ASTM E305-89(1994)e1

(Practice)Standard Practice for Establishing and Controlling Spectrochemical Analytical Curves (Withdrawn 2005)

Standard Practice for Establishing and Controlling Spectrochemical Analytical Curves (Withdrawn 2005)

SCOPE

1.1 This practice provides guidance for establishing and controlling spectrochemical analytical curves. The preparation of analytical curves and their routine control are considered as separate although interrelated operations. This practice is applicable to optical emission spectrographs, optical emission spectrometers, or X-ray emission spectrometers with linear or logarithmic readouts.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This practice provides guidance for establishing and controlling spectrochemical analytical curves. The preparation of analytical curves and their routine control are considered as separate although interrelated operations. This practice is applicable to optical emission spectrographs, optical emission spectrometers, or X-ray emission spectrometers with linear or logarithmic readouts.

Formerly under the jurisdiction of Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials, this practice was withdrawn in December 2004 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: E 305 – 89 (Reapproved 1994)

Standard Practice for

Establishing and Controlling Spectrochemical Analytical

Curves

This standard is issued under the fixed designation E 305; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 9 was added editorially in January 1995.

1. Scope linear and logarithmic readout systems. Calibration procedures

are given, including the reference materials to be used and the

1.1 This practice provides guidance for establishing and

generation of data. Procedures are provided for constructing

controlling spectrochemical analytical curves. The preparation

the analytical curve, fitting a regression curve and evaluating

of analytical curves and their routine control are considered as

curve fit. Control of curve shift and rotation is described.

separate although interrelated operations. This practice is

applicable to optical emission spectrographs, optical emission

5. Significance and Use

spectrometers, or X-ray emission spectrometers with linear or

5.1 This practice is intended as a fundamental guide for the

logarithmic readouts.

calibration, standardization, and daily control of the analytical

1.2 This standard does not purport to address all of the

curves on optical emission spectrographs and spectrometers,

safety concerns, if any, associated with its use. It is the

and X-ray spectrometers.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

6. Precautions

bility of regulatory limitations prior to use.

6.1 Systematic Errors:

2. Referenced Documents 6.1.1 Systematic Errors Due to Incorrect Calibration—In

the procedure for quantitative spectrochemical analysis, the

2.1 ASTM Standards:

initial construction of the analytical curve relates element

E 116 Practice for Photographic Photometry in Spectro-

2 concentration and spectral intensity or intensity ratio. The

chemical Analysis

accuracy of the calibration may be affected by a number of

E 135 Terminology Relating to Analytical Chemistry for

2 factors,suchasincorrectelementconcentrations,heterogeneity

Metals, Ores, and Related Materials

3 of the reference materials, spectral interferences, and matrix

E 178 Practice for Dealing with Outlying Observations

effects. Such errors may cause a rotation or bodily displace-

E 876 Practice for Use of Statistics in the Evaluation of

4 ment of the analytical curve, thereby leading to systematic

Spectrometric Data

errors in the analytical data generated.

3. Terminology 6.1.1.1 Calibration errors due to incorrect element concen-

trations may be minimized by the use of certified reference

3.1 For definitions of terms used in this practice, refer to

materials. When these are used, one or more other reference

Terminology E 135.

materials for which the chemical compositions have been

4. Summary of Practice carefully determined by approved methods of analysis, such as

ASTM or BSI (British Standards Institute), may be included to

4.1 Systematic and random errors that occur in obtaining

detect whether systematic errors exist because of differences in

data are reviewed. Background corrections are considered for

the metallurgical condition of the certified reference materials

and the specimens. In the absence of certified reference

This practice is under the jurisdiction of ASTM Committee E01 on Analytical

materials, it is helpful to use several reference materials from

Chemistry for Metals, Ores and Related Materials and is the direct responsibility of

a variety of sources to detect systematic differences in these

Subcommittee E01.20 on Fundamental Practices and Measurement Traceabillity .

