EN 15061:2007

(Main)Safety of machinery - Safety requirements for strip processing line machinery and equipment

Safety of machinery - Safety requirements for strip processing line machinery and equipment

This European Standard defines the health and safety requirements of strip processing lines (see 3.1).

This European Standard deals with all significant hazards, hazardous situations and events relevant for strip processing line machinery and equipment, when used as intended and under conditions foreseen by the manufacturer, but also includes foreseeable faults and malfunctions in case of misuse.

This European Standard specifies the requirements to ensure the safety of persons which are to be considered and met during the design, assembly, transport, commissioning, operation, maintenance and decommissioning of the equipment.

This European Standard applies to:

Strip processing lines for treating metal strip: from take-over point (see 3.6) of the entry section (terminal equipment, see 3.2) through the process (processing and terminal equipment, see 3.3 and 3.2) up to the take-over point of the exit section or interface to other lines (terminal equipment).

Terminal equipment for: Processing and terminal equipment for: Terminal equipment for:

Entry section

Pickling (5.3.5) (1)

Pre-treatment (5.3.6) (1)

Hot dipping (5.3.7) (1)

Electro plating (5.3.8) (1)

Tension levelling/scale breaking (5.3.9) (1)

Organic coating by roll coater (5.3.10) (1)

Chemical post-treating (5.3.11) (1)

Annealing (1), (2)

(1) it may include also terminal equipment according to 5.2

(2) for annealing lines the requirement for related processing equipment (5.3.5 to 5.3.11) is covered by

this standard. The requirements for the furnace of annealing lines are covered by EN 746-1, EN 746-2 and EN 746-3

Exit section

This European Standard does not cover:

Furnaces in accordance with EN 746-1, EN 746-2 and EN 746-3;

Dryers and ovens in accordance with EN 1539;

Coil transporting system before take-over-point at the entry section and after take-over-point at the exit section, e. g., hook conveyors, overhead cranes, fork lift and railway trucks a

Sicherheit von Maschinen - Sicherheitsanforderungen an Bandbehandlungsanlagen und Einrichtungen

Diese Europäische Norm beschreibt die Gesundheits- und Sicherheitsanforderungen an automatisierte Anlagen zur Bandbehandlung (siehe 3.1).

Diese Europäische Norm beschreibt alle signifikanten Gefährdungen, Gefährdungssituationen und -ereignisse für Bandbehandlungsanlagen und Ausrüstung, falls diese unter den vom Hersteller vorgesehenen Bedingungen eingesetzt wird, beinhaltet aber auch vorhersehbare Fehler und Fehlfunktionen bei fehlerhafter Nutzung.

Diese europäische Norm beschreibt die Anforderungen zur Gewährleistung der Sicherheit von Personen, die bei Konstruktion, Montage, Transport, Inbetriebnahme, Betrieb, Wartung und Außerbetriebsetzung der Anlage zu berücksichtigen sind.

Sécurité des machines - Prescriptions de sécurité pour machines et installations de traitement des bandes

La présente Norme européenne définit les prescriptions d’hygiène et de sécurité générales des lignes de traitement des bandes (voir 3.1).

La présente Norme européenne traite tous les phénomènes, situations et événements dangereux significatifs appropriés aux machines et équipements des lignes de traitement des bandes. Lorsqu’ils sont utilisés comme prévus et dans les conditions prévues par le fabricant, mais aussi incluse les défauts et les dysfonctionnements prévisibles.

Le présent document spécifie les prescriptions à satisfaire pour garantir la sécurité des personnes pendant la conception, la construction, le transport, la mise en service, le fonctionnement, la maintenance et la mise hors service de l’équipement.

