ISO 4081:2005

(Main)Rubber hoses and tubing for cooling systems for internal-combustion engines — Specification

Rubber hoses and tubing for cooling systems for internal-combustion engines — Specification

ISO 4081:2005 specifies the requirements for straight or pre-formed rubber hoses and tubing for use in pressurized or unpressurized cooling circuits containing 1,2-ethanediol-based coolants in internal-combustion engines for vehicles with an unladen mass of 3,5 t or less. In addition, this specification may also be applied as a classification system to enable original equipment manufacturers (OEMs) to detail a 'line call-out' of tests for specific applications where these are not covered by the main types specified. In this case, the hose or tubing would not carry any marking showing this ISO specification number but may detail the OEM's own identification markings as shown on their part drawings.

Tubes et tuyaux en caoutchouc pour systèmes de refroidissement pour moteurs à combustion interne — Spécifications

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 4081

Second edition

2005-04-15

Rubber hoses and tubing for cooling

systems for internal-combustion

engines — Specification

Tubes et tuyaux en caoutchouc pour systèmes de refroidissement pour

moteurs à combustion interne — Spécifications

Reference number

ISO 4081:2005(E)

©

ISO 2005

---------------------- Page: 1 ----------------------

ISO 4081:2005(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2005

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2005 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 4081:2005(E)

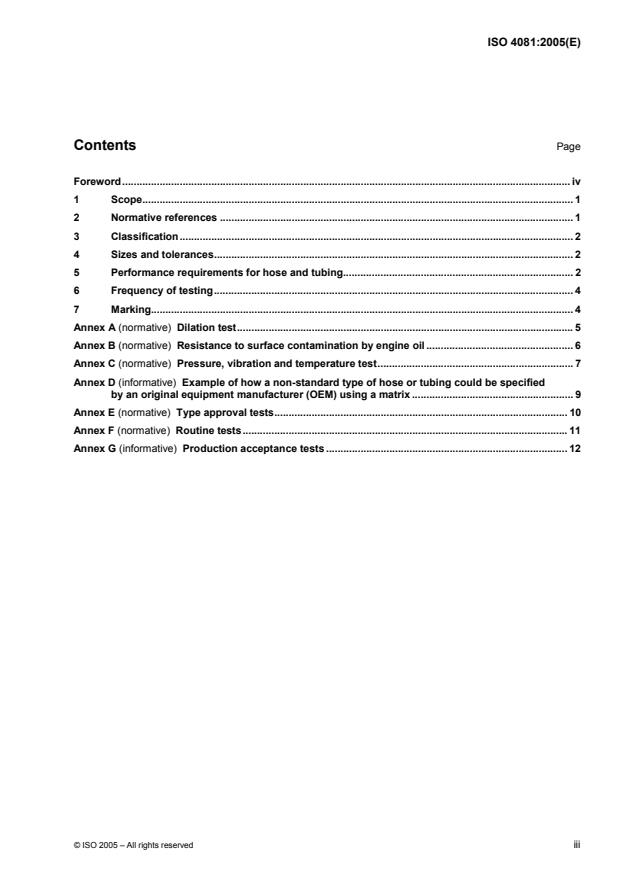

Contents Page

Foreword. iv

1 Scope. 1

2 Normative references. 1

3 Classification. 2

4 Sizes and tolerances. 2

5 Performance requirements for hose and tubing. 2

6 Frequency of testing. 4

7 Marking. 4

Annex A (normative) Dilation test. 5

Annex B (normative) Resistance to surface contamination by engine oil . 6

Annex C (normative) Pressure, vibration and temperature test. 7

Annex D (informative) Example of how a non-standard type of hose or tubing could be specified

by an original equipment manufacturer (OEM) using a matrix . 9

Annex E (normative) Type approval tests. 10

Annex F (normative) Routine tests.11

Annex G (informative) Production acceptance tests . 12

© ISO 2005 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 4081:2005(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 4081 was prepared by Technical Committee ISO/TC 45, Rubber and rubber products, Subcommittee

SC 1, Hoses (rubber and plastics).

This second edition cancels and replaces the first edition (ISO 4081:1987), which has been technically revised.

iv © ISO 2005 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 4081:2005(E)

Rubber hoses and tubing for cooling systems for internal-

combustion engines — Specification

WARNING — Persons using this International Standard should be familiar with normal laboratory

practice. This standard does not purport to address all of the safety problems, if any, associated with

its use. It is the responsibility of the user to establish appropriate safety and health practices and to

ensure compliance with any national regulatory conditions.

