EN 15512:2020+A1:2022

(Main)Steel static storage systems - Adjustable pallet racking systems - Principles for structural design

Steel static storage systems - Adjustable pallet racking systems - Principles for structural design

This document specifies the structural design requirements applicable to all types of adjustable beam pallet rack systems fabricated from steel members intended for the storage of unit loads and subject to predominantly static loads. Both un-braced and braced systems are included.

This document gives guidelines for the design of clad rack buildings where requirements are not covered in the EN 1993 series. The requirements of this document also apply to ancillary structures, where rack components are employed as the main structural members.

This document does not cover other generic types of storage structures. Specifically, this document does not apply to mobile storage systems, drive-in, drive-through, pallet live storage, push back, shuttle systems, systems where two or more cranes operates one above another in the same aisle and cantilever racks or static steel shelving systems.

For the specific design of adjustable pallet racking for use in seismic areas, this document is to be used in combination with EN 16681.

Ortsfeste Regalsysteme aus Stahl - Verstellbare Palettenregale - Grundlagen der statischen Bemessung

Dieses Dokument legt die Anforderungen an die statische Bemessung für sämtliche Arten von Palettenregalen mit verstellbaren Trägern fest, welche aus Stahlelementen hergestellt und zur Lagerung von Ladeeinheiten vorgesehen und vorwiegend statischen Lasten ausgesetzt sind. Sowohl Systeme mit als auch ohne Aussteifungsverbände sind berücksichtigt.

Dieses Dokument dient als Leitlinie zur statischen Bemessung von Gebäuden aus verkleideten Regalen, im Falle, dass deren Anforderungen nicht von der Normenreihe EN 1993 abgedeckt sind. Die Anforderungen dieses Dokuments gelten auch für Zusatzeinrichtungen, bei denen Regalbauteile als wichtiges Hauptbauteil eingesetzt sind.

Dieses Dokument deckt keine anderen generischen Arten von Lagerstrukturen ab. Dieses Dokument gilt ausdrücklich nicht für Verschieberegalsysteme, Einfahr- und Durchfahrregale, Paletten-Einfahr- und Durchlaufregale, Einschubregale, Shuttle-Systeme, Systeme, die aus zwei oder mehr RFZ (Regalförderzeugen) bestehen, welche übereinander im selben Gang arbeiten sowie Kragarmregale oder statische Regalsysteme aus Stahl.

Zur spezifischen Auslegung von verstellbaren Palettenregalen zur Verwendung in Erdbebengebieten ist dieses Dokument in Kombination mit EN 16681 zu verwenden.

Systèmes de stockage statiques en acier - Systèmes de rayonnages à palettes réglables - Principes applicables au calcul des structures

La présente Norme européenne spécifie les exigences de calcul des structures, applicables à tous les types de systèmes de rayonnages à palettes à lisses réglables fabriqués à partir d’éléments en acier, destinés au stockage d’unités de charge et soumis à des charges essentiellement statiques. Les systèmes non contreventés et contreventés sont inclus.

La présente Norme européenne donne les lignes directrices pour le calcul des bâtiments de stockage en tôle plaquée dont les exigences ne sont pas couvertes par la série EN 1993. Les exigences de la présente Norme européenne s’appliquent également aux structures annexes lorsque des éléments de rayonnage sont employés comme éléments structurels principaux.

La présente Norme européenne ne couvre pas les autres types génériques de structures de rayonnage. En particulier, elle ne s’applique pas aux systèmes de stockage mobiles, aux systèmes de rayonnages à accumulation statique, au stockage dynamique sur palettes, aux systèmes à gravité inversée, aux systèmes à navette, aux systèmes où deux ponts roulants ou plus fonctionnent l’un au-dessus de l’autre dans la même allée, aux rayonnages en porte-à-faux, ni aux systèmes de rayonnage à tablettes statiques en acier.

Pour la conception particulière de rayonnages à palettes réglables destinés à une utilisation en zones sismiques, il convient d’utiliser la présente norme en combinaison avec l’EN 16681.

Stabilni jekleni sistemi za skladiščenje - Sistemi za nastavljive regale za palete - Načela dimenzioniranja

Ta dokument določa zahteve glede dimenzioniranja, ki se uporabljajo za vse vrste sistemov za nastavljive regale za palete, izdelane iz jeklenih elementov, ki so namenjeni za skladiščenje tovornih enot in izpostavljeni pretežno statičnim obremenitvam. Vključeni so tako sistemi z oporo kot brez opore.

