ASTM G198-11(2016)

(Test Method)Standard Test Method for Determining the Relative Corrosion Performance of Driven Fasteners in Contact with Treated Wood

Standard Test Method for Determining the Relative Corrosion Performance of Driven Fasteners in Contact with Treated Wood

SIGNIFICANCE AND USE

5.1 This test method provides controlled environments which are utilized to produce corrosion of metal, metal-coated, or nonmetallic-coated smooth or deformed shank driven fasteners in contact with treated wood exposed to the given test environments. The test method provides information that can be used to evaluate the corrosion resistance of metal, metal-coated, or nonmetallic-coated smooth or deformed shank driven fasteners in contact with different chemical wood treatments.

5.2 The results shall be used for comparative purposes only and they shall not be correlated to exposure time in natural environments.

5.3 The reproducibility of results in these types of tests is highly dependent on the type of samples tested and the evaluation criteria selected, as well as the control of the operating variables.

SCOPE

1.1 This test method covers and focuses on the corrosion resistance of metal, metal-coated, and nonmetallic-coated smooth and deformed shank driven fasteners in contact with treated wood in exterior or high moisture exposure applications using comparative tests with control fastener specimens of standardized benchmarks. This test method may be used for preservative-treated wood.

1.2 This test method describes the apparatus, procedure, and conditions required to maintain test environments for the Cyclic Fog Test and the Steady State Moisture Test.

1.3 This test method describes the types of test samples, lists exposure periods, and gives guidance on interpretation of results.

1.4 Until experience is gained comparing laboratory-to-laboratory results with this test method, comparisons of fasteners, coatings, materials, or preservatives shall be made only within the results of the same test.

1.5 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G198 − 11 (Reapproved 2016)

Standard Test Method for

Determining the Relative Corrosion Performance of Driven

Fasteners in Contact with Treated Wood

This standard is issued under the fixed designation G198; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Iron and Steel Hardware

B117 Practice for Operating Salt Spray (Fog) Apparatus

1.1 This test method covers and focuses on the corrosion

B487 Test Method for Measurement of Metal and Oxide

resistance of metal, metal-coated, and nonmetallic-coated

Coating Thickness by Microscopical Examination of

smooth and deformed shank driven fasteners in contact with

Cross Section

treatedwoodinexteriororhighmoistureexposureapplications

B499 Test Method for Measurement of Coating Thicknesses

using comparative tests with control fastener specimens of

by the Magnetic Method: Nonmagnetic Coatings on

standardized benchmarks. This test method may be used for

Magnetic Basis Metals

preservative-treated wood.

B504 Test Method for Measurement of Thickness of Metal-

1.2 Thistestmethoddescribestheapparatus,procedure,and

lic Coatings by the Coulometric Method

conditions required to maintain test environments for the

D610 Practice for Evaluating Degree of Rusting on Painted

Cyclic Fog Test and the Steady State Moisture Test.

Steel Surfaces

1.3 Thistestmethoddescribesthetypesoftestsamples,lists D1165 Nomenclature of Commercial Hardwoods and Soft-

woods

exposure periods, and gives guidance on interpretation of

results. D1193 Specification for Reagent Water

D4442 Test Methods for Direct Moisture Content Measure-

1.4 Until experience is gained comparing laboratory-to-

ment of Wood and Wood-Based Materials

laboratory results with this test method, comparisons of

D4444 Test Method for Laboratory Standardization and

fasteners, coatings, materials, or preservatives shall be made

Calibration of Hand-Held Moisture Meters

only within the results of the same test.

