ASTM D2103-03

(Specification)Standard Specification for Polyethylene Film and Sheeting

Standard Specification for Polyethylene Film and Sheeting

SCOPE

1.1 This specification covers the classification of polyethylene film and sheeting up to 0.3 mm [0.012 in.] in thickness, inclusive. The film or sheeting may contain additives for the improvement of the surface properties, pigments, or stabilizers, or combinations thereof.

1.2 The values stated in SI units are to be regarded as standard. The values given in brackets are for information only.

1.3 The following precautionary caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This specification allows for the use of recycled polyethylene film or resin as feedstock, in whole or in part, as long as all the requirements as governed by the producer and end user are also met (see Note 1).

Note 1—Guide D 5033 describes terminology and definitions related to recycled plastics.

Note 2—There is no known ISO equivalent to this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 2103 – 03

Standard Specification for

1

Polyethylene Film and Sheeting

This standard is issued under the fixed designation D 2103; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* D 1505 Test Method for Density of Plastics by the Density-

3

Gradient Technique

1.1 This specification covers the classification of polyethyl-

D 1709 Test Methods for Impact Resistance of Plastic Film

ene film and sheeting up to 0.3 mm [0.012 in.] in thickness,

3

by the Free-Falling Dart Method

inclusive. The film or sheeting may contain additives for the

3

D 1746 Test Method for Transparency of Plastic Sheeting

improvementofthesurfaceproperties,pigments,orstabilizers,

5

D 1893 Test Method for Blocking of Plastic Film

or combinations thereof.

D 1894 Test Method for Static and Kinetic Coefficients of

1.2 The values stated in SI units are to be regarded as

3

Friction of Plastic Film and Sheeting

standard.Thevaluesgiveninbracketsareforinformationonly.

6

D 1898 Practice for Sampling of Plastics

1.3 The following precautionary caveat pertains only to the

D 1922 Test Method for Propagation Tear Resistance of

test method portion, Section 8, of this specification: This

3

Plastic Film and Thin Sheeting by Pendulum Method

standard does not purport to address all of the safety concerns,

D 1938 Test Method for Tear-Propagation Resistance

if any, associated with its use. It is the responsibility of the user

(Trouser Tear) of Plastic Film and Thin Sheeting by a

of this standard to establish appropriate safety and health

3

Single-Tear Method

practices and determine the applicability of regulatory limita-

D 2457 TestMethodforSpecularGlossofPlasticFilmsand

tions prior to use.

7

Solid Plastics

1.4 This specification allows for the use of recycled poly-

D 2578 Test Method for Wetting Tension of Polyethylene

ethylene film or resin as feedstock, in whole or in part, as long

7

and Polypropylene Films

as all the requirements as governed by the producer and end

D 2839 Practice for the Use of a Melt Index Strand for

user are also met (see Note 1).

8

Determining Density of Polyethylene

NOTE 1—Guide D 5033 describes terminology and definitions related 7

D 3892 Practice for Packaging/Packing of Plastics

to recycled plastics.

7

D 4321 Test Method for Package Yield of Plastic Film

NOTE 2—There is no known ISO equivalent to this specification.

D 4703 Practice for Compression Molding Thermoplastic

9

Materials into Test Specimens, Plaques, or Sheets

2. Referenced Documents

D 4976 SpecificationforPolyethylenePlasticsMoldingand

2.1 ASTM Standards:

8

Extrusion Materials

D 374 Test Methods for Thickness of Solid Electrical Insu-

D 5033 Guide for Development of ASTM Standards Relat-

2

lation

8

3 ing to Recycling and Use of Recycled Plastics

D 618 Practice for Conditioning Plastics for Testing

E 96 Test Methods for Water Vapor Transmission of Mate-

D 882 Test Methods for Tensile Properties of Thin Plastic

10

3 rials

Sheeting

F 1249 Test Method for Water Vapor Transmission Rate

3

D 883 Terminology Relating to Plastics

through Plastic Film and Sheeting Using a Modulated

D 1003 Test Method for Haze and Luminous Transmittance

11

3 Infrared Sensor

of Transparent Plastics

D 1434 Test Method for Determining Gas Permeability

3. Terminology

4

Characteristics of Plastic Film and Sheeting

3.1 Definitions:

1 5

This guide is under the jurisdiction of ASTM Committee D20 on Plastics and Discontinued; see 1990 Annual Book of ASTM Standards, Vol 08.01.

