ISO/TS 6084:2022

(Main)Steel and steel products - Vocabulary relating to chemical analysis

Steel and steel products - Vocabulary relating to chemical analysis

This document defines terms relating to methods of the determination of the chemical composition of steel and steel products.

General Information

Overview

ISO/TS 6084:2022, titled "Steel and steel products - Vocabulary relating to chemical analysis," is a comprehensive technical specification published by ISO in June 2022. This document provides standardized terminology related to the chemical composition determination methods of steel and steel products. It serves as an essential reference for professionals in steel manufacturing, quality control, chemical analysis, and metallurgical laboratories, ensuring consistent and unambiguous communication.

The technical specification covers terms for analytical processes, equipment characteristics, sample preparation, and chemical analysis techniques relevant to steel and steel products. This precise vocabulary enables clear interaction among manufacturers, analysts, and researchers involved in steel chemistry.

Key Topics

- Terminology for Steel and Cast Iron Types: Definitions include alloy steel, austenitic steel, ductile iron, malleable iron, non-alloyed steel, and others, outlining their chemical characteristics and structures.

- Chemical Analysis Methods: Terms related to analysis techniques and instruments used for determining chemical composition are clearly defined, supporting accurate reporting and interpretation.

- Sample Preparation and Handling: Clear descriptions of procedures such as grinding, milling, linishing, and sampling phases like primary sample, laboratory sample, and aliquot enhance the reliability of analysis results.

- Analytical Standards and Equipment: The standard elaborates on characteristics and properties of analytical equipment and addresses potential interferences, emphasizing precision in measurements.

- Conceptual Framework: The document organizes terminology to minimize misunderstandings and improve communication within technical and scientific communities.

Applications

ISO/TS 6084:2022 is vital in various domains related to steel and metallurgical industries, including:

- Steel Manufacturing: Facilitates uniform understanding of chemical analysis terms among production engineers and quality professionals, supporting product conformity to specifications.

- Quality Assurance Laboratories: Ensures consistent use of terminology in analytical methods, sample preparation, and results evaluation, improving testing accuracy.

- Research and Development: Enables researchers to describe and interpret chemical composition methods accurately, supporting innovation and material improvements.

- International Trade and Compliance: Promotes synchronized terminology across countries and organizations, easing trade negotiations and regulatory assessments related to steel products.

- Education and Training: Acts as a resource for educating students and technicians on standardized chemical analysis vocabulary in metallurgy.

Related Standards

Professionals using ISO/TS 6084:2022 may also consider these related ISO and international standards for comprehensive guidance in steel analysis and terminology:

- ISO 4948-series: Classification and nomenclature of steels-covers naming systems related to alloy content and heat treatment.

- ISO 15156-2: Materials for use in petroleum and natural gas industries, which includes definitions of iron alloys and their chemical characteristics.

- ISO 945-1: Defines graphite forms in cast irons, essential for interpreting cast iron analysis terms.

- ISO 15193: Addresses sampling methods applicable to analytical samples preparation.

- ASTM A941: Provides related alloy steel definitions widely recognized in steel chemistry.

Summary

ISO/TS 6084:2022 standardizes the vocabulary concerning chemical analysis methods for steel and steel products, offering critical support for accurate communication and quality control in metallurgical processes. By adopting this vocabulary, industries and laboratories improve reliability in chemical composition determination, fostering excellence in steel product manufacturing and testing worldwide.

Keywords: ISO 6084:2022, steel chemical analysis, steel product vocabulary, chemical composition of steel, steel terminology, alloy steel definitions, sample preparation steel, metallurgical analysis standards, steel quality control.

Frequently Asked Questions

ISO/TS 6084:2022 is a technical specification published by the International Organization for Standardization (ISO). Its full title is "Steel and steel products - Vocabulary relating to chemical analysis". This standard covers: This document defines terms relating to methods of the determination of the chemical composition of steel and steel products.

This document defines terms relating to methods of the determination of the chemical composition of steel and steel products.

ISO/TS 6084:2022 is classified under the following ICS (International Classification for Standards) categories: 01.040.77 - Metallurgy (Vocabularies); 77.080.20 - Steels. The ICS classification helps identify the subject area and facilitates finding related standards.

You can purchase ISO/TS 6084:2022 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 6084