E376 Practice for Measuring Coating Thickness by

1.5 The values stated in SI units are to be regarded as

Magnetic-Field or Eddy-Current (Electromagnetic) Test-

standard. The values in parentheses are for information only.

ing Methods

1.6 This standard does not purport to address all of the G1 Practice for Preparing, Cleaning, and Evaluating Corro-

safety concerns, if any, associated with its use. It is the sion Test Specimens

responsibility of the user of this standard to establish appro- G60 Practice for Conducting Cyclic Humidity Exposures

priate safety and health practices and determine the applica- G85 Practice for Modified Salt Spray (Fog) Testing

bility of regulatory limitations prior to use. G193 Terminology and Acronyms Relating to Corrosion

2.2 American Wood Protection Association:

2. Referenced Documents

U1-09 Use Category System: Use Specification for Treated

2.1 ASTM Standards:

Wood

A90/A90M Test Method for Weight [Mass] of Coating on

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

3. Terminology

A153/A153M Specification for Zinc Coating (Hot-Dip) on

3.1 Definitions—Terminology G193 contains other terms

and definitions relating to corrosion and corrosion testing.

Terminology D1165 contains other terms and definitions relat-

This test method is under the jurisdiction of ASTM Committee G01 on

ing to wood and wood testing.

Corrosion of Metals and is the direct responsibility of Subcommittee G01.14 on

Corrosion of Metals in Construction Materials.

3.2 Definitions of Terms Specific to This Standard:

Current edition approved July 15, 2016. Published July 2016. Originally

3.2.1 bright, adj—uncoated steel.

approved in 2011. Last previous edition approved in 2011 as G198 – 11.

DOI:10.1520/G0198–11R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American Wood Protection Association (AWPA), P.O. Box

the ASTM website. 361784, Birmingham, AL 35236-1784, http://www.awpa.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G198 − 11 (2016)

3.2.2 fastener, n—metallic, metal-coated, or nonmetallic- 6.1.2 A schematic diagram of a typical apparatus is shown

coated smooth or deformed shank driven fastener. in Practice G60, Figure 1.

6.1.3 The apparatus shall be capable of providing a relative

3.2.3 test sample, n—combination of fasteners installed into

humidity of 95 % for 24 h a day for a period of at least 120

a treated wood specimen.

days.

3.2.4 wood specimen, n—section of wood into which fas-

6.1.4 The apparatus shall be capable of providing a constant

teners are driven to form test samples. Specimens may be

temperature of 32 6 2°C (90 6 3°F).

treated for testing of materials, coatings, or chemicals or may

6.2 Cyclic Fog Test—The cyclic fog test shall consist of a

be untreated for use as controls.

fog chamber with a solution reservoir, a supply of suitably

3.2.4.1 Discussion—Wood cross-sectional dimensions are

conditioned compressed air, one or more atomizing nozzles,

given in exact numbers for SI units and nominal numbers for

specimen supports, provisions for heating the chamber and

inch-pound units.

necessary means of controlling fog spray and heating cycles

4. Summary of Test Method

and means of purging fog with fresh air prior to heat cycles for

4.1 This test method covers the preparation, testing and a period of at least 120 days.The material of construction shall

be such that it will not affect the corrosiveness of the fog.

evaluation of metal, metal-coated, or nonmetallic-coated

Similar tests are described in Practice B117 and Practice G85

smooth or deformed shank driven fasteners installed in treated

with the exception that these practices use salt solutions during

wood. Control specimens tested in the same conditions shall be

the testing.

hot-dip galvanized fasteners that are coated as described in

Specification A153/A153M or bright fasteners with no coat- 6.2.1 Drops of solution which accumulate on the ceiling or

cover of the chamber shall not be permitted to fall on the

ings. The fasteners are installed in the treated wood specimen

before testing so that the chemicals in the wood are in direct samples being exposed and shall not be returned to the

reservoir for respraying.

contact with the metal or coating. Test samples are then tested

in Steady State Moisture Tests or Cyclic Fog Tests. For each 6.2.2 Drops of solution which fall from the samples shall

not be returned to the solution reservoir for respraying.

type of sample, separate groups of test samples shall be tested

under either or both of the two test conditions. Procedures for

7. Reagents and Materials

conducting tests in two environmental conditions, Steady State

Moisture Tests and Cyclic Fog Tests, are described as well as

7.1 WaterusedforthistestmethodshallconformtoTypeIV

position of the samples and measurement techniques for

water as described in Specification D1193 and shall be referred

determining the degree of corrosion. Guidance is given for

to as purified water.

methods of exposure and inspection of corroded fasteners in

the two environmental conditions.

