ISO/DIS 8466-1

(Main)Water quality -- Calibration and evaluation of analytical methods

Water quality -- Calibration and evaluation of analytical methods

Qualité de l'eau -- Étalonnage et évaluation des méthodes d'analyse

General Information

RELATIONS

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 8466-1

ISO/TC 147/SC 2 Secretariat: DIN

Voting begins on: Voting terminates on:

2020-10-28 2021-01-20

Water quality — Calibration and evaluation of analytical

methods —

Part 1:

Linear calibration function

Qualité de l'eau — Étalonnage et évaluation des méthodes d'analyse —

Partie 1: Fonction linéare d'étalonnage

ICS: 13.060.01

THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

This document is circulated as received from the committee secretariat.

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 8466-1:2020(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2020

---------------------- Page: 1 ----------------------

ISO/DIS 8466-1:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 8466-1:2020(E)

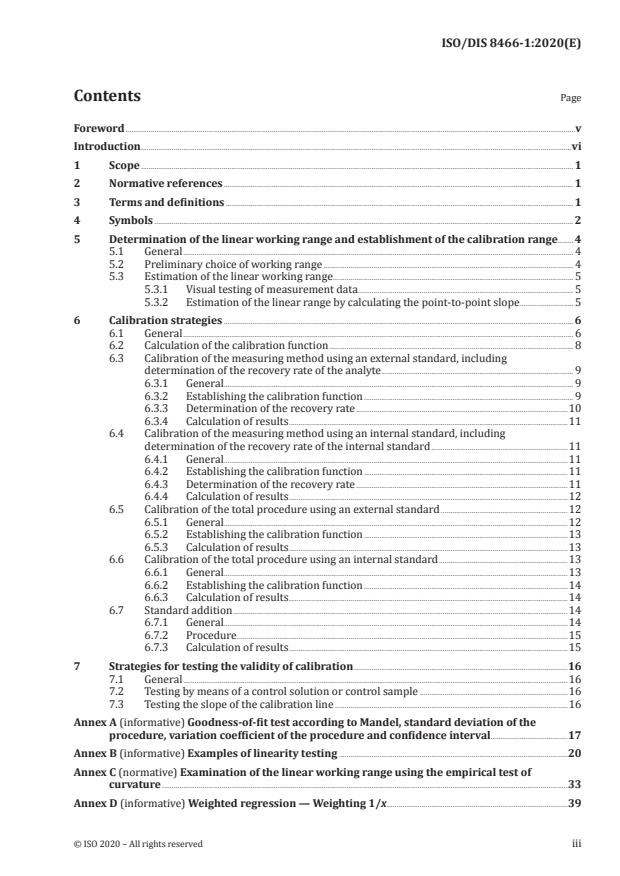

Contents Page

Foreword ..........................................................................................................................................................................................................................................v

Introduction ................................................................................................................................................................................................................................vi

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 Symbols .......................................................................................................................................................................................................................... 2

5 Determination of the linear working range and establishment of the calibration range ........4

5.1 General ........................................................................................................................................................................................................... 4

5.2 Preliminary choice of working range .................................................................................................................................. 4

5.3 Estimation of the linear working range ............................................................................................................................. 5

5.3.1 Visual testing of measurement data ................................................................................................................ 5

5.3.2 Estimation of the linear range by calculating the point-to-point slope ............................ 5

6 Calibration strategies ...................................................................................................................................................................................... 6

6.1 General ........................................................................................................................................................................................................... 6

6.2 Calculation of the calibration function ............................................................................................................................... 8

6.3 Calibration of the measuring method using an external standard, includingdetermination of the recovery rate of the analyte .................................................................................................... 9

6.3.1 General...................................................................................................................................................................................... 9

6.3.2 Establishing the calibration function ............................................................................................................. 9

6.3.3 Determination of the recovery rate ..............................................................................................................10

6.3.4 Calculation of results .................................................................................................................................................11

6.4 Calibration of the measuring method using an internal standard, includingdetermination of the recovery rate of the internal standard .......................................................................11

6.4.1 General...................................................................................................................................................................................11

6.4.2 Establishing the calibration function ..........................................................................................................11

6.4.3 Determination of the recovery rate ..............................................................................................................11

6.4.4 Calculation of results .................................................................................................................................................12

6.5 Calibration of the total procedure using an external standard ..................................................................12

6.5.1 General...................................................................................................................................................................................12

6.5.2 Establishing the calibration function ..........................................................................................................13

6.5.3 Calculation of results .................................................................................................................................................13

6.6 Calibration of the total procedure using an internal standard ...................................................................13