First edition

2022-06

Steel and steel products — Vocabulary

relating to chemical analysis

Reference number

© ISO 2022

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

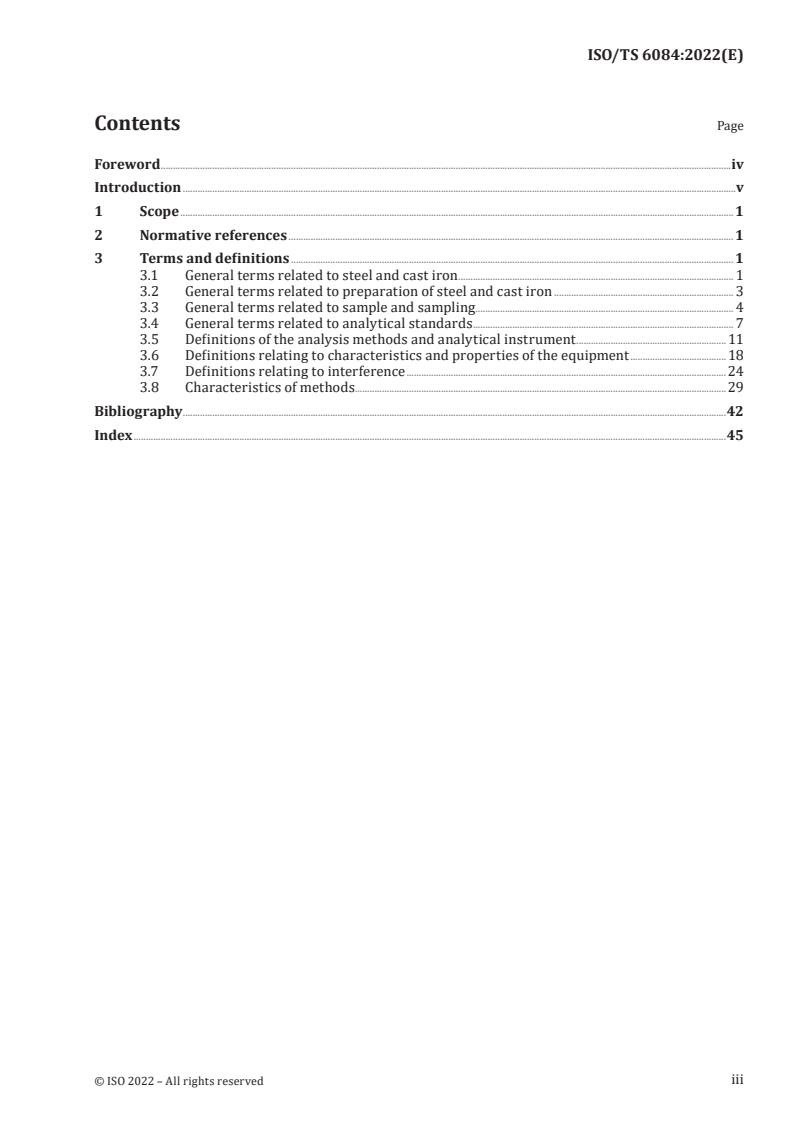

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

3.1 General terms related to steel and cast iron . 1

3.2 General terms related to preparation of steel and cast iron . 3

3.3 General terms related to sample and sampling. 4

3.4 General terms related to analytical standards . 7

3.5 Definitions of the analysis methods and analytical instrument . 11

3.6 Definitions relating to characteristics and properties of the equipment . 18

3.7 Definitions relating to interference . 24

3.8 Characteristics of methods.29

Bibliography .42

Index .45

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 17, Steel, Subcommittee SC 1, Methods of

determination of chemical composition.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

Introduction

To ensure that communication in a particular domain is effective and that difficulties in understanding

are minimized, it is essential that the various participants use the same concepts and concept

representations. Unambiguous communication related to analytical chemistry concepts is crucial given

the implications that can arise from misunderstandings with regard to equipment.

Different levels of scientific and technical knowledge can lead to widely divergent understandings and

assumptions about concepts. The result is poor communication that can lead into an increase of the risk

of accidents and duplication of efforts as different define concepts according to their perspectives.

Conceptual arrangement of terms and definitions is based on concepts systems that show corresponding

relationships analytical chemistry concepts. Such arrangement provides users with a structured view

of the analytical methods and will facilitate common understanding of all related concepts. Besides,

concepts systems and conceptual arrangement of terminological data will be helpful to any kind of user

because it will promote clear, accurate and useful communication.

v

TECHNICAL SPECIFICATION ISO/TS 6084:2022(E)

Steel and steel products — Vocabulary relating to chemical

analysis

1 Scope

This document defines terms relating to methods of the determination of the chemical composition of

steel and steel products.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1 General terms related to steel and cast iron

3.1.1

alloy steel

steel (3.1.17), other than a stainless steel, that conforms to a specification that requires one or more of

the following elements, by mass percent, to have a minimum content equal to or greater than: 0,30 for

aluminum; 0,000 8 for boron; 0,30 for chromium; 0,30 for cobalt; 0,40 for copper; 0,40 for lead; 1,65 for

manganese; 0,08 for molybdenum; 0,30 for nickel; 0,06 for niobium (columbium); 0,60 for silicon; 0,05

for titanium; 0,30 for tungsten (wolfram); 0,10 for vanadium; 0,05 for zirconium; or 0,10 for any other

alloying element, except sulphur, phosphorus, carbon, and nitrogen

[SOURCE: ASTM A941: 2018]

3.1.2

austenitic steel

steel (3.1.17) where the structure consists of austenite (3.1.3) at ambient temperature

Note 1 to entry: Cast austenitic steels can contain up to about 20 % of ferrite (3.1.8).

3.1.3

austenite

solid solution of one or more elements in gamma iron (3.1.19)

3.1.4

boriding

thermochemical treatment of a workpiece to enrich the surface of a workpiece with boron

Note 1 to entry: The medium in which boriding takes place should be specified, e.g. pack boriding, paste boriding,

etc.

