ASTM C1028-06

(Test Method)Standard Test Method for Determining the Static Coefficient of Friction of Ceramic Tile and Other Like Surfaces by the Horizontal Dynamometer Pull-Meter Method

Standard Test Method for Determining the Static Coefficient of Friction of Ceramic Tile and Other Like Surfaces by the Horizontal Dynamometer Pull-Meter Method

SCOPE

1.1 This test method covers the measurement of static coefficient of friction of ceramic tile or other surfaces under both wet and dry conditions while utilizing Neolite heel assemblies. This test method can be used in the laboratory or in the field.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information purposes only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1028–06

Standard Test Method for

Determining the Static Coefficient of Friction of Ceramic Tile

and Other Like Surfaces by the Horizontal Dynamometer

1

Pull-Meter Method

This standard is issued under the fixed designation C 1028; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 friction—the resistance developed between the physi-

cal contacting surface of two bodies when there is movement

1.1 This test method covers the measurement of static

or tendency for movement of one body relative to the other

coefficient of friction of ceramic tile or other surfaces under

parallel to the plane of contact.

both wet and dry conditions while utilizing Neolite heel

2

3.1.3 static coeffıcient of friction—the ratio of the horizontal

assemblies. This test method can be used in the laboratory or

component of force applied to a body that just overcomes the

in the field.

friction or resistance to slipping to the vertical component of

1.2 The values stated in inch-pound units are to be regarded

the weight of the object or force applied to it.

as the standard. The values given in parentheses are for

information purposes only.

4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 The horizontal dynamometer pull meter and heel assem-

safety concerns, if any, associated with its use. It is the

blies are designed to determine the static coefficient of friction

responsibility of the user of this standard to establish appro-

of tile and like materials.

priate safety and health practices and determine the applica-

4.2 The measurement made by this apparatus is believed to

bility of regulatory limitations prior to use.

be one important factor relative to slip resistance. Other factors

2. Referenced Documents can affect slip resistance, such as the degree of wear on the

shoe and flooring material; presence of foreign material, such

2.1 Rubber Manufacturing Association (RMA) Standard:

as water, oil, and dirt; the length of the human stride at the time

HS-3 Method of Test for Evaluating Adhesive Bondability

3

of slip; type of floor finish; and the physical and mental

of Shoe Soling Materials (1975)

condition of humans. Therefore, this test method should be

3. Terminology

used for the purpose of developing a property of the flooring

surface under laboratory conditions, and should not be used to

3.1 Definitions:

determine slip resistance under field conditions unless those

3.1.1 coeffıcient of friction—the ratio of the horizontal

conditions are fully described.

componentofforcerequiredtoovercomeorhaveatendencyto

4.3 Becausemanyvariablesmayenterintotheevaluationof

overcome friction to the vertical component of the object

slip resistance of a particular surface, this test method is

weight or normal force applied through the object which tends

designed to evaluate these surfaces under both laboratory and

to cause the friction.

actual site installation conditions.

4.4 The static coefficient of friction is determined under

both wet and dry conditions with Neolite heel assemblies over

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC21onCeramic

both unprepared and prepared (cleaned) test surfaces.

Whitewares and Related Products and is the direct responsibility of Subcommittee

C21.06 on Ceramic Tile.

