ASTM E230-98

(Specification)Standard Specification and Temperature-Electromotive Force (EMF) Tables for Standardized Thermocouples

Standard Specification and Temperature-Electromotive Force (EMF) Tables for Standardized Thermocouples

SCOPE

1.1 This specification contains reference tables (Tables 8-23) that give temperature-electromotive force (emf) relationships for Types B, E, J, K, N, R, S, and T thermocouples. These are the thermocouple types most commonly used in industry.

1.2 Also included are lists of standard and special tolerances on initial values of emf versus temperature for thermocouples (Table 1), thermocouple extension wires (Table 2), and compensating extension wires for thermocouples (Table 3).

1.3 Tables 4-5, included herein, give data on insulation color coding for thermocouple and thermocouple extension wires as customarily used in the United States.

1.4 Recommendations regarding upper temperature limits for the thermocouple types referred to in 1.1 are given in Table 6.

1.5 Tables 24-43 give temperature-emf data for single-leg thermoelements referenced to platinum (NIST Pt 67). The tables include values for Types BP, BN, JP, JN, KP (same as EP), KN, NP, NN, TP, and TN (same as EN).

1.6 Tables for Types RP, RN, SP, and SN thermoelements are not included since, nominally, Tables 18-21 represent the thermoelectric properties of Type RP and SP thermoelements referenced to pure platinum.

1.7 Polynomial coefficients that may be used for computation of thermocouple emf as a function of temperature are given in Table 7. Coefficients for the emf of each thermocouple pair as well as for the emf of individual thermoelements versus platinum are included.

1.8 Coefficients for sets of inverse polynomials are given in Table 44. These may be used for computing a close approximation of temperature (oC) as a function of thermocouple emf. Inverse functions are provided only for thermocouple pairs and are valid only over the emf ranges specified.

1.9 This specification is intended to define the thermoelectric properties of materials that conform to the relationships presented in the tables of this standard and bear the letter designations contained herein. Topics such as ordering information, physical and mechanical properties, workmanship, testing, and marking are not addressed in this specification. The user is referred to specific standards such as Specifications E235, E574, E585, E608, E1159, or E1223, as appropriate, for guidance in these areas.

1.10 The temperature-emf data in this specification are intended for industrial and laboratory use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 230 – 98 An American National Standard

Standard Specification and

Temperature-Electromotive Force (EMF) Tables for

Standardized Thermocouples

This standard is issued under the fixed designation E 230; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope tric properties of materials that conform to the relationships

presented in the tables of this standard and bear the letter

1.1 This specification contains reference tables (Tables

designations contained herein. Topics such as ordering infor-

8–23) that give temperature-electromotive force (emf) relation-

mation, physical and mechanical properties, workmanship,

ships for Types B, E, J, K, N, R, S, and T thermocouples.

testing, and marking are not addressed in this specification. The

These are the thermocouple types most commonly used in

user is referred to specific standards such as Specifications

industry.

E 235, E 574, E 585, E 608, E 1159, or E 1223, as appropriate,

1.2 Also included are lists of standard and special tolerances

for guidance in these areas.

on initial values of emf versus temperature for thermocouples

1.10 The temperature-emf data in this specification are

(Table 1), thermocouple extension wires (Table 2), and com-

intended for industrial and laboratory use.

pensating extension wires for thermocouples (Table 3).

1.3 Tables 4–5, included herein, give data on insulation

2. Referenced Documents

color coding for thermocouple and thermocouple extension

2.1 ASTM Standards:

wires as customarily used in the United States.

E 235 Specification for Thermocouples, Sheathed, Type K,

1.4 Recommendations regarding upper temperature limits

for Nuclear or for Other High-Reliability Applications

for the thermocouple types referred to in 1.1 are given in Table

E 574 Specification for Duplex, Base-Metal Thermocouple

6.

Wire with Glass Fiber or Silica Fiber Insulation

1.5 Tables 24–43 give temperature-emf data for single-leg

E 585 Specification for Sheathed Base-Metal Thermo-

thermoelements referenced to platinum (NIST Pt 67). The

couple Materials

tables include values for Types BP, BN, JP, JN, KP (same as

E 608 Specification for Metal-Sheathed Base-Metal Ther-

EP), KN, NP, NN, TP, and TN (same as EN).

mocouples

1.6 Tables for Types RP, RN, SP, and SN thermoelements

E 1159 Specification for Thermocouple Materials,

are not included since, nominally, Tables 18–21 represent the

Platinum-Rhodium Alloys, and Platinum

thermoelectric properties of Type RP and SP thermoelements

E 1223 Specification for Type N Thermocouple Wire

referenced to pure platinum.

