ASTM C16-02

(Test Method)Standard Test Method for Load Testing Refractory Shapes at High Temperatures

Standard Test Method for Load Testing Refractory Shapes at High Temperatures

SCOPE

1.1 This test method covers the determination of the resistance to deformation or shear of refractory shapes when subjected to a specified compressive load at a specified temperature for a specified time.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 16 – 02

Standard Test Method for

1

Load Testing Refractory Shapes at High Temperatures

This standard is issued under the fixed designation C 16; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 This test method is not applicable for refractory mate-

rials that are unstable in an oxidizing atmosphere unless means

1.1 This test method covers the determination of the resis-

are provided to protect the specimens.

tance to deformation or shear of refractory shapes when

subjected to a specified compressive load at a specified

4. Apparatus

temperature for a specified time.

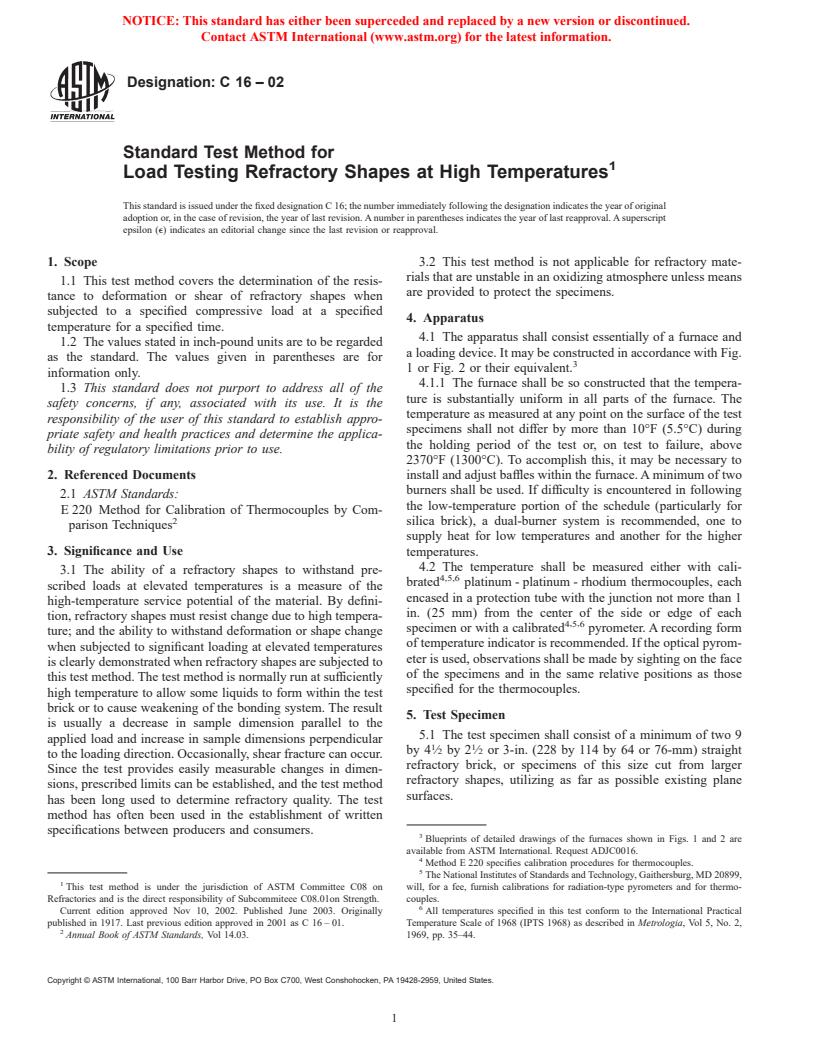

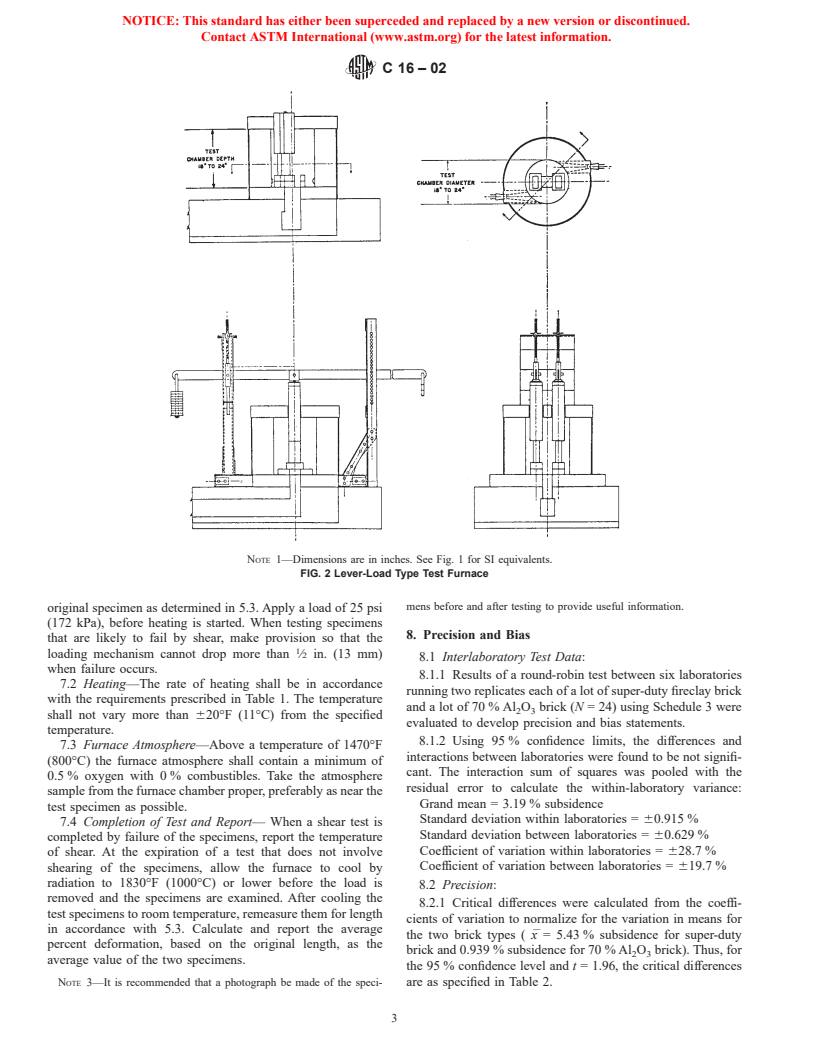

4.1 The apparatus shall consist essentially of a furnace and

1.2 The values stated in inch-pound units are to be regarded

a loading device. It may be constructed in accordance with Fig.

as the standard. The values given in parentheses are for

3

1 or Fig. 2 or their equivalent.

information only.

4.1.1 The furnace shall be so constructed that the tempera-

1.3 This standard does not purport to address all of the

ture is substantially uniform in all parts of the furnace. The

safety concerns, if any, associated with its use. It is the

temperature as measured at any point on the surface of the test

responsibility of the user of this standard to establish appro-

specimens shall not differ by more than 10°F (5.5°C) during

priate safety and health practices and determine the applica-

the holding period of the test or, on test to failure, above

bility of regulatory limitations prior to use.

2370°F (1300°C). To accomplish this, it may be necessary to

2. Referenced Documents install and adjust baffles within the furnace. A minimum of two

burners shall be used. If difficulty is encountered in following

2.1 ASTM Standards:

the low-temperature portion of the schedule (particularly for

E 220 Method for Calibration of Thermocouples by Com-

2 silica brick), a dual-burner system is recommended, one to

parison Techniques

supply heat for low temperatures and another for the higher

3. Significance and Use temperatures.

4.2 The temperature shall be measured either with cali-

