ASTM E209-00(2005)

(Practice)Standard Practice for Compression Tests of Metallic Materials at Elevated Temperatures with Conventional or Rapid Heating Rates and Strain Rates

Standard Practice for Compression Tests of Metallic Materials at Elevated Temperatures with Conventional or Rapid Heating Rates and Strain Rates

ABSTRACT

This practice covers compression test in which the specimen is heated to a constant and uniform temperature and held at temperature while an axial force is applied at a controlled rate of strain. Machines used for compression testing shall conform to the requirements prescribed. The apparatus and method for heating the specimens are not specified. The procedure for temperature control, temperature measurement, strain rate during test, and strain measurement are presented in detail. The complete compression-test system consisting of jig, strain instrument, and recorders should be qualified, in accordance with the requirements prescribed.

SCOPE

1.1 This practice covers compression test in which the specimen is heated to a constant and uniform temperature and held at temperature while an axial force is applied at a controlled rate of strain.Note 1In metals with extremely high elastic limit or low modulus of elasticity it is conceivable that 1.5 percent total strain under load could be reached before the 0.2 percent-offset yield strength is reached. In this event the 0.2 percent-offset yield strength will be the end point of the test unless rupture occurs before that point.Note 2

For acceptable compression tests it is imperative that the specimens not buckle before the end point is reached. For this reason the equipment and procedures, as discussed in this recommended practice, must be designed to maintain uniform loading and axial alignment.

1.2 Preferred conditions of testing are recommended so that data from different sources conducting the tests will be comparable.

1.3 The values stated in inch-pound units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E209–00 (Reapproved 2005)

Standard Practice for

Compression Tests of Metallic Materials at Elevated

Temperatures with Conventional or Rapid Heating Rates

1

and Strain Rates

This standard is issued under the fixed designation E209; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E83 Practice for Verification and Classification of Exten-

someter Systems

1.1 This practice covers compression test in which the

specimen is heated to a constant and uniform temperature and

3. Apparatus

held at temperature while an axial force is applied at a

3.1 TestingMachines—Machinesusedforcompressiontest-

controlled rate of strain.

ing shall conform to the requirements of Practices E4.

NOTE 1—In metals with extremely high elastic limit or low modulus of

3.2 Bearing Blocks and LoadingAdapters—Loadbothends

elasticity it is conceivable that 1.5 percent total strain under load could be

of the compression specimens through bearing blocks or

reached before the 0.2 percent-offset yield strength is reached. In this

through pin-type adapters that are part of the compression-

event the 0.2 percent-offset yield strength will be the end point of the test

testing assembly. Bearing blocks may be designed with flat

unless rupture occurs before that point.

bearing faces for sheet- or bar-type specimens. Sheet speci-

NOTE 2—For acceptable compression tests it is imperative that the

specimens not buckle before the end point is reached. For this reason the

mens may also be loaded through pin-type adapters that are

equipment and procedures, as discussed in this recommended practice,

clamped rigidly to the grip sections of specimens designed for

must be designed to maintain uniform loading and axial alignment. 4

theseadapters (1). Themainrequirementisthatthemethodof

1.2 Preferred conditions of testing are recommended so that applying the force be consistent with maintaining axial align-

data from different sources conducting the tests will be mentanduniformloadingonthespecimenthroughoutthetest.

comparable. When bearing blocks with flat faces are used, the load-bearing

1.3 Thevaluesstatedininch-poundunitsaretoberegarded surfacesshouldbesmoothandparallelwithinverycloselimits.

as the standard. Thetoleranceforparallelismforthesesurfacesshouldbeequal

1.4 This standard does not purport to address all of the to or closer than that specified for the loaded ends of the

safety concerns, if any, associated with its use. It is the specimens. The design of the equipment should provide

responsibility of the user of this standard to establish appro- adequate rigidity so that parallelism is maintained during

priate safety and health practices and determine the applica- heating and loading. The bearing blocks or pin-type adapters

bility of regulatory limitations prior to use. should be made of a material that is sufficiently hard at the

testing temperature to resist plastic indentation at maximum

2. Referenced Documents

force. They should also be of a material or coated with a

2

2.1 ASTM Standards:

material that is sufficiently oxidation resistant at the maximum

E4 Practices for Force Verification of Testing Machines testing temperature to prevent the formation of an oxide

E9 Test Methods for Compression Testing of Metallic

coating that would cause misalignment. In any compression

3

Materials at Room Temperature testitisimportantthatthespecimenbecarefullycenteredwith

E21 Test Methods for Elevated Temperature Tension Tests

respect to the bearing blocks, which in turn should be centered

of Metallic Materials with respect to the testing machine heads.

NOTE 3—Bearing blocks with straight cylindrical or threaded holes

1

depending on specimen design may be used for bar-type specimens

ThispracticeisunderthejurisdictionofASTMCommitteeE28onMechanical

providing the apparatus qualifies in accordance with Section 9.

TestingandisthedirectresponsibilityofSubcommitteeE28.04onUniaxialTesting.