6

is the direct responsibility of Subcommittee D20.19 on Film and Sheeting. Discontinued; see 1997 Annual Book of ASTM Standards, Vol 08.01.

7

Current edition approved August 10, 2003. Published October 2003. Originally Annual Book of ASTM Standards, Vol 08.02.

8

approved in 1991. Last previous edition approved in 1997 as D 1999 – 97. Annual Book of ASTM Standards, Vol 10.02.

2 9

Annual Book of ASTM Standards, Vol 10.01. Annual Book of ASTM Standards, Vol 08.03.

3 10

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 04.06.

4 11

Annual Book of ASTM Standards, Vol 09.01. Annual Book of ASTM Standards, Vol 15.09.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

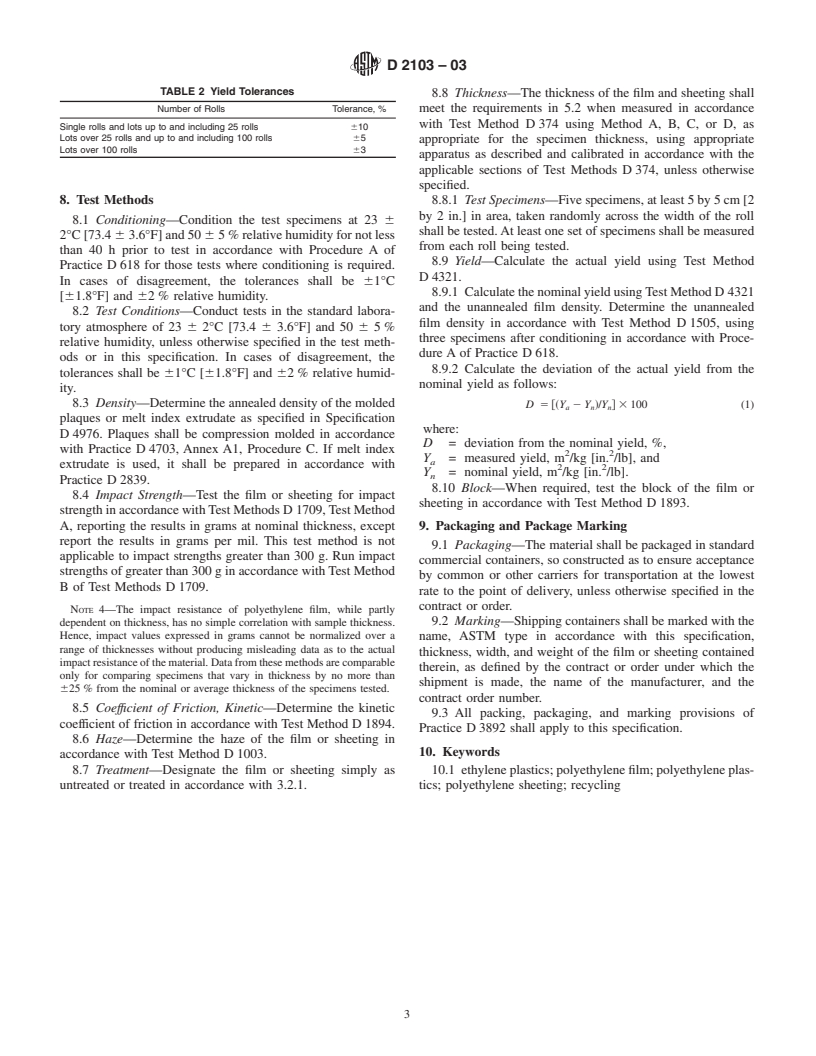

1

---------------------- Page: 1 ----------------------

D2103–03

3.1.1 Unless otherwise specified, the definitions of plastics purchaser and the seller. The recommended test to measure the

used in this specification are in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.