8. Air Supply

8.1 Thecompressedairsupplyshallbefreeofwater,grease,

5. Significance and Use

oil and dirt.

5.1 This test method provides controlled environments

which are utilized to produce corrosion of metal, metal-coated, NOTE 1—The air supply may be freed from oil and dust by passing it

through a suitable oil/water extractor (that is commercially available) to

or nonmetallic-coated smooth or deformed shank driven fas-

stop any oil from emerging. Many oil/water extractors have an expiration

teners in contact with treated wood exposed to the given test

indicator; proper preventive maintenance intervals should take these into

environments. The test method provides information that can

account.

be used to evaluate the corrosion resistance of metal, metal-

coated, or nonmetallic-coated smooth or deformed shank

9. Sampling, Test Specimens, and Test Units

driven fasteners in contact with different chemical wood

9.1 Fastener Specimens:

treatments.

9.1.1 Aminimum of 65 fasteners shall be used for complete

5.2 The results shall be used for comparative purposes only

evaluation per this test method using both test conditions on

and they shall not be correlated to exposure time in natural

any type of sample fastener; metal, metal-coated, or

environments.

nonmetallic-coated. Multiple fastener types may be tested in

the same cycle of testing with one set of control fasteners.

5.3 The reproducibility of results in these types of tests is

Different fastener lengths may require different wood sizes to

highly dependent on the type of samples tested and the

accommodate the length of the fasteners.

evaluation criteria selected, as well as the control of the

9.1.2 Initial Cleaning of Metal, Metal-Coated, or

operating variables.

Nonmetallic-Coated Smooth or Deformed Shank Driven

6. Apparatus

Fasteners—Initial cleaning of fastener shall be done by rinsing

6.1 Steady State Moisture Test—The apparatus required for with purified water and drying with forced hot air, air tempera-

steady state moisture tests shall consist of a test chamber, ture shall be between 40 to 60°C (104 to 140°F).

provisions for heating the chamber, a humidifying tower, a 9.1.3 Coating Mass—Five randomly selected fasteners shall

supply of compressed air, sample supports, and necessary be taken from the cleaned group of fasteners and shall be

means of control. stripped of coating and weighed to determine the average

6.1.1 There are no size or construction requirements other coating mass. Stripping and weighing of zinc and zinc-alloy

than those needed to meet the requirements of the test method. products shall be in accordance Test Method A90/A90M. The

G198 − 11 (2016)

mass for an individual fastener shall be determined to the ment of 62°C (3°F).The treated wood specimens shall be held

nearest 0.001 g (0.000032 oz). Coatings other than zinc shall in the chamber in these conditions until the treated wood

be stripped using an appropriate method to measure coating specimens reach equilibrium. Equilibrium is defined as no

mass of the corrosion-resistant layer(s). Coatings other than more than a 60.2 % change in a 24-h period of the average

zinc and zinc-alloys shall have their mass or coating thickness mass of ten randomly selected treated wood specimens. These

determined by one of the following methods; Test Method measurementsshallbeconductedevery24h,andmassshallbe

B487,TestMethodB499,TestMethodB504,orPracticeE376. recorded and the change calculated until such equilibrium is

9.1.4 Fastener Diameter—The sample group of five random achieved. Conditions for treated wood specimen conditioning

fasteners from 9.1.3 shall be used to measure the core diameter shall be the same as the Steady State Moisture Test conditions.

of the fastener. The diameter shall be measured at mid-length, 9.2.2.2 Moisture content of the treated wood specimen shall

610 mm (60.4 in.), on the shank of each fastener and is the be determined on one of the treated wood specimens. The

minimum diameter measurement at the selected cross section. beginning and final moisture content of the treated wood

For deformed shank fasteners the measurement shall be made specimen shall be determined using calibrated meters in

at a portion of the shank that has not been deformed, if such a accordance withTest Method D4444 for samples with a known

surface is available. Portions of nail shanks with gripper marks moisture adjustment for the preservative or by oven drying

shall also be avoided, if possible. The diameter shall be methods in accordance with Test Method D4442 for any

measured to the nearest 0.025 mm (0.001 in.) The five sample sample.

diameter measurements shall be averaged to obtain the group

9.3 Test Samples:

fastener diameter.