Ta dokument podaja smernice za dimenzioniranje objektov s platiranimi regali v primerih, ko zahteve niso zajete v skupini standardov EN 1993. Zahteve v tem dokumentu se uporabljajo tudi za pomožne konstrukcije, pri katerih so regalne komponente uporabljene kot glavni konstrukcijski elementi.

Ta dokument ne zajema drugih splošnih vrst skladiščnih konstrukcij. Ta dokument se natančneje ne uporablja za premične sisteme za skladiščenje, vstopne in prehodne regale, regale za pretočne palete, potisne in podajalne sisteme, sisteme, pri katerih se vsaj dva žerjava upravljata eden nad drugim v istem prehodu, ter konzolne regale ali stabilne jeklene sisteme polic.

Pri posebnih izvedbah nastavljivih regalov za palete za uporabo na potresnih območjih je treba ta dokument uporabljati skupaj s standardom EN 16681.

General Information

- Status

- Published

- Publication Date

- 15-Mar-2022

- Withdrawal Date

- 29-Sep-2022

- Technical Committee

- CEN/TC 344 - Steel static storage systems

- Drafting Committee

- CEN/TC 344 - Steel static storage systems

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 16-Mar-2022

- Completion Date

- 16-Mar-2022

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 18-Jan-2023

Overview

EN 15512:2020+A1:2022 - also published as EN 15512:2020+A1:2022 - is the European standard that specifies principles for the structural design of adjustable beam pallet racking systems fabricated from steel. It applies to steel static storage systems intended for the storage of unit loads and subject to predominantly static loads. The standard covers both braced and un‑braced pallet racks, provides guidance for clad rack buildings, and applies to ancillary structures where racking components act as primary structural members.

Key topics and technical requirements

The standard sets out the structural design framework rather than prescriptive construction details. Key technical topics include:

- Scope and exclusions: Applies to adjustable pallet racking; explicitly excludes mobile storage systems, drive‑in/drive‑through systems, pallet live, push‑back, shuttle systems, multi‑crane aisles, cantilever racks, and static steel shelving systems.

- Basis of design: Design working life, limit state design principles (ultimate and serviceability limit states), and required combinations of actions.

- Actions and loadings: Permanent, variable and accidental actions relevant to pallet racking, including combinations and partial factors consistent with Eurocode principles.

- Materials and durability: Requirements for steel material properties, floor material considerations (concrete, bituminous, etc.), and durability provisions.

- Structural analysis: Modelling assumptions, joint modelling, ground‑structure interaction, global analysis and stability, including effects of geometric imperfections.

- Member design: Resistance checks and buckling considerations for beams and uprights, buckling curves, torsional and flexural buckling lengths.

- Frame bracing and run spacers: Design of bracing systems, robustness and buckling length provisions.

- Joints and connectors: Design resistance for beam end connectors, locks, splices and combined actions.

- Serviceability: Deflection limits and serviceability checks for beams and rack‑supported floors.

- Seismic design: For seismic zones, EN 15512 is to be used in combination with EN 16681.

Practical applications and target users

This standard is essential for professionals involved in the design, manufacture, installation and regulation of pallet racking:

- Structural and warehouse engineers designing adjustable pallet racking systems

- Racking manufacturers and component designers

- Facility managers and warehouse planners specifying storage systems

- Building authorities, safety inspectors and compliance officers

- Consultants preparing structural reports for clad rack buildings or rack‑based ancillary structures

Use EN 15512 to ensure safe, code‑compliant structural racking design, to assess stability and durability, and to integrate racking with building structures when Eurocode guidance is insufficient.

Related standards

- EN 16681 - Seismic design of pallet racking (used alongside EN 15512 in seismic areas)

- EN 1993 series (Eurocode 3) - Steel structures (for general steel design principles referenced by EN 15512)

- EN 1990 - Basis of structural design (for limit state methodology and design principles)

Frequently Asked Questions

EN 15512:2020+A1:2022 is a standard published by the European Committee for Standardization (CEN). Its full title is "Steel static storage systems - Adjustable pallet racking systems - Principles for structural design". This standard covers: This document specifies the structural design requirements applicable to all types of adjustable beam pallet rack systems fabricated from steel members intended for the storage of unit loads and subject to predominantly static loads. Both un-braced and braced systems are included. This document gives guidelines for the design of clad rack buildings where requirements are not covered in the EN 1993 series. The requirements of this document also apply to ancillary structures, where rack components are employed as the main structural members. This document does not cover other generic types of storage structures. Specifically, this document does not apply to mobile storage systems, drive-in, drive-through, pallet live storage, push back, shuttle systems, systems where two or more cranes operates one above another in the same aisle and cantilever racks or static steel shelving systems. For the specific design of adjustable pallet racking for use in seismic areas, this document is to be used in combination with EN 16681.

