EN 10326:2004

(Main)Continuously hot-dip coated strip and sheet of structural steels - Technical delivery conditions

Continuously hot-dip coated strip and sheet of structural steels - Technical delivery conditions

1.1 This European Standard specifies requirements for continuously hot-dip coated products made of structural steels coated with zinc (Z), zinc-iron alloy (ZF), zinc-aluminium alloy (ZA), aluminium-zinc alloy (AZ) and aluminium-silicon alloy (AS) (see Table 1) with thicknesses from 0,35 mm up to 3,0 mm unless otherwise agreed (see 1.2). The thickness is the final thickness of the delivered product after coating.

This European Standard applies to strip of all widths and to sheets cut from it (= 600 mm width) and cut lengths

(< 600 mm width).

1.2 If agreed at the time of enquiry and order, this European Standard may also be applied to continuously hot-dip coated flat products in thicknesses > 3,0 mm. In this case the mechanical property, adhesion of coating and surface condition requirements shall also be agreed at the time of enquiry and order.

1.3 The products covered by this European Standard are mainly used where minimum yield strength and corrosion resistance are the most important factors. Corrosion resistance of the alloy is proportional to the coating thickness, hence to its mass (see also 7.3.2).

NOTE +ZF coated products should not be used without additional organic coating.

1.4 This European Standard is not applicable to:

· continuously hot-dip coated flat products of low-carbon steel strip and sheet for cold forming (see prEN 10327);

· electrolytic galvanized cold rolled steel flat products (see EN 10152);

· continuously organic coated (coil coated) flat steel products (see EN 10169-1, ENV 10169-2 and

EN 10169-3);

· continuously hot-dip coated strip and sheet of steels with higher yield strength for cold forming (see EN 10292).

Kontinuierlich schmelztauchveredeltes Band und Blech aus Baustählen - Technische Lieferbedingungen

1.1 Dieses Dokument legt die Anforderungen an kontinuierlich schmelztauchveredelte Flacherzeugnisse aus Baustählen mit Überzügen aus Zink (Z), Zink-Eisen-Legierung (ZF), Zink-Aluminium-Legierung (ZA), Aluminium-Zink-Legierung (AZ) und Aluminium-Silicium-Legierung (AS) (siehe Tabelle 1) in Dicken von

0,35 mm bis 3,0 mm fest, falls nicht anders vereinbart (siehe 1.2). Als Dicke gilt die Enddicke des gelieferten Erzeugnisses nach dem Schmelztauchveredeln.

Dieses Dokument gilt für Band aller Breiten sowie für daraus abgelängte Bleche (= 600 mm Breite) und Stäbe (< 600 mm Breite).

1.2 Nach Vereinbarung bei der Anfrage und Bestellung kann dieses Dokument auch auf kontinuierlich schmelztauchveredelte Flacherzeugnisse in Dicken > 3,0 mm angewendet werden. Die Anforderungen an die mechanischen Eigenschaften, die Haftung des Überzugs und die Oberflächenbeschaffenheit sind in diesem Fall ebenfalls bei der Anfrage und Bestellung zu vereinbaren.

1.3 Die Erzeugnisse nach diesem Dokument eignen sich für Verwendungszwecke, bei denen die Mindeststreckgrenze und die Korrosionsbeständigkeit von vorrangiger Bedeutung sind. Der durch den Überzug bewirkte Korrosionsschutz ist der Überzugsdicke und damit der Auflagenmasse proportional (siehe auch 7.3.2).

ANMERKUNG Erzeugnisse mit Überzug + ZF sollten nicht ohne einen zusätzlichen organischen Überzug verwendet werden.

1.4 Dieses Dokument Norm gilt nicht für

· kontinuierlich schmelztauchveredelte Flacherzeugnisse aus weichen Stählen zum Kaltumformen (siehe

EN 10327);

· elektrolytisch verzinkte kaltgewalzte Flacherzeugnisse aus Stahl (siehe EN 10152);

· kontinuierlich organisch beschichtete (bandbeschichtete) Flacherzeugnisse aus Stahl (siehe EN 10169-1,

ENV 10169-2 und EN 10169-3);

· kontinuierlich schmelztauchveredeltes Band und Blech aus Stählen mit hoher Streckgrenze zum Kaltumformen (siehe EN 10292).