Varnost strojev - Varnostne zahteve za linijske stroje in opremo za obdelavo (kovinskih) trakov

General Information

- Status

- Withdrawn

- Publication Date

- 31-Oct-2007

- Withdrawal Date

- 25-Nov-2008

- Drafting Committee

- CEN/TC 322/WG 4 - Strip processing lines

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 26-Nov-2008

- Completion Date

- 26-Nov-2008

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 19-Jan-2023

Frequently Asked Questions

EN 15061:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of machinery - Safety requirements for strip processing line machinery and equipment". This standard covers: This European Standard defines the health and safety requirements of strip processing lines (see 3.1). This European Standard deals with all significant hazards, hazardous situations and events relevant for strip processing line machinery and equipment, when used as intended and under conditions foreseen by the manufacturer, but also includes foreseeable faults and malfunctions in case of misuse. This European Standard specifies the requirements to ensure the safety of persons which are to be considered and met during the design, assembly, transport, commissioning, operation, maintenance and decommissioning of the equipment. This European Standard applies to: Strip processing lines for treating metal strip: from take-over point (see 3.6) of the entry section (terminal equipment, see 3.2) through the process (processing and terminal equipment, see 3.3 and 3.2) up to the take-over point of the exit section or interface to other lines (terminal equipment). Terminal equipment for: Processing and terminal equipment for: Terminal equipment for: Entry section Pickling (5.3.5) (1) Pre-treatment (5.3.6) (1) Hot dipping (5.3.7) (1) Electro plating (5.3.8) (1) Tension levelling/scale breaking (5.3.9) (1) Organic coating by roll coater (5.3.10) (1) Chemical post-treating (5.3.11) (1) Annealing (1), (2) (1) it may include also terminal equipment according to 5.2 (2) for annealing lines the requirement for related processing equipment (5.3.5 to 5.3.11) is covered by this standard. The requirements for the furnace of annealing lines are covered by EN 746-1, EN 746-2 and EN 746-3 Exit section This European Standard does not cover: Furnaces in accordance with EN 746-1, EN 746-2 and EN 746-3; Dryers and ovens in accordance with EN 1539; Coil transporting system before take-over-point at the entry section and after take-over-point at the exit section, e. g., hook conveyors, overhead cranes, fork lift and railway trucks a

This European Standard defines the health and safety requirements of strip processing lines (see 3.1). This European Standard deals with all significant hazards, hazardous situations and events relevant for strip processing line machinery and equipment, when used as intended and under conditions foreseen by the manufacturer, but also includes foreseeable faults and malfunctions in case of misuse. This European Standard specifies the requirements to ensure the safety of persons which are to be considered and met during the design, assembly, transport, commissioning, operation, maintenance and decommissioning of the equipment. This European Standard applies to: Strip processing lines for treating metal strip: from take-over point (see 3.6) of the entry section (terminal equipment, see 3.2) through the process (processing and terminal equipment, see 3.3 and 3.2) up to the take-over point of the exit section or interface to other lines (terminal equipment). Terminal equipment for: Processing and terminal equipment for: Terminal equipment for: Entry section Pickling (5.3.5) (1) Pre-treatment (5.3.6) (1) Hot dipping (5.3.7) (1) Electro plating (5.3.8) (1) Tension levelling/scale breaking (5.3.9) (1) Organic coating by roll coater (5.3.10) (1) Chemical post-treating (5.3.11) (1) Annealing (1), (2) (1) it may include also terminal equipment according to 5.2 (2) for annealing lines the requirement for related processing equipment (5.3.5 to 5.3.11) is covered by this standard. The requirements for the furnace of annealing lines are covered by EN 746-1, EN 746-2 and EN 746-3 Exit section This European Standard does not cover: Furnaces in accordance with EN 746-1, EN 746-2 and EN 746-3; Dryers and ovens in accordance with EN 1539; Coil transporting system before take-over-point at the entry section and after take-over-point at the exit section, e. g., hook conveyors, overhead cranes, fork lift and railway trucks a