Current edition approved Dec. 1, 2005 Published December 2005. Originally NOTE 4—Bearing blocks of an adjustable type to provide parallel

´1

approved in 1963. Last previous edition, approved in 2000 as E209–00 . DOI:

loading surfaces are discussed inTest Methods E9. Bearing blocks with a

10.1520/E0209-00R05.

spherical seat for the upper block are also shown.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

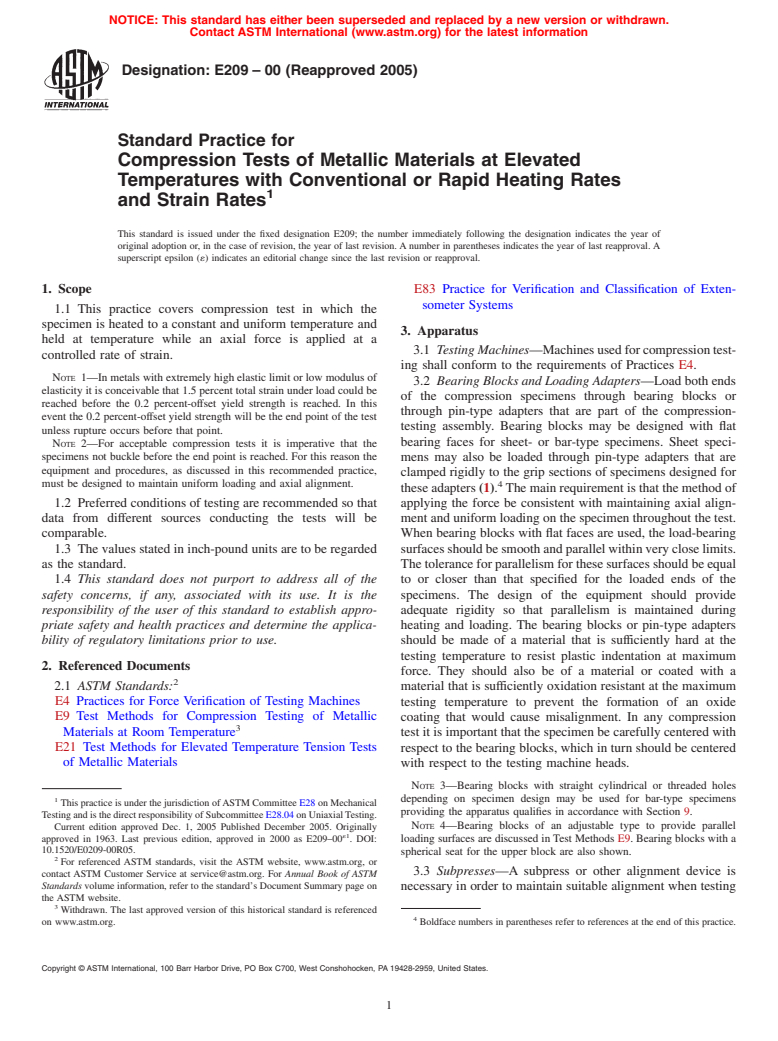

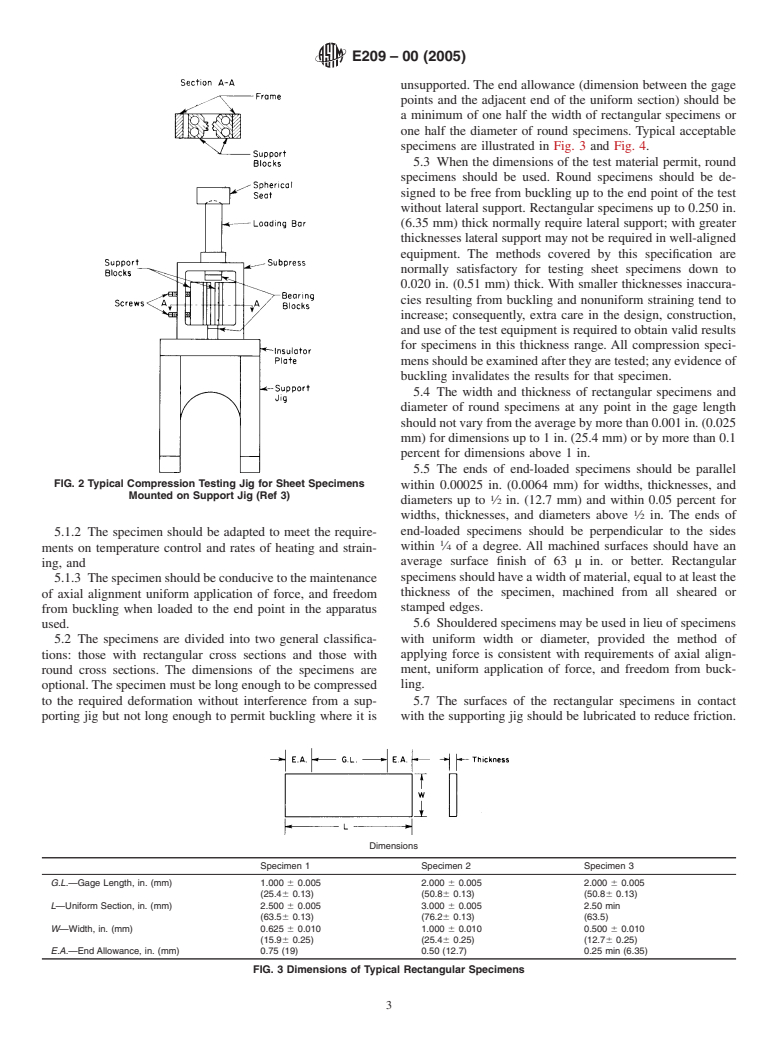

3.3 Subpresses—A subpress or other alignment device is

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

necessary in order to maintain suitab

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.