1 Scope

This International Standard specifies the requirements for straight or pre-formed rubber hoses and tubing for

use in pressurized or unpressurized cooling circuits containing 1,2-ethanediol-based coolants in internal-

combustion engines for vehicles with an unladen mass (as defined in ISO 1176) of 3,5 t or less. In addition,

this specification may also be applied as a classification system to enable original equipment manufacturers

(OEMs) to detail a “line call-out” of tests for specific applications where these are not covered by the main

types specified (see example in Annex D). In this case, the hose or tubing would not carry any marking

showing this ISO specification number but may detail the OEM's own identification markings as shown on

their part drawings.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 188, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

ISO 1176, Road vehicles — Masses — Vocabulary and codes

ISO 1307, Rubber and plastics hoses for general-purpose industrial applications — Bore diameters and

tolerances, and tolerances on length

ISO 1402, Rubber and plastics hoses and hose assemblies — Hydrostatic testing

ISO 1746, Rubber or plastics hoses and tubing — Bending tests

ISO 1817, Rubber, vulcanized — Determination of the effect of liquids

ISO 4672:1997, Rubber and plastics hoses — Sub-ambient temperature flexibility tests

ISO 6162-1, Hydraulic fluid power — Flange connectors with split or one-piece flange clamps and metric or

inch screws — Part 1: Flange connectors for use at pressures of 3,5 MPa (35 bar) to 35 MPa (350 bar),

DN 13 to DN 127

ISO 7233, Rubber and plastics hoses and hose assemblies — Determination of suction resistance

ISO 7326:1991, Rubber and plastics hoses — Assessment of ozone resistance under static conditions

ISO 8033, Rubber and plastics hoses — Determination of adhesion between components

© ISO 2005 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO 4081:2005(E)

ISO 23529, Rubber — General procedures for preparing and conditioning test pieces for physical test

methods

SAE J20:2004, Coolant System Hoses

SAE J1638, Compression Set of Hoses or Solid Discs

SAE J1684:2000, Test Method for Evaluating the Electrochemical Resistance of Coolant System Hoses and

Materials

3 Classification

The product shall consist of rubber materials with or without an integral reinforcement which may or may not

be pre-formed before final vulcanization. The hoses and tubing may be branched, in which case the method of

attachment of the branch shall be such that the integrity of the hose is maintained when it is tested to this

International Standard. This International Standard does not cover methods of attachment to mounting spigots.

Four types of hose and tubing for specific applications are specified, as follows:

Type 1 = Tubing and hoses for ambient operating temperatures from –40 °C to +100 °C

Type 2 = Tubing and hoses for ambient operating temperatures from –40 °C to +125 °C

Type 3 = Tubing and hoses for ambient operating temperatures from –40 °C to +150 °C

Type 4 = Tubing and hoses for ambient operating temperatures from –40 °C to +175 °C

Wherever economically and technically possible, hoses and tubing shall use in their construction materials

that are capable of being recycled. Also, wherever economically and technically possible, hoses and tubing

shall use in their construction materials that contain post-consumer or post-industrial recyclates.

4 Sizes and tolerances

Bore sizes and tolerances shall be in accordance with ISO 1307. Wall thicknesses shall be sufficient to meet

the requirements of this International Standard.

5 Performance requirements for hose and tubing

Tests shall be selected from the following list for each application of hose or tubing, based on the performance

requirements of the finished product. Type approval tests (as defined in Clause 7) for each hose or tubing type

are given in Annex E.

a) Burst pressure: When determined in accordance with ISO 1402 at standard laboratory temperature as

specified in ISO 23529, the minimum burst pressure shall be:

Tubing: 2 bar (0,2 MPa) for all diameters

Hose: 12 bar (1,2 MPa) for diameters up to and including 18 mm

9 bar (0,9 MPa) for diameters >18 mm up to and including 35 mm

5 bar (0,5 MPa) for diameters >35 mm

2 © ISO 2005 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 4081:2005(E)

b) Adhesion (for all constructions with two or more bonded layers only): When determined by the

appropriate procedure of ISO 8033, the adhesion between each pair of bonded layers shall not be less

than 1,75 kN/m for unaged hoses and not less than 1,25 kN/m for hoses aged as specified

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.