ISO 15371:2009

(Main)Ships and marine technology — Fire-extinguishing systems for protection of galley cooking equipment

Ships and marine technology — Fire-extinguishing systems for protection of galley cooking equipment

ISO 15371:2009 applies to the design, testing, and operation of pre-engineered fire extinguishing systems to protect the galley hoods, ducts, fryers and other grease laden appliances. Pre-engineered fire-extinguishing system units are also required to comply with requirements for the construction and components performance as applicable to specific types, designs, sizes and arrangements. ISO 15371:2009 also provides minimum requirements for the testing and evaluation of components. A product that contains features, characteristics, components, materials or systems that are new or different from those covered by the requirements in ISO 15371:2009 and that involve a risk of fire, electric shock, or injury to persons, shall be evaluated using the appropriate additional component and end-product testing.

Navires et technologie maritime — Systèmes d'extinction d'incendie des équipements de cuisine

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 15371

Second edition

2009-03-15

Ships and marine technology —

Fire-extinguishing systems for

protection of galley cooking

equipment

Navires et technologie maritime — Systèmes d'extinction d'incendie

des équipements de cuisine

Reference number

©

ISO 2009

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2009 – All rights reserved

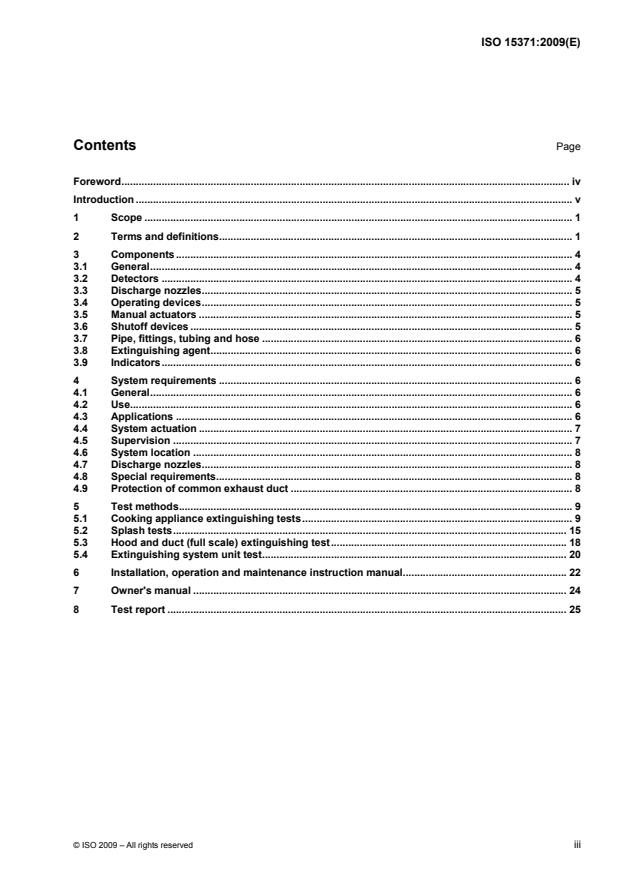

Contents Page

Foreword. iv

Introduction . v

1 Scope . 1

2 Terms and definitions. 1

3 Components . 4

3.1 General. 4

3.2 Detectors . 4

3.3 Discharge nozzles. 5

3.4 Operating devices. 5

3.5 Manual actuators . 5

3.6 Shutoff devices . 5

3.7 Pipe, fittings, tubing and hose . 6

3.8 Extinguishing agent. 6

3.9 Indicators. 6

4 System requirements . 6

4.1 General. 6

4.2 Use. 6

4.3 Applications . 6

4.4 System actuation . 7

4.5 Supervision . 7

4.6 System location . 8

4.7 Discharge nozzles. 8

4.8 Special requirements. 8

4.9 Protection of common exhaust duct . 8

5 Test methods. 9

5.1 Cooking appliance extinguishing tests. 9

5.2 Splash tests. 15

5.3 Hood and duct (full scale) extinguishing test. 18

5.4 Extinguishing system unit test. 20

6 Installation, operation and maintenance instruction manual. 22

7 Owner's manual . 24

8 Test report . 25

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 15371 was prepared by Technical Committee ISO/TC 8, Ships and marine technology, Subcommittee

SC 1, Lifesaving and fire protection.

This second edition cancels and replaces the first edition (ISO 15371:2000). Clause 5 has been technically

revised along with minor editorial corrections throughout this International Standard.

iv © ISO 2009 – All rights reserved

Introduction

While this International Standard provides the marine industry with a means for evaluating the effectiveness of

fire-extinguishing systems for a variety of grease-laden cooking appliances that may be found in a galley, it is

also referenced by the International Maritime Organization (IMO) International Convention for the Safety of

Life at Sea (SOLAS), 1974, as amended, and provides organizations who are party to SOLAS with a means of

ensuring conformance of deep-fat cooking equipment with the fire suppression requirements prescribed in

SOLAS.