This document specifies the structural design requirements applicable to all types of adjustable beam pallet rack systems fabricated from steel members intended for the storage of unit loads and subject to predominantly static loads. Both un-braced and braced systems are included. This document gives guidelines for the design of clad rack buildings where requirements are not covered in the EN 1993 series. The requirements of this document also apply to ancillary structures, where rack components are employed as the main structural members. This document does not cover other generic types of storage structures. Specifically, this document does not apply to mobile storage systems, drive-in, drive-through, pallet live storage, push back, shuttle systems, systems where two or more cranes operates one above another in the same aisle and cantilever racks or static steel shelving systems. For the specific design of adjustable pallet racking for use in seismic areas, this document is to be used in combination with EN 16681.

EN 15512:2020+A1:2022 is classified under the following ICS (International Classification for Standards) categories: 53.080 - Storage equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15512:2020+A1:2022 has the following relationships with other standards: It is inter standard links to EN 15512:2020/FprA1, EN 15512:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase EN 15512:2020+A1:2022 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2022

Stabilni jekleni sistemi za skladiščenje - Sistemi za nastavljive regale za palete -

Načela dimenzioniranja

Steel static storage systems - Adjustable pallet racking systems - Principles for structural

design

Ortsfeste Regalsysteme aus Stahl - Verstellbare Palettenregale - Grundlagen der

statischen Bemessung

Systèmes de stockage statiques en acier - Systèmes de rayonnages à palettes réglables

- Principes applicables au calcul des structures

Ta slovenski standard je istoveten z: EN 15512:2020+A1:2022

ICS:

53.080 Skladiščna oprema Storage equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15512:2020+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2022

EUROPÄISCHE NORM

ICS 53.080 Supersedes EN 15512:2020

English Version

Steel static storage systems - Adjustable pallet racking

systems - Principles for structural design

Systèmes de stockage statiques en acier - Systèmes de Ortsfeste Regalsysteme aus Stahl - Verstellbare

rayonnages à palettes réglables - Principes applicables Palettenregale - Grundlagen der statischen Bemessung

au calcul des structures

This European Standard was approved by CEN on 8 June 2020 and includes Amendment 1 approved by CEN on 14 January 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15512:2020+A1:2022 E

worldwide for CEN national Members.

