ASTM E1154-89(2003)

(Specification)Standard Specification for Piston or Plunger Operated Volumetric Apparatus

Standard Specification for Piston or Plunger Operated Volumetric Apparatus

ABSTRACT

This specification covers piston or plunger operated volumetric apparatus (POVA), in particular, the requirements, operating conditions, and test methods. POVA covered by this specification are pipettes, dispensers (with and without valve), dilutors, and displacement burets (with and without valve). Single measurement, replicate delivery, durability, functional (such as tests for leakage, broken parts, existence of air bubbles, and contamination), volumetric, and gravimetric tests shall be performed and shall conform to the requirements specified.

SCOPE

1.1 This specification covers requirements, operating conditions, and test methods for piston or plunger operated volumetric apparatus (POVA).

1.2 This specification includes specifications applicable for all types of POVA or those given by the manufacturer. The following precautionary caveat pertains only to the test method portion, Section , of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1154 – 89 (Reapproved 2003)

Standard Specification for

1

Piston or Plunger Operated Volumetric Apparatus

This standard is issued under the fixed designation E1154; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 disposable—those parts of an instrument that are

intended to be used once only and then discarded. Disposable

1.1 This specification covers requirements, operating con-

parts are generally intended for use in applications where

ditions, and test methods for piston or plunger operated

sample carryover is intolerable.

volumetric apparatus (POVA).

3.1.4 maximum error—the maximum difference between

1.2 This specification includes specifications applicable for

thenominalvolumeandanysingleindividualvolumeobtained

all types of POVA or those given by the manufacturer. The

by applying the test procedure specified in Section 13 of this

followingprecautionarycaveatpertainsonlytothetestmethod

ISO Standard.

portion, Section 13, of this specification: This standard does

3.1.5 maximum expectable error—with more than 95%

not purport to address all of the safety concerns, if any,

probability, the maximum expectable error is calculated as

associated with its use. It is the responsibility of the user of this

follows:

standard to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior

6~1E 1 12s! (1)

T

to use.

where:

2. Referenced Documents

E = inaccuracy of the mean, and

2 T

2.1 ISO Documents:

s = standard deviation from the repeatability test in

ISO3534 Statistics—Vocabulary and Symbols

Section 13.

ISO653 Long Solid-Stem Thermometers for Precision Use

3.1.6 nominal volume(s)—the stated volume(s) for which

ISO655 Long Enclosed-Scale Thermometers for Precision

performance is specified.

Use

3.1.7 unit of volume—themillilitreorthemicrolitre,thatare

ISO4787 Laboratory Glassware—Volumetric Glassware—

accepted substitutes for the cubic centimetre or cubic millime-

Methods for Testing and Use

tre.

3.1.7.1 Discussion—Itisrecommendedthatvolumesshould

3. Terminology

be specified in microlitres up to 999 µL, and in millilitres from

3.1 Definitions of Terms Specific to This Standard:

1 mL.

3

3.1.1 accuracy —the accuracy of an instrument is the

3.1.8 piston or plunger operated volumetric apparatus

closeness of agreement between the nominal volume and the

(POVA)—the volume of liquid to be measured with POVA is

mean volume, obtained by applying the test procedure speci-

defined by one or more strokes of one or more pistons or

fied in Section 13 of this specification. It is quantified by the

plungers. POVA may be operated manually or mechanically

inaccuracy of the mean.

(for example, electrically, pneumatically or by hydrostatic

3.1.2 dead volume—thedeadvolumeisthatpartofthetotal

pressure).

liquidvolume,heldintheoperationalpartofthedevice,which

3.1.8.1 Discussion—In the following text the word8 piston’

is not delivered.

means8 piston or plunger.’

3.1.2.1 Discussion—The dead volume should not be con-

3

3.1.9 precision —the closeness of agreement between the

fused with the dead space of an air displacement instrument.

individual volumes obtained by applying the test procedure

specified in this specification. It is quantified by the impreci-

sion.

1

This specification is under the jurisdiction of ASTM Committee E41 on

3.1.9.1 Discussion—Thetestprocedurespecifiedgivesonly

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.06 on

a measure of the repeatability (see ISO 3534) under controlled

Weighing Devices.

Current edition approved April 4, 1989. Published May 1989. Originally

conditions.

published as E1154-87. Last previous edition E1154-87.

3.1.10 reusable—thosepartsofaninstrumentthataremeant

2

Available from American National Standards Institute, 1430 Broadway, New

tobeusedmorethanonce.Asthereusabilityofsomepartscan

York, NY 10018.