EN 15061:2007 is classified under the following ICS (International Classification for Standards) categories: 77.180 - Equipment for the metallurgical industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15061:2007 has the following relationships with other standards: It is inter standard links to EN 15061:2007+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15061:2007 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 15061:2007 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Varnost strojev - Varnostne zahteve za linijske stroje in opremo za obdelavo (kovinskih) trakovSicherheit von Maschinen - Sicherheitsanforderungen an Bandbehandlungsanlagen und EinrichtungenSécurité des machines - Prescriptions de sécurité pour machines et installations de traitement des bandesSafety of machinery - Safety requirements for strip processing line machinery and equipment77.180Oprema za metalurško industrijoEquipment for the metallurgical industry13.110Varnost strojevSafety of machineryICS:Ta slovenski standard je istoveten z:EN 15061:2007SIST EN 15061:2008en,fr01-april-2008SIST EN 15061:2008SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15061November 2007ICS 77.180 English VersionSafety of machinery - Safety requirements for strip processingline machinery and equipmentSécurité des machines - Prescriptions de sécurité pourmachines et installations de traitement des bandesSicherheit von Maschinen - Sicherheitsanforderungen anBandbehandlungsanlagen und EinrichtungenThis European Standard was approved by CEN on 23 September 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15061:2007: ESIST EN 15061:2008

Safety requirements and/or measures for electrical equipment.72 A.1 Foreword.72 A.2 Special requirements for controls.72 A.3 Special requirements for shut-down equipment.73 A.3.1 Stop functions/emergency stop functions.73 A.3.2 Specific hazards at mechanical equipment.73 A.3.3 Selection of stop functions.73 A.3.4 Emergency stop areas.74 A.3.5 Stop functions.74 Annex B (normative)

Noise test code.76 B.1 Introduction.76 B.2 Determination of A-weighted sound power level.76 B.3 Determination of A-weighted emission sound pressure levels at work stations.77 B.3.1 Determination of the A-weighted emission sound pressure levels at specified measuring points.77 B.3.2 Determination of A-weighted emission sound pressure levels at work stations.77 B.4 Measurement uncertainty.77 B.5 Operating conditions.77 B.6 Information to be recorded and reported.78 B.7 Declaration and verification of noise emission values.78 Annex C (informative)

Example for manufacturer's safety instructions for maintenance at strip processing lines.80 C.1 Hazards caused by a lack of instructions.80 C.2 Hazards caused by visual or audible checks at machinery in motion (see 5.1.4 for access to danger zones).80 C.3 Hazards caused by unintentional movements during maintenance.80 C.4 Hazards at work during standstill with safeguards disabled.81 C.5 Hazards arising from work with hazardous substances.81 C.6 Hazards arising from plant re-start.81 Annex D (informative)

Exemplary solutions.82 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC.88 Bibliography.89