9.3.1 When preparation of the fastener specimens and the

9.1.5 Control Fastener Group—There shall be a group of

treated wood specimens are complete, the fastener specimens

hot-dip galvanized fasteners that are galvanized to Specifica-

shall be installed in contact with the treated wood specimens.

tion A153/A153M. When testing some coated fasteners, the

9.3.2 The evaluation of the fasteners shall be conducted by

moreappropriatecontrolfastenergroupwillbebrightfasteners

installing them into the treated wood specimen as done in

rather than galvanized fasteners. Fasteners in the control

application, that is, by hand driving or power driving with no

samples shall be of the same nominal diameter and length as

pre-drilled pilot holes. When the test objective is the compari-

the fasteners that are being tested and shall have similar

son of wood treatments, the use of pilot holes is permitted to

geometry to the fasteners that are being tested.

reduce variables associated with fastener installation. Fastener

9.2 Treated Wood Specimens: heads shall be installed such that the bottom of the fastener

9.2.1 Each treated wood specimen used in this procedure head is in contact with the surface of the treated wood

shall be weighed using a balance or scale to the nearest 0.5 g specimen and shall not be installed so deep that the top of the

(0.001 lb). Wood for this test method shall be Southern Pine fastener head is below the surface of the treated wood

sapwood.The sapwood of other wood species may be added to specimen. Fastener placement shall avoid knots in the wood.

the testing program and details of the additional wood species Fasteners shall not be installed into sections of the wood that

shall be provided in the final test report. contain heartwood as this wood does not accept a uniform

9.2.2 The treated wood specimens used in this procedure chemicaltreatment.Atestsampleshallnolongerbeconsidered

require a conditioning period prior to installation or contact valid if the fasteners cause a split that exceeds two fastener

with the fasteners to be evaluated. diameters in length. A test sample that has any observable

9.2.2.1 The conditioning of the treated wood specimens splitting around more than one fastener shall not be used in

shall be accomplished in an environmental chamber at a environmental condition tests.

