ASTM F2162-01e1

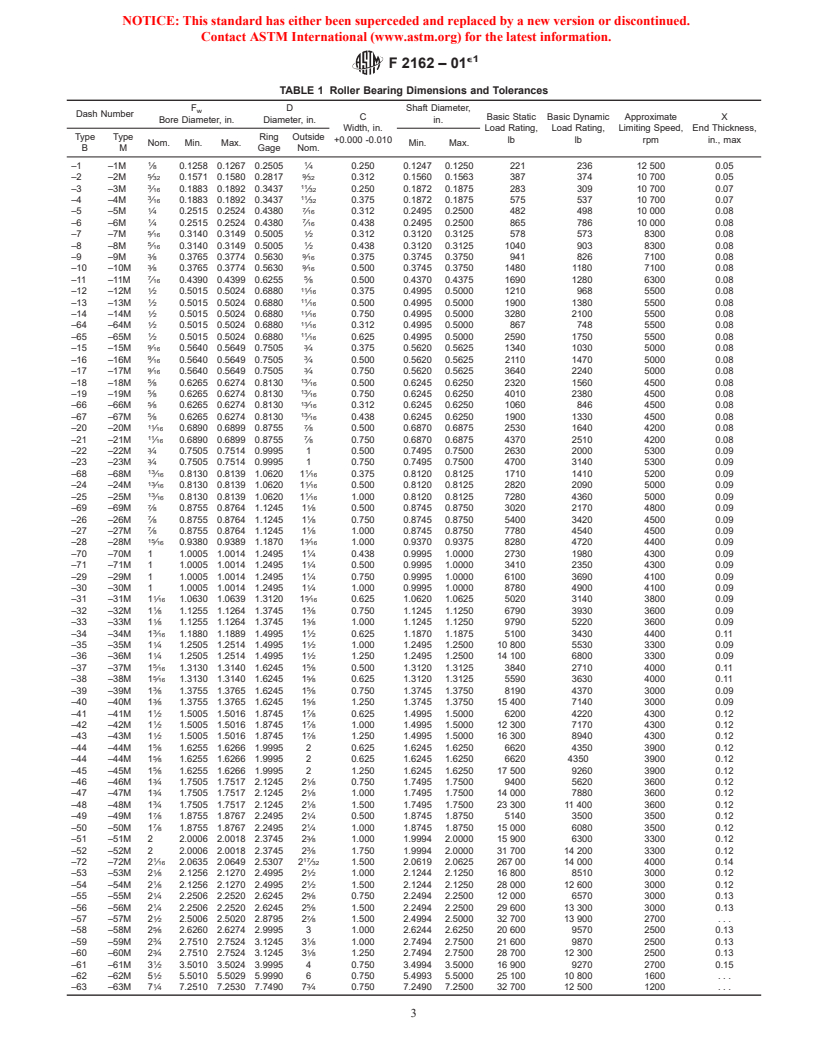

(Specification)Standard Specification for Bearing, Roller, Needle: Drawn Outer Ring, Full Complement, Without Inner Ring, Open and Closed End, Standard Type

Standard Specification for Bearing, Roller, Needle: Drawn Outer Ring, Full Complement, Without Inner Ring, Open and Closed End, Standard Type

SCOPE

1.1 This specification covers standard-type needle roller bearings having drawn outer rings, full complement, without inner rings, with either open or closed ends.

1.2 The use of recycled materials that meet the requirements of the applicable material specification without jeopardizing the intended use of the item is encouraged.

1.3 The inner rings specified in this specification are not intended for use in flight critical systems of aircraft.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only.

Note 1—This specification was originally developed by the Department of Defense and maintained by the Defense Supply Center Richmond. It is intended to replicate the requirements of MS 17130.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: F 2162 – 01

Standard Specification for

Bearing, Roller, Needle: Drawn Outer Ring, Full

Complement, Without Inner Ring, Open and Closed End,

1

Standard Type

This standard is issued under the fixed designation F 2162; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Note 1 was changed editorially in June 2002.