5. Apparatus

Current edition approved March 15, 2006. Published April 2006. Originally

approved in 1984, (formerly P 155). Last previous edition approved in 1996 as

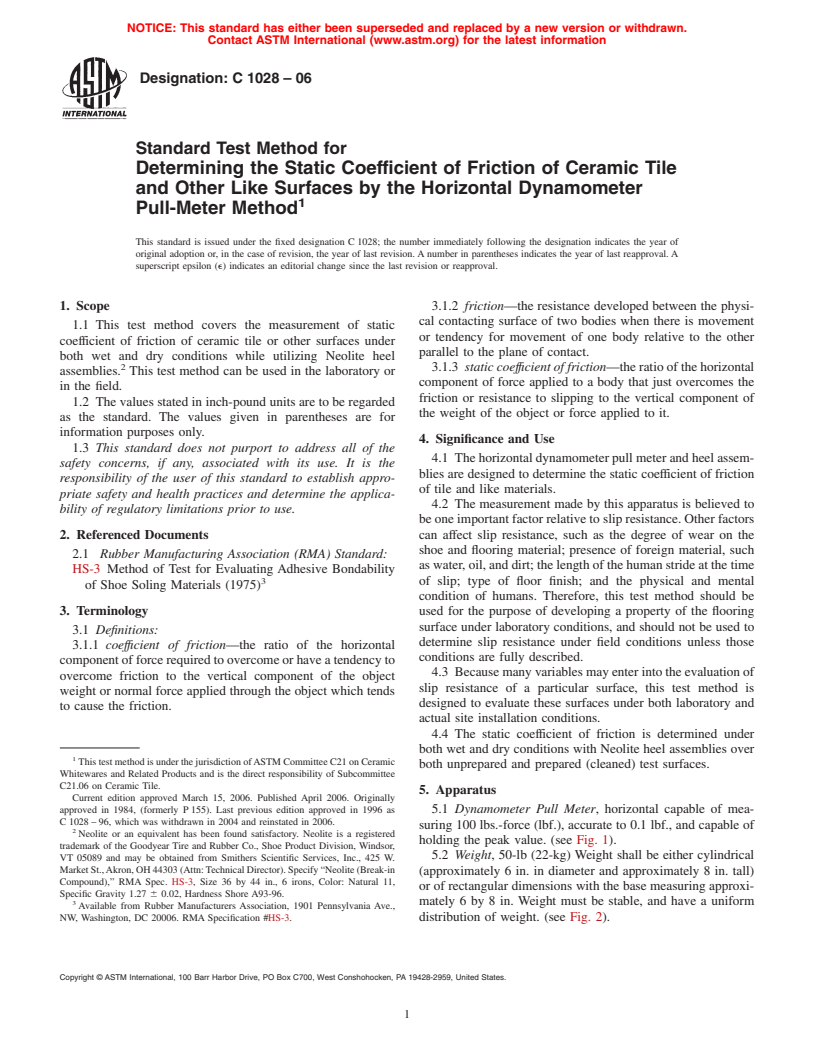

5.1 Dynamometer Pull Meter, horizontal capable of mea-

C 1028 – 96, which was withdrawn in 2004 and reinstated in 2006.

suring 100 lbs.-force (lbf.), accurate to 0.1 lbf., and capable of

2

Neolite or an equivalent has been found satisfactory. Neolite is a registered

holding the peak value. (see Fig. 1).

trademark of the Goodyear Tire and Rubber Co., Shoe Product Division, Windsor,

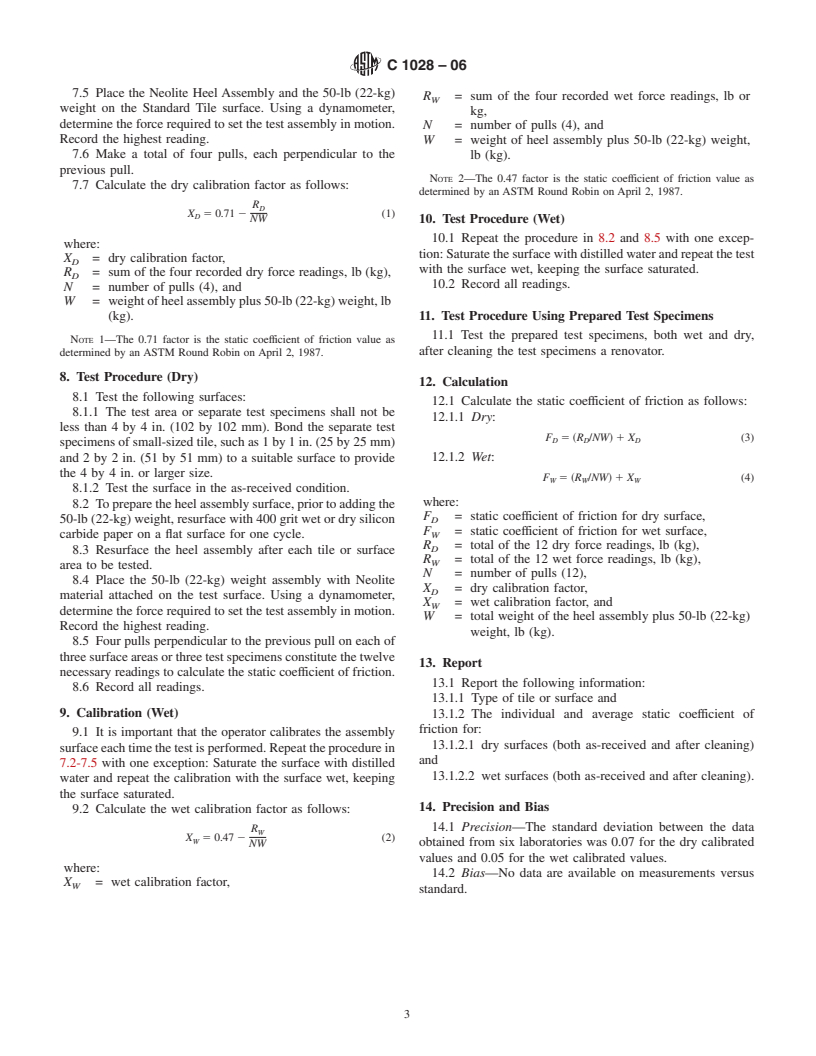

5.2 Weight, 50-lb (22-kg) Weight shall be either cylindrical

VT 05089 and may be obtained from Smithers Scientific Services, Inc., 425 W.

MarketSt.,Akron,OH44303(Attn:TechnicalDirector).Specify“Neolite(Break-in

(approximately 6 in. in diameter and approximately 8 in. tall)

Compound),” RMA Spec. HS-3, Size 36 by 44 in., 6 irons, Color: Natural 11,

or of rectangular dimensions with the base measuring approxi-

Specific Gravity 1.27 6 0.02, Hardness Shore A93-96.

3 mately 6 by 8 in. Weight must be stable, and have a uniform

Available from Rubber Manufacturers Association, 1901 Pennsylvania Ave.,

NW, Washington, DC 20006. RMA Specification #HS-3. distribution of weight. (see Fig. 2).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Con

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.