2.2 NIST Monograph:

1.7 Polynomial coefficients that may be used for computa-

NIST Monograph 175 Temperature-Electromotive Force

tion of thermocouple emf as a function of temperature are

Reference Functions and Tables for the Letter-Designated

given in Table 7. Coefficients for the emf of each thermocouple

Thermocouple Types Based on the ITS-90

pair as well as for the emf of individual thermoelements versus

2.3 IEC Standard:

platinum are included.

IEC 584–3 First edition, 1989

1.8 Coefficients for sets of inverse polynomials are given in

Table 44. These may be used for computing a close approxi-

3. Source of Data

mation of temperature (°C) as a function of thermocouple emf.

3.1 The data in these tables are based upon the SI volt and

Inverse functions are provided only for thermocouple pairs and

the International Temperature Scale of 1990.

are valid only over the emf ranges specified.

3.2 The temperature-emf data in Tables 8–43 and the

1.9 This specification is intended to define the thermoelec-

corresponding equations in Tables 7 and 44 for all of the

These tables are under the jurisdiction of ASTM Committee E-20 on Tempera-

ture Measurement and are the direct responsibility of Subcommittee E20.04 on

Thermocouples.

Current edition approved June 10, 1998. Published March 1999. Originally Annual Book of ASTM Standards, Vol 14.03.

e1 4

published as E 230 – 63. Last previous edition E 230 – 96 . Available from National Institute of Standards and Technology, U.S. Depart-

These temperature-emf relationships have been revised as required by the ment of Commerce, Gaithersburg, MD 20899.

international adoption in 1989 of a revised International Temperature Scale Discussed in NIST Technical Note 1263, Guidelines for Implementing the New

(ITS-90). Representations of the Volt and Ohm Effective January 1, 1990.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 230

thermocouple types have been extracted from NIST Mono- 4.5 An overall suffix letter “X” (for example KX, TX, EPX,

graph 175. JNX) denotes an “extension grade” material whose thermo-

electric properties will match those of the corresponding

NOTE 1—It is beyond the scope of this standard to discuss the origin of

thermocouple type within the stated extension grade tolerances

these tables, but if further information is desired, the reader should consult

over a limited temperature span. Most base metal extension

the NIST reference noted above.

wires have the same nominal composition as the thermocouple

3.3 These tables give emf values to three decimal

wires with which they are intended to be used, whereas the

places (1 μV) at temperature intervals of one degree. Such

compensating extension wires for noble metal thermocouple

tables are satisfactory for most industrial uses but may not be

types (S, R, or B) are usually of a different, more economical

adequate for computer and similar applications. If greater

composition whose properties nonetheless closely approximate

precision is required, the reader should refer to the NIST

those of the precious metal thermocouples with which they are

reference noted above which includes tables giving emf values

to be used.

to four decimal places (0.1 μV). Equations which permit easy

and unique generation of the temperature-emf relationships

5. Tolerances on Initial Values of EMF versus

will be found in Table 7. For convenience, coefficients of

Temperature

inverse polynomials that may be used to compute approximate

5.1 Thermocouples and matched thermocouple wire pairs

temperature (°C) as a function of thermocouple emf are given

are normally supplied to the tolerances on initial values of emf

in Table 44.

versus temperature listed in Table 1.

5.1.1 Tolerances on initial values of emf versus temperature

4. Thermocouple Types and Letter Designations

for single-leg thermoelements referenced to platinum have

4.1 The letter symbols identifying each reference table are

been established only for Types KP and KN. These are

those which are in common use throughout industry and

supplied, by common practice, to a tolerance equivalent to one

identify the following thermocouple calibrations:

half the millivolt tolerance of the Type K thermocouple.

4.1.1 Type B—Platinum-30% rhodium (+) versus platinum-

5.1.2 For all other thermocouple types, tolerances on initial

6 % rhodium (−).

values of emf versus temperature for single thermoelements,

4.1.2 Type E—Nickel-10 % chromium (+) versus copper-

when required, should be established by agreement between

45% nickel (constantan) (−).

the consumer and the producer.

4.1.3 Type J—Iron (+) versus copper-45% nickel (constan-

5.1.3 In reference Tables 32, 33, 42, and 43, the thermoele-

tan) (−).

ments are identified by two thermoelement symbols indicating

4.1.4 Type K—Nickel-10 % chromium (+) versus nickel-

their applicability to two thermocouple types. This indicates

5 % (aluminum, silicon) (−) (Note 2).

that the temperature-electromotive force relationship of the

NOTE 2—Silicon, or aluminum and silicon, may be present in combi-

table is typical of the referenced thermoelements over the

nation with other elements.

temperature range given in Table 1 for the corresponding

4.1.5 Type N—Nickel-14 % chromium, 1 ⁄2 % silicon ( + ) thermocouple type. It should not be assumed, however, that

1 1

thermoelements used with one thermocouple type are inter-

versus nickel-4 ⁄2 % silicon- ⁄10 % magnesium (−).