Current edition approved Sept. 29, 1989. Published November 1989. Originally materials. In general, the use of a large number of reference

e1

published as E 305 – 66T. Last previous edition E 305 – 83 .

materials will aid in the detection and rejection of those which

Annual Book of ASTM Standards, Vol 03.05.

are obviously inaccurate. In cases where it is necessary to

Annual Book of ASTM Standards, Vol 14.02.

synthesize reference materials, the synthesis of each one

Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

E 305 – 89 (1994)

should be independent of the remainder, thereby avoiding an cant analytical error, especially when reading a weak line

accumulation of errors arising from a series of successive which is only slightly more intense than the background.

dilutions.

NOTE 2—The need for background correction varies with the type of

material being analyzed. Make sure that background correction is neces-

NOTE 1—Errors in determining the average intensity or intensity ratio

sary and can be accomplished accurately before proceeding with the

from reference materials occur because of statistical variations, excitation

correction.

parameters, and specimen inhomogeneity. In optical emission spectrom-

NOTE 3—Theprocedureforbackgroundcorrectionvarieswithdifferent

etry, increasing the number of replicate determinations will reduce the

instrumentation. This section is intended to be representative, but not

effect of statistical variation and specimen inhomogeneity. The use of

necessarily inclusive, of the types available. The user should evaluate his

optimum excitation conditions, including sufficient preburn and exposure

system in regard to its limitations and his particular application before

times, will also reduce statistical variations and increase accuracy. In

attempting to apply background correction.

X-ray spectrometry, increasing the exposure area will reduce the effect of

inhomogeneity;increasingthecountingtimewillreducerelativestatistical

7.1.1 Backgound Correction with Photographic Systems—

variation; and the use of optimum excitation voltage will produce the best

Refer to Practice E 116 for background correction methods.

measurement.

7.1.2 Background Correction with Linear Systems—Three

6.1.2 Systematic Errors Due to Experimental Variations— methods of background correction are available in linear

Systematic errors may arise from experimental variations systems, two of which are normally used in optical emission

occurring within the operational procedure (for example, spectrometry and the other in X-ray spectrometry:

change in optics, source parameters, etc.). Such changes may 7.1.2.1 Bias control is a static baseline compensation used

result in displacement of the analytical curve which, if unde- to subtract a background from readings, making zero concen-

tected, will introduce systematic errors. This practice is based tration read zero (See Note 4). It is applicable only when

on the assumption that such errors are negligible during the excitation conditions are nearly constant and may be used to

initial calibration procedure but can be detected, when they do provide a convenient display in which readings have a simple

occur, during subsequent operations, as described in 8.1.

proportion to concentration. In such cases, multiplying read-

6.2 Random Errors: ings by some simple factor will result in a “direct reading” of

6.2.1 Measurement of Random Errors—In addition to the

the concentration.

normal variation of reading in any measurement system,

NOTE 4—Bias in a linear readout system is a counter voltage applied to

randomness occurring in the excitation process causes varia-

either the reference of a capacitor used to integrate a signal or to a final

tion in the intensities obtained from excitation of the same

reading so as to suppress the portion of signal attributable to background.

specimen. The best numerical measure of such variability is

Bias can also be used to suppress readings from concentrations that are

below the level of interest.

given by the standard deviation, s. With a normal distribution,

68.3 % of the values will fall within6 1s of the mean, 95.4 %

7.1.2.2 In dynamic background correction, a selected por-

will fall within 62s and 99.7 % within 63s of the mean.

tion of the background of a spectrum is integrated simulta-

While the “true” standard deviation is designated s,an

neously with analytical signals. When this integrated measure-

estimate of standard deviation calculated from a limited

ment is large enough, a proportion of it can be used to bias the

number of values is designated by the symbol s. Equations for

measurement of an analytical line, effectively subtracting out

calculating the value of s are given in Practice E 876.