6.6.1 General...................................................................................................................................................................................13

6.6.2 Establishing the calibration function ..........................................................................................................14

6.6.3 Calculation of results .................................................................................................................................................14

6.7 Standard addition ..............................................................................................................................................................................14

6.7.1 General...................................................................................................................................................................................14

6.7.2 Procedure ............................................................................................................................................................................15

6.7.3 Calculation of results .................................................................................................................................................15

7 Strategies for testing the validity of calibration ...............................................................................................................16

7.1 General ........................................................................................................................................................................................................16

7.2 Testing by means of a control solution or control sample .............................................................................16

7.3 Testing the slope of the calibration line .........................................................................................................................16

Annex A (informative) Goodness-of-fit test according to Mandel, standard deviation of the

procedure, variation coefficient of the procedure and confidence interval ........................................17

Annex B (informative) Examples of linearity testing .......................................................................................................................20

Annex C (normative) Examination of the linear working range using the empirical test of

curvature ...................................................................................................................................................................................................................33

Annex D (informative) Weighted regression — Weighting 1/x ..............................................................................................39

© ISO 2020 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 8466-1:2020(E)

Bibliography .............................................................................................................................................................................................................................41

iv © ISO 2020 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 8466-1:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 147, Water quality, Subcommittee SC 2,

Physical, chemical and biochemical methods.This second edition cancels and replaces the first edition (ISO 8466-1:1990), which has been technically

revised.The main changes compared to the previous edition are as follows:

— the title has been modified;

— the scope of the document is the calibration for routine analysis;

— calculation of performance characteristics has been moved to the informative Annex A;

— the calibration range has been extended to several decadeorders of magnitudes;— the verification of the homogeneity of variances has been deleted;

— the linearity test has been modified;

— various calibration strategies are described;

— the document has been editorially revised.

A list of all parts in the ISO 8466 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.© ISO 2020 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/DIS 8466-1:2020(E)

Introduction

Calibration is a prerequisite for the quantification of analytes by means of physicochemical and

chemical methods. In most cases, simple linear regression is applied because many measuring methods

show a linear relationship between the indicated value and the sample content.Since the publication of ISO 8466-1 in 1990, a huge progress has been made in the field of instrumental

analysis, a consequence of which is that various calibration strategies have been developed in order to

make best use of the equipment. The calibration range of many analytical methods was constrained to

a maximum of one order of magnitude by the theoretical statistical requirement to only apply simple

linear regression if homogeneity of variances exists across the selected working range. Due to the

estimation of measurement uncertainty by calculation of the confidence interval in ISO 8466-1:1990, it

had been necessary to conform to the required homogeneity of variances. Meanwhile, other methods for

the estimation of measurement uncertainty that are independent of calibration have been established

(e.g. ISO 11352).Calibration is always done in two steps. The first step comprises the determination of the linear

range, the second step is the calculation of the calibration function. The calibration strategies that are

described in this document enable the analyst to individually define the calibration effort according

to specified requirements. The method that is described in ISO 8466-1:1990 remains part of the

informative annex since it can still be useful for specific purposes (e.g. method validation).

vi © ISO 2020 – All rights reserved---------------------- Page: 6 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 8466-1:2020(E)

Water quality — Calibration and evaluation of analytical

methods —

Part 1:

Linear calibration function

1 Scope

This document specifies various calibration strategies for physicochemical and chemical analytical

methods and specifies the calculation of analytical results.It defines the general context for linear calibration so that individual standards dealing with analytical

methods for the examination of water quality can make reference to it.2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 11352, Water quality — Estimation of measurement uncertainty based on validation and quality

control data3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at http:// www .electropedia .org/

3.1

working range

interval, determined by calibration, between the highest and the lowest content, where the lowest

possible limit of the working range is the limit of quantification of the analytical method

3.2one-point calibration

calibration between the origin and the indicated value corresponding to the content in the

calibration sample3.3

two-point calibration

calibration using two calibration samples with different contents at the upper and at the lower working

range limit© ISO 2020 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO/DIS 8466-1:2020(E)

3.4

indicated value

quantity value provided by a measuring instrument or a measuring system

Note 1 to entry: In accordance with definition 4.1 “indication” of ISO/IEC Guide 99 [6].

3.5content

general term for the quantitative expression of the concentration or fraction of a substance in or of a

substance mixtureNote 1 to entry: For example, it is the generic term for mass concentration, molar concentration, mass fraction.