4.1.6 Type R—Platinum-13 % rhodium ( + ) versus plati- changeable with those of the other, or that they have the same

millivolt tolerances for the initial values of emf versus tem-

num (−).

perature.

4.1.7 Type S—Platinum-10 % rhodium ( + ) versus platinum

5.2 Thermocouple extension wires and compensating exten-

(−).

sion wires are supplied to the tolerances on initial values of emf

4.1.8 Type T—Copper ( + ) versus copper-45% nickel (con-

versus temperature shown in Tables 2–3.

stantan) (−).

5.2.1 The initial tolerances of extension grade materials and

4.2 Each letter designation of 4.1 identifies a specific

compensating extension materials apply over a more limited

temperature-emf relationship (Tables 8–23) and may be ap-

span of temperature than the corresponding thermocouple

plied to any thermocouple conforming thereto within stated

grade materials. Applicable temperature ranges, consistent with

tolerances on initial values of emf versus temperature, regard-

typical usage, are given in Tables 2–3.

less of its composition.

4.3 The thermoelement identifying symbols in Tables 24 to

6. Color Coding

43 use the suffix letters P and N to denote, respectively, the

6.1 Color codes for insulation on thermocouple grade ma-

positive and negative thermoelement of a given thermocouple

terials, along with corresponding thermocouple and thermoele-

type.

ment letter designations, are given in Table 4.

4.4 Tables 24 to 43 identify specific temperature-emf rela-

6.2 Extension wires for thermocouples are distinguished by

tionships of individual thermoelements with respect to plati-

having an identifying color in the outer jacket as shown in

num (NIST Pt-67). Although tolerances on initial values of emf

Table 5, where letter designations for the extension thermoele-

versus temperature, in most cases, are not established for

ments and pairs are also presented.

individual thermoelements with respect to platinum, the appro-

6.3 Information in Tables 4–5 is based on customary United

priate letter designation may be applied to any thermoelement

States practice.

which, when combined with its mating thermoelement, will

form a thermocouple conforming to the corresponding table

NOTE 3—Other insulation color coding conventions may be found in

within the stated tolerances. use elsewhere in the world.