INTERNATIONAL STANDARD ISO 15371:2009(E)

Ships and marine technology — Fire-extinguishing systems

for protection of galley cooking equipment

1 Scope

This International Standard applies to the design, testing, and operation of pre-engineered fire extinguishing

systems to protect the galley hoods, ducts, fryers and other grease-laden appliances.

Pre-engineered fire-extinguishing system units are also required to comply with requirements for the

construction and components performance as applicable to specific types, designs, sizes and arrangements.

This International Standard also provides minimum requirements for the testing and evaluation of components.

A product that contains features, characteristics, components, materials or systems that are new or different

from those covered by the requirements in this International Standard and that involve a risk of fire, electric

shock, or injury to persons, shall be evaluated using the appropriate additional component and

end-product testing.

NOTE Only deep-fat cooking equipment, among the types of galley cooking equipment covered by this International

Standard, are required by SOLAS chapter II-2 Regulation 10.6.4 to have fixed fire-extinguishing systems.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

auxiliary equipment

equipment used in conjunction with the extinguishing system

EXAMPLE Auxiliary equipment can be used to shut down power, fuel or ventilation to the hazard area being

protected or to initiate alarm or signalling devices.

2.2

cooking appliance

cooking device that has, or is capable of having, a surface of liquid grease or one in which cooking with

grease is involved

EXAMPLE Deep fat fryer, griddle, range, chain-broiler, electric char-broiler, charcoal broiler, mesquite broiler, gas

radiant char broiler, wok, tilt skillet/braising pan and similar appliances.

NOTE The protected area is limited to the cooking area of the appliance only.

2.3

cooking grease

grease

vegetable shortening incorporating an antifoaming agent

2.4

cylinder/valve assembly

container that incorporates a valve and that provides storage for the extinguishing agent and expellant gas

until the valve is actuated

NOTE For cartridge-operated units, this assembly includes the extinguishing-agent storage container and cartridge

mechanism.

2.5

deep fat fryer

commercially available electric cooking appliance in which cooking greases in depth are used

2.6

discharge nozzle

device that is used to distribute the extinguishing agent over or into a specific area

2.7

discharge rate

ratio of the quantity of the extinguishing agent discharged from a nozzle to the discharge time measured to

within ± 1 s, expressed in kg/s

2.8

discharge time

time interval between the first appearance of the extinguishing agent at the nozzle and the time at which the

discharge becomes predominantly gaseous or ceases

2.9

duct

duct system

continuous enclosed passageway for the transmission of air and cooking vapours

2.10

expellent gas

nitrogen air or other gas used to facilitate the discharge of the extinguishing agent

2.11

extinguishing system unit

identified components that can be assembled into a system for the discharge of an extinguishing agent

through fixed piping and nozzles for the purpose of extinguishing fires

2.12

gas cartridge

container that provides storage for an expellant gas only

2.13

grease filter

component of a grease vapour removal system that deflects the air and vapours passing through it in such a

manner as to result in the grease vapours concentrating, condensing, or both, for the purpose of grease

collection

2.14

hood

device provided as part of an exhaust system to direct and capture grease vapours and exhaust gases from a

cooking appliance

2.15

indicator

mechanical or electrical device that shows when an extinguishing system or one of its critical components is

ready to operate or has already operated

2 © ISO 2009 – All rights reserved

2.16

inspection

visual examination of the system or portion thereof to verify that it appears to be in operating condition and is

free of physical damage

2.17

low quality fatty beef steak

beef steak containing 20 % to 30 % fat or gristle, well marbled and uniform in size

2.18

maintenance

work, including, but not limited to, repair, replacement and service, performed to ensure that the equipment

operates properly

2.19

manual means of actuation

means of system actuation in which a system is discharged by manual means

2.20

manufacturer's installation and maintenance manual

document containing the design, installation and maintenance instructions which is prepared and approved as

a complimentary part of the extinguishing system

2.21

multiple-vat deep fat fryer

multiple electric fryers that are mechanically joined together

NOTE Each vat incorporates a separately controlled heating source.

2.22

operable pressure

pressure developed in a fully charged container conditioned at 21 °C for at least 24 h

2.23

operable pressure range

pressure range corresponding to the pressures in the storage container at the specified minimum and

maximum temperatures for which the extinguishing system is intended to be operable

2.24

operating devices

mechanical, electrical or pneumatic devices involved in the operation of a system

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.