Bandes et tôles en aciers de construction doux revêtues en continu par immersion à chaud - Conditions techniques de livraison

1.1 Le présent document a pour objet de spécifier les exigences relatives aux produits en acier de construction revêtus par immersion à chaud en continu de zinc (Z), d'alliage de zinc et de fer (ZF), d'alliage de zinc et d'aluminium (ZA), d'alliage d'aluminium et de zinc (AZ) et d'alliage d'aluminium et de silicium (AS) (voir Tableau 1), avec des épaisseurs allant de 0,35 mm à 3,0 mm sauf indication contraire (voir 1.2). L'épaisseur considérée est l'épaisseur finale du produit livré après revêtement.

Le présent document est applicable aux bandes et bandes refendues de toutes largeurs (largeur ³ 600 mm) de même qu'aux feuilles et aux flans qui y sont découpées (largeur < 600 mm).

1.2 Par accord lors de la commande, le présent document peut également être utilisé pour les produits plats en acier revêtus par immersion à chaud en continu d'épaisseur > 3,0 mm. Dans ce cas, les propriétés mécaniques et les caractéristiques d'adhérence du revêtement et de finition doivent également faire l'objet d'un accord à la commande.

1.3 Les produits conformes au présent document sont principalement utilisés lorsque la limite d'élasticité minimale et la résistance à la corrosion sont les facteurs primordiaux. La résistance du revêtement à la corrosion est proportionnelle à la masse du revêtement pour une famille de revêtements donnée (voir aussi 7.3.2).

NOTE L'utilisation de produits revêtus +ZF n'est pas recommandée sans revêtement organique supplémentaire.

1.4 Le présent document ne s'applique pas :

- aux bandes et tôles en acier doux revêtues par immersion à chaud en continu pour formage à froid (voir EN 10327) ;

- aux produits plats en acier, laminés à froid, revêtus de zinc par voie électrolytique (voir EN 10152) ;

- aux produits plats en acier revêtus en continu de matières organiques (prélaqués) (voir EN 10169-1, ENV 10169-2 et EN 10169-3) ;

Kontinuirno vroče prevlečeni trakovi in pločevine konstrukcijskih jekel – Tehnični dobavni pogoji

General Information

- Status

- Withdrawn

- Publication Date

- 06-Jul-2004

- Withdrawal Date

- 10-Mar-2009

- Technical Committee

- ECISS/TC 109 - Coated and uncoated flat products to be used for cold forming

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 11-Mar-2009

- Completion Date

- 11-Mar-2009

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Replaced By

EN 10346:2009 - Continuously hot-dip coated steel flat products - Technical delivery conditions - Effective Date

- 23-Mar-2009

Frequently Asked Questions

EN 10326:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Continuously hot-dip coated strip and sheet of structural steels - Technical delivery conditions". This standard covers: 1.1 This European Standard specifies requirements for continuously hot-dip coated products made of structural steels coated with zinc (Z), zinc-iron alloy (ZF), zinc-aluminium alloy (ZA), aluminium-zinc alloy (AZ) and aluminium-silicon alloy (AS) (see Table 1) with thicknesses from 0,35 mm up to 3,0 mm unless otherwise agreed (see 1.2). The thickness is the final thickness of the delivered product after coating. This European Standard applies to strip of all widths and to sheets cut from it (= 600 mm width) and cut lengths (< 600 mm width). 1.2 If agreed at the time of enquiry and order, this European Standard may also be applied to continuously hot-dip coated flat products in thicknesses > 3,0 mm. In this case the mechanical property, adhesion of coating and surface condition requirements shall also be agreed at the time of enquiry and order. 1.3 The products covered by this European Standard are mainly used where minimum yield strength and corrosion resistance are the most important factors. Corrosion resistance of the alloy is proportional to the coating thickness, hence to its mass (see also 7.3.2). NOTE +ZF coated products should not be used without additional organic coating. 1.4 This European Standard is not applicable to: · continuously hot-dip coated flat products of low-carbon steel strip and sheet for cold forming (see prEN 10327); · electrolytic galvanized cold rolled steel flat products (see EN 10152); · continuously organic coated (coil coated) flat steel products (see EN 10169-1, ENV 10169-2 and EN 10169-3); · continuously hot-dip coated strip and sheet of steels with higher yield strength for cold forming (see EN 10292).