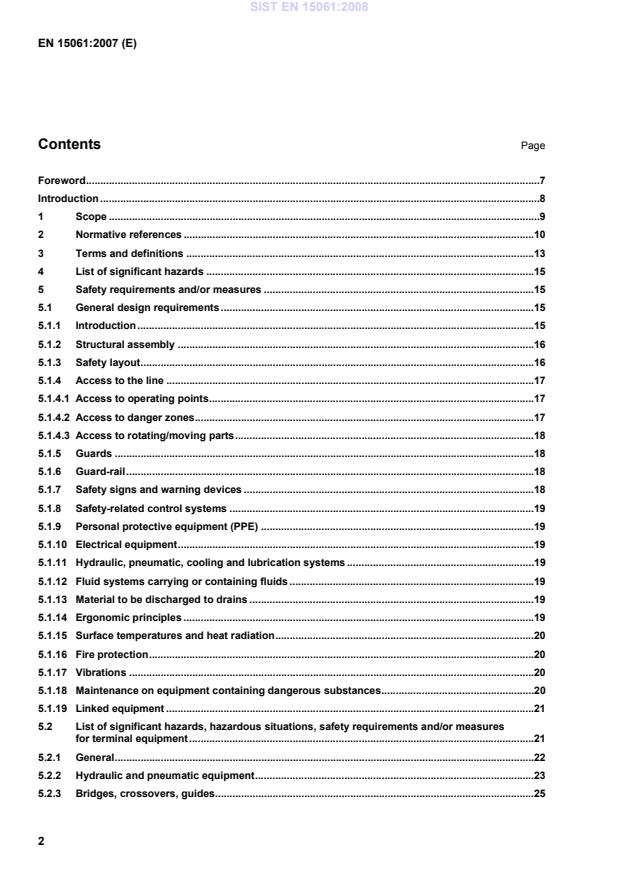

Tables Table 1 — List of significant hazards, hazardous situations, safety requirements and/or measures for terminal equipment.22 Table 2 — List of significant hazards, hazardous situations, safety requirements and/or measures for processing equipment.39 Table 3 — Noise sources of strip processing lines and exemplary noise reduction measures.67 Table A.1 — Stop functions.74 Table B.1 — Example of declared dual-number noise emission values for work stations and specified measuring points.79

This European Standard applies to: Strip processing lines for treating metal strip: from take-over point (see 3.6) of the entry section (terminal equipment, see 3.2) through the process (processing and terminal equipment, see 3.3 and 3.2) up to the take-over point of the exit section or interface to other lines (terminal equipment). Terminal equipment for: Processing and terminal equipment for: Terminal equipment for: Entry section

Pickling (5.3.5) (1)

Pre-treatment (5.3.6) (1)

Hot dipping (5.3.7) (1)

Electro plating (5.3.8) (1)

Tension levelling/scale breaking (5.3.9) (1)

Organic coating by roll coater (5.3.10) (1)

Chemical post-treating (5.3.11) (1) Annealing (1), (2) (1) it may include also terminal equipment according to 5.2 (2) for annealing lines the requirement for related processing equipment (5.3.5 to 5.3.11) is covered by this standard. The requirements for the furnace of annealing lines are covered by EN 746-1, EN 746-2 and EN 746-3

Exit section

This European Standard does not cover: Furnaces in accordance with EN 746-1, EN 746-2 and EN 746-3; Dryers and ovens in accordance with EN 1539; Coil transporting system before take-over-point at the entry section and after take-over-point at the exit section, e. g., hook conveyors, overhead cranes, fork lift and railway trucks and other vehicles; Storage equipment for coils; Rolling mill stands (i. e., skin pass and reduction stands) according to prEN 15094; SIST EN 15061:2008

EN 13480-4, Metallic industrial piping — Part 4: Fabrication and installation EN 13480-5, Metallic industrial piping — Part 5: Inspection and testing EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General requirements (IEC 60204-1:2005, modified) prEN 60825-1, Safety of laser products — Part 1: Equipment classification and requirements EN 60825-4, Safety of laser products - Part 4: Laser guards (IEC 60825-4:2006)

1) Will be replaced by prEN ISO 14121-1. 2 Attention, see 5.1.11 SIST EN 15061:2008

EN ISO 11064-6, Ergonomic design of control centres - Part 6: Environmental requirements for control centres (ISO 11064-6:2005) EN ISO 11064-7, Ergonomic design of control centres - Part 7: Principles for the evaluation of control centres (ISO 11064-7:2006)

EN ISO 11202, Acoustics - Noise emitted by machinery and equipment - Measurement of emission sound pressure levels at a work station and at other specified positions - Survey method in situ (ISO 11202:1995) EN ISO 11688-1, Acoustics - Recommended practice for the design of low-noise machinery and equipment - Part 1: Planning (ISO/TR 11688-1:1995) EN ISO 12100-1:2003, Safety of machinery - Basic concepts, general principles for design - Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2:2003, Safety of machinery - Basic concepts, general principles for design - Part 2: Technical principles (ISO 12100-2:2003) EN ISO 13732-1, Ergonomics of the thermal environment - Methods for the assessment of human responses to contact with surfaces - Part 1: Hot surfaces (ISO 13732-1:2006)