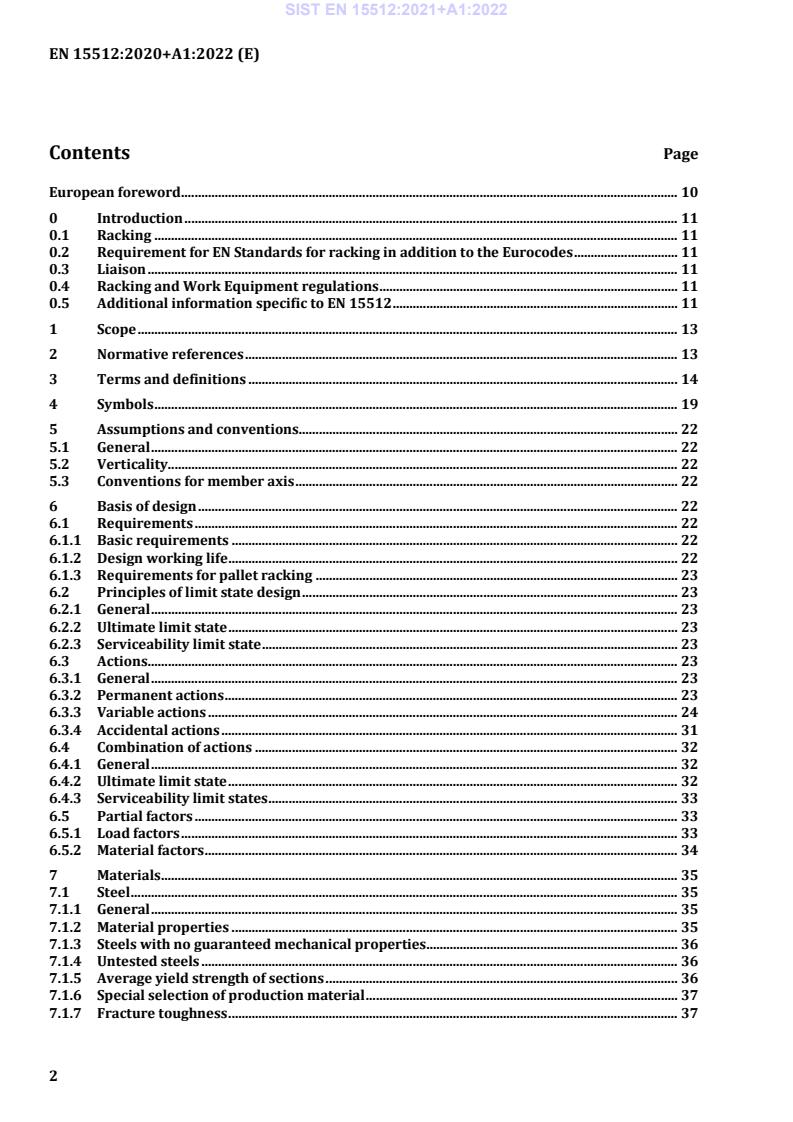

Contents Page

European foreword . 10

0 Introduction . 11

0.1 Racking . 11

0.2 Requirement for EN Standards for racking in addition to the Eurocodes . 11

0.3 Liaison . 11

0.4 Racking and Work Equipment regulations . 11

0.5 Additional information specific to EN 15512 . 11

1 Scope . 13

2 Normative references . 13

3 Terms and definitions . 14

4 Symbols . 19

5 Assumptions and conventions . 22

5.1 General . 22

5.2 Verticality. 22

5.3 Conventions for member axis . 22

6 Basis of design . 22

6.1 Requirements . 22

6.1.1 Basic requirements . 22

6.1.2 Design working life . 22

6.1.3 Requirements for pallet racking . 23

6.2 Principles of limit state design . 23

6.2.1 General . 23

6.2.2 Ultimate limit state . 23

6.2.3 Serviceability limit state . 23

6.3 Actions . 23

6.3.1 General . 23

6.3.2 Permanent actions . 23

6.3.3 Variable actions . 24

6.3.4 Accidental actions . 31

6.4 Combination of actions . 32

6.4.1 General . 32

6.4.2 Ultimate limit state . 32

6.4.3 Serviceability limit states . 33

6.5 Partial factors . 33

6.5.1 Load factors . 33

6.5.2 Material factors . 34

7 Materials . 35

7.1 Steel . 35

7.1.1 General . 35

7.1.2 Material properties . 35

7.1.3 Steels with no guaranteed mechanical properties. 36

7.1.4 Untested steels . 36

7.1.5 Average yield strength of sections . 36

7.1.6 Special selection of production material . 37

7.1.7 Fracture toughness . 37

7.1.8 Dimensional tolerances . 37

7.2 Floor materials . 38

7.2.1 Concrete floors. 38

7.2.2 Bituminous floors . 38

7.2.3 Other floor materials . 38

8 Durability. 38

9 Structural analysis . 39

9.1 Structural modelling for analysis . 39

9.1.1 Structural modelling for analysis and basic assumption . 39

9.1.2 Joint modelling . 39

9.1.3 Ground-structure interaction . 42

9.1.4 Racks braced against the building structure . 45

9.2 Global analysis . 45

9.2.1 Effects of deformed geometry of the structure . 45

9.2.2 Method of analysis . 46

9.2.3 Structural stability of frames . 47

9.3 Imperfections . 53

9.3.1 General . 53

9.3.2 Global imperfections . 53

9.3.3 Local bracing imperfections . 55

9.3.4 Member imperfections . 56

10 Ultimate limit states . 57

10.1 Resistance of cross-sections and members . 57

10.1.1 General . 57

10.1.2 Section properties . 57

10.1.3 Compression members . 58

10.1.4 Bending members . 60

10.1.5 Tension members . 60

10.2 Design of beams. 62

10.2.1 General . 62

10.2.2 Effects of interaction between unit load and beam . 62

10.2.3 Correction for looseness . 63

10.2.4 Plastic design resistance . 63

10.2.5 Buckling length of beams in braced pallet racks . 63

10.2.6 Beams subject to bending and torsion . 64

10.2.7 Beams affected by distortion . 65

10.3 Design of uprights . 65

10.3.1 General . 65

10.3.2 Buckling curves . 65

