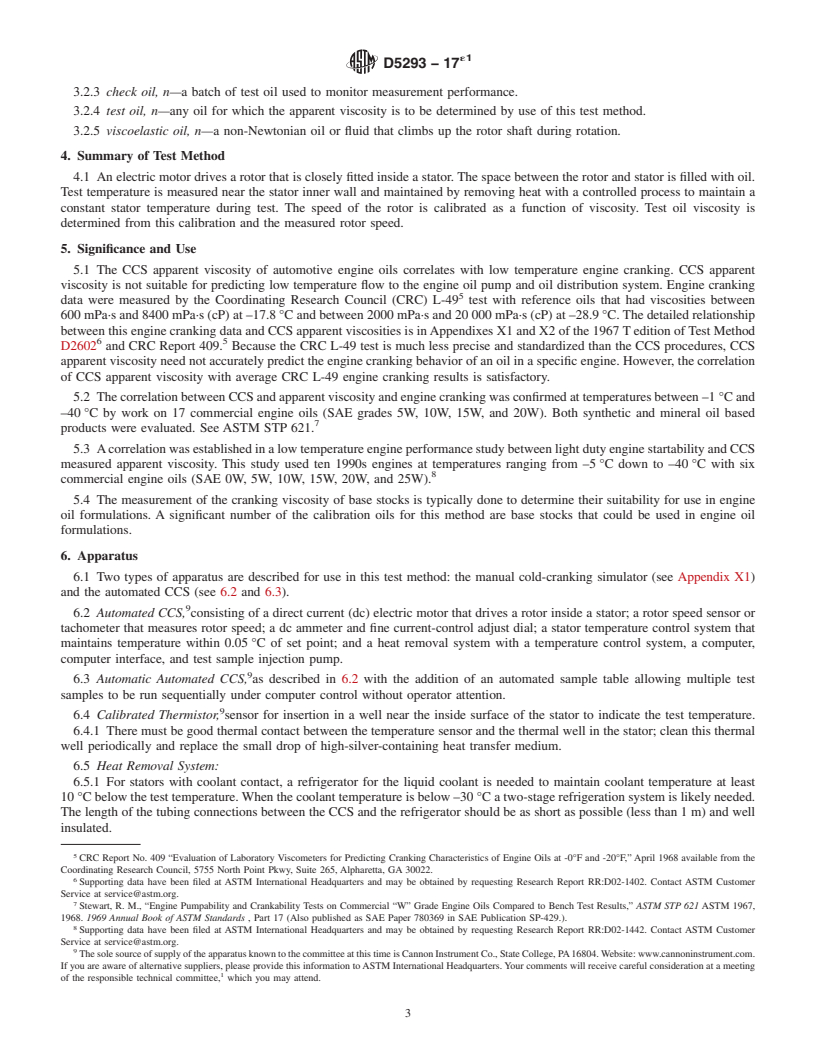

ε NOTE—Bold emphasis was added editorially to values in Table 1 in August 2017.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method covers the laboratory determination of

apparent viscosity of engine oils and base stocks by cold D2162 Practice for Basic Calibration of Master Viscometers

and Viscosity Oil Standards

cranking simulator (CCS) at temperatures between –10 °C and

–35 °C at shear stresses of approximately 50 000 Pa to D2602 Test Method for Apparent Viscosity of Engine Oils

5 4 –1

At Low Temperature Using the Cold-Cranking Simulator

100 000 Pa and shear rates of approximately 10 to 10 s for

3

viscosities of approximately 900 mPa·s to 25 000 mPa·s. The (Withdrawn 1993)

D4057 Practice for Manual Sampling of Petroleum and

range of an instrument is dependent on the instrument model

and software version installed. Apparent Cranking Viscosity Petroleum Products

results by this method are related to engine-cranking charac-

2.2 ISO Standard:

teristics of engine oils.

ISO 17025 General Requirements for the Competence of

4

Testing and Calibration Laboratories

1.2 A special procedure is provided for measurement of

highly viscoelastic oils in manual instruments. See Appendix

3. Terminology

X2.

3.1 Definitions:

1.3 Procedures are provided for both manual and automated

3.1.1 Newtonian oil or fluid, n—one that exhibits a constant

determination of the apparent viscosity of engine oils using the

viscosity at all shear rates.

cold-cranking simulator.