3.6total procedure

analytical method comprising all steps from sample pretreatment to the report of results

3.7calibration solution

standard solution without a matrix

3.8

calibration sample

standard solution with a matrix

3.9

measurement procedure

comprises all details of a measurement including all calculations for obtaining the measurement result

3.10responsivity

input–output gain of a detector system, i.e. indicated value divided by the corresponding content in the

calibration sampleNote 1 to entry: For a system that responds linearly to its input, there is a unique responsivity. For nonlinear

systems, the responsivity is the local slope.4 Symbols

A recovery rate for the sample

A recovery rate of the internal standard

a intercept of the calibration line or the regression line for standard addition

b slope of the calibration line or the regression line for standard addition or the coefficient of

the linear term of the second-order calibration functionb point-to-point slope i

b median of the slopes b

m i

c regression coefficient of the quadratic term of the second-order calibration function

F factor (taking into account sample preparation, e.g. enrichment factor)f conversion factor (e.g. 100 for expression in %)

2 © ISO 2020 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/DIS 8466-1:2020(E)

f or f degree of freedom

1 2

i index of the calibration solutions (1, 2, …, N)

m number of replicate measurements per spiking level for standard addition

N number of calibration solutions

n number of spiking levels for the method of standard addition (including unspiked sample)

P confidence levelR responsivity

R responsivity threshold

R responsivity median

V volume of the spiking solution i

ssi

V volume of the measurement solution

V volume of the sample

V volume of the sub-samples

x analyte content

mean value of the contents x

x content of the spiked sample

x content of the spiking solution

x analyte content in the calibration solution

x analyte content in the spiked calibration sample

x analyte content in the sample after calibration of the total procedure

x content of the internal standard I in the calibration solution

x content of the internal standard I in the calibration sample

Ieg

x content of the internal standard I in the sample

x measured content of the internal standard I in the measurement solution

x analyte content in the calibration solution i

x analyte content in the measurement solution

x analyte content in the original sample

x analyte content in the sample

x content of the spiked sample

x content of the spiking solution

x spiked content in the sample

© ISO 2020 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO/DIS 8466-1:2020(E)

x spiked content in the sub-samples i

y indicated value

mean value of the indicated values y

y indicated value for external calibration

y indicated value for external calibration of the total procedure

y indicated value of the analyte in the sample

y indicated value of the internal standard I for calibration of the measuring method

y indicated value of the internal standard I for calibration of the total procedure

Iegy indicated value of the internal standard I in the sample

y indicated value of the calibration solution i or indicated value of the sub-sample i for standard

additiony indicated value of the (unspiked) sample

Δb difference between the slope b and the median of the slopes b

i m

im−

5 Determination of the linear working range and establishment of the

calibration range

5.1 General

Linearity of the analytical measuring method is tested within the practice-oriented working range in

accordance with the following pattern:First step: Establishment of the preliminary working range.

Prepare and analyse calibration solutions (with or without internal standards, analyte-dependent but

matrix-independent) over one or more orders of magnitude.Second step: Test linearity and establishment of the linear working range.

Calculate the linear calibration function.

5.2 Preliminary choice of working range

Each calibration starts with the selection of a preliminary working range. This is subject to:

— the objective with respect to the practical application.The working range should largely cover a wide application range for the purpose in hand.

— the technically feasible possibilities.The available measuring instruments often allow the choice of a wide linear working range (sometimes

over several orders of magnitude). On the other hand, it is required that the indicated values obtained

near the lower limit of the working range can be at least distinguished from the indicated values of the

procedure blank. A lower limit of the working range is only reasonable if it is greater than or equal to

the limit of quantification of this method. Moreover, dilution and concentration steps are required to be

feasible and accurate.— the linearity of the functional relationship between the indicated values and the contents.

4 © ISO 2020 – All rights reserved---------------------- Page: 10 ----------------------

ISO/DIS 8466-1:2020(E)

5.3 Estimation of the linear working range

For testing the linearity of a working range covering one or more orders of magnitude, the following

procedure which is based on the first-order calibration function has proved to be effective:

Prepare a minimum of five calibration solutions with different contents (x) and determine the

corresponding indicated values (y ). Subsequently, plot both the measuring points and the point-to-

point slopes in a diagram and visually estimate the linear working range (see 6.3.1).

Here, the contents may be equidistant or be based on geometric series (e.g. 1; 2; 4; 8; …) or, when testing

linear working ranges that are expected to be large, such as for ICP-MS, be based on the power of ten.

Multiple measurements increase the reliability of the statement.For many measuring methods showing a linear behaviour over two to five orders of magnitude, a series

of contents (x ) in the form of … 0,1; 0,2; 0,5; 1; 2; 5; 10; 20; 50; 100; … is suitable.