10.3.3 Flexural buckling length . 66

10.3.4 Torsional buckling length . 68

10.4 Design of frame bracing . 71

10.4.1 General . 71

10.4.2 Robustness . 71

10.4.3 Buckling length of frame bracing . 71

10.5 Design of run spacers . 73

11 Serviceability limit states . 74

11.1 General . 74

11.2 Beams . 74

11.3 Beams in walkways or rack supported floors . 74

12 Design of joints . 74

12.1 General . 74

12.2 Design of beam end connectors . 74

12.2.1 Design resistance of moment and shear . 74

12.2.2 Combination of moment and shear . 74

12.2.3 Reversed moment . 74

12.3 Design of beam connector locks . 75

12.4 Design of splices . 75

12.5 Design of base plates . 75

12.5.1 General . 75

12.5.2 Compression . 76

12.5.3 Tension . 77

12.6 Design of anchorages . 77

12.6.1 General . 77

12.6.2 Robustness. 77

13 Design assisted by testing . 77

13.1 General . 77

13.2 Requirements for tests . 78

13.2.1 Equipment . 78

13.2.2 Support conditions . 78

13.2.3 Application of the load . 78

13.2.4 Increments of the test load . 79

13.2.5 Test materials . 79

13.2.6 Assembly of test specimens . 79

13.2.7 Test reports . 79

13.3 Interpretation of test results . 80

13.3.1 Definition of failure load . 80

13.3.2 Adjustment of test results . 80

13.3.3 Derivation of characteristic values . 82

13.3.4 Characteristic values for a family of tests . 83

13.3.5 Interpolation between test results . 84

14 Marking and labelling – Identification of performance of rack installations. 84

Annex A (normative) Testing . 85

A.1 Materials tests . 85

A.1.1 Tensile tests . 85

A.1.1.1 General . 85

A.1.1.2 Tensile test from beam end connector . 85

A.1.2 Bend tests . 85

A.2 Tests on components . 86

A.2.1 Stub column compression test . 86

A.2.1.1 Purpose of the test . 86

A.2.1.2 Test arrangement and method . 86

A.2.1.3 Corrections to the observations. 87

A.2.1.4 Derivation of the results . 88

A.2.2 Compression tests on uprights – Checks for the effects of distortional buckling . 88

A.2.2.1 Purpose of the test . 88

A.2.2.2 Test arrangement and method . 88

A.2.2.3 Corrections to the observations . 89

A.2.2.4 Derivation of the test results . 89

A.2.3 Compression tests on uprights – Determination of buckling curves . 90

A.2.3.1 Purpose of the test . 90

A.2.3.2 Test arrangement . 91

A.2.3.3 Test method . 92

A.2.3.4 Corrections to the observations . 92

A.2.3.5 Derivation of the column curve . 93

A.2.4 Frame shear stiffness tests . 94

A.2.4.1 Purpose of the tests . 94

A.2.4.2 Method A, loading the frame in the longitudinal direction . 94

A.2.4.2.1 Test arrangement . 94

A.2.4.2.2 Test method . 96

A.2.4.2.3 Corrections to the observations . 96

A.2.4.2.4 Derivation of results . 96

A.2.4.3 Alternative method B using a cross-aisle reversible shear load on a frame . 97