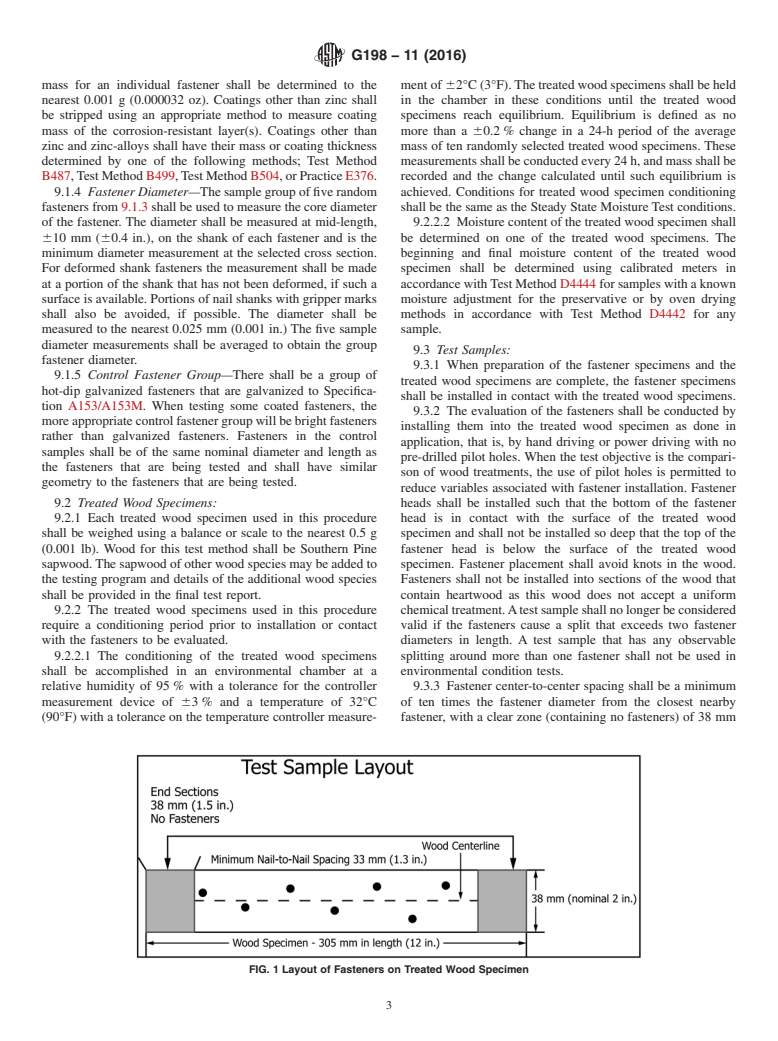

relative humidity of 95 % with a tolerance for the controller 9.3.3 Fastener center-to-center spacing shall be a minimum

measurement device of 63 % and a temperature of 32°C of ten times

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G198 − 11 G198 − 11 (Reapproved 2016)

Standard Test Method for

Determining the Relative Corrosion Performance of Driven

Fasteners in Contact with Treated Wood

This standard is issued under the fixed designation G198; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers and focuses on the corrosion resistance of metal, metal-coated, and nonmetallic-coated smooth and

deformed shank driven fasteners in contact with treated wood in exterior or high moisture exposure applications using comparative

tests with control fastener specimens of standardized benchmarks. This test method may be used for preservative-treated wood.

1.2 This test method describes the apparatus, procedure, and conditions required to maintain test environments for the Cyclic

Fog Test and the Steady State Moisture Test.

1.3 This test method describes the types of test samples, lists exposure periods, and gives guidance on interpretation of results.

1.4 Until experience is gained comparing laboratory-to-laboratory results with this test method, comparisons of fasteners,

coatings, materials, or preservatives shall be made only within the results of the same test.

1.5 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A90/A90M Test Method for Weight [Mass] of Coating on Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

A153/A153M Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware

B117 Practice for Operating Salt Spray (Fog) Apparatus

B487 Test Method for Measurement of Metal and Oxide Coating Thickness by Microscopical Examination of Cross Section

B499 Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis

Metals

B504 Test Method for Measurement of Thickness of Metallic Coatings by the Coulometric Method

D610 Practice for Evaluating Degree of Rusting on Painted Steel Surfaces

D1165 Nomenclature of Commercial Hardwoods and Softwoods

D1193 Specification for Reagent Water

D4442 Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based Materials

D4444 Test Method for Laboratory Standardization and Calibration of Hand-Held Moisture Meters

E376 Practice for Measuring Coating Thickness by Magnetic-Field or Eddy-Current (Electromagnetic) Testing Methods

G1 Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens

G60 Practice for Conducting Cyclic Humidity Exposures

G85 Practice for Modified Salt Spray (Fog) Testing

G193 Terminology and Acronyms Relating to Corrosion

2.2 American Wood Protection Association:

U1-09 Use Category System: Use Specification for Treated Wood

This test method is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.14 on Corrosion of

Metals in Construction Materials.

Current edition approved March 1, 2011July 15, 2016. Published March 2011July 2016. DOI:10.1520/G0198–11.Originally approved in 2011. Last previous edition

approved in 2011 as G198 – 11. DOI:10.1520/G0198–11R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American Wood Protection Association (AWPA), P.O. Box 361784, Birmingham, AL 35236-1784, http://www.awpa.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G198 − 11 (2016)

3. Terminology

3.1 Definitions—Terminology G193 contains other terms and definitions relating to corrosion and corrosion testing.

Terminology D1165 contains other terms and definitions relating to wood and wood testing.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 bright, adj—uncoated steel.

3.2.2 fastener, n—metallic, metal-coated, or nonmetallic-coated smooth or deformed shank driven fastener.

3.2.3 test sample, n—combination of fasteners installed into a treated wood specimen.

3.2.4 wood specimen, n—section of wood into which fasteners are driven to form test samples. Specimens may be treated for

testing of materials, coatings, or chemicals or may be untreated for use as controls.

3.2.4.1 Discussion—

Wood cross-sectional dimensions are given in exact numbers for SI units and nominal numbers for inch-pound units.