1.1 This European Standard specifies requirements for continuously hot-dip coated products made of structural steels coated with zinc (Z), zinc-iron alloy (ZF), zinc-aluminium alloy (ZA), aluminium-zinc alloy (AZ) and aluminium-silicon alloy (AS) (see Table 1) with thicknesses from 0,35 mm up to 3,0 mm unless otherwise agreed (see 1.2). The thickness is the final thickness of the delivered product after coating. This European Standard applies to strip of all widths and to sheets cut from it (= 600 mm width) and cut lengths (< 600 mm width). 1.2 If agreed at the time of enquiry and order, this European Standard may also be applied to continuously hot-dip coated flat products in thicknesses > 3,0 mm. In this case the mechanical property, adhesion of coating and surface condition requirements shall also be agreed at the time of enquiry and order. 1.3 The products covered by this European Standard are mainly used where minimum yield strength and corrosion resistance are the most important factors. Corrosion resistance of the alloy is proportional to the coating thickness, hence to its mass (see also 7.3.2). NOTE +ZF coated products should not be used without additional organic coating. 1.4 This European Standard is not applicable to: · continuously hot-dip coated flat products of low-carbon steel strip and sheet for cold forming (see prEN 10327); · electrolytic galvanized cold rolled steel flat products (see EN 10152); · continuously organic coated (coil coated) flat steel products (see EN 10169-1, ENV 10169-2 and EN 10169-3); · continuously hot-dip coated strip and sheet of steels with higher yield strength for cold forming (see EN 10292).

EN 10326:2004 is classified under the following ICS (International Classification for Standards) categories: 77.140.10 - Heat-treatable steels; 77.140.50 - Flat steel products and semi-products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10326:2004 has the following relationships with other standards: It is inter standard links to EN 10154:2002, EN 10147:2000, EN 10215:1995, EN 10214:1995, EN 10346:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase EN 10326:2004 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Continuously hot-dip coated strip and sheet of structural steels - Technical delivery conditionsBandes et tôles en aciers de construction doux revetues en continu par immersion a chaud - Conditions techniques de livraisonKontinuierlich schmelztauchveredeltes Band und Blech aus Baustählen - Technische Lieferbedingungen77.140.50SROL]GHONLFlat steel products and semi-products77.140.10Jekla za toplotno obdelavoHeat-treatable steelsICS:SIST EN 10326:2004enTa slovenski standard je istoveten z:EN 10326:200401-november-2004SIST EN 10326:2004SLOVENSKI

STANDARDSIST EN 10214:1997SIST EN 10215:1998SIST EN 10147:2001SIST EN 10154:20031DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 10326

July 2004 ICS 77.140.50; 77.140.10 Supersedes EN 10147:2000,EN 10154:2002,EN 10214:1995,and EN 10215:1995English version

Continuously hot-dip coated strip and sheet of structural steels -Technical delivery conditions

Bandes et tôles en aciers de construction doux revêtues en continu par immersion à chaud - Conditions techniques de livraison

Kontinuierlich schmelztauchveredeltes Band und Blech aus Baustählen - Technische Lieferbedingungen This European Standard was approved by CEN on 23 April 2004.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2004 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 10326:2004: E