A.2.4.3.1 General . 97

A.2.4.3.2 Test arrangement . 97

A.2.4.3.3 Test method . 98

A.2.4.3.4 Corrections to the observations . 99

A.2.4.3.5 Derivation of results . 99

A.2.5 Bending tests on upright sections . 100

A.2.5.1 Purpose of the test . 100

A.2.5.2 Test arrangement . 100

A.2.5.3 Test method . 102

A.2.5.4 Corrections to the observations . 102

A.2.5.5 Derivation of results . 102

A.2.6 Bending tests on beams . 102

A.2.6.1 Purpose of the test . 102

A.2.6.2 Test arrangement . 102

A.2.6.3 Test method . 104

A.2.6.4 Corrections to the observations . 104

A.2.6.5 Derivation of the results . 104

A.3 Tests on connections . 105

A.3.1 Bending tests on beam end connectors . 105

A.3.1.1 Purpose of the test . 105

A.3.1.2 Test arrangements . 105

A.3.1.3 Test procedure . 107

A.3.1.4 Corrections to the observations. 107

A.3.1.5 Derivation of the results and procedure to define curves . 108

A.3.1.5.1 Procedure 1: . 108

A.3.1.5.2 Procedure 2: . 108

A.3.1.5.3 General . 108

A.3.1.5.4 Procedure to derive a bi-linear curve . 109

A.3.1.5.5 Procedure to derive a multilinear curve . 109

A.3.2 Looseness tests on beam end connectors . 111

A.3.2.1 Purpose of the test . 111

A.3.2.2 Alternative 'A' Test arrangement using a double acting jack . 111

A.3.2.2.1 General . 111

A.3.2.2.2 Test Method . 111

A.3.2.2.3 Corrections to the observations . 112

A.3.2.2.4 Derivation of results . 112

A.3.2.3 Alternative ‘B’ using two cantilever beams and a central upright . 112

A.3.2.3.1 Test arrangement . 112

A.3.2.3.2 Test Method . 114

A.3.2.3.3 Corrections to the observations . 114

A.3.2.3.4 Derivation of results . 114

A.3.3 Shear tests on beam end connectors and connector locks . 114

A.3.3.1 Purpose of the test . 114

A.3.3.2 Test arrangement . 114

A.3.3.3 Test method . 116

A.3.3.4 Corrections to the observations. 116

A.3.3.5 Derivation of results . 116

A.3.4 Moment-shear interaction test of beam end connectors . 116

A.3.4.1 Purpose of the test . 116

A.3.4.2 Test arrangement . 116

A.3.4.3 Test procedure . 116

A.3.4.4 Corrections to the observations. 116

A.3.4.5 Derivation of the bending and shear resistance . 116

A.3.4.6 Derivation of the moment-shear interaction curve . 117

A.3.4.7 Generalized moment-shear relationship . 117

A.3.5 Floor connections test . 117

A.3.5.1 Purpose of the test . 117

A.3.5.2 Reuse of concrete blocks . 118

A.3.5.3 Alternative ‘A’ using two lengths of upright with a central concrete block . 118

A.3.5.3.1 Test arrangement . 118

A.3.5.3.2 Test method . 120

A.3.5.4 Alternative ‘B’ using a single length of upright with an end concrete block . 121

A.3.5.4.1 Test arrangement . 121

A.3.5.4.2 Test Method . 123

A.3.5.5 Corrections to the observations . 123

A.3.5.6 Derivation of the Results . 123

A.3.6 Upright splices test . 124

A.3.6.1 Purpose of the test . 124

A.3.6.2 Test arrangement . 124

A.3.6.3 Test method . 125

A.3.6.4 Corrections to observations. 125

A.3.6.5 Derivation of results . 125

Annex B (informative) Approximate method . 126

B.1 General . 126

B.2 Approximate down-aisle stability analysis – Amplified sway method. 126

B.2.1 General . 126

B.2.2 Amplification factor . 128

B.2.3 Linear elastic analysis . 128

B.2.4 Elastic critical value . 128

B.3 Approximate down-aisle analysis of a regular storage rack . 128

B.3.1 Approximate equation for regular construction . 128

B.3.2 Additional bending moments due to pattern loading . 131

B.3.3 Design Moments . 131

B.3.4 Design loads in outer columns . 132

B.4 Approximate cross-aisle stability analysis . 133

B.4.1 General . 133

B.4.2 Global buckling of upright frames . 133

B.4.3 Shear stiffness of upright frame . 133

B.4.4 Amplification factor β . 134

B.5 Approximate design for symmetrically loaded beams . 137

B.5.1 Mid-span bending moment . 137

B.5.2 Deflection . 138

B.5.3 Shear force . 138

B.5.4 Beam end connector . 139

B.5.5 Equivalent beam loads . 139

Annex C (informative) Correction of beam moments and deflection due to looseness . 141

Annex D (informative) Frame looseness. 143

D.1 General . 143

D.2 Frame bracing types . 143

D.3 Looseness . 144

Annex E (normative) Resistance of compression member according to EN 1993-1-1 and −3 . 146

E.1 Cross-sectional verification . 146

E.2 Design strength with respect to flexural buckling .

...

SIST EN 15512:2021+A1:2022に関するレビューを行います。この標準は、主に静的荷重に対応するために設計されたスチール製の可動パレットラックシステムの構造設計に関する要求事項を規定しています。主に可動ビームパレットラックシステムに焦点を当て、その設計原則を明確に示しています。 標準のスコープは、ブレースの有無にかかわらず、すべてのタイプのパレットラックシステムを対象としています。この包括的なアプローチにより、設計者はさまざまな構造形式に対応できるため、非常に実用的であります。また、EN 1993シリーズでカバーされていないクlad ラックビルディングの設計に関するガイドラインを提供している点も大きな強みです。これにより、設計の柔軟性が増し、特に特定のプロジェクト要件に応じて調整可能です。 この文書は、ラックコンポーネントが主構造部材として使用されている補助構造物にも適用されるため、設計と施工の一貫性が確保される点が重要です。また、可動パレットラックを地震地域で使用するための具体的な設計には、EN 16681と組み合わせて利用することが求められるため、さらなる安全性が追加されています。 ただし、柔軟な設計の可能性にもかかわらず、モバイルストレージシステム、ドライブイン/ドライブスルーシステム、パレットライブストレージ、プッシュバック、シャトルシステム、同じ通路でのクレーンの上下操作、さらにはカンチレバーラックや静的スチールシェルビングシステムなど、他の一般的なストレージ構造には適用されない点には注意が必要です。この明確さにより、適用範囲が限定的であることが利用者にとっての利点となります。 全体として、SIST EN 15512:2021+A1:2022は、スチール製の可動パレットラックの設計に関する貴重な指針を提供しており、その適用範囲、強み、及び関連性は、格納システムにおける安全性と効率性を向上させるための重要な要素となっています。