thebackgroundwhichcanbepresumedtohavebeenpartofthe

6.2.2 Constancy of Random Error:

measurement of the analytical line. Background may be made

6.2.2.1 In photographic photometry, the standard deviation

to have a strong signal by using a wide exit slit for the

of the logarithm of the intensity ratio is constant (within the

background reading, increasing the dynode voltage on the

limits of random statistical variations) over the normally

photomultiplier tube used for background, using an extra-

employed intensity ratio range. This constancy is affected

sensitive photomultiplier tube for the measurement, or by a

adversely by increased microphotometer reading errors intro-

combination of these. The dynamic approach is difficult to

duced by the measurement of very high and very low optical

controlsinceitdependsonmaintainingconsistentresponseson

densities, and also by the variability of spectral background.

thephotomultipliertubesusedfortheanalyticallinesaswellas

Thestandarddeviationislargewhenmeasurementsfalloutside

for the background. Changing a dynode setting on either the

the range of 60 to 20 % T (optical densities of 0.2 to 0.7).

background or analytical line photomultiplier tube affects the

6.2.2.2 With optical emission spectrometers, the random

correction. If a specimen is available which has none of the

error is constant from the point at which the background is

elements being measured, such as a piece of the pure matrix

small compared to the line signal up to the point where the

element, this may be run and the background control adjusted,

analytical curve begins to deviate from linearity such as can

after the integration, to make the element reading be zero.

occur from self-absorption.

NOTE 5—A pure piece of the matrix element is applicable only if the

6.2.2.3 In linear readout systems, the constancy of random

excitation of such a specimen is consistent with the type of excitation

error is expressed in terms of relative standard deviation rather

obtained when a normal specimen is run. This is a direct step in systems

than standard deviation.

thatbiasthevoltageontheelementintegratorssothatchangesingainwill

not affect the correction. If matrix materials with “zero” concentrations of

the elements of interest are not available, trial and error excitations may

7. Calibration

have to be made until the analytical curve shows zero concentration

7.1 Spectral Background—Background intensities vary

reading zero. In systems that bias the final reading rather than the

throughout the spectral region. Including the background in

integrated voltage, dynamic background corrections are generally not

measurements of spectral line intensities can introduce signifi- applicable.

e1

E 305 – 89 (1994)