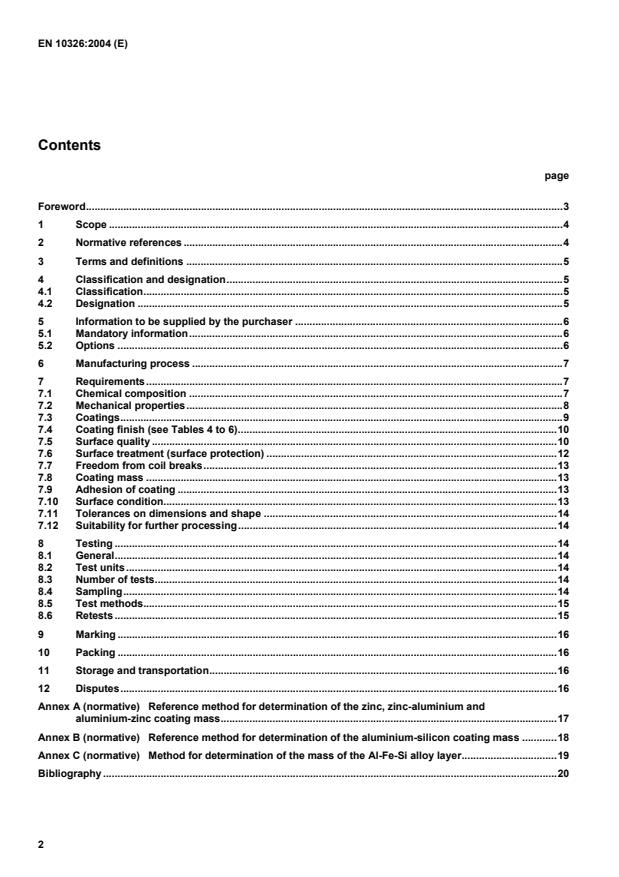

Reference method for determination of the zinc, zinc-aluminium and aluminium-zinc coating mass.17 Annex B (normative)

Reference method for determination of the aluminium-silicon coating mass.18 Annex C (normative)

Method for determination of the mass of the Al-Fe-Si alloy layer.19 Bibliography.20

EN 10169-3); • continuously hot-dip coated strip and sheet of steels with higher yield strength for cold forming (see EN 10292). 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 10002-1, Metallic materials - Tensile testing - Part 1: Method of test at ambient temperature. EN 10020:2000, Definition and classification of grades of steel. EN 10021:1993, General technical delivery requirements for steel and steel products. EN 10027-1, Designation systems for steels - Part 1: Steel names, principal symbols. EN 10027-2, Designation systems for steels - Part 2: Numerical system. EN 10079:1992, Definition of steel products. EN 10143, Continuously hot-dip metal coated steel sheet and strip - Tolerances on dimensions and shape. EN 10204:1991, Metallic products - Types of inspection documents. CR 10260, Designation systems for steel - Additional symbols.

special tolerances; e) term "steel"; f) number of this document (EN 10326); g) steel name or steel number and symbol for the type of hot-dip coating as given in Table 1; h) number designating the nominal mass of coating (e.g. 275 = 275 g/m² including both surfaces, see

Tables 3 to 6); i) letter denoting the coating finish (N, M or R, see 7.4 and Tables 4 and 5); j) letter denoting the surface quality (A, B or C, see 7.5 and Tables 4 to 6); k) letter denoting the surface treatment (C, O, CO and S, see 7.6). EXAMPLE 1 sheet, delivered with dimensional tolerances in accordance with EN 10143 with nominal thickness of 0,80 mm, ordered with special thickness tolerances (S), nominal width 1 200 mm, ordered with special width tolerances (S), nominal length 2 500 mm, ordered with special flatness tolerances (FS), made of steel S320GD+Z (1.0250+Z) in accordance with EN 10326, coating mass 275 g/m² (275), coating finish M, surface quality B, chemically passivated (C):

1 sheet EN 10143-0,80Sx1200Sx2500FS

steel EN 10326-S320GD+Z275-M-B-C or:

1 sheet EN 10143-0,80Sx1200Sx2500FS

steel EN 10326-1.0250+Z275-M-B-C 5.2 Options A number of options are specified in this document and listed below. lf the purchaser does not indicate his wish to implement one of these options, the products shall be supplied in accordance with the basis specification

(see 5.1). a) delivery of products in thicknesses > 3 mm (see 1.2); b) verification of the product analysis (see 7.1.2);