3.1.2 non-Newtonian oil or fluid, n—one that exhibits a

1.4 The values stated in SI units are to be regarded as

viscosity that varies with changing shear stress or shear rate.

standard. No other units of measurement are included in this

3.1.3 viscosity, η,n—the property of a fluid that determines

standard.

its internal resistance to flow under stress, expressed by:

1.5 This standard does not purport to address all of the

τ

safety concerns, if any, associated with its use. It is the

η 5 (1)

γ

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

where:

bility of regulatory limitations prior to use. Specific warning

τ = the stress per unit area, and

statements are given in Section 8.

γ = the rate of shear.

1.6 This international standard was developed in accor-

3.1.3.1 Discussion—It is sometimes called the coefficient of

dance with internationally recognized principles on standard-

dynamic viscosity. This coefficient is thus a measure of the

ization established in the Decision on Principles for the

resistance to flow of the liquid. In the SI, the unit of viscosity

Development of International Standards, Guides and Recom-

is the pascal-second; for practical use, a submultiple

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This test method is under the jurisdiction of ASTM Committee D02 on Standards volume information, refer to the standard’s Document Summary page on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of the ASTM website.

3

Subcommittee D02.07 on Flow Properties. The last approved version of this historical standard is referenced on

Current edition approved July 1, 2017. Published August 2017. Originally www.astm.org.

4

approved in 1991. Last previous edition approved in 2015 as D5293 – 15. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/D5293-17E01. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D5293 − 17

TABLE 1 Calibration Oil Sets by Test Temperature

Test Temp –35 °C –30 °C –25 °C –20 °C –15 °C –10 °C

CL080 A . . . . .

CL090 A . . . . .

CL100 A A . . . .

CL110 B A . . . .

CL120 B A A . . .

CL130 B B A . . .

CL140 B B A A . .

CL150 B B B A . .

CL160 B B B A . .

CL170 B B B B A .

CL190 B B B B A .

CL200 B B BBAA

CL220 C B

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D5293 − 17 D5293 − 17

Standard Test Method for

Apparent Viscosity of Engine Oils and Base Stocks

1

Between –10 °C and –35 °C Using Cold-Cranking Simulator

This standard is issued under the fixed designation D5293; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Bold emphasis was added editorially to values in Table 1 in August 2017.

1. Scope*

1.1 This test method covers the laboratory determination of apparent viscosity of engine oils and base stocks by cold cranking

simulator (CCS) at temperatures between –10 °C and –35 °C at shear stresses of approximately 50 000 Pa to 100 000 Pa and shear

5 4 –1

rates of approximately 10 to 10 s for viscosities of approximately 900 mPa·s to 25 000 mPa·s. The range of an instrument is

dependent on the instrument model and software version installed. Apparent Cranking Viscosity results by this method are related

to engine-cranking characteristics of engine oils.

1.2 A special procedure is provided for measurement of highly viscoelastic oils in manual instruments. See Appendix X2.

1.3 Procedures are provided for both manual and automated determination of the apparent viscosity of engine oils using the

cold-cranking simulator.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific warning statements are given in Section 8.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D2162 Practice for Basic Calibration of Master Viscometers and Viscosity Oil Standards

D2602 Test Method for Apparent Viscosity of Engine Oils At Low Temperature Using the Cold-Cranking Simulator (Withdrawn

3

1993)

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

2.2 ISO Standard:

4

ISO 17025 General Requirements for the Competence of Testing and Calibration Laboratories

3. Terminology

3.1 Definitions:

3.1.1 Newtonian oil or fluid, n—one that exhibits a constant viscosity at all shear rates.

3.1.2 non-Newtonian oil or fluid, n—one that exhibits a viscosity that varies with changing shear stress or shear rate.

3.1.3 viscosity, η, n—the property of a fluid that determines its internal resistance to flow under stress, expressed by:

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.07 on Flow Properties.

Current edition approved July 1, 2017. Published August 2017. Originally approved in 1991. Last previous edition approved in 2015 as D5293 – 15. DOI:

10.1520/D5293-17.10.1520/D5293-17E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D5293 − 17

TABLE 1 Calibration Oil Sets by Test Temperature

Test Temp –35 °C –30 °C –25 °C –20 °C –15 °C –10 °C

CL080 A . . . . .

CL090 A . . . . .

CL100 A A . . . .

CL110 B A . . . .

CL120 B A A . . .

CL130 B B A . . .

CL140 B B A A . .

CL150 B B B A . .

CL160 B B B A . .

CL170 B B B B A .

CL190 B B B B A .

CL200 B B B B A A

CL220 C B B B B A

CL240 C B

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.