ASTM E1854-07

(Practice)Standard Practice for Ensuring Test Consistency in Neutron-Induced Displacement Damage of Electronic Parts

Standard Practice for Ensuring Test Consistency in Neutron-Induced Displacement Damage of Electronic Parts

SCOPE

1.1 This practice sets forth requirements to ensure consistency in neutron-induced displacement damage testing of silicon and gallium arsenide electronic piece parts. This requires controls on facility, dosimetry, tester, and communications processes that affect the accuracy and reproducibility of these tests. It provides background information on the technical basis for the requirements and additional recommendations on neutron testing. In addition to neutrons, reactors are used to provide gamma-ray pulses of intensities and durations that are not achievable elsewhere. This practice also provides background information and recommendations on gamma-ray testing of electronics using nuclear reactors.

1.2 Methods are presented for ensuring and validating consistency in neutron displacement damage testing of electronic parts such as integrated circuits, transistors, and diodes. The issues identified and the controls set forth in this practice address the characterization and suitability of the radiation environments. They generally apply to reactor and 14-MeV neutron sources when used for displacement damage testing, and apply to 252Cf testing when this source is used for this application. Facility and environment characteristics that introduce complications or problems are identified, and recommendations are offered as to how problems can be recognized and minimized or solved. This practice may be used by facility users, test personnel, facility operators, and independent process validators to determine the suitability of a specific environment within a facility and of the testing process as a whole, with the exception of the electrical measurements, which are addressed in other standards. Additional information on conducting irradiations can be found in Practices E 798 and F 1190. This practice also may be of use to test sponsors (that is, organizations that establish test specifications or otherwise have a vested interest in the performance of electronics in neutron environments).

1.3 Methods for evaluation and control of undesired contributors to damage are discussed in this practice, and references to relevant ASTM standards and technical reports are provided. Processes and methods used to arrive at the appropriate test environments and specification levels for electronics systems are beyond the scope of this practice; however, the process for determining the 1-MeV equivalent displacement specifications from operational environment neutron spectra should employ the methods and parameters described herein. Some important considerations are addressed in through (Nonmandatory information)..

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1854 − 07

StandardPractice for

Ensuring Test Consistency in Neutron-Induced

1

Displacement Damage of Electronic Parts

This standard is issued under the fixed designation E1854; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.3 Methods for evaluation and control of undesired con-

tributors to damage are discussed in this practice, and refer-

1.1 This practice sets forth requirements to ensure consis-

ences to relevant ASTM standards and technical reports are

tency in neutron-induced displacement damage testing of

provided. Processes and methods used to arrive at the appro-

silicon and gallium arsenide electronic piece parts. This re-

priatetestenvironmentsandspecificationlevelsforelectronics

quires controls on facility, dosimetry, tester, and communica-

systems are beyond the scope of this practice; however, the

tions processes that affect the accuracy and reproducibility of

process for determining the 1-MeV equivalent displacement

thesetests.Itprovidesbackgroundinformationonthetechnical

specifications from operational environment neutron spectra

basis for the requirements and additional recommendations on

should employ the methods and parameters described herein.

neutron testing. In addition to neutrons, reactors are used to

Some important considerations are addressed in Appendix X1

provide gamma-ray pulses of intensities and durations that are

through X1.3.1 (Nonmandatory information).

not achievable elsewhere. This practice also provides back-

1.4 This standard does not purport to address all of the

ground information and recommendations on gamma-ray test-

safety concerns, if any, associated with its use. It is the

ing of electronics using nuclear reactors.

responsibility of the user of this standard to establish appro-

1.2 Methods are presented for ensuring and validating

priate safety and health practices and determine the applica-

consistency in neutron displacement damage testing of elec-

bility of regulatory limitations prior to use.

tronic parts such as integrated circuits, transistors, and diodes.