1. Scope 2.3 SAE Standard:

4

SAE J-404 Chemical Composition of SAE Alloy Steels

1.1 This specification covers standard-type needle roller

2.4 Military Standard:

bearings having drawn outer rings, full complement, without

MIL-STD-130 Identification Marking of US Military Prop-

inner rings, with either open or closed ends.

5

erty

1.2 The use of recycled materials that meet the requirements

2.5 American Bearing Manufacturer’s Association (ABMA)

of the applicable material specification without jeopardizing

Standard:

the intended use of the item is encouraged.

STD 4 Tolerance Definitions and Gauging Practices For

1.3 The inner rings specified in this specification are not

6

Ball and Roller Bearings

intended for use in flight critical systems of aircraft.

2.6 ISO Standards:

1.4 The values stated in inch-pound units are to be regarded

7

ISO 5593 Rolling Bearings—Vocabulary

as the standard. The values given in parentheses are provided

7

ISO 1132 Rolling Bearings—Tolerances—Definitions

for information only.

NOTE 1—This specification contains many of the requirments of 3. Terminology

MS17131, which was originally developed by the Department of Defense

3.1 Definitions—For definitions of terms used in this speci-

and is currently maintained by the Defense Supply Center Richmond.

fication, refer to ABMA STD 4 Tolerance Definitions and

Gauging Practices for Ball and Roller Bearings, ISO 1132

2. Referenced Documents

Roller Bearings—Tolerances—Definitions, and to ISO 5593

2.1 ASTM Standards:

Rolling Bearings—Vocabulary

E 18 Test Methods for Rockwell Hardness and Rockwell

2 3.2 Definitions of Terms Specific to This Standard:

Superficial Hardness of Metallic Materials

3.2.1 average life (L ), n—for a radial roller bearing, the

50

E 140 Standard Hardness Conversion Tables for Metals

number of revolutions that 50 % of a group of bearings will

(Relationship Among Brinell Hardness, Vickers Hardness,

complete or exceed before the first evidence of fatigue devel-

Rockwell Hardness, Rockwell Superficial Hardness,

ops.

2

Knoop Hardness, and Scleroscope Hardness)

3.2.1.1 Discussion—The average life maybe as much as five

2

E 384 Test Method for Microindentation Hardness

times the rating life.

F 2163 Specification for Ring, Bearing, Inner: for Needle

3.2.2 basic dynamic load rating (C ), n—for a radial roller

2

r

Roller Bearing With Drawn Outer Ring

bearing, that calculated, constant radial load that a group of

2.2 ASME Standard:

apparently identical bearings with stationary outer rings can

ASME B 46.1 Surface Texture Surface Roughness, Wavi-

theoretically endure for a rating life of one million revolutions

3

ness, and Lay

of the inner ring.

1 4

This specification is under the jurisdiction of ASTM Committee F34 on Rolling Available from SAI International, 400 Commonwealth Dr., Warrendale, PA

Element Bearings and is the direct responsibility of Subcommittee F34.01 on 15096-0001.

5

Rolling Element. Available from USA Information Systems, 1092 Laskin Rd., Ste. 208, Virginia

Current edition approved Dec. 12, 2001. Published March 2002. Beach, VA 23451.

2 6

Annual Book of ASTM Standards, Vol 03.01. Available from the American Bearing Manufacturer’s Association, 1200 19th

3

Available from Global Engineering Documents, 15 Inverness Way, East St. NW, Ste. 300, Washington, DC 20036–2401.

7

Englewood, CO 80112. Available from ANSI, 1819 L St. NW, Ste. 600, Washington, DC 20036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

F2162–01

3.2.2.1 Discussion—Since applied loading as great as the 5.1.5 Load rating, including basic static load rating, lb and

basic dynamic load rating tends to cause local plastic defor- basic dynamic load rating, lb;

mation of the rolling surfaces, it is not anticipated that such

5.1.6 Approximate limiting speed, rpm; and

heavy loading would normally be applied.

5.1.7 Maximum end thickness.

3.2.3 basic static load rating (C ), n—for a radial roller

or

bearing, that uniformly distributed static radial load w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.