4. Summary of Test Method

4.1 This test method covers the preparation, testing and evaluation of metal, metal-coated, or nonmetallic-coated smooth or

deformed shank driven fasteners installed in treated wood. Control specimens tested in the same conditions shall be hot-dip

galvanized fasteners that are coated as described in Specification A153/A153M or bright fasteners with no coatings. The fasteners

are installed in the treated wood specimen before testing so that the chemicals in the wood are in direct contact with the metal or

coating. Test samples are then tested in Steady State Moisture Tests or Cyclic Fog Tests. For each type of sample, separate groups

of test samples shall be tested under either or both of the two test conditions. Procedures for conducting tests in two environmental

conditions, Steady State Moisture Tests and Cyclic Fog Tests, are described as well as position of the samples and measurement

techniques for determining the degree of corrosion. Guidance is given for methods of exposure and inspection of corroded fasteners

in the two environmental conditions.

5. Significance and Use

5.1 This test method provides controlled environments which are utilized to produce corrosion of metal, metal-coated, or

nonmetallic-coated smooth or deformed shank driven fasteners in contact with treated wood exposed to the given test

environments. The test method provides information that can be used to evaluate the corrosion resistance of metal, metal-coated,

or nonmetallic-coated smooth or deformed shank driven fasteners in contact with different chemical wood treatments.

5.2 The results shall be used for comparative purposes only and they shall not be correlated to exposure time in natural

environments.

5.3 The reproducibility of results in these types of tests is highly dependent on the type of samples tested and the evaluation

criteria selected, as well as the control of the operating variables.

6. Apparatus

6.1 Steady State Moisture Test—The apparatus required for steady state moisture tests shall consist of a test chamber, provisions

for heating the chamber, a humidifying tower, a supply of compressed air, sample supports, and necessary means of control.

6.1.1 There are no size or construction requirements other than those needed to meet the requirements of the test method.

6.1.2 A schematic diagram of a typical apparatus is shown in Practice G60, Figure 1.

6.1.3 The apparatus shall be capable of providing a relative humidity of 95%95 % for 24 h a day for a period of at least 120

days.

6.1.4 The apparatus shall be capable of providing a constant temperature of 32 6 2°C (90 6 3°F).

6.2 Cyclic Fog Test—The cyclic fog test shall consist of a fog chamber with a solution reservoir, a supply of suitably conditioned

compressed air, one or more atomizing nozzles, specimen supports, provisions for heating the chamber and necessary means of

controlling fog spray and heating cycles and means of purging fog with fresh air prior to heat cycles for a period of at least 120

days. The material of construction shall be such that it will not affect the corrosiveness of the fog. Similar tests are described in

Practice B117 and Practice G85 with the exception that these practices use salt solutions during the testing.

6.2.1 Drops of solution which accumulate on the ceiling or cover of the chamber shall not be permitted to fall on the samples

being exposed and shall not be returned to the reservoir for respraying.

6.2.2 Drops of solution which fall from the samples shall not be returned to the solution reservoir for respraying.

7. Reagents and Materials

7.1 Water used for this test method shall conform to Type IV water as described in Specification D1193 and shall be referred

to as purified water.

G198 − 11 (2016)

8. Air Supply

8.1 The compressed air supply shall be free of water, grease, oil and dirt.

NOTE 1—The air supply may be freed from oil and dust by passing it through a suitable oil/water extractor (that is commercially available) to stop

any oil from emerging. Many oil/water extractors have an expiration indicator; proper preventive maintenance intervals should take these into account.

9. Sampling, Test Specimens, and Test Units

9.1 Fastener Specimens:

9.1.1 A minimum of 65 fasteners shall be used for complete evaluation per this test method using both test conditions on any

type of sample fastener; metal, metal-coated, or nonmetallic-coated. Multiple fastener types may be tested in the same cycle of

testing with one set of control fasteners. Different fastener lengths may require different wood sizes to accommodate the length

of the fasteners.