3) To be amended by EN 61496-1/prA1 (2006-06). SIST EN 15061:2008

EN ISO 14122-1, Safety of machinery - Permanent means of access to machinery - Part 1: Choice of fixed means of access between two levels (ISO 14122-1:2001) EN ISO 14122-2, Safety of machinery - Permanent means of access to machinery - Part 2: Working platforms and walkways (ISO 14122-2:2001) EN ISO 14122-3, Safety of machinery - Permanent means of access to machinery - Part 3: Stairs, stepladders and guard-rails (ISO 14122-3:2001) EN ISO 14122-4, Safety of machinery - Permanent means of access to machinery - Part 4: Fixed ladders (ISO 14122-4:2004) EN ISO 15004-1, Ophthalmic instruments - Fundamental requirements and test methods - Part 1: General requirements applicable to all ophthalmic instruments (ISO 15004-1:2006) ISO 3864-1, Graphical symbols — Safety colours and safety signs — Part 1: Design principles for safety signs in workplaces and public areas ISO 7000, Graphical symbols for use on equipment — Index and synopsis IEC 61496-2, Safety of machinery — Electro-sensitive protective equipment — Part 2: Particular requirements for equipment using active opto-electronic protective devices (AOPDs) CLC/R 044-001:1999, Safety of machinery — Guidance and recommendations for the avoidance of hazards due to static electricity 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN ISO 12100-1:2003 and the following apply. NOTE Definitions used in EN and ISO standards referred to in this document are also valid for this document. 3.1 strip processing line interconnection of equipment described in 3.2 and 3.3 in which several machines or stages are linked 3.2 terminal equipment equipment for moving, guiding, connecting, dividing and trimming the metal strip, coil handling equipment and related auxiliary equipment like hydraulic and pneumatic equipment 3.3 processing equipment equipment for treating the surface and/or modifying the product properties 3.4 plating section various number of electroplating cells in the process section of an electro processing line NOTE E. g., see Figure D.7. SIST EN 15061:2008

...

La norme EN 15061:2007 définit les exigences de santé et de sécurité pour les lignes de traitement de bandes métalliques, offrant ainsi un cadre essentiel pour la sécurité des machines dans ce secteur. Son champ d'application est particulièrement pertinent, car il aborde toutes les situations et événements dangereux significatifs liés à l'utilisation de machines et équipements de lignes de traitement de bandes, tant dans les conditions prévues par le fabricant que dans le cadre d'une utilisation incorrecte anticipée. L'un des points forts de cette norme est sa capacité à couvrir une large gamme d'équipements utilisés dans le traitement des bandes métalliques. En précisant les exigences de sécurité pertinentes lors de la conception, de l'assemblage, du transport, de la mise en service, de l'exploitation, de l'entretien et du déclassement des équipements, la norme garantit une approche complète de la sécurité des personnes impliquées dans ces processus. La norme EN 15061:2007 s'applique aux lignes de traitement de bandes, y compris les équipements terminaux pour diverses opérations telles que le pickling, le prétraitement, le galvanisage, et d'autres traitements spécialisés comme l'électrodéposition et le revêtement organique. Cela renforce sa pertinence, car elle inclut des aspects essentiels de la transformation de métaux qui doivent respecter des normes de sécurité strictes. En se concentrant sur la sécurité des machines, cette norme joue un rôle crucial dans la prévention des accidents sur le lieu de travail. Elle permet non seulement de protéger les travailleurs contre des situations dangereuses, mais aussi de promouvoir des pratiques de fonctionnement sécurisées dans l'industrie, ce qui est d'une importance capitale dans le contexte actuel des normes de sécurité et de santé. Cependant, il est à noter que la norme n'inclut pas certains équipements tels que les fours, les séchoirs et les systèmes de transport de bobines après le premier point de prise de l'entrée ou avant le point de prise de la section de sortie, ce qui peut être considéré comme une limitation. Malgré cela, la norme reste une ressource inestimable pour garantir la conformité de la machinerie aux exigences de sécurité. En conclusion, la norme EN 15061:2007 pour la sécurité des machines dans les lignes de traitement de bandes métalliques est une référence incontournable, offrant des directives claires et complètes qui assurent la sécurité des personnes en interaction avec ces machines et contribuent à des opérations industrielles sûres et efficaces.