3.1.5

cast/heat analysis

chemical analysis determined by the steel producer as being representative of a specific heat of steel

(3.1.17)

Note 1 to entry: Where the analysis reported by the steel producer is not sufficiently complete for conformance

with the heat analysis (3.1.5) requirements of the applicable product specification to be fully assessed, the

manufacturer can complete the assessment of conformance with such heat analysis (3.1.5) requirements by using

a product analysis (3.1.16) for the specified elements that were not reported by the steel producer, provided that

product analysis (3.1.16) tolerances are not applied and the heat analysis (3.1.5) is not altered

[SOURCE: ASTM A941: 2018]

3.1.6

cast iron

alloy of iron, carbon and silicon where the carbon content is approximately more than 2 %

3.1.7

ductile iron

nodular cast iron

cast iron (3.1.6) that has been treated while molten with an element (usually magnesium or cerium)

that spheroidizes the graphite

[SOURCE: ISO 15156-2:2020, 3.5.4]

3.1.8

ferrite

body-centred cubic lattice structure of iron or steel (3.1.17)

3.1.9

forged steel

steel (3.1.17) product obtained by forging and that does not undergo subsequent hot conversion

Note 1 to entry: These products are mainly in the form of circles or squares.

3.1.10

grey cast iron

cast material, mainly iron and carbon based, carbon being present mainly in the form of flake (lamellar)

graphite particles

Note 1 to entry: Grey cast iron is also known as flake graphite cast iron, and less commonly as lamellar graphite

cast iron.

Note 2 to entry: Graphite form, distribution and size are specified in ISO 945-1.

[SOURCE: EN 1561:2011, 3.1]

3.1.11

killed steel

steel (3.1.17) deoxidized to such a level that essentially no reaction occurred between carbon and

oxygen during solidification

[SOURCE: ASTM A941: 2018]

3.1.12

malleable iron

white cast iron (3.1.18) that is thermally treated to convert most or all of the cementite to graphite

(temper carbon)

[SOURCE: ISO 15156-2:2020, 3.5.3]

3.1.13

martensite

(phase) formed in carbon containing steels (3.1.17) by the cooling of austenite (3.1.3) at such a high rate

that carbon atoms do not have time to diffuse out of the crystal structure in large enough quantities to

form cementite (Fe C)

3.1.14

nitriding

case-hardening process in which nitrogen is introduced into the surface of metallic materials (most

commonly ferrous alloys)

EXAMPLE Liquid nitriding, gas nitriding, ion nitriding and plasma (3.6.32) nitriding.

[SOURCE: ISO 15156-2:2020, 3.11]

3.1.15

non-alloyed steel

steel in which the percentage of each element is less than specific limiting values specified

Note 1 to entry: See Table in ISO 4948-1:1982, 3.1.2.

3.1.16

product analysis

chemical analysis carried out on a sample of the product taken after the final hot rolling operation

3.1.17

steel

ferrous material the principal element of which is iron and the carbon content of which is not more than

2 % of mass

Note 1 to entry: The presence of large quantities of carbide-forming elements can modify the upper limit of the

carbon content.

Note 2 to entry: The nomenclature for unalloyed steels suitable for heat treatment and for alloyed steels is given

in ISO 4948-1 and ISO 4948-2.

Note 3 to entry: Small amount of alloying elements added to non-alloy steels can cause the product to be defined

as a micro-alloy steel.

3.1.18

white cast iron

cast iron (3.1.6) that displays a white fracture surface due to the presence of cementite

[SOURCE: ISO 15156-2:2020, 3.5.2]

3.1.19

gamma iron

pure iron with face-centred cubic lattice structure

3.2 General terms related to preparation of steel and cast iron

3.2.1

grinding

method of preparing a sample of metal for a physical method of analysis in which the surface of the test

sample (3.3.15) is abraded using an abrasive wheel

3.2.2

linishing

method of preparing a sample of metal for a physical method of analysis in which the surface of the

test sample (3.3.15) is abraded using a flexible rotating disc or continuous belt coated with an abrasive

substance

3.2.3

milling

method of preparing sample chips or the surface of a sample for a physical method of analysis in which

the surface of the sample is machined using a rotating, multi-edged cutting tool

3.3 General terms related to sample and sampling

3.3.1

aliquot

known amount of a homogeneous material, assumed to be taken with negligible sampling error

Note 1 to entry: The term "aliquot" is usually applied to fluids.

Note 2 to entry: The term "aliquot" is usually used when the fractional part is an exact divisor of the whole; the

term "aliquant" has been used when the fractional part is not exact divisor of the whole (e.g. a 15 ml portion is an

aliquant of 100 ml).

Note 3 to entry: When a laboratory sample (3.3.7) or a test sample (3.3.15) is "aliquoted" or otherwise subdivided,

the portions have been called split samples.

3.3.2

analyte

component of a system to be analysed

[SOURCE: PAC, 1989, 61, 1657 (Nomenclature for automated and mechanised analysis (Recommendations

1989))]

3.3.3

analytical sample

sample prepared from the laboratory sample (3.3.7) and from which analytical portions can be taken

Note 1 to entry: The analytical sample can be subjected to various treatments before an analytical portion is

taken.

Note 2 to entry: Where no homogenization or subdivision is necessary, the laboratory sample (3.3.7), the test

sample (3.3.15), and, if the latter requires no further chemical or physical treatment, the analytical samples are

identical. With some homogeneous materials such as waters or oils, the laboratory sample (3.3.7) may be taken

directly from a sample unit and, if no further subdivision or homogenization is carried out, the laboratory sample

(3.3.7) is the test sample (3.3.15). Similarly, with atmospheric particulates collected on a filter, the sample unit is

the laboratory sample (3.3.7) and, if no further subdivision or homogenization is carried out, also the test sample

(3.3.15).