Table 1 — Steel grades and mechanical properties (longitudinal test pieces) Designation Chemical composition % by mass max. Mechanical properties Steel grade Steel name Steel number Symbols for the types of hot-dip coating C Si Mn P S 0,2 %-proof strength Rp0,2 a MPa * min. Tensile strength Rm b MPa * min. Elongation A80 c % min. S220GD 1.0241 +Z,+ZF,+ZA,+AZ 220 300 20 S250GD 1.0242 +Z,+ZF,+ZA,+AZ,+AS 250 330 19 S280GD 1.0244 +Z,+ZF,+ZA,+AZ,+AS 280 360 18 S320GD 1.0250 +Z,+ZF,+ZA,+AZ,+AS 320 390 17 S350GD 1.0529 +Z,+ZF,+ZA,+AZ,+AS 350 420 16 S550GD 1.0531 +Z,+ZF,+ZA,+AZ

0,20

0,60

1,70

0,10

0,045550 560 - * 1MPa = 1 N/mm2. a If the yield point is pronounced, the values apply to the upper yield point (ReH). b For all grades except S550GD, a range of 140 MPa can be expected for tensile strength. c For product thicknesses ≤ 0,70 mm (including coating) the minimum elongation values (A80) shall be reduced by 2 units.

Table 2 — Permissible deviations of the product analysis from specified limits on cast analysis given in Table 1 Element Specified limit of the cast analysis in Table 1 % by mass Permissible deviation of the product analysis % by mass C 0,20 + 0,02 Si 0,60 + 0,03 Mn 1,70 + 0,10 P 0,10 + 0,01 S 0,045 + 0,005

7.2 Mechanical properties 7.2.1 The products shall be supplied on the basis of the mechanical property requirements in Table 1. 7.2.2 lf so agreed at the time of enquiry and order, products specified in Table 1 may be supplied with suitability for manufacturing a specific part. In this case the values given in Table 1 do not apply. The reject tolerances arising when the material is processed shall not exceed a specific proportion to be agreed at the time of enquiry and order. 7.2.3 A reduction in the formability of all the coated products specified in this standard may occur by ageing. Therefore it is in the interest of the user to use the products as soon as possible after receiving them. 7.2.4 The tensile test values apply to longitudinal test pieces and are related to the test piece cross section without coating.

...

SIST EN 10326:2004 표준은 구조용 강으로 제작된 연속적으로 열침탄 코팅된 스트립 및 시트의 기술적 공급 조건을 규정합니다. 이 표준의 범위는 0.35 mm에서 3.0 mm까지의 두께를 가진 아연(Z), 아연-철 합금(ZF), 아연-알루미늄 합금(ZA), 알루미늄-아연 합금(AZ), 알루미늄-실리콘 합금(AS)으로 코팅된 제품들을 포함하며, 일정 조건 하에 3.0 mm 이상의 두께에도 적용될 수 있습니다. 이 표준은 최소 항복강도와 부식 저항성이 중요한 요소로 요구되는 응용 분야에 주로 사용되며, 코팅 두께에 비례하여 합금의 부식 저항성이 증가함을 명시합니다. 이러한 특성은 사용자가 구조적 강재 제품의 내구성을 체크하고, 필요에 따라 추가 유기 코팅이 요구되는 ZF 코팅 제품의 사용 지침을 제공함으로써 대처할 수 있습니다. SIST EN 10326:2004 표준의 강점은 명확한 제품 사양과 함께 다양한 합금의 조합을 포함하여, 특별한 요구사항이 있을 경우 유연성을 제공합니다. 두께와 폭에 대한 세부 규정을 통해 고객 요구에 부합하는 제품의 안정성을 보장하며, 선택 가능한 추가 조건들로 인해 다양한 산업 및 응용 분야에서 활용될 수 있는 가능성을 제시합니다. 또한, 저탄소강 스트립 및 시트, 전해 아연도금 냉간 압연 강재, 및 유기 코팅된 평강 제품과 같은 특정 제품군에 대하여 적용되지 않음을 분명히 하여 혼동을 방지하고 있습니다. 이로 인해 관련 산업 분야에서의 정확한 사용 지침이 마련되어 있어, 엔지니어와 제조업체가 제품 선택 시 보다 명확한 방향성을 갖출 수 있도록 돕습니다. 결론적으로, SIST EN 10326:2004 표준은 구조용 강재의 연속적으로 열침탄 코팅 제품에 대한 기술적 요구 사항을 명확히 정의하며, 그 강도와 부식 저항성이 중요한 응용에서의 신뢰성을 보장합니다.