The standard EN 15512:2020+A1:2022 provides comprehensive guidelines for the structural design of adjustable pallet racking systems fabricated from steel, catering specifically to environments where unit loads are predominantly subjected to static loads. The scope of this standard is both broad and focused, covering all types of adjustable beam pallet rack systems, which are crucial for efficient storage solutions in various industrial settings. One of the primary strengths of this standard is its inclusive approach, addressing both un-braced and braced systems, thereby providing flexibility in design choices. This is particularly relevant for businesses looking to optimize their storage capacity while ensuring safety and compliance with structural integrity requirements. Additionally, the guidelines extend to the design of clad rack buildings, which are not sufficiently covered by the EN 1993 series, thus offering added value in contexts where these structures are utilized. Another significant aspect of EN 15512:2020+A1:2022 is its applicability to ancillary structures that incorporate rack components as primary structural members, promoting a comprehensive understanding of how these systems interact within larger frameworks. This integration emphasizes the importance of structural coherence and safety in complex storage environments. However, it is important to note the limitations of the standard as well. EN 15512:2020+A1:2022 does not extend to other types of storage systems such as mobile storage systems, drive-in, or cantilever racks. This clearly delineates its focus, which ensures that users are aware of the specific contexts applicable to the standard, thus promoting informed decision-making during the design process. The relevance of this standard is underscored in contexts where adjustable pallet racking systems are essential for operational efficiency. While the standard conveniently provides structural guidelines, it must be noted that for adjustable pallet racking systems designed for seismic areas, users need to consult EN 16681 concurrently. This additional specification highlights the standard's commitment to safety, particularly in regions susceptible to seismic activity. In summary, the EN 15512:2020+A1:2022 standard is a vital reference for anyone involved in the design and implementation of adjustable pallet racking systems in static load environments, affirming its strengths in structural integrity, flexibility in design, and safety compliance, while clearly stating its scope and limitations concerning various types of storage systems.

La norme SIST EN 15512:2021+A1:2022 fournit des directives claires et précises pour la conception structurelle des systèmes de rayonnage à palettes ajustables fabriqués en acier, destinés au stockage de charges unitaires sous principalement des charges statiques. En englobant à la fois les systèmes non écharpés et écharpés, cette norme répond à un large éventail d'applications, offrant des exigences de conception essentielles pour garantir la sécurité et la fiabilité des installations de stockage. Un des points forts de cette norme est son approche exhaustive, qui inclut non seulement les rayonnages mais aussi les bâtiments à rayonnage habillés lorsque des critères spécifiques ne sont pas couverts par la série EN 1993. Cette capacité d'adaptation à des structures auxiliaires, où les composants de rayonnage jouent un rôle prépondérant, témoigne de sa pertinence dans le contexte moderne du stockage. De plus, la norme souligne l'importance d'une conception structurale rigoureuse, en précisant qu'elle ne s'applique pas à d'autres types de structures de stockage génériques telles que les systèmes de stockage mobiles ou les rayonnages cantilever. Cela permet de clarifier les limites de son application, garantissant que les utilisateurs soient bien informés des spécificités couvertes. Par ailleurs, pour les zones sismiques, elle est conçue pour être utilisée en combinaison avec la norme EN 16681, renforçant ainsi la sécurité des installations dans des conditions variables. En somme, la norme SIST EN 15512:2021+A1:2022 se distingue par sa capacité à offrir des exigences de conception détaillées et pertinentes pour les systèmes de rayonnage à palettes, solidifiant ainsi sa position en tant que référence clé dans le domaine des systèmes de stockage en acier.

