ISO 115:2024

(Main)Unalloyed aluminium ingots for remelting — Classification and composition

Unalloyed aluminium ingots for remelting — Classification and composition

This document defines the requirements for grades of unalloyed aluminium ingots intended for remelting. It specifies the classification and designation applicable to these grades, the conditions in which they are produced, their properties and the marks by which they are identified.

Aluminium non allié en lingots pour refusion — Classification et composition

L'ISO 115:2003 définit les exigences relatives aux nuances d'aluminium non allié en lingots destinés à la refusion. Elle spécifie la classification et la désignation applicables à ces nuances, leurs conditions de production, leurs caractéristiques et leurs marques d'identification.

General Information

Relations

Standards Content (Sample)

International

Standard

ISO 115

Second edition

Unalloyed aluminium ingots for

2024-12

remelting — Classification and

composition

Aluminium non allié en lingots pour refusion — Classification et

composition

Reference number

© ISO 2024

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

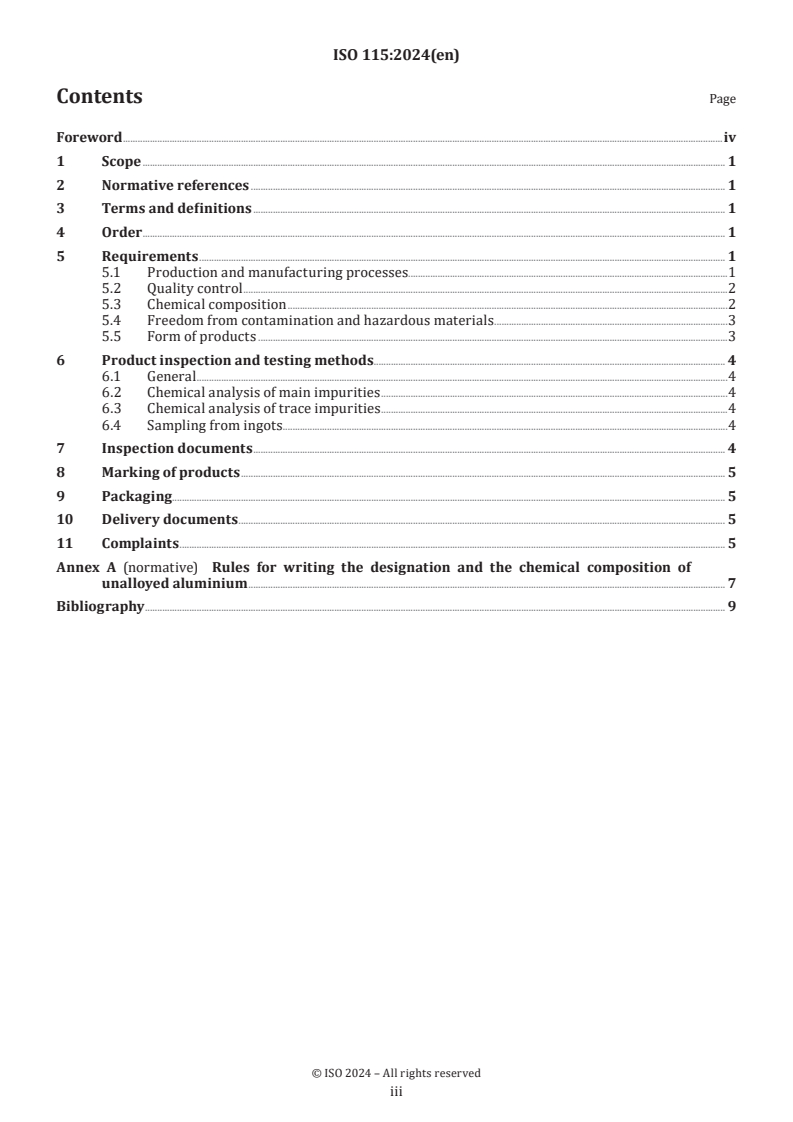

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Order . 1

5 Requirements . 1

5.1 Production and manufacturing processes.1

5.2 Quality control .2

5.3 Chemical composition .2

5.4 Freedom from contamination and hazardous materials .3

5.5 Form of products .3

6 Product inspection and testing methods . 4

6.1 General .4

6.2 Chemical analysis of main impurities .4

6.3 Chemical analysis of trace impurities .4

6.4 Sampling from ingots.4

7 Inspection documents . 4

8 Marking of products . 5

9 Packaging. 5

10 Delivery documents . 5

11 Complaints . 5

Annex A (normative) Rules for writing the designation and the chemical composition of

unalloyed aluminium . 7

Bibliography . 9

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO document should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 79, Light metals and their alloys, Subcommittee

SC 4, Unalloyed (refined) aluminium ingots.

This second edition cancels and replaces the first edition (ISO 115:2003), which has been technically revised.

The main changes are as follows:

— five grades were added to Table 2.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

International Standard ISO 115:2024(en)

Unalloyed aluminium ingots for remelting — Classification

and composition

1 Scope

This document defines the requirements for grades of unalloyed aluminium ingots intended for remelting.