The EN 10326:2004 standard offers a comprehensive framework for the specifications of continuously hot-dip coated strip and sheet products made of structural steels, specifically tailored for professionals in the metal industry. The scope of this standard delineates the requirements for products coated with zinc, zinc-iron, zinc-aluminium, aluminium-zinc, and aluminium-silicon alloys, detailing that the thickness ranges from 0.35 mm to 3.0 mm, a vital consideration for manufacturers and suppliers in processing and distributing hot-dip coated products. One of the standard's strengths lies in its emphasis on corrosion resistance, which is of paramount importance in structural applications. By establishing a direct relationship between the coating thickness and corrosion resistance, the standard provides clear guidance for material selection based on environmental exposure and durability requirements. This facet makes it highly relevant for professionals who prioritize performance in harsh conditions, ensuring that the right material is chosen for structural integrity and longevity. Furthermore, the standard accommodates the possibility of special agreements for thicker products exceeding 3.0 mm, allowing flexibility in the production process without compromising on quality. This adaptability, coupled with clearly defined mechanical property and adhesion requirements, enhances the usability of the standard across various applications in the construction and manufacturing sectors. However, it is important to note the exclusions defined in the standard. It does not apply to low-carbon steel flat products for cold forming, electrolytic galvanized products, or organic coated flat steel products. This specification assists users in correctly identifying the applicability of EN 10326:2004, thus streamlining the selection process for professionals and ensuring compliance with the appropriate standards. Overall, EN 10326:2004 is a robust standard that addresses essential characteristics of continuously hot-dip coated structural steel products, reinforcing its significance in manufacturing, quality control, and construction. Its focus on corrosion resistance and structural performance makes it a critical reference point for industry professionals engaged in the use of coated steel materials.

La norme EN 10326:2004, intitulée "Produits en bandes et feuilles d'aciers structuraux revêtus par immersion à chaud - Conditions techniques de livraison", apporte des spécifications claires et précises concernant les produits en acier structuraux continuellement revêtus à chaud de zinc, d'alliages de zinc-fer, de zinc-aluminium, d'aluminium-zinc et d'aluminium-silicium. Son domaine d'application s'étend aux bandes de toutes largeurs et aux feuilles découpées, ce qui en fait un document essentiel pour l'industrie de la fabrication métallique. Une des forces majeures de cette norme réside dans son attention portée aux conditions de livraison techniques. En réglementant des épaisseurs de revêtement allant de 0,35 mm à 3,0 mm, tout en offrant la possibilité d'adapter ces spécifications pour des produits de plus de 3,0 mm sur demande, elle démontre sa flexibilité pour répondre aux besoins variés des utilisateurs. Ce niveau de détail dans les exigences techniques est particulièrement pertinent dans les applications où la résistance minimale à la traction et la résistance à la corrosion sont primordiales, deux critères essentiels dans le choix des matériaux pour des constructions durables. De plus, la norme souligne que la résistance à la corrosion est proportionnelle à l'épaisseur du revêtement, ce qui constitue une information cruciale pour les concepteurs et les ingénieurs. Cela permet d'optimiser le choix des matériaux en fonction des environnements d'utilisation, assurant ainsi leur longévité et leur fiabilité. Il est important de noter que la norme exclut certains types de produits, ce qui renforce sa clarté et sa pertinence dans le domaine ciblé. En précisant que les produits en acier faiblement carburé et les produits électro-galvanisés ne sont pas couverts, la norme évite toute confusion pour les utilisateurs potentiels et garantit une application rigoureuse des critères de qualité indiqués. En somme, la norme EN 10326:2004 s'impose comme un document fondamental pour les acteurs du marché des aciers structuraux revêtus, en apportant des lignes directrices précises et adaptées aux défis contemporains de l'industrie. Sa pertinence et sa structure technique en font un outil indispensable pour garantir la qualité et la durabilité des produits en acier.