3.1 The ability of a refractory shapes to withstand pre-

4,5,6

brated platinum - platinum - rhodium thermocouples, each

scribed loads at elevated temperatures is a measure of the

encased in a protection tube with the junction not more than 1

high-temperature service potential of the material. By defini-

in. (25 mm) from the center of the side or edge of each

tion, refractory shapes must resist change due to high tempera-

, ,

4 5 6

specimen or with a calibrated pyrometer. A recording form

ture; and the ability to withstand deformation or shape change

of temperature indicator is recommended. If the optical pyrom-

when subjected to significant loading at elevated temperatures

eter is used, observations shall be made by sighting on the face

is clearly demonstrated when refractory shapes are subjected to

of the specimens and in the same relative positions as those

this test method. The test method is normally run at sufficiently

specified for the thermocouples.

high temperature to allow some liquids to form within the test

brick or to cause weakening of the bonding system. The result

5. Test Specimen

is usually a decrease in sample dimension parallel to the

5.1 The test specimen shall consist of a minimum of two 9

applied load and increase in sample dimensions perpendicular

1 1

by 4 ⁄2 by 2 ⁄2 or 3-in. (228 by 114 by 64 or 76-mm) straight

to the loading direction. Occasionally, shear fracture can occur.

refractory brick, or specimens of this size cut from larger

Since the test provides easily measurable changes in dimen-

refractory shapes, utilizing as far as possible existing plane

sions, prescribed limits can be established, and the test method

surfaces.

has been long used to determine refractory quality. The test

method has often been used in the establishment of written

specifications between producers and consumers.

3

Blueprints of detailed drawings of the furnaces shown in Figs. 1 and 2 are

available from ASTM International. Request ADJC0016.

4

Method E 220 specifies calibration procedures for thermocouples.

5

The National Institutes of Standards and Technology, Gaithersburg, MD 20899,

1

This test method is under the jurisdiction of ASTM Committee C08 on will, for a fee, furnish calibrations for radiation-type pyrometers and for thermo-

Refractories and is the direct responsibility of Subcommiteee C08.01on Strength. couples.

6

Current edition approved Nov 10, 2002. Published June 2003. Originally All temperatures specified in this test conform to the International

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.