3

These definitions apply only in the cases where the distributions are Gaussian. rarely be quantified, any institution or individual who reuses a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E 1154 – 89 (2003)

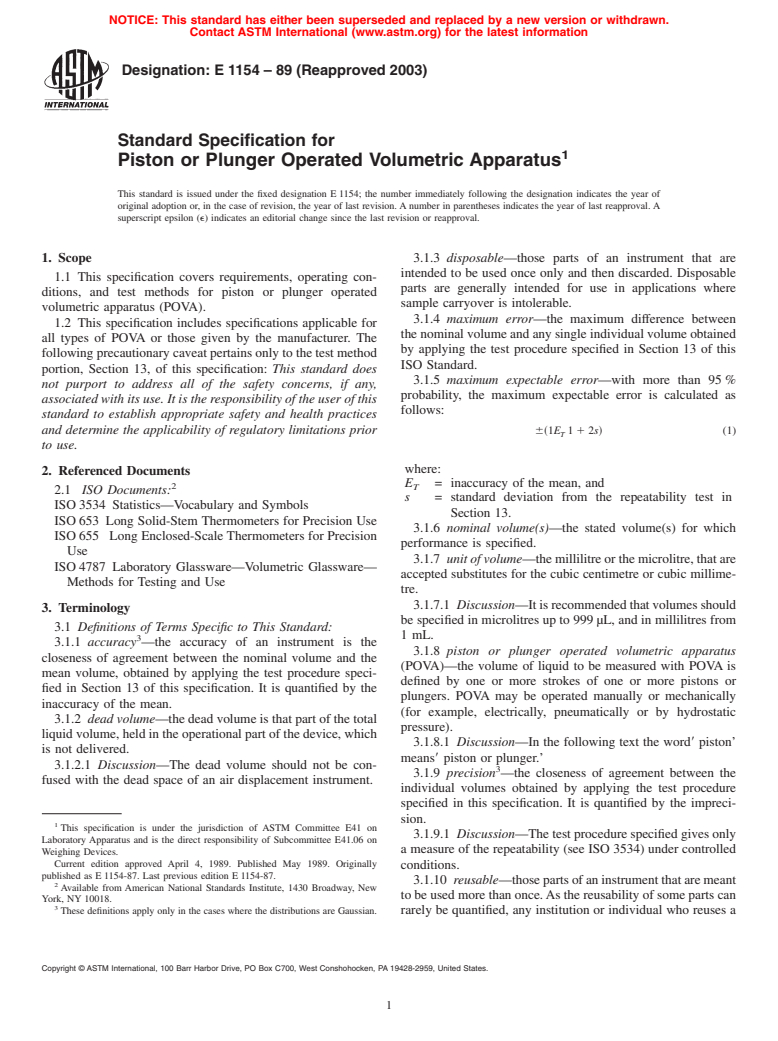

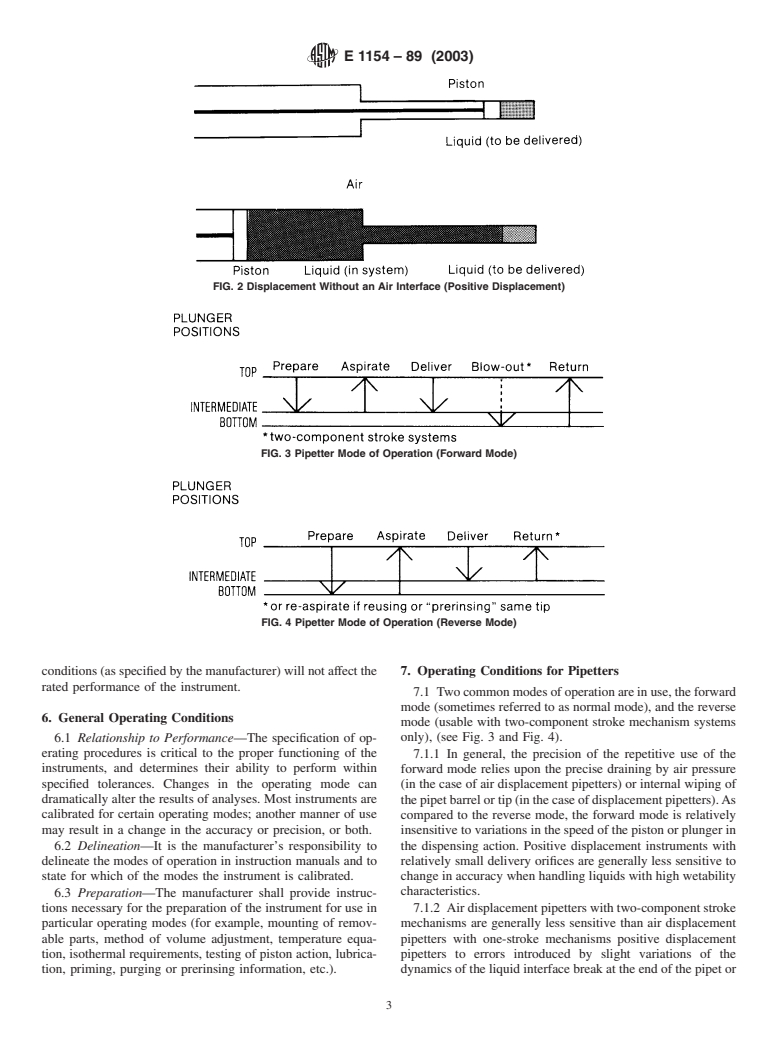

reusable part must see to its safety and effectiveness. Reusable liquid interface (indirect action) or by actual contact with the

parts are generally intended for use in applications where piston (direct action), (see Fig. 3 and Fig. 4).

sample carryover is tolerable, or can be adequately prevented.

5. Performance Requirements

3.1.11 sample carryover—that portion of the sample

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.