The issues identified and the controls set forth in this practice

2. Referenced Documents

address the characterization and suitability of the radiation

2.1 The ASTM standards listed below present methods for

environments. They generally apply to reactor and 14-MeV

ensuring proper determination of neutron spectra and fluences,

neutron sources when used for displacement damage testing,

252

gamma-ray doses, and damage in silicon and gallium arsenide

and apply to Cf testing when this source is used for this

devices.The proper use of these standards is the responsibility

application.Facilityandenvironmentcharacteristicsthatintro-

of the radiation metrology or dosimetry organization that is

duce complications or problems are identified, and recommen-

often closely affiliated with facility operations. The references

dations are offered as to how problems can be recognized and

listed in each standard are also relevant to all participants as

minimized or solved. This practice may be used by facility

background material for testing consistency.

users, test personnel, facility operators, and independent pro-

2

cess validators to determine the suitability of a specific

2.2 ASTM Standards:

environment within a facility and of the testing process as a

E170Terminology Relating to Radiation Measurements and

whole, with the exception of the electrical measurements,

Dosimetry

whichareaddressedinotherstandards.Additionalinformation

E181Test Methods for Detector Calibration andAnalysis of

on conducting irradiations can be found in Practices E798 and

Radionuclides

F1190. This practice also may be of use to test sponsors (that

E261Practice for Determining Neutron Fluence, Fluence

is, organizations that establish test specifications or otherwise

Rate, and Spectra by Radioactivation Techniques

have a vested interest in the performance of electronics in

E262Test Method for Determining Thermal Neutron Reac-

neutron environments).

tion Rates and Thermal Neutron Fluence Rates by Radio-

activation Techniques

E263Test Method for Measuring Fast-Neutron Reaction

1

This practice is under the jurisdiction of ASTM Committee E10 on Nuclear

Technology and Applicationsand is the direct responsibility of Subcommittee

2

E10.07 on Radiation Dosimetry for Radiation Effects on Materials and Devices. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJune1,2007.PublishedJuly2007.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1996. L

...

Questions, Comments and Discussion

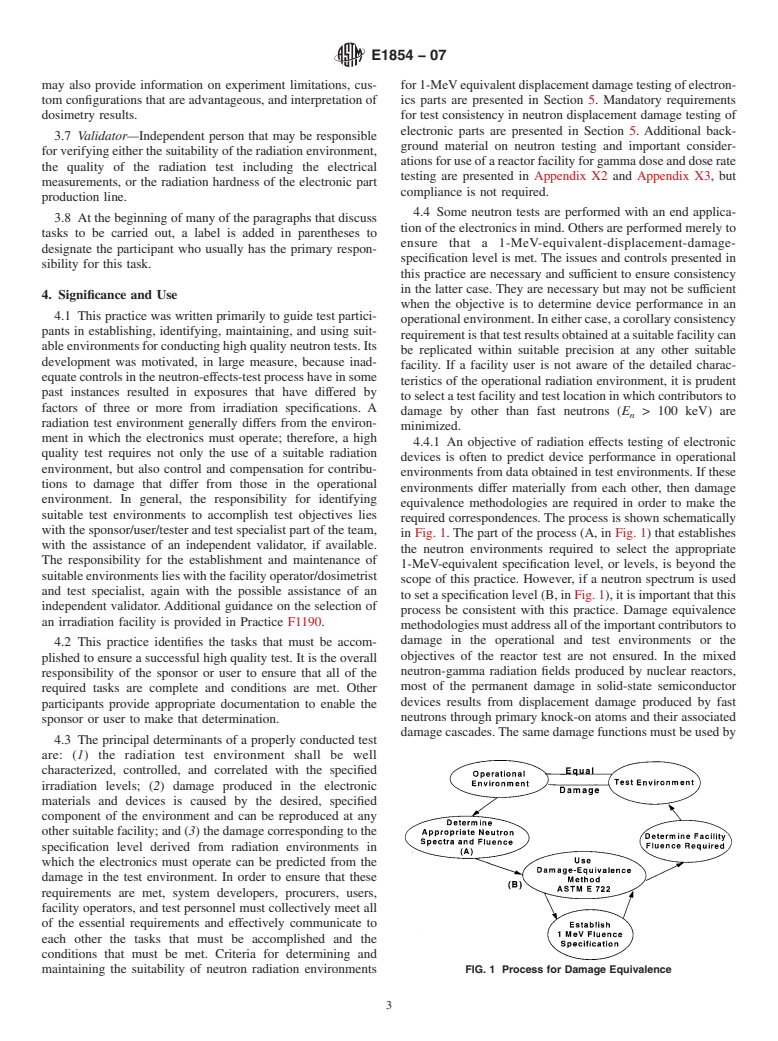

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.