It specifies the classification and designation applicable to these grades, the conditions in which they are

produced, their properties and the marks by which they are identified.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

4 Order

The order, in the form agreed upon between the supplier and the purchaser, shall contain the following

information:

a) designation of the unalloyed aluminium in accordance with this document or the customer code after

agreement between the supplier and the purchaser;

b) specification of the form of the products, including the mass and dimensions of individual ingots and

bundles;

c) quantity: mass, in tonnes (quantity tolerances if required);

d) any requirements for certificates of conformity, test and/or analysis reports or inspection certificates;

e) any additional requirements agreed between the supplier and the purchaser.

5 Requirements

5.1 Production and manufacturing processes

The production and manufacturing processes shall be left to the discretion of the manufacturer.

No obligation shall be placed on the manufacturer to use the same processes for subsequent and similar orders.

5.2 Quality control

The supplier shall be responsible for carrying out all inspection and tests required by this document prior to

shipment of the product. If the purchaser wishes to inspect the product at the supplier's works, the purchaser

shall stipulate this at the time of placing the order.

5.3 Chemical composition

Each grade of unalloyed aluminium, including refined aluminium, with a specified minimum aluminium

content shall be in accordance with the designations and chemical composition given in Table 1.

Each grade of unalloyed aluminium without a specified minimum aluminium content shall be in accordance

with the designations and chemical compositions given in Table 2.

The compositions, except that for aluminium, shown in Table 1 and Table 2 are given in maximum mass

fractions, in per cent.

For the interpretation of the results of chemical analysis, the number representing the result of the

determination of an element content shall be rounded to the same number of decimal places as the

corresponding number in this document.

The writing rules for designations and chemical compositions shall be applied in accordance with Annex A.

If the purchaser requires content limits for elements not specified in this document, these limits shall be

stated on the order, after agreement between the supplier and the purchaser.

Table 1 — Unalloyed aluminium with specified minimum aluminium content — Chemical

composition in maximum mass fractions

Others Al

Designation Si Fe Cu Mn Mg Zn Ti Ga V

each min.

a

Al 99,995 0,002 0 0,002 0 0,002 0 0,001 0,003 0 0,001 0,001 0,002 0,001 0,001 99,995

a

Al 99,990 0,003 0 0,003 0 0,004 0 0,001 0,003 0 0,001 0,001 0,002 0,001 0,001 99,990

a

Al 99,99 0,004 0 0,003 0 0,002 0 0,001 0,001 0 0,004 0,002 0,003 0 0,001 0,001 99,99

a

Al 99,98 0,006 0,006 0,002 0 0,002 0,002 0,004 0,002 0,003 0,001 0,001 99,98

a

Al 99,97 0,008 0,008 0,004 0,003 0,002 0,005 0,002 0,004 0,001 0,001 99,97

a

Al 99,94 0,030 0,030 0,005 0,010 0,010 0,010 0,005 0,02 — 0,010 99,94

a

Al 99,70 0,10 0,20 0,01 — 0,02 0,03 0,02 0,03 0,03 0,03 99,70

a, b

Al 99,7E 0,07 0,20 0,01 0,005 0,02 0,04 — — — 0,03 99,70

a, c

Al 99,6E 0,10 0,30 0,01 0,007 0,02 0,04 — — — 0,03 99,60

a

Cd + Hg + Pb max. 0,009 5; As max. 0,009.

b

B max. 0,04; Cr max. 0,004; Mn + Ti + Cr + V max. 0,020.

c

B max. 0,04; Cr max. 0,005; Mn + Ti + Cr + V max. 0,030.

Table 2 — Unalloyed aluminium without specified minimum aluminium content — Chemical

composition in maximum mass fractions

Others Others

Designation Si Fe Zn Ga V Al

each total

a

P0202A 0,02 0,02 0,02 0,02 0,01 0,01 0,02 Remainder

a

P0304A 0,03 0,04 0,03 0,03 0,01 0,01 0,02 Remainder

a

P0404A 0,04 0,04 0,03 0,03 0,01 0,01 0,03 Remainder

a

P0406A 0,04 0,06 0,03 0,03 0,02 0,02 0,04 Remainder

a

P0506A 0,05 0,06 0,03 0,03 0,02 0,02 0,05 Remainder

a

P0608A 0,06 0,08 0,03 0,03 0,02 0,02 0,05 Remainder

a

P0610A 0,06 0,10 0,03 0,04 0,02 0,02 0,05 Remainder

a

P1020A 0,10 0,20 0,03 0,04 0,03 0,03 0,10 Remainder

a, b

P1020G 0,10 0,20 0,03 0,04 0,03 0,03 0,10 Remainder

a

P1520A 0,15 0,20 0,03 0,04 0,03 0,03 0,10 Remainder

a

P1535A 0,15 0,35 0,03 0,04 0,03 0,03 0,10 Remainder

a

Cd + Hg + Pb max. 0,009 5; As max. 0,009.

b

Mg max. 0,003; Na max. 0,001 0; Li max. 0,000 1.

5.4 Freedom from contamination and hazardous materials

The ingots shall be free from asbestos and other hazardous foreign materials and show no indication of

increased radioactivity.

To a standard agreed between the supplier and the purchaser, the ingots shall be free from a) to c), if they

are harmful in use:

a) visible surface conditions and contamination such as grease, dirt, products of corrosion, dross or any

other foreign bodies including paint, apart from that which is approved for marking purposes;

b) metallic or non-metallic inclusions;

c) gas porosity.

The ingots may have shrinkage holes or cavities which can retain water. Ingots shall therefore be thoroughly

dried and preheated by the purchaser before charging to a melting furnace, in order to reduce the risk of

vi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.