9.1.2 Initial Cleaning of Metal, Metal-Coated, or Nonmetallic-Coated Smooth or Deformed Shank Driven Fasteners—Initial

cleaning of fastener shall be done by rinsing with purified water and drying with forced hot air, air temperature shall be between

40 to 60°C (104 to 140°F).

9.1.3 Coating Mass—Five randomly selected fasteners shall be taken from the cleaned group of fasteners and shall be stripped

of coating and weighed to determine the average coating mass. Stripping and weighing of zinc and zinc-alloy products shall be

in accordance Test Method A90/A90M. The mass for an individual fastener shall be determined to the nearest 0.001 g (0.000032

oz). Coatings other than zinc shall be stripped using an appropriate method to measure coating mass of the corrosion-resistant

layer(s). Coatings other than zinc and zinc-alloys shall have their mass or coating thickness determined by one of the following

methods; Test Method B487, Test Method B499, Test Method B504, or Practice E376.

9.1.4 Fastener Diameter—The sample group of five random fasteners from 9.1.3 shall be used to measure the core diameter of

the fastener. The diameter shall be measured at mid-length, 610 mm (60.4 in.), on the shank of each fastener and is the minimum

diameter measurement at the selected cross section. For deformed shank fasteners the measurement shall be made at a portion of

the shank that has not been deformed, if such a surface is available. Portions of nail shanks with gripper marks shall also be

avoided, if possible. The diameter shall be measured to the nearest 0.025 mm (0.001 in.) The five sample diameter measurements

shall be averaged to obtain the group fastener diameter.

9.1.5 Control Fastener Group—There shall be a group of hot-dip galvanized fasteners that are galvanized to Specification

A153/A153M. When testing some coated fasteners, the more appropriate control fastener group will be bright fasteners rather than

galvanized fasteners. Fasteners in the control samples shall be of the same nominal diameter and length as the fasteners that are

being tested and shall have similar geometry to the fasteners that are being tested.

9.2 Treated Wood Specimens:

9.2.1 Each treated wood specimen used in this procedure shall be weighed using a balance or scale to the nearest 0. 5 0.5 g

(0.001 lb). Wood for this test method shall be Southern Pine sapwood. The sapwood of other wood species may be added to the

testing program and details of the additional wood species shall be provided in the final test report.

9.2.2 The treated wood specimens used in this procedure require a conditioning period prior to installation or contact with the

fasteners to be evaluated.

9.2.2.1 The conditioning of the treated wood specimens shall be accomplished in an environmental chamber at a relative

humidity of 95%95 % with a tolerance for the controller measurement device of 63%63 % and a temperature of 32°C (90°F) with

a tolerance on the temperature controller measurement of 62°C (3°F). The treated wood specimens shall be held in the chamber

in these conditions until the treated wood specimens reach equilibrium. Equilibrium is defined as no more than a 60.2%60.2 %

change in a 24-h period of the average mass of ten randomly selected treated wood specimens. These measurements shall be

conducted every 24 h, and mass shall be recorded and the change calculated until such equilibrium is achieved. Conditions for

treated wood specimen conditioning shall be the same as the Steady State Moisture Test conditions.

9.2.2.2 Moisture content of the treated wood specimen shall be determined on one of the treated wood specimens. The

beginning and final moisture content of the treated wood specimen shall be determined using calibrated meters in accordance with

Test Method D4444 for samples with a known moisture adjustment for the preservative or by oven drying methods in accordance

with Test Method D4442 for any sample.

9.3 Test Samples:

9.3.1 When preparation of the fastener specimens and the treated wood specimens are complete, the fastener specimens shall

be installed in contact with the treated wood specimens.

9.3.2 The evaluation of the fasteners shall be conducted by installing them into the treated wood specimen as done in

application, that is, by hand driving or power driving with no pre-drilled pilot holes. When the test objective is the comparison

of wood treatments, the use of pilot holes is permitted to reduce variables associated with fastener installation. Fastener heads shall

be installed such that the bottom of the fastener head is in contact with the surface of the treated wood specimen and shall not be

installed so deep that the top of the fastener head is below the surface of the treated wood specimen. Fastener placement shall avoid

knots in the wood. Fast

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.