[SOURCE: ISO 15193:2009, 3.3, modified — Note to entry added.]

3.3.4

consignment

quantity of metal delivered at one time

3.3.5

duplicate samples

replicate samples

multiple (or two) samples taken under comparable conditions

Note 1 to entry: This selection can be accomplished by taking units adjacent in time or space. Although the

replicate samples are expected to be identical, often the only thing replicated is the act of taking the physical

sample. A duplicate sample is a replicate sample consisting of two portions. The umpire samples usually used to

settle a dispute; the replicate sample is usually used to estimate sample variability.

[SOURCE: PAC, 1990, 62, 1193 (Nomenclature for sampling in analytical chemistry (Recommendations

1990))]

3.3.6

increment

quantity of metal obtained by sampling at one time from a consignment (3.3.4)

3.3.7

laboratory sample

sample or subsample(s) (3.3.13) sent to or received by the laboratory

Note 1 to entry: When the laboratory sample is further prepared (reduced) by subdividing, mixing, grinding

(3.2.1), or by combinations of these operations, the result is the test sample (3.3.15). When no preparation of the

laboratory sample is required, the laboratory sample is the test sample (3.3.15). A test portion (3.3.14) is removed

from the test sample (3.3.15) for the performance of the test or for analysis.

Note 2 to entry: The laboratory sample is the final sample from the point of view of sample collection but it is the

initial sample from the point of view of the laboratory.

Note 3 to entry: Several laboratory samples can be prepared and sent to different laboratories or to the same

laboratory for different purposes. When sent to the same laboratory, the set is generally considered as a single

laboratory sample and is documented as a single sample.

[SOURCE: IUPAC orange book: 2002, 18.3.6, Sampling stages]

3.3.8

lot

quantity of material that is assumed to be a single population for sampling purposes

[SOURCE: PAC, 1990, 62, 1193 (Nomenclature for sampling in analytical chemistry (Recommendations

1990))]

3.3.9

matrix

components of the sample other than the analyte (3.3.2)

Note 1 to entry: to entry. In analysis.

[SOURCE: PAC, 1989, 61, 1657 (Nomenclature for automated and mechanised analysis (Recommendations

1989))]

3.3.10

primary sample

collection of one or more increments (3.3.6) or units initially taken from a population

Note 1 to entry: The portions can be either combined (composited or bulked sample) or kept separate (gross

sample). If combined and mixed to homogeneity, it is a blended bulk sample.

Note 2 to entry: The term "bulk sample" is commonly used in the sampling literature as the sample formed by

combining increments (3.3.6). The term "bulk sample" is ambiguous since it could also mean a sample from a

bulk lot (3.3.8) and it does not indicate whether the increments (3.3.6) or units are kept separate or combined.

Such use should be discouraged because less ambiguous alternative expressions (composite sample, aggregate

sample) are available.

Note 3 to entry: "Lot sample" and "batch sample" have also been used for this concept, but they are self-limiting

terms.

Note 4 to entry: The use of "primary" in this sense is not meant to imply the necessity for multistage sampling.

[SOURCE: IUPAC orange book: 2002, 18.3.6, Sampling stages]

3.3.11

representative sample

sample that has the same properties as a defined batch of material and represents the bulk material,

within a defined confidence limit

[SOURCE: ISO 14488:2007, 3.7]

3.3.12

specimen

one or more pieces taken from each product in the sample, for the purpose of producing test pieces

[SOURCE: ISO 6361-1:2011, 3.7]

3.3.13

subsample

sample obtained by procedures in which the items of interest are randomly distributed in parts of equal

or unequal size

Note 1 to entry: A sub-sample can be any of the following:

a) a portion of the sample obtained by selection or division;

b) an individual unit of the lot (3.3.8) taken as part of the sample;

c) the final unit of multistage sampling.

Note 2 to entry: The term “subsample” is used either in the sense of a “sample of a sample” or as a synonym for

“unit”. In practice, the meaning is usually apparent from the context or is defined.

[SOURCE: ISO 11074:2015, 4.1.34]

3.3.14

test portion

part of the test sample, or part of the sample taken from the melt, submitted to analysis, in certain

cases, the test portion can be selected from the sample product itself

Note 1 to entry: The following special types of test portions in the form of a solid mass obtained from a probe

sample are distinguished

— disc originating from the sampling of molten metal (from a special sampler or a small ingot), used for OES or

XRF

— test portion in the shape of a small disc, commonly described as a slug, obtained by punching,

— test portion in the form of a small appendage, commonly described as a lug,

— test portion in the form of a small-diameter rod, commonly described as a pin, obtained by cutting.

Note 2 to entry: When the test sample is in the form of chips or powder, or when a sample in the form of a solid

mass is analysed by a thermal method, the test portion (3.3.14) is obtained by weighing. In the case of a physical

method of analysis, the part actually analysed will constitute only a small mass of the test sample. In an optical

emission spectrometric method, the mass of metal consumed in an electrical discharge (3.6.14) is about 0,5 mg

to 1 mg, in an X-ray fluorescence spectrometric method, the characteristic radiation is produced from a very thin

surface layer of the sample.