SIST EN 10326:2004は、構造用鋼で製造された連続的に熱浸 galvanized コーティングのストリップおよびシートに関する技術的な納品条件を規定する欧州標準です。この標準は、亜鉛(Z)、亜鉛-鉄合金(ZF)、亜鉛-アルミニウム合金(ZA)、アルミニウム-亜鉛合金(AZ)、およびアルミニウム-シリコン合金(AS)でコーティングされた製品に対して適用される要件を明確に示しています。具体的には、厚さ0.35 mmから3.0 mmの範囲で、幅に関しては全てのストリップおよび600 mm未満のカットシートに適用可能です。 この標準の強みは、主に最小降伏強度と耐腐食性が重要な要素である用途に向けて設計されている点にあります。コーティングの厚さは、この合金の耐腐食性に比例し、その質量にも影響を与えます。加えて、顧客が問い合わせ時および注文時に合意すれば、厚さが3.0 mmを超える製品にも適用可能であり、その場合は機械的特性、コーティングの密着性、表面状態の要件も事前に合意する必要があります。 さらに、標準は低炭素鋼のストリップ及びシートに対しては適用されず、電解亜鉛メッキされた冷間圧延鋼や連続有機コーティング施されたフラット鋼製品の規格も含まれていません。これにより、特定の用途に対する適切な基準を確立し、必要な品質を保つことができます。 このように、SIST EN 10326:2004は、構造用鋼の連続熱浸コーティング製品に関する厳格な要件を規定しており、その応用範囲、強み、関連性において、業界内での重要な基準となっています。

Die EN 10326:2004 beschreibt umfassend die technischen Lieferbedingungen für kontinuierlich feuerverzinkte Produkte aus Baustählen. Diese europäische Norm ist besonders relevant für die Metallindustrie, da sie präzise Anforderungen an Produkte stellt, die mit verschiedenen Zinklegierungen beschichtet sind, einschließlich Zink (Z), Zink-Eisen-Legierung (ZF), Zink-Aluminium-Legierung (ZA), Aluminium-Zink-Legierung (AZ) und Aluminium-Silizium-Legierung (AS). Der Anwendungsbereich umfasst sowohl Streifen als auch Platten, die nach Kundenwunsch in unterschiedlichen Breiten und Längen gefertigt werden können, wobei die Dicke der Produkte zwischen 0,35 mm und 3,0 mm variieren kann. Ein bemerkenswerter Vorteil dieser Norm liegt in ihrer Flexibilität. Bei Vereinbarung kann sie auch auf plattierte Flachprodukte mit einer Dicke von mehr als 3,0 mm angewendet werden, was eine Anpassung an spezifische Kundenbedürfnisse ermöglicht. Die Norm hebt die Bedeutung der mechanischen Eigenschaften und der Haftung der Beschichtung hervor, welche ebenfalls individuell beim Auftrag festgelegt werden können. Ein wesentlicher Grund für die Anwendung dieser Norm ist die Gewährleistung einer minimalen Streckgrenze und einer hohen Korrosionsbeständigkeit, die in vielen industriellen Anwendungen kritisch ist. Die Norm dokumentiert, dass die Korrosionsbeständigkeit direkt mit der Dicke der Beschichtung korreliert, was für Designer und Ingenieure von Bedeutung ist, die die Lebensdauer und Zuverlässigkeit ihrer Produkte optimieren möchten. Die EN 10326:2004 schließt jedoch spezifische Produktgruppen aus, darunter kontinuierlich feuerverzinkte Produkte aus niedriglegiertem Stahl für die Kaltumformung sowie elektrolytisch verzinkte Flachprodukte. Dies stellt sicher, dass die Norm klar und fokussiert bleibt, ohne Verwirrung durch nicht relevante Produkte herbeizuführen. Insgesamt bietet die EN 10326:2004 eine solide Grundlage für die Herstellung und Lieferung von hochbelastbaren, korrosionsbeständigen Stahlprodukten, die in verschiedenen Anwendungen eingesetzt werden, und bestätigt somit ihre große Relevanz im Bereich der Baustähle.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...