Die Norm EN 15512:2020+A1:2022 legt spezifische Anforderungen an die Tragwerksplanung von verstellbaren Palettenregalsystemen aus Stahl fest, die für die Lagerung von Einheitladungen und die überwiegende Belastung durch statische Lasten ausgelegt sind. Diese Norm umfasst sowohl nicht abgestützte als auch abgestützte Systeme. Durch die klare Definition der strukturellen Anforderungen sorgt die Norm für ein hohes Maß an Sicherheit und Effizienz in der Gestaltung und Nutzung von Lagerregalen. Ein wesentlicher Vorteil dieser Norm ist ihr umfassender Anwendungsbereich. Sie bietet Richtlinien für die Planung von bekleideten Regalanlagen, wo die Anforderungen nicht durch die EN 1993-Serie abgedeckt sind. Dies ist besonders relevant für Unternehmen, die komplexe Lagerstrukturen realisieren und dabei sicherstellen müssen, dass alle gesetzlichen Sicherheitsanforderungen eingehalten werden. Darüber hinaus wird in der Norm auch die Anwendung auf Nebengebäude behandelt, in denen Regalbestandteile als Hauptbauelemente fungieren. Dies trägt dazu bei, die Vielseitigkeit der Regelung zu erhöhen und ermöglicht es Planern, innovative Lagerlösungen zu entwickeln, die höchste Sicherheitsstandards erfüllen. Die ERWÄHNUNG, dass diese Norm nicht für mobile Lagersysteme, Durchfahrtssysteme, lebende Palettenlager oder andere spezifische Lagersysteme gilt, erhöht die Klarheit über den Anwendungsbereich. Damit können Unternehmen gezielt entscheiden, welche Normen für ihre spezifischen Anforderungen relevant sind. Ein weiterer wichtiger Aspekt ist die Integration der Norm in die Planung von verstellbaren Palettenregalen in erdbebengefährdeten Gebieten, wo sie zusammen mit der EN 16681 verwendet werden sollte. Dies zeigt die Relevanz der Norm im Hinblick auf sicherheitstechnische Überlegungen in kritischen geografischen Regionen und unterstreicht die Notwendigkeit, bei der Planung und Umsetzung von Lagerprojekten höchste Standards zu berücksichtigen. Die EN 15512:2020+A1:2022 stellt somit ein unverzichtbares Dokument für Ingenieure und Architekten dar, die mit der Konstruktion von Lagerhäusern und Regalsystemen beschäftigt sind. Ihre detaillierten Vorgaben fördern nicht nur die Sicherheit, sondern auch die Funktionalität und Effizienz von Lagerhaltungsstrategien.

EN 15512:2020+A1:2022 표준은 조정 가능한 팔레트 랙 시스템의 구조 설계를 위한 원칙을 규정하고 있으며, 이 표준은 주로 고정 하중을 받는 단위 적재물을 저장하기 위해 제작된 강철 구성 요소로 된 모든 유형의 조정 가능한 빔 팔레트 랙 시스템에 적용됩니다. 이 표준의 강점 중 하나는 비보강 및 보강 시스템 모두를 포함하고 있다는 점입니다. 따라서 다양한 저장 요구 사항에 대한 포괄적인 내용을 제공하는 것이 특징입니다. 이 문서는 또한 EN 1993 시리즈에 포함되지 않은 경우 클래드 랙 건물의 설계를 위한 지침을 제공합니다. 이는 특정 분야에서의 규모와 복잡도가 증가함에 따라 매우 중요해지는 부분으로, 저장 시스템 설계의 범위를 넓히는 데 기여합니다. 추가적으로, 랙 구성 요소가 주요 구조물로 사용되는 부가 구조물에 대해서도 동일한 요구 사항이 적용됩니다. 그러나 이 문서는 다른 일반적인 유형의 저장 구조에 대해서는 다루지 않고 있습니다. 예를 들어, 이동식 저장 시스템, 드라이브인 및 드라이브 스루 시스템, 팔레트 라이브 저장, 푸시백 시스템, 셔틀 시스템, 한 통로에서 두 개 이상의 크레인이 작동하는 시스템, 그리고 칸틸레버 랙이나 정적 강철 선반 시스템에는 적용되지 않습니다. 이러한 명확한 범위 설정은 사용자가 특정 저장 요구 사항에 맞는 시스템을 선택할 수 있도록 도와줍니다. 특히 지진 지역에 사용되는 조정 가능한 팔레트 랙의 특정 설계에 대해서는 EN 16681과의 병행 사용을 요구하는 점이 강조됩니다. 이는 이러한 지역에서 안정성을 보장하기 위한 필수적인 절차로, 표준의 중요성을 더욱 부각시킵니다. 이러한 특성과 규정들은 EN 15512:2020+A1:2022가 현대의 저장 시스템 설계 및 안전성에 있어 특히 중요한 지침임을 시사합니다.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...