3.3.15

test sample

sample taken or formed from the laboratory sample (3.3.7), by a process involving homogenization

using physical or mechanical treatments such as grinding (3.2.1), drilling, milling (3.2.3) or sieving

Note 1 to entry: The test sample is then in a form suitable for subsampling for analytical purposes, for storing for

future analysis or for using for test purposes other than analytical.

[SOURCE: IUPAC orange book: 2002, 10.3.4.9]

3.3.16

test solution

analytical solution

solution prepared by dissolving, with or without reaction, the test portion (3.3.14) in a liquid

[SOURCE: IUPAC orange book: 2002, 18.3.6 Sampling stages]

3.3.17

trace element

element having an average concentration of less than about 100 parts per million atoms (ppm) or less

than 0,01 % by weight

[SOURCE: PAC, 1979, 51, 2243 (General aspects of trace analytical methods - IV. Recommendations

for nomenclature, standard procedures and reporting of experimental data for surface analysis

techniques)]

3.4 General terms related to analytical standards

3.4.1

blank test solution

solution that contains all the chemicals except for the element to be determined in the same

concentration as required for the preparation of a reference standard solution (3.4.17) of that element

[SOURCE: OIML R 100-1:2013, 3.3.2]

3.4.2

blank reference solution

solution used to set the zero absorbance on the spectrometer (3.5.22) and that normally consists of a

pure solvent such as deionized water

[SOURCE: OIML R 100-1:2013, 3.3.1]

3.4.3

blank value

reading or result originating from the matrix (3.3.9), reagents and any residual bias (3.8.5) in the

measurement device or process, which contributes to the value obtained for the quantity in the

analytical procedure

[SOURCE: PAC, 1989, 61, 1657 (Nomenclature for automated and mechanised analysis (Recommendations

1989))]

3.4.4

bracketing technique

analytical method consisting of bracketing the measured absorption or machine reading of the sample

between two measurements made on calibration solutions (3.4.8) of neighbouring concentrations

within the optimum working range

[SOURCE: ISO 6486-2:1999, 3.3]

3.4.5

calibration

operation that, under specified conditions, in a first step, establishes a relation between the

quantity values (3.4.16) with measurement uncertainties provided by measurement standards and

corresponding indications with associated measurement uncertainties (3.8.20) and, in a second step,

uses this information to establish a relation for obtaining a measurement result from an indication

Note 1 to entry: A calibration can be expressed by a statement, calibration function, calibration diagram,

calibration curve (3.4.7), or calibration table. In some cases, it can consist of an additive or multiplicative

correction of the indication with associated measurement uncertainty (3.8.20).

Note 2 to entry: Calibration should not be confused with adjustment of a measuring system, often mistakenly

called “self-calibration”, nor with verification (3.8.47) of calibration.

[SOURCE: ISO/IEC Guide 99:2007, 2.39]

3.4.6

calibration blank solution

solution prepared in the same way as the calibration solution (3.4.8) but leaving out the analyte (3.3.2),

also called “zero member” of the calibration (3.4.5) series

[SOURCE: ISO 21400:2018, 3.8, modified]

3.4.7

calibration curve

expression of the relation between indication and corresponding measured quantity value (3.4.16.2)

Note 1 to entry: A calibration curve expresses a one-to-one relation that does not supply a measurement result as

it bears no information about the measurement uncertainty (3.8.20).

[SOURCE: ISO/IEC Guide 99:2007, 4.31]

3.4.8

calibration solution

solution used to calibrate the instrument, prepared from a stock solution (3.4.21) or a certified standard

by adding acids, buffer (3.6.5), reference element (3.7.7) and salts as needed

[SOURCE: ISO 21400:2018, 3.9]

3.4.9

certified reference material

CRM

reference material (RM) characterized by a metrologically valid procedure for one or more specified

properties, accompanied by an RM certificate that provides the value of the specified property, its

associated uncertainty (3.8.20), and a statement of metrological traceability

Note 1 to entry: The concept of value includes a nominal property or a qualitative attribute such as identity or

sequence. Uncertainties for such attributes can be expressed as probabilities or levels of confidence.

[SOURCE: ISO Guide 30:2015, 2.1.2, modified —Notes 2, 3 and 4 to entry deleted.]

3.4.10

internal standard

compound added to a sample in a fixed amount that has similar properties (spectral, physical, isobaric

etc.) to the target analyte (3.3.2) used to correct for instrument drift (3.6.15) and matrix interference

(3.7.11)

[SOURCE: ISO/TS 20593:2017, 3.6, modified]

3.4.11

internal standard line

spectral line (3.6.40) of an internal standard (3.4.10), to which the radiant energy of an analytical line is

compared

[SOURCE: ASTM E135: 2021]

3.4.12

matrix solution

synthetic solution consisting of the solvent and containing, if possible, all the constituents of the

analytical sample (3.3.3) except the analyte (3.3.2)

3.4.13

primary reference material

primary RM

high purity material of the analyte (3.3.2), certified for the mass/mole fraction of the analyte (3.3.2)

in the material, and which constitutes the realization of the International System of Units (SI) for the

analyte (3.3.2) of interest

Note 1 to entry: A primary reference material has its value assigned either directly by a primary RMP or indirectly

by determining the impurities of the material by appropriate analytical methods (e.g. mass balance method).