EN 15061:2007 표준은 기계 안전 및 안전 요구사항을 규정한 유럽 표준으로, 스트립 가공 라인에 특화된 기계 및 장비의 건강 및 안전 요구 사항을 정의합니다. 이 표준은 스트립 가공 라인에서 발생할 수 있는 모든 중요한 위험과 위험 상황을 다루며, 제조자가 의도한 대로 사용될 때와 예측 가능한 오작동이 발생할 경우까지 포함하고 있습니다. 이 표준의 강점 중 하나는 설계, 조립, 운송, 설치, 운영, 유지보수 및 폐기 과정에서 사람의 안전을 보장하기 위해 고려해야 할 요구 사항을 명확하게 제시한다는 점입니다. 이는 사용자 안전성을 높이는 데 매우 중요합니다. 특히, 금속 스트립 처리에 필요한 전체적인 과정과 장비를 포함하여, 다양한 접점에서 발생할 수 있는 위험이 체계적으로 관리될 수 있도록 합니다. EN 15061:2007은 금속 스트립의 가공을 위한 장비에 관련된 구체적인 요구 사항을 명시하고 있어, 사용자가 직면할 수 있는 실제 위험들을 사전에 예방할 수 있는 장점을 제공합니다. 스트립 가공 라인의 입구 섹션에서부터 출구 섹션에 이르기까지 모든 단계를 포괄적으로 다루며, 화학 후 처리, 열처리 등의 다양한 처리 방식도 포함하여 다각적인 위험 요소를 관리합니다. 더불어, 이 표준은 EN 746-1, EN 746-2 및 EN 746-3에서 규정된 용광로와 같은 특정 장비를 제외하는 것에 따른 명확한 경계를 설정하고 있습니다. 이는 사용자가 해당 장비의 적용 가능성과 안전 요구 사항을 명확히 이해할 수 있도록 도와줍니다. 결론적으로, EN 15061:2007 표준은 기계 안전성과 관련된 중요한 요구 사항을 체계적으로 정리해 놓아 스트립 가공 라인에서의 안전성을 한층 더 높일 수 있는 필수적인 문서로 자리잡고 있습니다.

EN 15061:2007は、ストリップ加工ラインの機械および設備に関する安全要求事項を明確に定義した欧州標準であり、その範囲は非常に広いです。この標準は、ストリップ加工ラインの使用に関連するすべての重要な危険、有害な状況、イベントを網羅しており、製造者が想定した条件で意図通りに使用される場合の安全性を確保します。また、使用上の誤りに対する予見可能な故障や不具合についても取り扱っています。 この標準の主な強みは、設計、組立、輸送、運用、保守、廃棄に至るまで、機器の安全性を確保するための要件を明確に規定している点です。特に、金属ストリップを処理するためのストリップ加工ラインのエントリーセクションから出口セクションまでのプロセスを包括しています。具体的には、酸洗いや前処理、加熱浸漬、電気めっき、張力平準化、スケール破壊、有機コーティング、化学後処理など、さまざまな終端装置に対応しています。 さらに、EN 15061:2007は、熔炉や乾燥機、コイル輸送システムなど、適用外となる設備についても明記しています。この明確さが、ユーザーがどの要件に従うべきかを理解する上での助けとなり、機器の安全性を高めるための重要なガイドラインとして機能しています。 この標準の関連性は、高いレベルの安全性を求める産業において特に重要です。ストリップ加工ラインを使用する企業は、この安全要求事項を遵守することで、従業員や作業環境の安全を守ることができます。したがって、EN 15061:2007は、ストリップ加工ラインの運用における不可欠な資源であると言えるでしょう。