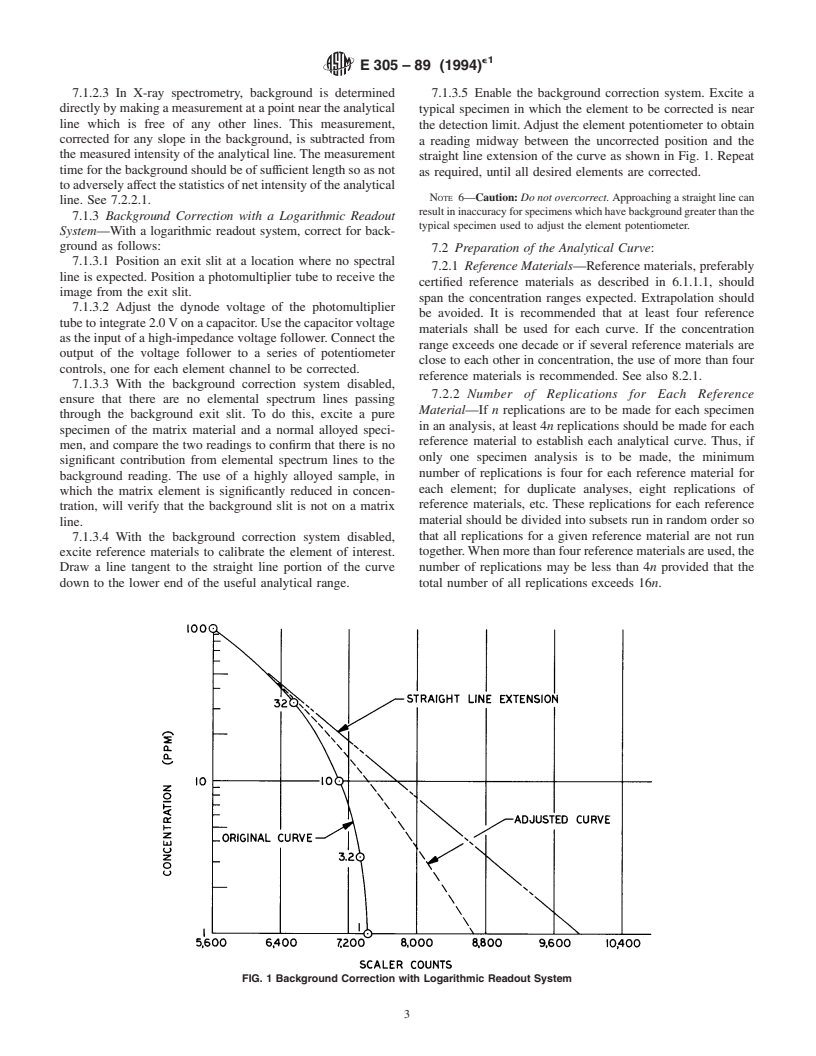

7.1.2.3 In X-ray spectrometry, background is determined 7.1.3.5 Enable the background correction system. Excite a

directlybymakingameasurementatapointneartheanalytical typical specimen in which the element to be corrected is near

line which is free of any other lines. This measurement,

the detection limit. Adjust the element potentiometer to obtain

corrected for any slope in the background, is subtracted from

a reading midway between the uncorrected position and the

the measured intensity of the analytical line. The measurement

straight line extension of the curve as shown in Fig. 1. Repeat

time for the background should be of sufficient length so as not

as required, until all desired elements are corrected.

toadverselyaffectthestatisticsofnetintensityoftheanalytical

NOTE 6—Caution: Do not overcorrect. Approaching a straight line can

line. See 7.2.2.1.

resultininaccuracyforspecimenswhichhavebackgroundgreaterthanthe

7.1.3 Background Correction with a Logarithmic Readout

typical specimen used to adjust the element potentiometer.

System—With a logarithmic readout system, correct for back-

ground as follows:

7.2 Preparation of the Analytical Curve:

7.1.3.1 Position an exit slit at a location where no spectral

7.2.1 Reference Materials—Reference materials, preferably

line is expected. Position a photomultiplier tube to receive the

certified reference materials as described in 6.1.1.1, should

image from the exit slit.

span the concentration ranges expected. Extrapolation should

7.1.3.2 Adjust the dynode voltage of the photomultiplier

be avoided. It is recommended that at least four reference

tubetointegrate2.0Vonacapacitor.Usethecapacitorvoltage

materials shall be used for each curve. If the concentration

as the input of a high-impedance voltage follower. Connect the

range exceeds one decade or if several reference materials are

output of the voltage follower to a series of potentiometer

close to each other in concentration, the use of more than four

controls, one for each element channel to be corrected.

reference materials is recommended. See also 8.2.1.

7.1.3.3 With the background correction system disabled,

7.2.2 Number of Replications for Each Reference

ensure that there are no elemental spectrum lines passing

Material—If n replications are to be made for each specimen

through the background exit slit. To do this, excite a pure

in an analysis, at least 4n replications should be made for each

specimen of the matrix material and a normal alloyed speci-

reference material to establish each analytical curve. Thus, if

men, and compare the two readings to confirm that there is no

only one specimen analysis is to be made, the minimum

significant contribution from elemental spectrum lines to the

number of replications is four for each reference material for

background reading. The use of a highly alloyed sample, in

each element; for duplicate analyses, eight replications of

which the matrix element is significantly reduced in concen-

reference materials, etc. These replications for each reference

tration, will verify that the background slit is not on a matrix

material should be divided into subsets run in random order so

line.

that all replications for a given reference materi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.