[SOURCE: ISO 17511:2020, 3.35]

3.4.14

reference material

RM

material, sufficiently homogeneous and stable with respect to one or more specified properties, which

has been established to be fit for its intended use in a measurement process

Note 1 to entry: RM is a generic term.

Note 2 to entry: Properties can be quantitative or qualitative, e.g. identity of substances or species.

Note 3 to entry: Uses can include the calibration (3.4.5) of a measurement system, assessment of a measurement

procedure, assigning values to other materials, and quality control (3.8.26).

Note 4 to entry: ISO/IEC Guide 99:2007, 5.13 has an analogous definition, but restricts the term “measurement”

to apply to quantitative values. However, Note 3 of ISO/IEC Guide 99:2007, 5.13, specifically includes qualitative

properties, called “nominal properties”.

[SOURCE: ISO/Guide 30:2015, 2.1.1]

3.4.15

reference method

reference measurement procedure

measurement procedure accepted as providing measurement results fit for their intended use in

assessing measurement trueness (3.8.46) of measured quantity values (3.4.16.2) obtained from other

measurement procedures for quantities of the same kind, in calibration (3.4.5), or in characterizing

reference materials (3.4.14)

Note 1 to entry: The accuracy (3.8.1) of a reference method must be demonstrated through direct comparison

with a definitive method or with a primary Reference Material (3.4.13).

[SOURCE: ISO/IEC Guide 99:2007, 2.7, modified — New preferred term added, Note to entry added.]

3.4.16

quantity value

number and reference together expressing magnitude of a quantity

[SOURCE: JCGM 200:2012 1.19]

3.4.16.1

reference quantity value

reference value

quantity value (3.4.16) used as a basis for comparison with values of quantities of the same kind

Note 1 to entry: A reference quantity value can be a true quantity value (3.8.45) of a measurand, in which case it is

unknown, or a conventional quantity value, in which case it is known.

Note 2 to entry: A reference quantity value with associated measurement uncertainty (3.8.20) is usually provided

with reference to:

a) a material, e.g. a certified reference material (3.4.9);

b) a device, e.g. a stabilized laser;

c) a reference measurement procedure (3.4.15);

d) a comparison of measurement standards.

[SOURCE: JCGM 200:2012, 5.18]

3.4.16.2

measured quantity value

value of a measured quantity

measured value

quantity value (3.4.16) representing a measurement result

[SOURCE: JCGM 200:2012, 2.10]

3.4.17

reference standard solution

solution containing an accurately known concentration of a sample element or elements of interest and

that is used for testing and calibrating the instrument

[SOURCE: OIML R 100-1:2013, 3.4]

3.4.18

spike

known quantity of determinand that is added to a sample, usually for the purpose of estimating the

systematic error (3.8.44) of an analytical system by means of a recovery exercise

Note 1 to entry: "Spiking" is a way of creating a control material (3.8.8) in which a value is assigned by a

combination of formulation and analysis. This method is feasible when a test material essentially free of the

analyte (3.3.2) is available. After exhaustive analytical checks to ensure the background level is adequately low,

the material is spiked with a known amount of analyte (3.3.2). The reference sample prepared in this way is thus

of the same matrix (3.3.9) as the test materials to be analysed and of known analyte (3.3.2) level - the uncertainty

(3.8.20) in the assigned concentration is limited only by the possible error (3.8.11) in the unspiked determination.

However, it can be difficult to ensure that the speciation, binding and physical form of the added analyte (3.3.2) is

the same as that of the native analyte (3.3.2) and that the mixing is adequate.

[SOURCE: ISO 5667-14:2014, 3.7, modified — Note to entry added.]

3.4.19

standardization

process of adjusting instrument output to a previously established calibration (3.4.5) (that is, drift

correction (3.6.16)); the experimental establishment of the concentration of a reagent solution

[SOURCE: ASTM E135: 2021]

3.4.20

standard solution

solution of accurately known concentration of an element, an ion, a compound or a group derived from

the substance used for its preparation

Note 1 to entry: Standard solutions are prepared using standard substances in one of several ways. A primary

standard is a substance of known high purity, which can be dissolved in a known volume of solvent to give a

primary standard solution. If stoichiometry is used to establish the strength of a titrant, it is called a secondary

standard solution. The term secondary standard can also be applied to a substance whose active agent contents

have been found by comparison against a primary standard.

[SOURCE: ISO 78-2:1999, 3.6, modified — Note to entry added.]

3.4.21

stock solution

solution with accurately known analyte (3.3.2) concentration(s), prepared from pure chemicals such as

a primary standard

[SOURCE: ISO 21400:2018, 3.11]

3.4.22

titration curve

plot of a variable related to a relevant concentration (activity) as the ordinate versus some measure of

the amount of titrant, usually titration volume (titre), as the abscissa

Note 1 to entry: If the variable is linearly related to concentrations, such as the electrical conductance or the

photometric absorbance, the expression "linear titration curve" is used. When a logarithmic expression of the

concentration or activity is used, such as the pH, pM, or the electrical potential in mV, the curve is referred to as a

logarithmic titration curve.