The standard EN 15061:2007 titled "Safety of machinery - Safety requirements for strip processing line machinery and equipment" provides critical guidelines that ensure the health and safety of personnel interacting with strip processing lines. With its comprehensive scope, this European Standard meticulously outlines safety requirements for various stages of a strip processing line, which includes machinery used for treating metal strips from the entry point to the exit section. One of the key strengths of this standard is its systematic approach to identifying and addressing significant hazards associated with strip processing line machinery. By considering all potentially hazardous situations and events during the design, assembly, operation, and maintenance of equipment, the standard seeks to preemptively mitigate risks. This proactive stance enhances the overall safety of the equipment and promotes a safer working environment. The EN 15061:2007 standard is particularly relevant for manufacturers and operators of strip processing lines, as it provides clear requirements that must be followed to maintain compliance and ensure safety. The inclusion of considerations for foreseeable faults and malfunctions reinforces its practical applicability under various scenarios, including potential misuse of the machinery. This feature makes the standard a vital reference for risk assessments and safety evaluations in industrial settings. Moreover, the standard delineates its applicability to substantial processing equipment including pickling, pre-treatment, hot dipping, electroplating, tension leveling, and chemical post-treating. By specifying the terminal equipment across different sections of the processing line, the standard fosters consistency in safety practices throughout the manufacturing process. However, it is essential to note the boundaries of this standard, as it does not cover furnaces or drying ovens which are regulated under specific existing standards (EN 746 series and EN 1539). This delineation helps avoid overlap and confusion regarding compliance and safety measures required for different types of machinery. In conclusion, EN 15061:2007 stands out as a fundamental document for enhancing safety in the equipment used within strip processing lines. Its thorough examination of health and safety requirements, along with its comprehensive scope, ensures that operators are well-equipped to address potential hazards, ultimately driving improvements in safety standards across the industry.

Die Norm EN 15061:2007 definiert die Sicherheitsanforderungen für Maschinen und Ausrüstungen von Walzbetrieben. Durch ihre umfassende Betrachtung deckt sie alle signifikanten Gefahren und risikobehafteten Situationen ab, die im Zusammenhang mit der Nutzung von Walzlinien entstehen können. Ein zentrales Merkmal dieser Norm ist die präzise Definition des Anwendungsbereichs, der sich auf die gesamte Prozesskette von der Übernahme am Eingangsbereich bis zur Übergabe am Ausgangsbereich erstreckt. Besonders hervorzuheben ist die detaillierte Behandlung von Gefahren für Personen, die während des gesamten Lebenszyklus der Maschinen berücksichtigt werden müssen: von der Planung über die Montage bis hin zu Betrieb, Wartung und Außerbetriebnahme. Dies stellt sicher, dass die Sicherheit von Mitarbeitern an oberster Stelle steht und somit ein verantwortungsvoller und sicherer Umgang mit der Technologie gefördert wird. Die Norm ist sowohl für die Verarbeitung von Metallstreifen als auch für die relevante Terminalausrüstung wie Beiz-, Vorbehandlungs- und Warmtauchanlagen anwendbar. Ihre Relevanz zeigt sich in der Berücksichtigung von voraussehbaren Fehlfunktionen oder Missbrauchsszenarien, was die Flexibilität und Anwendbarkeit in realistischen Betriebsumgebungen anhebt. Ein weiterer klarer Vorteil der EN 15061:2007 ist die Anforderung, dass Sicherheitsvorkehrungen während der Auslegung und des Betriebs stets berücksichtigt werden müssen. Dadurch wird nicht nur der Schutz der Bediener verbessert, sondern auch die Langlebigkeit und Effizienz der Maschinen gefördert. Wichtig ist auch, dass die Norm bestimmte Ausnahmen klar definiert – wie beispielsweise für Öfen, die unter anderen Normen wie EN 746-1 geregelt sind. Dies ermöglicht eine klarere Struktur und hilft Anwendern, sich in den jeweiligen technischen Anforderungen besser zurechtzufinden. Insgesamt zeigt die EN 15061:2007 durch ihre umfassende und detaillierte Herangehensweise, wie wichtig Sicherheit im Bereich der Maschinenbaukunst ist. Die Norm leistet einen entscheidenden Beitrag zur Gewährleistung einer sicheren und leistungsfähigen Arbeitsumgebung innerhalb der Industrie der Walzbetriebe.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...