E 230

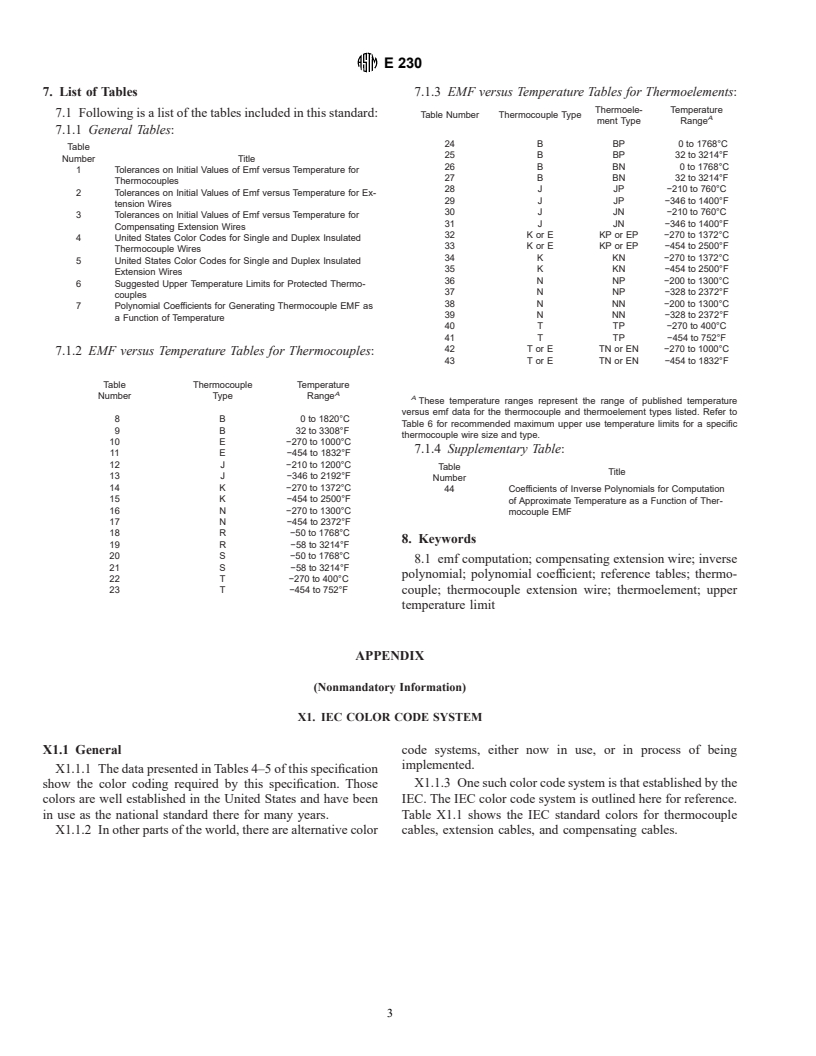

7. List of Tables 7.1.3 EMF versus Temperature Tables for Thermoelements:

Thermoele- Temperature

7.1 Following is a list of the tables included in this standard:

Table Number Thermocouple Type

A

ment Type Range

7.1.1 General Tables:

24 B BP 0 to 1768°C

Table

25 B BP 32 to 3214°F

Number Title

26 B BN 0 to 1768°C

1 Tolerances on Initial Values of Emf versus Temperature for

27 B BN 32 to 3214°F

Thermocouples

28 J JP −210 to 760°C

2 Tolerances on Initial Values of Emf versus Temperature for Ex-

29 J JP −346 to 1400°F

tension Wires

30 J JN −210 to 760°C

3 Tolerances on Initial Values of Emf versus Temperature for

31 J JN −346 to 1400°F

Compensating Extension Wires

32 K or E KP or EP −270 to 1372°C

4 United States Color Codes for Single and Duplex Insulated

33 K or E KP or EP −454 to 2500°F

Thermocouple Wires

34 K KN −270 to 1372°C

5 United States Color Codes for Single and Duplex Insulated

35 K KN −454 to 2500°F

Extension Wires

36 N NP −200 to 1300°C

6 Suggested Upper Temperature Limits for Protected Thermo-

37 N NP −328 to 2372°F

couples

38 N NN −200 to 1300°C

7 Polynomial Coefficients for Generating Thermocouple EMF as

39 N NN −328 to 2372°F

a Function of Temperature

40 T TP −270 to 400°C

41 T TP −454 to 752°F

42 T or E TN or EN −270 to 1000°C

7.1.2 EMF versus Temperature Tables for Thermocouples:

43 T or E TN or EN −454 to 1832°F

Table Thermocouple Temperature

A

Number Type Range

A

These temperature ranges represent the range of published temperature

versus emf data for the thermocouple and thermoelement types listed. Refer to

8 B 0 to 1820°C

Table 6 for recommended maximum upper use temperature limits for a specific

9 B 32 to 3308°F

thermocouple wire size and type.

10 E −270 to 1000°C

7.1.4 Supplementary Table:

11 E −454 to 1832°F

12 J −210 to 1200°C

Table

Title

13 J −346 to 2192°F

Number

14 K −270 to 1372°C

44 Coefficients of Inverse Polynomials for Computation

15 K −454 to 2500°F

of Approximate Temperature as a Function of Ther-

16 N −270 to 1300°C

mocouple EMF

17 N −454 to 2372°F

18 R −50 to 1768°C

8. Keywords

19 R −58 to 3214°F

20 S −50 to 1768°C

8.1 emf computation; compensating extension wire; inverse

21 S −58 to 3214°F

polynomial; polynomial coefficient; reference tables; thermo-

22 T −270 to 400°C

23 T −454 to 752°F couple; thermocouple extension wire; thermoelement; upper

temperature limit

APPENDIX

(Nonmandatory Information)

X1. IEC COLOR CODE SYSTEM

X1.1 General code systems, either now in use, or in process of being

implemented.

X1.1.1 The data presented in Tables 4–5 of this specification

X1.1.3 One such color code system is that established by the

show the color coding required by this specification. Those

colors are well established in the United States and have been IEC. The IEC color code system is outlined here for reference.

Table X1.1 shows the IEC standard colors for thermocouple

in use as the national standard there for many years.

X1.1.2 In other parts of the world, there are alternative color cables, extension cables, and compensating cables.

E 230

TABLE 1 Tolerances on Initial Values of Emf vs. Temperature for Thermocouples

NOTE 1—Tolerances in this table apply to new essentially homogeneous thermocouple wire, normally in the size range 0.25 to 3 mm in diameter

(No. 30 to No. 8 Awg) and used at temperatures not exceeding the recommended limits of Table 6. If used at higher temperatures these tolerances may

not apply.

NOTE 2—At a given temperature that is expressed in °C, the tolerance expressed in °F is 1.8 times larger than the tolerance expressed in °C. Note that

wherever applicable, percentage-based tolerances must be computed from temperatures that are expressed in °C.

NOTE 3—Caution: Users should be aware that certain characteristics of thermocouple materials, including the emf versus temperature relationship may

change with time in use; consequently, test results and performance obtained at time of manufacture may not necessarily apply throughout an extended

period of use. Tolerances given in this table apply only to new wire as delivered to the user and do not allow for cha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.