[SOURCE: IUPAC orange book: 2002]

3.4.23

working reference materials

reference materials (3.4.14) used for routine analytical control and traceable to NIST standards and

other recognized standards when appropriate standards are available

[SOURCE: ASTM A751: 2020, 3.2.6]

3.4.24

working standard solution

solution, prepared by dilution of the stock standard solution(s), that contains the analyte(s) (3.3.2)

of interest at a concentration(s) better suited to preparation of calibration solutions (3.4.8) than the

concentration(s) of the analyte(s) (3.3.2) in the stock standard solution(s)

[SOURCE: ISO 15202-3:2004, 3.2.13]

3.5 Definitions of the analysis methods and analytical instrument

3.5.1

atomic absorption spectrometry

AAS

spectroanalytical method for qualitative determination and quantitative evaluation of element

concentrations wherein the technique determines these concentrations by measuring the atomic

absorption of free atoms

Note 1 to entry: The technique of analysis by AAS falls into two main categories, according to the method of

atomization, that is, flame atomic absorption spectrometry (FAAS) (3.5.6) and electrothermal atomic absorption

(ETAAS) (3.5.5) [also called graphite furnace atomic absorption spectrometry (GFAAS)].

[SOURCE: ISO 6486-1:2019, 3.2, modified — Note to entry added.]

3.5.2

atomic emission spectrometry

AES

pertaining to emission spectrometry in the ultraviolet, visible, or infrared (3.5.16) wavelength regions

of the electromagnetic spectrum

Note 1 to entry: Atomic emission spectroscopy (3.5.26) is considered mainly in the ultraviolet and visible regions

of the spectrum, i.e. the optical range, and makes use of different sampling sources that give rise to the different

categories of optical emission spectroscopy (OES) (3.5.20), including flame, plasma (3.6.32), glow discharge, spark,

direct current arc optical emission spectroscopy (3.5.20).

[SOURCE: ASTM E135: 2021, modified — Note to entry added.]

3.5.3

atomic fluorescence spectrometry

AFS

method of determining chemical elements based on the measurement of the re-emission of characteristic

electromagnetic radiation by atoms, following the absorption of radiation in the vapour phase

Note 1 to entry: The wavelengths of the absorbed and re-emitted radiation can be identical (atomic resonance

fluorescence spectrometry) or different.

3.5.4

chemical vapour generation system

analyte (3.3.2) is separated from the sample matrix (3.3.9) by the generation of gaseous species as a

result of a chemical reaction

Note 1 to entry: This technique has received its widest application in atomic absorption spectrometry (AAS) (3.5.1)

in the forms of cold vapour AAS (CVAAS) for the determination of mercury and hydride generation AAS (HGAAS)

for elements forming gaseous covalent hydrides (As, Bi, Ge, In, Pb, Sb, Se, Sn and Te). Chemical vapour generation

is also used in combination with optical emission (3.5.20) and atomic fluorescence spectrometry (3.5.3).

[SOURCE: IUPAC orange book: 2002, 10.3.4.6]

3.5.4.1

cold vapour atomic absorption spectrometry

CVAAS

type of atomic absorption spectrometry (3.5.1) where no vaporisation step is required because the

sample is a volatile heavy metal such as mercury, which is a vapour at room temperature

3.5.4.2

hydride generation atomic absorption spectrometry

HGAAS

type of atomic absorption spectrometry (3.5.1) where metal samples such as As, Sb and Se are vaporised

by converting them into volatile hydrides

3.5.5

electrothermal atomic absorption spectrometry

ETAAS

type of spectrometry that uses a graphite-coated furnace to vaporize the sample

Note 1 to entry: This technique has largely been developed for use in atomic absorption spectrometry (3.5.1). It

has also been applied in atomic emission (3.5.2) and atomic fluorescence spectrometry (3.5.3), with appropriate

analogous phrases, such as electrothermal atomic emission spectrometry (ETAES) and electrothermal atomic

fluorescence spectrometry (ETAFS).

3.5.6

flame atomic absorption spectrometry

measurement of the absorption of electromagnetic radiation, emitted by an element at a determined

wavelength, by an absorbent medium (flame) formed of atoms of the same element that are in the

ground state

Note 1 to entry: Each element absorbs radiation of specific wavelengths and the intensity of the absorbed

radiation is proportional to the concentration of the said element.

[SOURCE: ISO 3750:2006, 3.1]

3.5.7

flame emission spectrometry

FES

chemical analysis method based on the measurement of light in a given range of wavelengths emitted

by a sample atomized in a flame according to the Beer-Lambert law

Note 1 to entry: The functions of an analytical flame spectrometer in general are:

a) Transformation of the solution to be analyzed into a vapour containing free atoms or molecular compounds

of the analyte (3.3.2) in the flame;

b) Selection and detection of the optical signal (arising from the analyte (3.3.2) vapour) which carries

information on the kind and concentration of the analyte (3.3.2);

c) Amplification and read-out of the electrical signal.

[SOURCE: ISO 9555-3:1992, 3.1.6, modified — Note to entry added.]

3.5.8

Fourier transform infrared spectrometry

FT-IR spectrometry

form of infrared spectrometry in which an interferogram is obtained; which is then subjected to a

Fourier transform to obtain an amplitude-wavenumber (or wave-length) spectrum

Note 1 to entry: The abbreviation FTIR is not recommended.