NOTE 1 For the recommended series of contents, the measuring points for the contents are nearly equidistant

on a logarithmic scale. Instead of a series of contents of e.g. [… 0,2; 2; 20; …], the series of contents of [… 0,25; 2,5;

25; …] can also be applied.NOTE 2 Multiple calibration solutions increase the reliability more than multiple determination.

5.3.1 Visual testing of measurement dataTesting using the x/y-diagram:

The measuring points are plotted in a content/indicated value-diagram and the developing of the

measuring points is visually assessed.NOTE 1 When using a spreadsheet programme, the additional presentation of a linear regression function

and a comparing second-order regression function (stating the correlation coefficient or the coefficient of

determination) can be helpful.NOTE 2 Analysis of residuals using a preliminary linear regression may give additional information.

5.3.2 Estimation of the linear range by calculating the point-to-point slope— For estimation of the linear working range calculate section-wise the slope b from the data sets of

each two consecutive measuring points.In case of a linear calibration function, a constant slope can be expected. Since there might be a non-

linear sub-section, the median of the slope values should be used instead of the arithmetic mean value.

In case of a linear working range, the section-wise calculated slopes should scatter around the median.

A non-linear range at the beginning or at the end will be recognised by systematically increasing or

decreasing deviations from the median of the slopes b .— For evaluation, plot the differences (Δb = b − b ) between the slopes b and the median of the

i−m i m islopes b in a diagram.

If the procedure is linear across the selected working range, the differences will be normally distributed

around zero (vary unsystematically around zero). Emerging trends indicate a non-linear relationship

between content and indicated value.If, in addition, a tolerance range with limiting lines above and below the zero-line is entered, then the

working range that is accepted to be linear can be easily estimated. The tolerance range is defined in

accordance with the accuracy requirements for analysis. The linear working range ends (or starts) at

the measuring point (characterized as continuous index) that is just located within the accepted scatter

around the zero-line or from which a systematic trend is recognized.© ISO 2020 – All rights reserved 5

---------------------- Page: 11 ----------------------

ISO/DIS 8466-1:2020(E)

Annex B describes this procedure and gives examples.

NOTE 1 The tolerance range may affect measurement uncertainty.

NOTE 2 Especially in the case of measuring points not being equidistantly distributed, single points can

visually lead to a false estimation of linearity. The limit of the linear working range can be specified more precisely

by adding further measuring points. As an alternative to the estimation of the linear range by determining the

point-to-point slope, Annex C describes the testing of the linear working range by means of the empirical test of

curvature. Both methods lead to the same result.NOTE 3 An Excel spreadsheet for the testing of the linear working range can be downloaded from the website

of the Wasserchemische Gesellschaft — Fachgruppe in der Gesellschaft Deutscher Chemiker (GDCh, en: Water

Chemistry Society — Expert Group of the German Chemical Society). It includes several sample data sets.

6 Calibration strategies6.1 General

The calibration function that has been determined for a substance is only valid for the covered working

range. Moreover, it depends on the operating condition of the measuring instrument and shall be tested

within each series of measurements (see Clause 7). The calibration function is valid as long as the

requirements for the measurement uncertainty are fulfilled.The measurement uncertainty of analytical results comprises contributions from random and

systematic deviations. The determination of the measurement uncertainty using quality assurance

data is described in ISO 11352. Calibration itself contributes to the random and systematic deviations

depending on the number of calibration levels applied and the number of parallel determinations, or to

what extent a correction of matrix-related systematic deviations is done during calibration. Therefore,

more or less complex calibration strategies can be selected according to the required measurement

uncertainty for analysis. In this context, this document does not clearly specify the number of calibration

levels, the number of standard additions or the number of parallel determinations.

For establishing the calibration functions, five modes of operation are described:

a) calibration of the measuring method using an external standard;b) calibration of the measuring method using an internal standard;

c) calibration of the total procedure using an external standard;

d) calibration of the total procedure using an internal standard;

e) calibration according to the method of standard addition.

The following options for working ranges and for the number of calibration levels can be applied:

— for one-point calibration, selection of a content level at the upper working range limit. Blanks shall

be negligible (below the limit of detection);— if blanks are not negligible or are varying, measurement of at least one more content level near the

lower working range limit and exclusion of the origin for the calculation of the calibration function;

— for multi-point calibration, distribution of content levels across the calibration range;

— for one-point and two-point calibration, a minimum of three measurements for each content level.

The lowest content level of the calibration range shall be greate...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.