Note 2 to entry: When FT-IR spectrometers are interfaced with other instruments, a slash should be used to

denote the interface; for example, GC/FT-IR; HPLC/FT-IR, and the use of FT-IR should be explicit, that is, FT-IR not

IR.

[SOURCE: ASTM E131: 2010]

3.5.9

glow discharge spectrometry

GDS

method in which a spectrometer (3.5.22) is used to measure relevant intensities emitted from a glow

discharge generated at a surface

Note 1 to entry: This is a general term that encompasses GDOES and GDMS.

[SOURCE: ISO 18115-1:2013, 3.10]

3.5.10

glow discharge optical emission spectrometry

GDOES

method in which an optical emission spectrometer is used to measure the wavelength and intensity of

light emitted from a glow discharge (3.6.14) generated at a surface

Note 1 to entry: This method is a spectroscopic method for the quantitative analysis of metals and other non-

metallic solids. The metallic samples are used as a cathode in a direct current plasma (3.6.32). From the surface,

the sample is removed in layers by sputtering with argon ions. The removed atoms pass into the plasma (3.6.32)

by diffusion. Photons are emitted with excited waves and have characteristic wavelengths that are recorded

by means of a downstream spectrometer and subsequently quantified. Glow discharge spectroscopy (3.5.9) is an

established method for the characterization of steels (3.1.17) and varnishes.

[SOURCE: ISO 18115-1:2013, 3.9, modified — Note to entry added.]

3.5.11

gravimetry

set of methods used in analytical chemistry for the quantitative determination of an analyte (3.3.2)

based on its mass

Note 1 to entry: The four main types of this method of analysis are precipitation, volatilization, electro-

analytical and miscellaneous physical method. The methods involve changing the phase of the analyte (3.3.2) to

separate it in its pure form from the original mixture and are quantitative measurements.

3.5.12

inductively coupled plasma

ICP

high-temperature discharge (3.6.14) generated in flowing argon by an alternating magnetic field

induced by a radio frequency (RF) load coil that surrounds the tube carrying the gas

Note 1 to entry: In inductively coupled plasmas (inductively coupled RF plasmas or inductively coupled argon

plasmas), energy transfer to the gas is achieved with the help of an induction coil or inductor (the terms coil,

load coil and work coil are discouraged). The frequency at which the source operates should be given, e.g. 27 or

12 MHz, and the gas type should be defined. The plasma (3.6.32) is formed within and/or above a set of refractory

tubes arranged coaxially with the induction coil, the whole forming a plasma torch.

[SOURCE: ISO 30011:2010, 3.3.5, modified — Note to entry added.]

3.5.13

inductively coupled plasma optical emission spectrometry

ICP-OES

measurement of the intensity of electromagnetic radiation emitted by the components of a sample

when excited by a plasma (3.6.32)

Note 1 to entry: Sample atoms entering the plasma emit light radiation, whose characteristic wavelengths and

intensities are used to identify the elements and determine concentrations, respectively. Samples are usually

presented to the plasma (3.6.32) in solution form.

[SOURCE: ISO 3815-2:2005, 3.1]

3.5.14

inductively coupled plasma mass spectrometry

ICP-MS

analytical technique comprising a sample introduction system, an inductively coupled plasma (3.5.12)

source for ionization of the analytes (3.3.2), a plasma/vacuum interface and a mass spectrometer

comprising an ion focusing, separation and detection system

[SOURCE: ISO/TS 80004-6:2021, 5.23]

3.5.15

ion-selective electrode

ISE

potentiometric probe, the output potential of which, when measured against a suitable reference

electrode, is proportional to the activity of the selected ion in the solution under test

Note 1 to entry: This is an electrochemical sensor, based on a thin selective membrane or film as recognition

element and is an electrochemical half-cell equivalent to other half-cells of the zeroth (inert metal in a redox

electrolyte), 1st, 2nd and 3rd kinds. These devices are distinct for half-cells that involve electrode redox reactions

(electrodes of zeroth, 1st, 2nd and 3rd kinds), although they often contain a second kind electrode as the “inner”

or “internal” reference electrode. The potential difference is the response (i.e. that of ISE versus outer reference

electrode potentials) as its principal component of the Gibbs energy change associated with permselective mass

transfer of ions (e.g. by ion-exchange, solvent extraction or some other mechanism) across a phase boundary.

The ISE shall be used in conjunction with a reference electrode (i.e. “outer” or “external” reference electrode) to

form a complete electrochemical cell. The measured potential difference s (ISE versus outer reference electrode

potentials) are linearly dependent on the logarithm of the activity of a given ion in solution. The expression "ion-

specific electrode" is not recommended. "Specific" implies that the electrode does not respond to additional ions.

Since no electrode is truly specific for one ion, "ion-selective" is recommended as more appropriate. "Selective

ion-sensitive electrode" is rarely used to describe an ion-selective electrode. "Principal" or "primary" ions are

those for determination of which an electrode is designed. It is never certain that the ISE is more sensitive to the

"principal" ion than to interferences, e.g. nitrate ISEs.

[SOURCE: 8.3.2.1, IUPAC orange book: 2002]

3.5.16

infrared radiation

IR

infrared

optical radiation for which the wavelengths are longer than those for visible radia

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...